As the fashion world gears up for Summer 2025, textile manufacturers and garment producers have a golden opportunity to meet growing demands with innovative materials, smart production techniques, and trend-driven designs. This season is all about sustainability, tech-infused textiles, and nostalgic yet bold aesthetics, making it crucial for manufacturers to stay ahead of the curve.

Consumers are ready to refresh their wardrobes, and retailers will be on the lookout for efficient, cost-effective solutions to stock their shelves with the latest trends. But how can manufacturers prepare for this seasonal surge without compromising on quality, speed, or sustainability?

Let’s explore the top Summer 2025 fashion trends and uncover ways textile producers can maximize their production capabilities while minimizing costs.

Fashion Trends Manufacturers Must Watch

Fashion is a dynamic industry that continuously reinvents itself. As we move into summer, some exciting trends have emerged that manufacturers should integrate into their production planning.

1. Sustainable Elegance: Eco-Friendly Fabrics Take Center Stage

Sustainability is more than just a buzzword—it’s a movement shaping fashion’s future. Consumers are increasingly aware of their environmental impact, leading to a surge in demand for eco-friendly textiles such as:

- Organic cotton

- Recycled polyester

- Plant-based dyes

- Biodegradable fabrics

For manufacturers, adopting sustainable textile options can open doors to new partnerships with eco-conscious brands and appeal to consumers seeking ethical fashion.

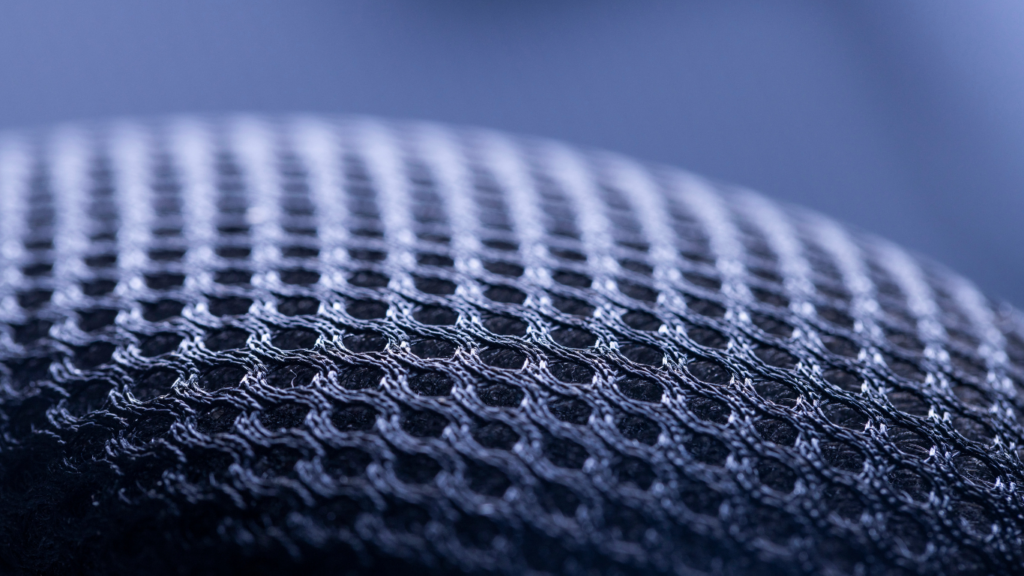

2. Tech-Infused Textiles: The Future of Fabric Innovation

Innovation isn’t just for smartphones—it’s transforming textiles too! Expect to see high-tech materials gaining popularity, including:

- Moisture-wicking fabrics for activewear

- UV-resistant textiles for summer essentials

- Temperature-regulating fabrics for everyday wear

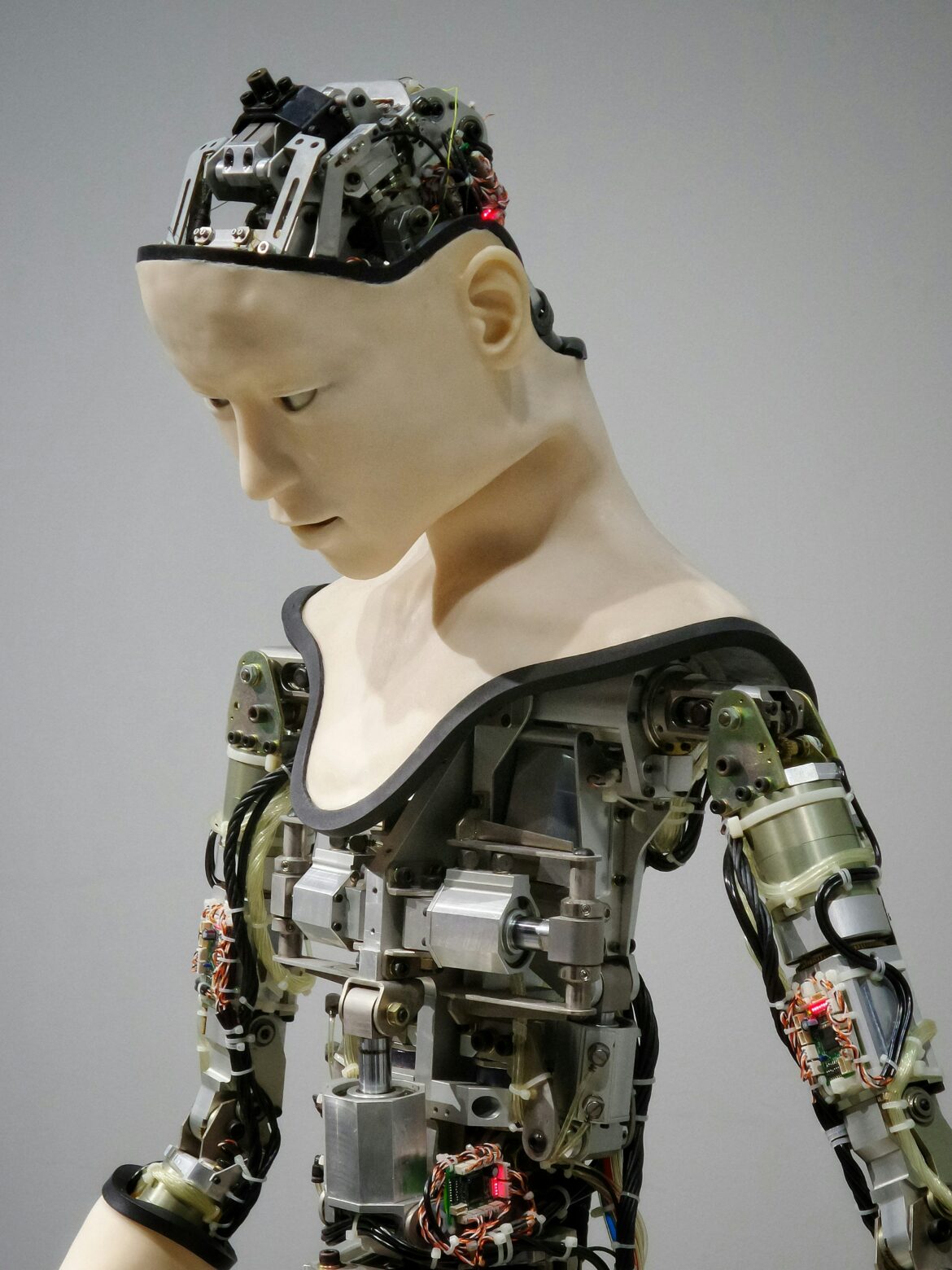

- Smart textiles with embedded sensors for health & wellness tracking

By incorporating cutting-edge textile machinery, manufacturers can streamline production processes for these innovative fabrics, ensuring high demand doesn’t slow down efficiency.

3. Retro Revival & Bold Colors: Nostalgic Yet Fresh

Fashion takes a trip down memory lane with 90s-inspired silhouettes, vibrant hues, and retro prints. Think oversized blazers, wide-leg pants, and bright florals.

Manufacturers should focus on:

– Versatile multi-use fabrics

– Cost-effective digital printing techniques for bold designs

– Flexible dyeing processes to create custom hues

With bold statement pieces leading the season, production processes need to be agile while ensuring quality craftsmanship.

How Textile Manufacturers Can Stay Ahead of the Competition

With demand soaring, efficiency is key. Here’s how manufacturers can optimize production and take advantage of fashion’s seasonal boom:

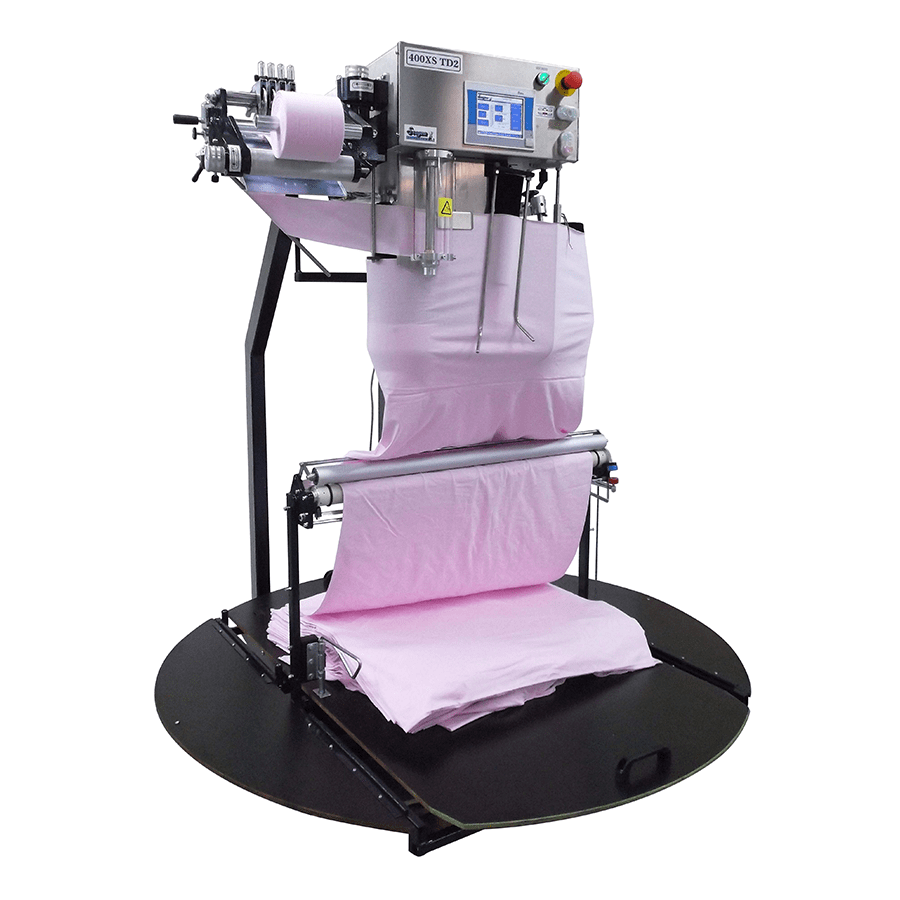

1. Upgrade to Advanced Textile Machinery

The backbone of textile manufacturing is high-performance machinery. Investing in automated systems and AI-driven technologies can dramatically boost production speed while reducing labor costs.

