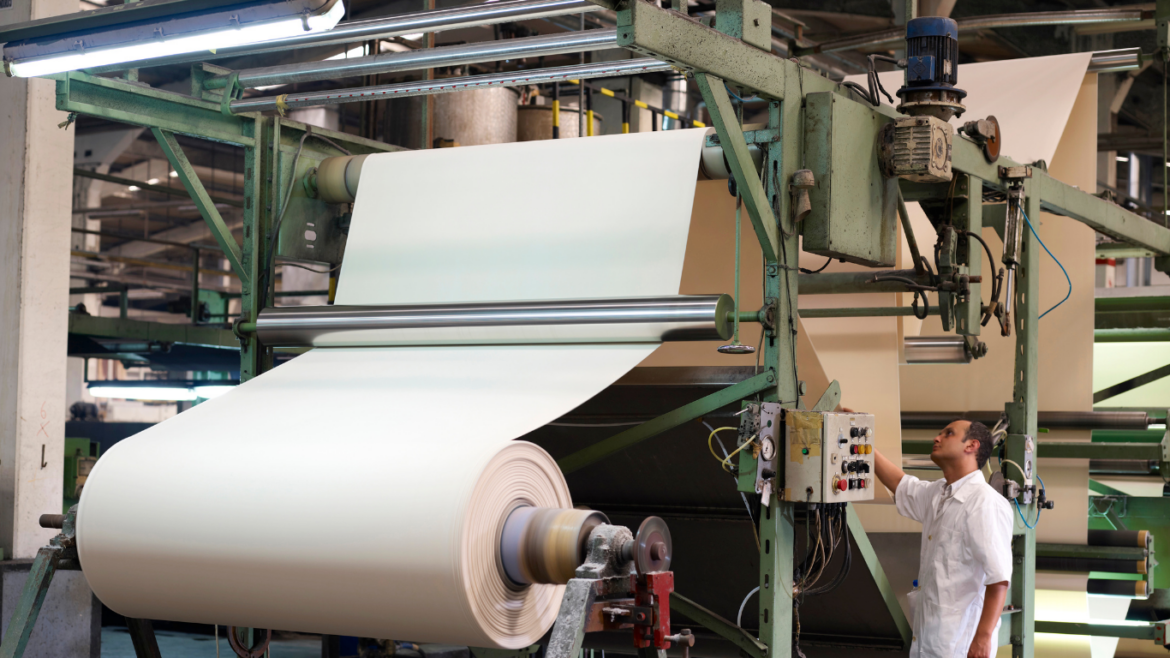

Garment factories across India, Bangladesh, Vietnam, and South America are facing a new reality. Global demand is rising, lead times are shrinking, and buyers expect consistent quality at competitive prices. To stay ahead, manufacturers must rethink how they produce — and that starts with smarter machines.

One of the most effective ways to improve efficiency is by investing in intelligent textile machines for apparel production. These machines don’t just automate tasks. They optimize them. From slitting tubular knits to cutting collarettes, intelligent systems help reduce waste, speed up output, and increase return on investment.

The Hidden Cost of Manual Processing

Many factories still rely on manual or semi-automated systems for fabric preparation. While this may seem cost-effective at first, it often leads to:

- Uneven cuts and inconsistent sizing

- Higher fabric waste

- Slower production cycles

- Increased labor fatigue and errors

These issues add up. Over time, they affect profitability, delivery timelines, and customer satisfaction.

Smarter Machines, Better Results

Intelligent textile machines for apparel production solve these problems with precision and consistency. They’re designed to handle high volumes with minimal supervision, making them ideal for export-driven factories and fast fashion suppliers.