For manufacturers looking to upgrade with minimal expenses, innovative textile machinery from industry leaders like Svegea can provide cost-effective solutions tailored for mass production.

2. Adopt Sustainable Production Methods

Green practices aren’t just a trend—they’re a necessity. Implementing low-waste production techniques and using renewable energy sources in factories can:

– Improve brand image

– Attract eco-conscious retailers

– Reduce long-term costs

3. Leverage Automation for Faster Turnaround

Automated cutting, digital printing, and AI-driven production systems allow manufacturers to:

– Scale production without increasing overhead

– Meet tight deadlines effortlessly

– Reduce fabric waste through precision cutting

Preparing for the Summer 2025 Rush

Textile manufacturers and garment producers have a prime opportunity to take advantage of the Summer 2025 fashion wave. With sustainability, smart textiles, and retro-inspired designs dominating the industry, manufacturers need to stay flexible and innovative.

To supercharge production and reduce costs, partnering with Svegea of Sweden for state-of-the-art textile machinery is a game-changer.

Contact Hakan Steene today at h.steene@svegea.se and get ready to transform your production capabilities!

The textile industry is transforming. With growing concerns about environmental impact, manufacturers are shifting towards sustainable textile practices. From reducing waste to adopting energy-efficient machinery, the industry is embracing innovation to create a greener future.

The Rise of Circular Fashion

Circular fashion is revolutionizing the textile industry. Instead of the traditional linear model, where clothes are made, used, and discarded, circular fashion promotes recycling and reusing materials. Brands are now designing garments with longevity in mind, using biodegradable fabrics and closed-loop production systems.

Key Circular Fashion Strategies:

-

- Recycling & Upcycling: Old textiles are repurposed into new garments, reducing landfill waste.

- Closed-Loop Production: Materials are continuously reused, minimizing resource depletion.

- Biodegradable Fabrics: Natural fibers like organic cotton and hemp decompose without harming the environment.

Zero-Waste Manufacturing: Eliminating Textile Waste

Traditional textile production generates excessive waste. However, zero-waste manufacturing aims to eliminate fabric scraps and optimize material usage.

How Zero-Waste Manufacturing Works:

-

- Precision Cutting: Advanced machinery ensures minimal fabric waste.

- Fabric Optimization: Designers create patterns that maximize fabric efficiency.

- Waste Repurposing: Leftover materials for accessories or insulation.

Eco-Friendly Dyeing Techniques: Reducing Water & Chemical Usage

Dyeing is one of the most polluting processes in textile manufacturing. Fortunately, eco-friendly dyeing techniques are emerging to reduce water consumption and chemical waste.

Sustainable Dyeing Methods:

- Natural Dyes: Extracted from plants and minerals, these dyes are biodegradable.

- Waterless Dyeing: Innovative technologies like CO₂ dyeing eliminate water usage.

- Low-Impact Dyes: Require fewer chemicals, reducing environmental harm.

Automation & Advanced Machinery: Reducing Energy Consumption

Automation is reshaping textile manufacturing by driving smarter, more sustainable operations. With advanced machinery and AI-powered systems, manufacturers reduce energy consumption, cut material waste, and boost productivity. These technologies fine-tune power usage to lower carbon footprints while delivering consistent speed and precision. By minimizing errors and maximizing efficiency, automation gives textile producers a competitive edge and a cleaner path forward.

Sustainable Textile Manufacturing

Svegea is at the forefront of sustainable textile production. Their innovative machinery enhances efficiency while reducing environmental impact. By integrating automation and precision engineering, Svegea helps manufacturers adopt greener practices without compromising quality.

For more information on sustainable textile manufacturing and product demos, contact Hakan Steene at h.steene@svegea.se.

The textile industry is undergoing a digital revolution, and AI in textile manufacturing is at the forefront of this transformation. Artificial intelligence reshapes how textiles are created, manufactured, and distributed, from optimizing design processes to enhancing production efficiency.

AI in Textile Design: Innovation Meets Creativity

AI is revolutionizing textile design by enabling faster, smarter, and more efficient pattern-making. Designers now use AI-powered tools to generate intricate patterns, predict fashion trends, and customize designs based on consumer preferences.

How AI Enhances Textile Design:

-

- Automated Pattern Generation: AI algorithms analyze vast datasets to create unique textile patterns.

- Trend Prediction: Machine learning models forecast upcoming fashion trends, helping designers stay ahead.

- Customization: AI-driven tools allow brands to personalize designs based on customer preferences.

AI in Textile Production: Efficiency and Precision

AI is streamlining textile production by automating processes, reducing waste, and improving quality control. Manufacturers are integrating AI into machinery to optimize operations and enhance productivity.

Key AI Applications in Textile Production:

AI is transforming textile production through targeted, high-impact applications. Automated  fabric inspection systems now use advanced vision technology to identify defects with precision, ensuring only high-quality materials move forward in the process. On the factory floor, smart manufacturing machines continuously adjust their settings in real time, maximizing efficiency and minimizing downtime. Meanwhile, AI-driven supply chain tools analyze demand patterns and guide resource allocation, keeping operations agile and responsive.

fabric inspection systems now use advanced vision technology to identify defects with precision, ensuring only high-quality materials move forward in the process. On the factory floor, smart manufacturing machines continuously adjust their settings in real time, maximizing efficiency and minimizing downtime. Meanwhile, AI-driven supply chain tools analyze demand patterns and guide resource allocation, keeping operations agile and responsive.

AI-Driven Innovations in the Textile Industry

AI is not just improving efficiency—it’s driving groundbreaking innovations in textile production.

Examples of AI-Driven Innovations:

-

- AI-Powered Smart Textiles: Fabrics embedded with AI sensors for enhanced functionality.

- Predictive Maintenance: AI anticipates machine failures, reducing downtime.