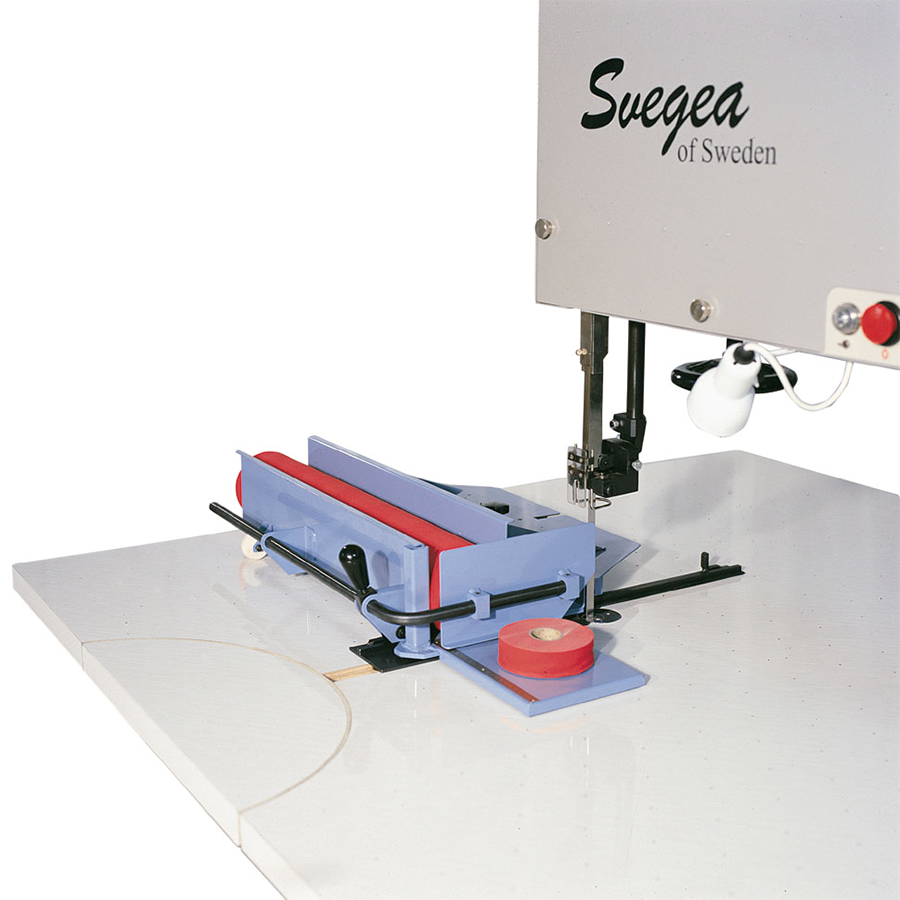

Take the Svegea TSO 380 Tubular Knit Slitter, for example. This machine is built for speed and accuracy. It slits tubular knitted fabrics open with clean edges, ready for further processing. It’s easy to operate, requires minimal maintenance, and integrates smoothly into existing production lines.

Efficiency That Pays Off

Factories using machines like the TSO 380 report:

- Up to 15% reduction in fabric waste

- Faster turnaround times

- Fewer production errors

- Lower labor costs

These improvements lead to measurable ROI — often within the first year of installation. That’s why more manufacturers are turning to intelligent textile machines for apparel production as a long-term strategy.

Flexibility and Integration

Modern apparel production demands flexibility. Machines must adapt to different fabric types, styles, and order volumes. The best systems are designed to handle knits, wovens, and technical textiles without constant retooling.

Svegea’s machines are known for their versatility. Whether you’re processing tubular knits or cutting narrow strips, their equipment delivers consistent results across a wide range of materials.

Reliability You Can Count On

Downtime is expensive. That’s why reliability matters. Manufacturers need machines that run smoothly, require minimal maintenance, and come with strong technical support.

Svegea of Sweden has built its reputation on engineering excellence and long-term durability. High-volume factories around the world — including across Asia and Latin America — rely on the intelligent textile machinery backed by responsive teams for support.

Investing in Smart Solutions

The future of garment manufacturing belongs to those who invest in smart, scalable solutions. By integrating intelligent textile machines for apparel production, factories can boost efficiency, reduce waste, and stay competitive in a fast-moving global market.

If you’re ready to upgrade your production line, explore Svegea’s TSO 380 Tubular Knit Slitter and other solutions at www.svegea.se.

For a product demo, email Håkan Steene at h.steene@svegea.se

In modern textile manufacturing, adaptability is no longer optional—it’s essential. As demand grows for flexible production, especially in knitwear and activewear, manufacturers are turning to adaptive garment machinery to streamline operations and maintain quality.

Why Tubular Knit Slitting Matters

Tubular knit fabrics are produced in a continuous loop, which is ideal for circular knitting but not for cutting, printing, or sewing. Before these fabrics can be processed further, they must be slit and opened into flat sheets.

Without proper slitting:

– Edges may distort or curl

– Automated cutting systems can misalign

– Waste increases due to poor edge control

– Finished garments may suffer in quality

This step, though often overlooked, directly affects efficiency and product consistency.