- Eco-Friendly AI Solutions: AI optimizes dyeing processes to minimize environmental impact.

The Future of AI in Textile

AI is transforming the textile industry, making design and production more efficient, sustainable, and innovative. As AI continues to evolve, manufacturers and designers must embrace these advancements to stay competitive.

For more information on AI in textile manufacturing and product demos, contact Hakan Steene at h.steene@svegea.se.

In the competitive garment and textile manufacturing world, efficiency and precision are paramount. Svegea of Sweden, a leader in textile machinery, offers cutting-edge solutions that transform production processes, ensuring higher ROI and safer operations.

Efficiency Meets Innovation

Svegea’s machines are designed to streamline operations and reduce waste. The EC300, known for its precision, ensures consistent quality and faster production times. The Tube Sewing Unit 200A simplifies the creation of bias binding by sewing open fabric into continuous tubular pieces. This innovation minimizes operator assistance while maintaining high productivity.

Adding to their achievements, Svegea received the prestigious New Technology Innovation Award at Texprocess 2023, recognizing the innovative and sustainable design of their textile machinery. Their solutions, such as the award-winning EC-450XF Collarette Cutting System, set benchmarks for precision, efficiency, and eco-friendly manufacturing practices.

Versatility in Production

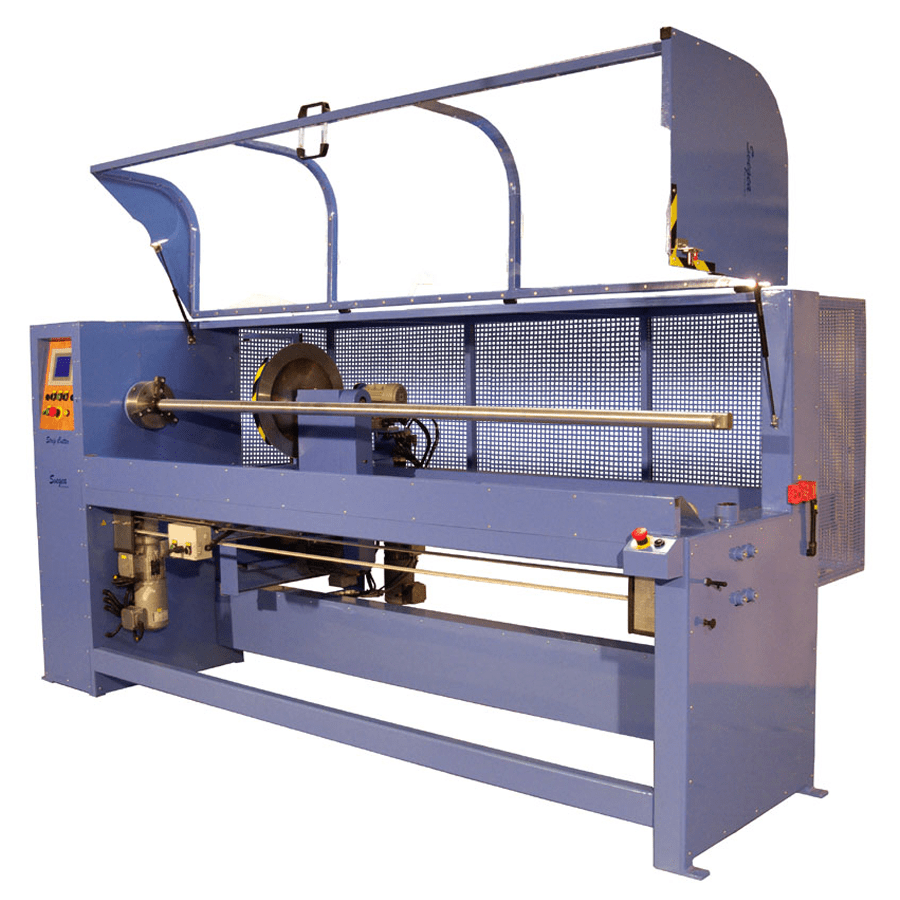

Svegea’s Bias-Cutting Systems are ideal for slitting, sewing, and rolling bias-cut fabrics. These systems handle various fabric types, ensuring strong and stretchable materials for diverse applications. Roll Slitting Machines, such as the FA600, offer fully automated solutions for cutting materials like PVC, polyester, and non-wovens.

Customized Solutions for Your Unique Needs

Every garment manufacturer has unique production requirements, and Svegea understands that one size doesn’t fit all. Their ability to customize textile machines to suit your specific needs ensures smarter, more efficient operations. Whether it’s tailoring machinery to fit fabric types, production volumes, or unique manufacturing goals, Svegea provides solutions that seamlessly integrate into your existing workflows. This flexibility makes their machines a smart investment for companies looking to maximize efficiency and adaptability.

Safety and Sustainability

Modern textile machinery prioritizes operator safety and environmental sustainability. Svegea’s machines incorporate intelligent sensors and energy-efficient designs, reducing workplace hazards and supporting eco-friendly practices.

Why Invest in Textile Machinery?

Acquiring advanced machinery is not just an expense—it’s a strategic investment. Svegea’s equipment enhances production efficiency, reduces operational costs, and boosts workforce productivity. With minimal maintenance and optimized resource utilization, these machines guarantee a robust ROI.

Explore Svegea’s Best-Selling Machines

Explore Svegea’s Best-Selling Machines

Svegea’s portfolio includes:

- Collarette Cutters: Precision-driven textile cutting

- Tube Sewing Unit 200A: Seamless bias binding creation

- Bias Cutting Systems: High-speed slitting and rolling

- Roll Slitting Machines: Automated material cutting

Take the Next Step

Ready to elevate your textile manufacturing? Contact Håkan Steene (h.steene@svegea.se) today for a product demo and discover how Svegea’s innovative machinery can revolutionize your operations.