The Role of Adaptive Machinery

Adaptive garment machinery refers to equipment that adjusts dynamically to different fabric types, production speeds, and operational conditions. In tubular knit slitting, this means:

- Automatic edge guiding for alignment

- Adjustable slitting widths for varied outputs

- High-speed operation with minimal waste

- Compatibility with both light and heavy knits

These features allow manufacturers to respond quickly to changing production needs without sacrificing precision.

Integration into Production Lines

Slitting machines are typically placed early in the workflow—after knitting and before cutting or printing. To integrate effectively, they must:

- Fit within existing layouts

- Offer intuitive controls for operators

- Require minimal maintenance

- Support continuous, high-volume use

When adaptive slitting technology is used, production lines become more responsive and less prone to bottlenecks.

Industry Applications

This machinery is especially relevant for:

- On-demand fashion production

- Mass customization models

- Sustainable textile workflows

- Technical and performance apparel

By enabling consistent slitting across diverse knit fabrics, adaptive systems support manufacturers aiming for speed, flexibility, and reduced waste.

A Significant Small Step

Tubular knit slitting may seem like a small step, but its impact is significant. With adaptive garment machinery, manufacturers gain the precision and flexibility needed to meet modern demands.

If you’re exploring ways to improve your knitwear production, consider how adaptive slitting can elevate your workflow.

To learn more or request a consultation, email Håkan at (mailto:hakan@svegea.se) or contact us.

Have you ever wondered what goes into creating the luxurious fabrics that grace high-end fashion runways and premium home textiles? The journey from raw material to finished fabric is a fascinating process that combines traditional craftsmanship with cutting-edge technology. In this blog, we’ll uncover the secrets behind high-end fabric production, featuring insights from industry leaders like Svegea of Sweden.

The Foundation: Selecting the Finest Fibers

The first step in fabric production is selecting the highest quality fibers. Whether it’s natural fibers like cotton, silk, and wool, or synthetic fibers such as polyester and nylon, the choice of raw material significantly impacts the final product’s quality. Choose only the finest fibers to craft luxury fabrics that exude durability, softness, and a premium feel.

Spinning Magic: Transforming Fibers into Yarn

Once the fibers are selected, they undergo a spinning process to be transformed into yarn. This step involves drawing out and twisting the fibers to create a continuous thread. Advanced spinning techniques ensure that the yarn is strong and uniform, which is crucial for producing high-quality fabric. Modern spinning machines, like those used by leading manufacturers, offer precision and efficiency, resulting in superior yarn quality.

Weaving Wonders: Crafting the Fabric

Weaving is where the magic truly happens. This process involves interlacing two sets of yarns—the warp and the weft—to create a fabric. The type of weave pattern used can vary, from simple plain weaves to intricate jacquard designs. High-end fabric production often employs state-of-the-art weaving machines that can produce complex patterns with remarkable precision. Companies like Vandewiele Sweden are renowned for their advanced weaving technology, which ensures high-quality fabric production.

Dyeing and Finishing: Adding Color and Texture

After weaving, the fabric undergoes dyeing and finishing processes to achieve the desired color and texture. Dyeing involves immersing the fabric in dye solutions while finishing treatments can include processes like brushing, calendaring, and coating to enhance the fabric’s appearance and performance. Sustainable dyeing practices are becoming increasingly important, with many manufacturers adopting eco-friendly methods to reduce environmental impact.

Cutting-Edge Technology: Svegea of Sweden’s Innovations

Svegea of Sweden is a pioneer in the textile machinery industry, known for its innovative solutions that enhance fabric production efficiency and quality. One of their standout products is the Tubular Knit Slitter TSO 380. This machine revolutionizes the way tubular knit fabrics are processed, offering massive fabric savings and precision cutting. With features like advanced tension control and semi-automatic blade sharpening, the TSO 380 ensures perfect cuts every time, making it an invaluable asset for garment manufacturers.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of high-end fabric production. Each piece of fabric undergoes rigorous inspection to ensure it meets the highest standards. This includes checking for defects, measuring fabric weight and thickness, and testing for colorfastness and durability. Advanced fabric inspection machines, like those from Svegea, play a crucial role in maintaining quality by detecting even the smallest imperfections.

Sustainable Practices: The Future of Fabric Production

Sustainability is at the forefront of modern fabric production. Manufacturers are increasingly adopting eco-friendly practices to minimize their environmental footprint. This includes using organic fibers, reducing water and energy consumption, and recycling waste materials. Svegea of Sweden commits to sustainability by offering machinery that supports greener production methods. Their advanced textile-cutting systems reduce waste, increase efficiency, and contribute to a more sustainable textile industry.

The Role of Innovation in High-End Fabric Production

Innovation is key to staying ahead in the competitive world of high-end fabric production. From automated cutting machines to smart weaving technology, continuous advancements are driving the industry forward. Companies like Svegea are leading the way with their cutting-edge machinery that combines precision, efficiency, and sustainability. By investing in innovative solutions, manufacturers can produce superior fabrics that meet the demands of discerning customers.

Embracing the Future of Fabric Production

The secrets behind high-end fabric production lie in the meticulous selection of fibers, advanced spinning and weaving techniques, and cutting-edge technology. Companies like Svegea of Sweden are at the forefront of this industry, offering innovative solutions that enhance quality and efficiency while promoting sustainability. As the textile industry evolves, embracing these advancements will be crucial for producing the luxurious fabrics that define high-end fashion and home textiles.

Ready to learn more about the latest innovations in fabric production? Contact us to learn more about the range of advanced textile machinery designed to revolutionize your production process.

In the dynamic world of textile manufacturing, automation is a cornerstone of innovation, driving unprecedented efficiency, precision, and sustainability. As an expert with over two decades of experience in textile automation, we have witnessed firsthand the transformative power of these technologies. Today, we’ll explore how automation is reshaping the fabric of our industry.

The Evolution of Textile Automation

The journey from hand-spun fibers to today’s high-tech production lines tells a story of relentless innovation. Early mechanization during the Industrial Revolution laid the groundwork, but modern automation has catapulted us into a new era of manufacturing excellence.

Key milestones include:

1. 1960s-1970s: Introduction of computer-controlled looms

2. 1980s-1990s: Development of robotic systems for material handling

3. 2000s-2010s: Integration of AI and machine learning in quality control

4. 2020s and beyond: Emergence of fully automated, smart textile factories

Core Areas Transformed by Automation

Spinning: Precision at Lightning Speeds

Modern spinning systems, such as rotor and air-jet technologies, have revolutionized yarn production. These systems can produce yarn up to 20 times faster than traditional ring spinning, with unparalleled consistency.

Weaving: Intelligent Looms for Flawless Fabrics

Today’s computerized looms are marvels of engineering. There are machines for example that use real-time adaptive tension control to adjust warp tension on the fly, ensuring fabric quality remains consistent even as conditions change during production. This level of precision was unthinkable just a decade ago.

Dyeing and Finishing: Sustainability Meets Efficiency

Automated dyeing and finishing processes have dramatically reduced water and energy consumption while improving color consistency. Digital textile printing, exemplified by machines can print complex designs directly onto fabric at up to 1,000 m²/hour, revolutionizing small-batch and customized production.