For more details, visit www.svegea.se.

The textile industry is transforming significantly as companies increasingly bring production back to local markets. This trend, known as onshoring and reshoring, is gaining momentum in regions such as Europe and North America. Various factors, including supply chain resilience, cost-effectiveness, and the desire for high-quality production, drive the shift. In this blog, we will explore the global trend of onshoring and reshoring in the textile industry, discuss how Svegea’s machinery can support manufacturers in achieving their goals, and highlight the benefits of reduced supply chain risks and faster turnaround times.

The Global Trend of Onshoring and Reshoring

In recent years, the textile industry has seen a notable shift towards onshoring and reshoring. This movement involves relocating production processes closer to home, reversing the decades-long trend of offshoring to countries with lower labor costs. Several factors contribute to this shift:

1. Supply Chain Resilience: The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting companies to reconsider their reliance on distant manufacturing hubs. By bringing production closer to home, businesses can mitigate risks associated with disruptions and ensure a more stable supply chain.

2. Cost-Effectiveness: Rising labor costs in traditional offshoring destinations, coupled with increased tariffs and transportation expenses, have eroded the cost advantages of overseas production. Onshoring allows companies to better control costs and improve profitability.

3. Quality Control: Local production enables manufacturers to maintain higher quality standards and ensure compliance with stringent regulations. This is particularly important in the textile industry, where product quality and sustainability are paramount.

Benefits of Reduced Supply Chain Risks and Faster Turnaround Times

Onshoring and reshoring offer several benefits that can significantly impact the textile industry:

1. Reduced Supply Chain Risks: By relocating production closer to home, companies can reduce their exposure to geopolitical tensions, transportation delays, and other disruptions. This leads to a more reliable and resilient supply chain.

2. Faster Turnaround Times: Local production allows for quicker response to market demands and faster delivery of products. This agility is crucial in the textile industry, where fashion trends and consumer preferences can change rapidly.

3. Improved Customer Satisfaction: Faster turnaround times and higher quality control contribute to better customer satisfaction. When products are delivered on time and meet quality expectations, customer loyalty and brand reputation are enhanced.

Reshaping the Textile Industry

The trend of onshoring and reshoring in the textile industry is reshaping the global production landscape. By bringing manufacturing processes closer to home, companies can achieve cost-effective, high-quality production while reducing supply chain risks and improving turnaround times. Svegea’s advanced machinery plays a pivotal role in supporting this transition, offering efficiency, sustainability, and flexibility to manufacturers.

Enabling Cost-Effective, High-Quality Production

Svegea, a leading provider of advanced textile machinery, plays a crucial role in supporting manufacturers as they transition to onshoring and reshoring. Svegea’s innovative equipment offers several advantages:

1. Efficiency and Automation: Svegea’s automated textile machines, such as the Fully Automatic Roll Slitting Machine, enhance production efficiency by minimizing waste and maximizing consistency. These machines are designed to handle large volumes quickly and reliably, helping manufacturers meet tight deadlines without compromising quality.

2. Sustainability: Modern textile machinery from Svegea is built with sustainability in mind. These machines consume less energy, use fewer chemicals, and produce less waste. For example, advanced dyeing machines from Svegea use less water and chemicals, reducing the environmental footprint of the dyeing process.

3. Flexibility: Svegea’s equipment is highly adaptable, allowing manufacturers to produce various materials and meet diverse client needs. This flexibility is essential for staying competitive in a rapidly evolving market.

As the textile industry continues to evolve, embracing onshoring and reshoring will be essential for staying competitive and meeting the demands of a dynamic market. To learn more about how Svegea’s machinery can help your business achieve its goals, visit www.svegea.se and contact Hakan Steene at h.steene@svegea.se for personalized assistance.

Photo by Remy Gieling on Unsplash | Photo by Geoff Oliver on Unsplash

The Impact of Fast Fashion vs. Slow Fashion

The fashion industry is at a crossroads. On one side, fast fashion dominates with its rapid production cycles, low-cost garments, and ever-changing trends. Conversely, slow fashion is gaining momentum, advocating for sustainability, ethical production, and long-lasting quality. Understanding the differences between these two approaches is crucial for consumers and manufacturers alike.

The Environmental and Social Implications of Fast Fashion

Fast fashion has revolutionized the industry, making trendy clothing accessible. However, this convenience comes at a significant cost.

Environmental Consequences

The fast fashion industry is one of the most significant contributors to pollution worldwid e. It generates excessive textile waste, consumes vast amounts of water, and releases harmful chemicals into the environment. Consider these alarming statistics:

e. It generates excessive textile waste, consumes vast amounts of water, and releases harmful chemicals into the environment. Consider these alarming statistics:

- The fashion industry accounts for 10% of global carbon emissions and produces 20% of global wastewater.

- A single cotton shirt requires 2,700 liters of water—enough to sustain one person for 2.5 years.

- Synthetic fibers used in fast fashion take up to 200 years to decompose.

These figures highlight the urgent need for sustainable alternatives.

Social Consequences

Beyond environmental concerns, fast fashion has severe social implications. Many garment factories operate under challenging conditions, where workers often receive wages that may not fully meet the cost of living. In regions like Bangladesh, where the textile industry is a vital economic driver, efforts continue to improve labor standards and create more sustainable working environments. Supporting ethical production and fair compensation remains essential in shaping a more responsible and equitable fashion industry.

The widespread demand for affordable clothing presents challenges in ensuring ethical labor practices. As the fashion industry evolves, businesses and consumers play a key role in promoting fair wages and responsible sourcing to create a more sustainable and equitable future.