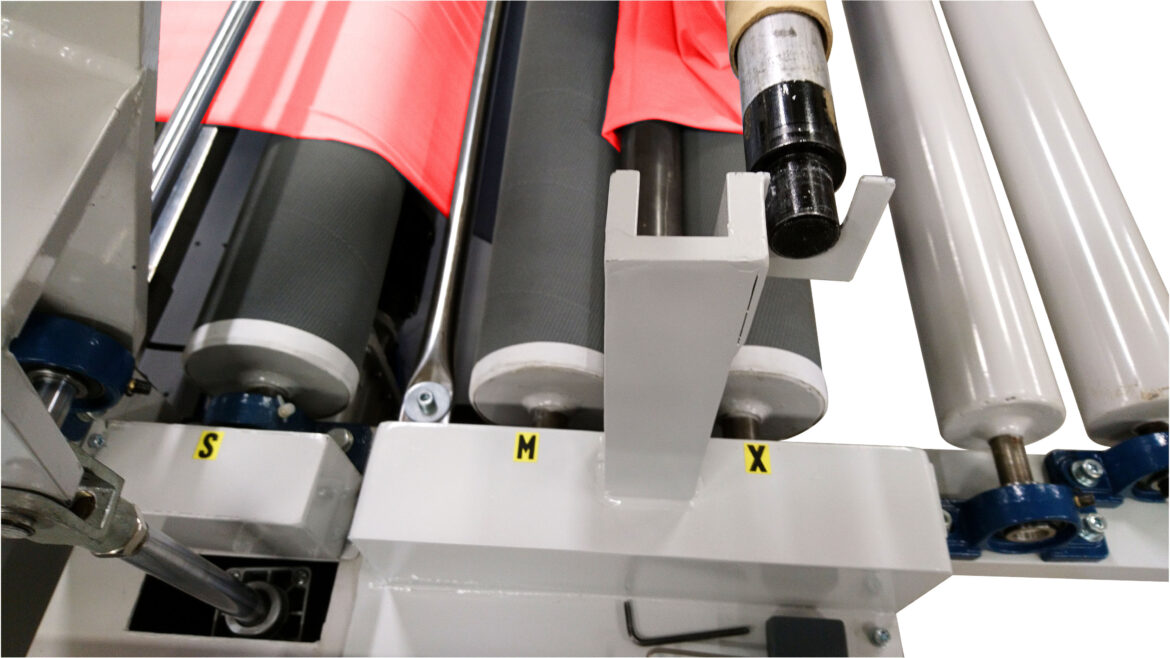

Spotlight on Innovation: Svegea’s EC 450 XF Collarette Cutting System

The EC 450 XF Collarette Cutting System by Svegea represents the cutting edge of textile automation. As the winner of the Texprocess Americas 2023 Innovation Award, this system exemplifies how targeted automation can solve specific industry challenges.

Key features include:

– Multi-material compatibility for unparalleled versatility

– Precision cutting with minimal waste

– Rapid changeover times, boosting overall productivity

The EC 450 XF doesn’t just cut fabric; it redefines efficiency in garment manufacturing. For manufacturers looking to stay competitive, systems like this are not just beneficial—they’re essential.

The Tangible Benefits of Automation

1. Quality Assurance: Automated systems consistently produce high-quality textiles, reducing defects by up to 90% compared to manual processes.

2. Increased Productivity: Modern automated lines can operate 24/7, increasing output by 200-300% over traditional methods.

3. Cost Reduction: While initial investment is significant, automated systems can reduce labor costs by 40-60% and material waste by 20-30% over their lifetime.

4. Customization at Scale: Automation enables quick changeovers, making small-batch and customized production economically viable.

5. Enhanced Safety: Automation minimizes human exposure to hazardous processes, reducing workplace accidents by up to 80% in some facilities.

Overcoming Implementation Challenges

While the benefits of automation are clear, implementation comes with challenges:

1. Initial Investment: The upfront cost of automation can be substantial. However, ROI typically occurs within 2-5 years, depending on the scale of implementation.

2. Workforce Transition: Shifting to automated systems requires retraining staff. Forward-thinking companies are investing in upskilling programs to transition workers into higher-value roles.

3. System Integration: Ensuring new automated systems work seamlessly with existing processes is crucial. Careful planning and phased implementation can mitigate disruptions.

The Future of Textile Automation

Looking ahead, several trends will shape the future of textile automation:

1. AI and Machine Learning: These technologies will enable predictive maintenance and real-time quality control, further improving efficiency and reducing downtime.

2. Internet of Things (IoT): Connected devices will create smart factories where every aspect of production is monitored and optimized in real-time.

3. Sustainable Automation: Future systems will focus even more on reducing environmental impact, with closed-loop water systems and energy-efficient processes.

4. Collaborative Robotics: Cobots will work alongside humans, handling repetitive tasks while allowing human workers to focus on high-value activities.

Embracing the Automated Future

Automation in textile manufacturing isn’t just about replacing human labor—it’s about augmenting human capabilities, driving innovation, and creating a more sustainable, efficient industry. As we look to the future, it’s clear that automation will play an increasingly central role in shaping the textiles of tomorrow.

For manufacturers, the message is clear: embrace automation or risk being left behind. The future of textiles is automated, and that future is now.

To explore cutting-edge automation solutions like Svegea’s EC 450 XF Collarette Cutting System, contact us now! For those ready to take the next step in their automation journey, now is the time to act.

In the fast-paced realm of textile manufacturing, precision and innovation reign supreme, shaping industry standards and pushing boundaries. Svegea of Sweden AB emerges as a beacon of cutting-edge technology, offering various products and services that redefine the textile landscape. A standout in their lineup is the Tubular Knit Slitter, a product that epitomizes Svegea’s commitment to excellence and efficiency in textile production.

Cutting-Edge Technology

A steadfast commitment to cutting-edge technology lies at the core of Svegea’s success. The EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, epitomizes this dedication. This advanced system achieves unparalleled precision and efficiency, setting new benchmarks in production excellence. From automatic roll-cutting/slitting machines to the Strip Cutter CMS-1800A, Svegea’s lineup showcases technological prowess.