Slow Fashion and Sustainability

Slow fashion prioritizes quality over quantity, focusing on durable, ethically produced garments. This movement is supported by innovative textile machines that enhance sustainability and efficiency.

Tips for Manufacturers Transitioning to Sustainable Practices

For manufacturers looking to embrace slow fashion, adopting sustainable practices is essential. Here are key strategies to facilitate the transition:

1. Optimize Energy Efficiency

Investing in energy-efficient textile machines can significantly reduce operational costs and environmental impact. Technologies such as variable frequency drives and energy recovery systems help minimize energy consumption.

2. Use Sustainable Raw Materials

Choosing organic cotton, recycled fabrics, and biodegradable materials can drastically reduce pollution and resource depletion. Sustainable sourcing ensures ethical production while maintaining high-quality standards.

3. Implement Waste Reduction Strategies

Advanced textile machines, like those from Svegea, help manufacturers cut fabric efficiently, reducing excess material waste. Additionally, adopting zero-waste design techniques can further minimize environmental impact.

4. Reduce Water Usage and Pollution

Traditional textile production consumes vast amounts of water. Modern dyeing machines now recycle water, significantly lowering consumption. Manufacturers should also explore low-impact dyeing techniques to reduce chemical pollution.

5. Promote Supply Chain Sustainability

Partnering with ethical suppliers and ensuring fair labor practices throughout the supply chain is crucial. Transparency in sourcing and production fosters consumer trust and strengthens brand reputation.

6. Foster a Culture of Sustainability

Educating employees and stakeholders about sustainable practices encourages long-term commitment to eco-friendly production. Companies should integrate sustainability goals into their business strategies to drive meaningful change.

Sustainable Textile Production

Svegea of Sweden specializes in innovative textile machinery that supports sustainable and efficient garment production. Their advanced solutions help manufacturers reduce waste and optimize processes by:

- Maximizing fabric usage through precision cutting and automation, minimizing material waste.

- Enhancing energy efficiency, reducing overall consumption and environmental impact.

- Improving garment durability, promoting longevity, and contributing to a circular economy.

By integrating Svegea’s technology, manufacturers can transition to eco-friendly production methods without compromising efficiency or profitability.

More than a Trend

The battle between fast fashion and slow fashion is more than a trend—it’s a movement toward a more sustainable future. While fast fashion continues to dominate, its environmental and social consequences cannot be ignored. Slow fashion, supported by innovative textile machines like those from Svegea of Sweden, offers a viable solution for manufacturers seeking ethical and sustainable production.

By adopting energy-efficient technology, sustainable materials, and waste reduction strategies, manufacturers can contribute to a greener industry while maintaining profitability. The shift toward slow fashion is not just necessary—it’s inevitable.

Let’s embrace sustainability and redefine the future of fashion. If you’re looking to enhance the productivity and sustainability of your garment production processes, reach out to Håkan Steene at h.steene@svegea.se to learn more about Svegea’s advanced textile machinery and solutions.

Image credits: Photo by Alina Bordunova on Unsplash | Photo by Hannah Morgan on Unsplash

In an era where OOTD (Outfit of the Day) reigns supreme on social media, our relationship with clothing has become increasingly complicated. The fashion industry stands at a crossroads. Fast fashion pulls us one way—slow, sustainable production beckons from another direction. Let’s unzip the truth about these contrasting approaches and explore how quality textile production could be the thread that weaves a more sustainable future.

The True Cost of Fast Fashion: More Than Just a Price Tag

Remember that $5 t-shirt you couldn’t resist? While your wallet might have thanked you, our planet tells a different story. According to the United Nations Environment Programme, the fashion industry accounts for 10% of global carbon emissions and generates 20% of global wastewater. Stop and think about that. It’s more than all international flights and maritime shipping combined! The numbers are staggering. The implications are worse.

Fast fashion’s environmental impact reads like a horror story:

- One cotton shirt requires 2,700 liters of water – enough to keep one person hydrated for 2.5 years

- Synthetic fibers take up to 200 years to decompose

- The industry produces 92 million tons of textile waste annually

But environmental concerns are just the beginning. The human cost of fast fashion includes poor working conditions, minimal wages, and unsafe environments. A 2021 report by the Business & Human Rights Resource Centre revealed over 100 cases of worker exploitation in major fashion brands’ supply chains. These aren’t just statistics. They’re real people’s lives.

The Slow Fashion Revolution: Quality Over Quantity

Think of slow fashion as the farm-to-table movement of the textile world. It’s about creating garments that last. Simple as that. This approach emphasizes quality over quantity, craftsmanship over mass production, and sustainability over quick profits.

Quality Materials and Craftsmanship

High-quality textile production isn’t just about using better materials. Every thread counts. Manufacturers who invest in quality control and precise cutting techniques create garments that maintain their shape and durability through countless washes. It’s an investment in the future.

Innovation in Sustainable Manufacturing

Small and medium-sized enterprises (SMEs) often lead the way in sustainable innovation. Take Svegea of Sweden, for instance. This family-owned SME has spent decades perfecting bias-cutting technology that significantly reduces fabric waste. Their commitment to quality and sustainability shows how smaller companies can make a big impact. Through continuous innovation and unwavering dedication to quality, such companies prove that sustainable manufacturing isn’t just possible – it’s profitable.

Sustainable Production Methods

Modern textile manufacturing doesn’t have to choose between efficiency and sustainability. Advanced bias cutting machines can reduce fabric waste by up to 15% compared to traditional methods, while maintaining precise, high-quality cuts. Technology and sustainability can work hand in hand. They must.

Fair Labor Practices

Slow fashion emphasizes fair wages and safe working conditions. No compromises. When workers aren’t rushed to meet impossible quotas, they can focus on craftsmanship and quality control. The result? Superior products that last longer.