Global Presence and Bespoke Services

With a global presence across continents, Svegea delivers innovative solutions and bespoke services to clients worldwide. Whether it’s fabric inspection machines such as the CMI 210 R or the Complete Bias System, Svegea’s commitment to meeting client needs remains steadfast. Their tailored approach ensures that each solution addresses specific requirements, ensuring customer satisfaction and success.

Award-Winning Innovation

Svegea’s relentless pursuit of excellence has earned them recognition and accolades in the textile industry. Their award-winning innovation is evident in every product, from the Tube Sewing Unit 200 A/AF to the Euro Collarette range. This dedication to pushing boundaries positions Svegea as a leader in innovation and customer satisfaction.

Tubular Knit Slitter TSO 380

In essence, Svegea’s Tubular Knit Slitter is a remarkable machine that converts tubular knit fabric from its tube form into a single-width roll of material, ready to be slit into tape. This innovative approach brings huge fabric savings compared to the traditional method of producing two rolls of open-knit fabric from tubular knit for tape or binding production.

Experience Excellence

Svegea of Sweden AB stands as a testament to innovation, quality, and customer-centricity in the textile industry. They continue to redefine standards and shape the future of textile manufacturing with cutting-edge technology and a diverse product portfolio. Their global presence, bespoke services, and award-winning innovation set them apart. Experience excellence with Svegea – where innovation meets precision, and possibilities are limitless.

If you want to elevate your textile production, consider the Tubular Knit Slitter from Svegea. Let us know by pressing the contact button!

The textile industry is undergoing transformative changes driven by trends around sustainability, automation, customization, and circularity. Leading machinery manufacturers offer cutting-edge solutions to help textile producers capitalize on these powerful market shifts.

Sustainability Imperative

Environmental consciousness is fueling the demand for eco-friendly textiles, currently, a global textile trend that we cannot ignore. Innovative machinery enables sustainable manufacturing practices like energy efficiency and waste reduction, minimizing environmental impact while maintaining competitive operations.

Automation & Industry 4.0

Principles like robotics, AI, and IoT are optimizing production through automation. Advanced textile machinery seamlessly integrates these technologies to streamline operations, boost productivity, and reduce costs – keeping manufacturers at the forefront of the digital revolution.

Customization & Diversification

Evolving consumer tastes favor personalized products and unique experiences. Flexible machinery allows for customized, diverse offerings tailored to changing market demands.

Circular Economy Transition

Resource efficiency is paramount, with textile circularity reducing waste. Circular knitting machines and recycling technologies enable closed-loop supply chains by repurposing waste into new materials.

As these trends reshape the global landscape, machinery manufacturers position textile producers for success. By adopting innovative solutions for sustainability, automation, customization, and circularity, industry leaders can drive sustainable growth and gain a lasting competitive edge.

For inquiries, brochures, or further information about Svegea of Sweden’s cutting-edge textile machinery, visit our contact page.

In the fast-paced realm of textile manufacturing, precision and innovation reign supreme, shaping industry standards and pushing boundaries. Svegea of Sweden AB emerges as a beacon of cutting-edge technology, offering a wide array of products and services that redefine the textile landscape.

Cutting-Edge Technology

A steadfast commitment to cutting-edge technology lies at the core of Svegea’s success. The Svegea EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, epitomizes this dedication. This advanced system achieves unparalleled precision and efficiency, setting new benchmarks in production excellence. From automatic roll cutting/slitting machines like the SWS to the Strip Cutter CMS-1800A3, Svegea’s lineup showcases technological prowess.