Making the Transition: A Guide for Manufacturers

Transitioning to sustainable practices isn’t just good for the planet – it’s good for business. A recent McKinsey survey found that 67% of consumers consider the use of sustainable materials an important purchasing factor. The message is clear. The time is now.

Start Small, Think Big

1. Audit your current waste levels and identify areas for improvement

2. Invest in precision cutting technology to reduce fabric waste

3. Train staff in sustainable practices and quality control

4. Consider implementing a circular production model

Embrace Technology Wisely

Modern machinery isn’t just about speed. It’s about precision and efficiency. The right equipment can help reduce waste, improve quality, and maintain consistency while reducing overall production costs. Smart choices lead to better results.

Build Transparency

Document your sustainability journey and share it with customers. Today’s consumers want to know the story behind their clothes. Transparency builds trust. Trust builds loyalty. Loyalty builds success.

The Future is in Our Hands

The fashion industry’s future doesn’t have to be a choice between profitability and sustainability. By focusing on quality textile production, manufacturers can create products that benefit everyone – from workers to consumers to the planet itself. The choice is ours. The time is now.

Want to learn more about sustainable textile production methods or see how modern technology can support your sustainability goals? Visit www.svegea.se to explore innovative solutions for quality textile production. For personalized guidance on implementing sustainable practices in your manufacturing process, reach out to our sustainability expert at h.steene@svegea.se.

*Author’s Note: This article was crafted with care to provide accurate information about sustainable fashion practices. All statistics and facts have been sourced from reputable industry reports and research papers. While specific solutions mentioned may vary in effectiveness depending on individual circumstances, the principles of sustainable production remain universal.*

The textile industry is experiencing a significant transformation, with Artificial Intelligence (AI) at its core. AI is revolutionizing textile design by automating processes, predicting trends, and promoting sustainability. This technological advancement is reshaping how designers and manufacturers approach creativity and production.

What is Textile Design AI?

Textile design AI involves utilizing artificial intelligence to enhance and automate the creation of textile patterns and designs. By analyzing extensive datasets, AI can generate unique designs and forecast consumer preferences. For instance, AI can blend historical patterns with current trends to produce innovative designs, expediting the creative process and fostering unprecedented innovation.

How AI is Transforming Textile Design

1. Automating Repetitive Tasks – AI streamlines tasks such as pattern creation and color adjustments, allowing designers to focus on creativity. Tools like Adobe’s Sensei automate pattern generation and color matching, enhancing efficiency.

2. Predicting Trends – By analyzing data from social media and fashion platforms, AI predicts upcoming trends. Platforms like Heuritech scan millions of images to identify emerging patterns, helping brands stay ahead.

3. Personalization at Scale – AI enables mass customization, allowing consumers to personalize products without hindering production. Companies like Unmade offer personalized knitwear, letting customers select colors and patterns.

4. Sustainable Design Solutions – AI optimizes material usage and reduces waste by calculating efficient fabric-cutting methods and suggesting eco-friendly materials, aiding brands in adopting sustainable practices.

Real-World Applications of Textile Design AI

- Fashion Brands Leading the Way – Brands like Stitch Fix use AI to analyze customer preferences and recommend personalized clothing. Similarly, Zara employs AI to monitor real-time sales data and adjust designs accordingly.

- Textile Machinery and AI Integration – Companies are integrating AI into textile machinery to optimize production, ensuring high-quality results with minimal waste. For example, advanced systems use AI to adjust settings based on fabric types automatically, reducing errors and improving efficiency.

Why Textile Design AI Matters

- For Designers – AI empowers designers to experiment with new ideas and streamline workflows, bringing visions to life faster. By automating routine tasks, designers can focus more on creativity and innovation.

- For Consumers – AI-driven design offers consumers more options, including personalized clothing and eco-friendly fabrics, meeting individual preferences and reducing wait times for new collections.

- For the Planet – The textile industry is a significant polluter. AI helps reduce environmental impact by optimizing resource usage and promoting sustainable practices, contributing to a more sustainable future.

Challenges and Opportunities

While AI offers numerous benefits, challenges include potential job displacement due to automation and the need for high-quality data for effective AI systems. However, AI can create new roles focusing on creativity and strategy, and as technology advances, data collection barriers are likely to decrease.

Challenges

-

Job Displacement & Workforce Adaptation

One of the biggest concerns with AI automation is job displacement. Tasks that were once done manually, such as pattern-making, color matching, and quality control, are now being automated, reducing the demand for traditional roles. However, this shift doesn’t necessarily mean mass unemployment. Instead, the workforce needs to adapt by acquiring new skills in AI-assisted design, data analysis, and machine operation.

-

Need for High-Quality Data

AI relies on vast amounts of high-quality data to function effectively. In textile design, this means collecting and organizing fabric patterns, color schemes, consumer preferences, and trend data. Poor data quality—such as incomplete, outdated, or biased datasets—can lead to inaccurate predictions and ineffective designs.

-

Implementation Costs & Infrastructure

Small and mid-sized textile businesses may struggle with the high cost of AI implementation, which includes purchasing software, integrating AI with existing production lines, and training employees. Companies need to balance initial investments with long-term gains in efficiency and productivity.

-

Creativity vs. Standardization

While AI can generate unique patterns and automate design processes, it still lacks human intuition and artistic expression. Over-reliance on AI might lead to standardized, repetitive designs, reducing originality in fashion and textile production.

Opportunities

-

New Job Roles & Upskilling

- As AI automates repetitive tasks, new roles will emerge that require human expertise in:

- AI-driven textile design

- Digital trend forecasting

- AI model training and management

- Sustainable material innovation

- This shift creates opportunities for upskilling and cross-functional roles, blending AI knowledge with traditional design expertise.