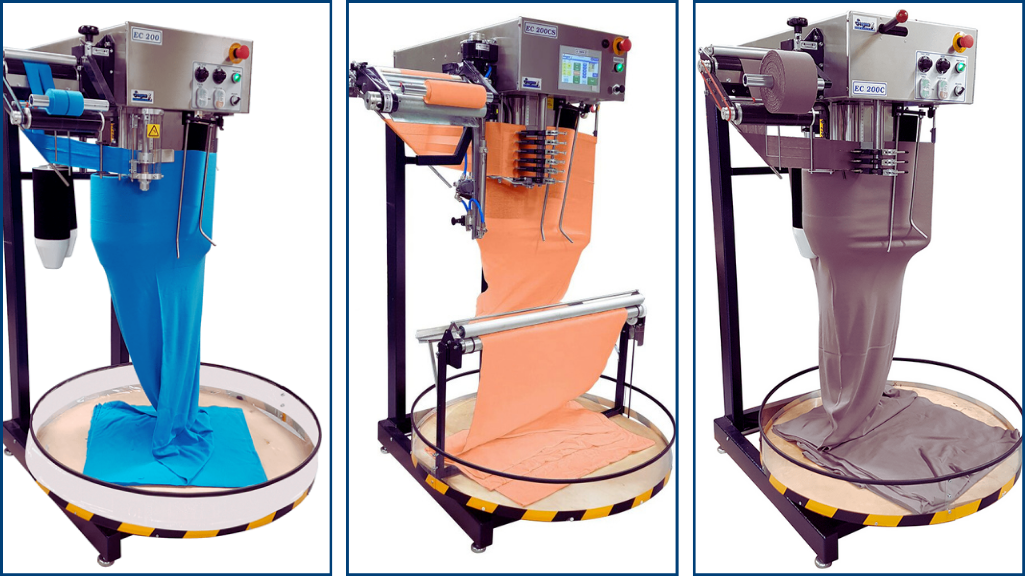

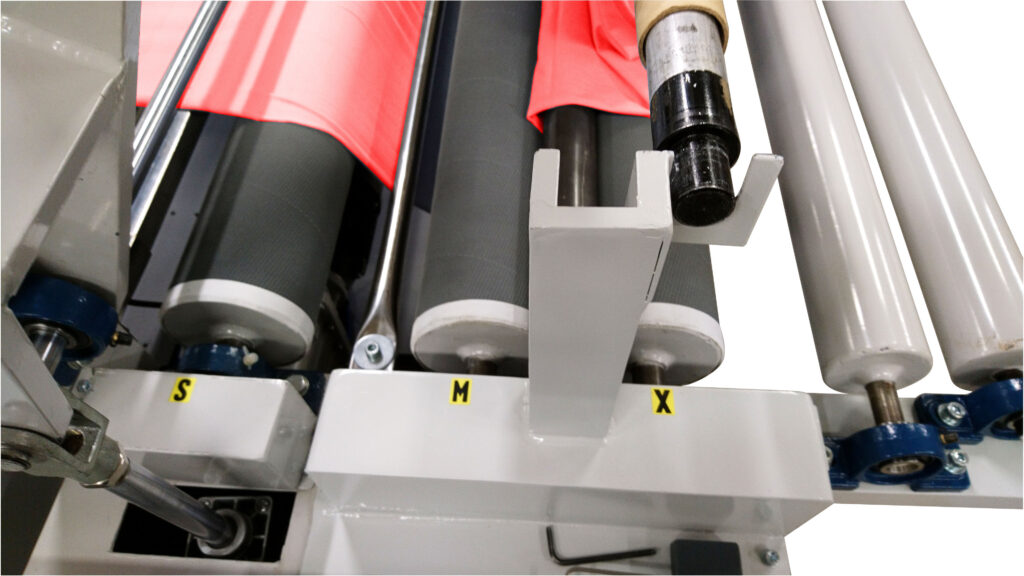

Product Portfolio

Diversity and quality define Svegea’s product portfolio. The Tube Sewing Unit 200, Roll to Roll Slitter RRS 800, and Strip Cutter FA 600 are just a glimpse of the diverse offerings tailored to meet the textile industry’s demands. The Euro Collarette range, featuring models like the EC200C and EC200CS, is designed for exceptional performance, ensuring seamless operations and optimal results.

Global Presence and Bespoke Services

With a global presence extending across continents, Svegea delivers innovative solutions and bespoke services to clients worldwide. Whether it’s fabric inspection machines such as the CMI 210 R or the Complete Bias System, Svegea’s commitment to meeting client needs remains steadfast. Their tailored approach ensures that each solution addresses specific requirements, ensuring customer satisfaction and success.

Award-Winning Innovation

Svegea’s relentless pursuit of excellence has earned them recognition and accolades in the textile industry. Their award-winning innovation is evident in every product, from the Tube Sewing Unit 200 A/AF to the Euro Collarette range. This dedication to pushing boundaries positions Svegea as a leader in innovation and customer satisfaction.

Svegea of Sweden AB stands as a testament to innovation, quality, and customer-centricity in the textile industry. With cutting-edge technology, a diverse product portfolio, a global presence, bespoke services, and award-winning innovation, Svegea continues to redefine standards and shape the future of textile manufacturing. Experience excellence with Svegea – where innovation meets precision, and possibilities are limitless.

In the fast-paced world of textile manufacturing, the key to seamless operations and consistent quality lies in the proper maintenance of production machinery. Whether it’s cutting-edge equipment like Svegea’s innovative solutions or industry-standard machines, regular upkeep is essential to ensure optimal performance and longevity. Let’s dive into some expert tips on maintaining textile production machinery for peak efficiency.

Follow Manufacturer Guidelines

First and foremost, it’s crucial to follow the manufacturer’s guidelines for maintenance. This includes adhering to recommended maintenance schedules, using approved cleaning agents and lubricants, and following specific calibration and part replacement procedures. By following these guidelines diligently, you can prevent premature wear and tear and ensure the machinery operates at its best.

Regular Cleaning and Inspection

Keeping the machinery clean and well-maintained is key to preventing breakdowns and ensuring smooth operation. Regularly clean all components to remove dust, debris, and buildup that can affect performance. Conduct thorough inspections to identify any signs of wear, damage, or loose parts that may require attention. Addressing minor issues early can prevent them from escalating into major problems later on.

Lubrication and Calibration

Proper lubrication is essential for reducing friction, preventing overheating, and prolonging the life of moving parts. Follow the recommended lubrication schedule and use the correct type and amount of lubricant for each component. Additionally, ensure that the machinery is calibrated regularly to maintain accuracy and consistency in performance, especially for cutting and sewing machines.

Training and Monitoring

Invest in training for machine operators to ensure they understand how to use the machinery correctly, follow maintenance procedures, and identify early signs of issues. Encourage them to monitor the machinery’s performance regularly, including production output, efficiency metrics, and any abnormal sounds or vibrations. Promptly addressing any anomalies can prevent downtime and costly repairs.

Implement Preventive Maintenance

Establish a proactive approach to maintenance by implementing a preventive maintenance schedule. This should include routine inspections, cleaning, lubrication, and minor adjustments as needed. Keep detailed records of maintenance activities to track maintenance history, identify recurring issues, and plan for future maintenance needs effectively.

Professional Assistance from Svegea

Don’t hesitate to seek professional assistance from Svegea’s team of experts for complex maintenance tasks or troubleshooting. They have the knowledge, experience, and resources to handle maintenance and repairs efficiently, ensuring your textile production machinery operates optimally. Contact Svegea’s team today to discuss your maintenance needs and maximize the performance of your machinery.

Proactive maintenance is the cornerstone of efficient and reliable textile production machinery. By following these tips and working with trusted professionals like Svegea, you can prolong the lifespan of your equipment, minimize downtime, and achieve consistent quality in your manufacturing processes. Schedule regular maintenance, train your operators, and partner with experts for a seamless production experience.

A Legacy of Excellence: Svegea’s Sustainable Journey

Since its establishment in 1952, Svegea of Sweden has epitomized excellence in the textile industry. With a steadfast commitment to sustainability, Svegea has embarked on a transformative journey towards greener manufacturing practices.

Innovating with the Environment in Mind

At the heart of Svegea’s green initiatives is a focus on innovation. By integrating sustainable materials and energy-efficient technologies into its machines, Svegea reduces its environmental impact while delivering top-notch performance. Notably, Svegea’s sustainable textile machines yield minimal wastage, contributing significantly to its environmentally friendly approach.

Environmental Responsibility in Action

Svegea’s manufacturing facilities are a testament to its environmental responsibility. From efficient waste management to eco-conscious production methods, every step is taken to minimize waste and conserve resources. Additionally, Svegea assists in making adjustments to prolong the lifespan of its sustainable textile machines, further enhancing sustainability efforts.

Promoting Product Longevity and Durability

Sustainability extends beyond manufacturing to product design. Svegea engineers sustainable textile machines for longevity, reducing the need for frequent replacements and contributing to a circular economy. With proper maintenance and adjustments, Svegea’s sustainable textile machines can last for a long time, preserving resources and minimizing environmental impact.

Collaborating for a Greener Future

Svegea collaborates with eco-friendly suppliers and supports initiatives promoting environmental stewardship in the textile industry. Together, these efforts drive positive change and pave the way for a greener future.

Leading by Example

Svegea’s dedication to sustainability sets a high standard for the industry. By prioritizing environmental responsibility, Svegea demonstrates that business success can go hand in hand with environmental stewardship.

A Promise for Future Generations

Svegea’s green initiatives in manufacturing underscore its commitment to sustainability. With a legacy of excellence and a vision for a cleaner, greener future, Svegea leads the way in redefining manufacturing practices for the betterment of our planet.