- As AI automates repetitive tasks, new roles will emerge that require human expertise in:

-

Improved Efficiency & Cost Savings

- AI streamlines design, manufacturing, and inventory management, reducing waste and increasing efficiency.

- Brands can cut production costs by optimizing material usage and minimizing trial-and-error design iterations.

-

Enhanced Personalization & Sustainability

- AI allows for mass customization, where consumers can personalize clothing designs at scale.

- AI-driven sustainability solutions, such as fabric waste reduction algorithms and eco-friendly material selection, are helping the industry move towards a greener future.

-

Data-Driven Design & Trend Forecasting

- AI tools can analyze social media, runway trends, and past consumer behavior to predict upcoming fashion trends.

- This helps brands stay ahead of the curve, reducing the risk of overproduction and unsold inventory.

The Future of Textile Design AI

The future holds endless possibilities for AI in textile design, including creating adaptive fabrics and designs that change based on user preferences. Continued innovation and sustainability efforts will drive the industry forward.

Join the Textile AI Revolution!

Don’t miss out on the future of textile design powered by AI. Embrace innovation, sustainability, and personalization in your textile creations. For more details on how AI can transform your designs and production processes, contact h.steene@svegea.se.

As we step into 2025, the textile manufacturing industry is poised for significant transformations. Driven by technological advancements and evolving consumer demands, the industry is embracing new trends that promise to reshape the landscape. This blog explores the key textile trends for 2025, highlighting how innovative solutions are leading the charge.

Sustainability Takes Center Stage

Sustainability continues to be a dominant trend in textile manufacturing. Consumers are increasingly demanding eco-friendly products, pushing manufacturers to adopt sustainable practices. In 2025, we will see a rise in the use of organic and recycled materials, such as organic cotton, bamboo, and Tencel. These materials are not only environmentally friendly but also offer superior quality and comfort.

Moreover, manufacturers are focusing on reducing their carbon footprint by optimizing production processes and minimizing waste. Advanced textile machinery, such as cutting-edge collarette cutting systems, exemplifies this commitment to sustainability. These systems reduce fabric waste and enhance production efficiency, aligning with the industry’s green goals.

The Rise of Smart Textiles

Smart textiles are revolutionizing the industry by integrating advanced technology into fabrics. These textiles can monitor health, regulate temperature, and even change color based on environmental conditions. In 2025, we expect to see more widespread adoption of smart textiles in various applications, from fashion to healthcare.

Innovative solutions are at the forefront of this trend. Automated systems, like advanced roll-cutting/slitting machines, incorporate cutting-edge technology to enhance precision and efficiency. These advancements not only improve product quality but also open new possibilities for smart textile applications.

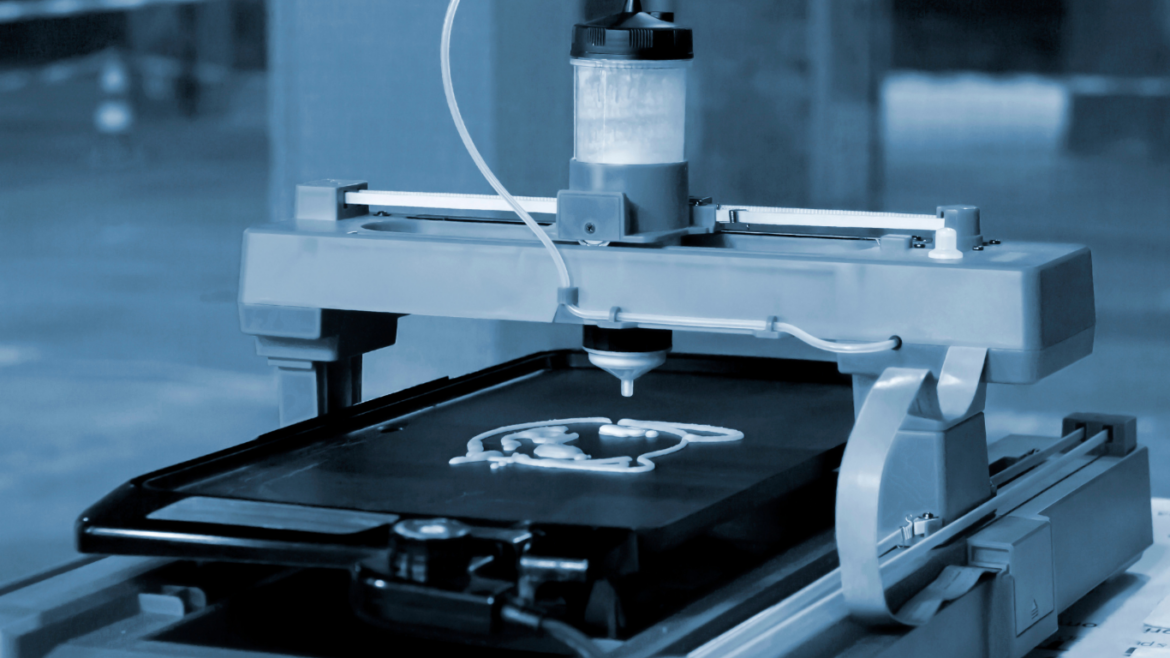

Digital Printing Innovations

Digital printing is transforming textile design by allowing for greater creativity and customization. Traditional printing methods are being replaced by digital techniques that enable intricate designs and vibrant colors. This trend is expected to grow in 2025, with more manufacturers adopting digital printing to meet consumer demands for unique and personalized products.

Precise cutting capabilities, offered by advanced strip cutters, ensure that digitally printed fabrics are handled with the utmost care and accuracy. These innovations are integral to maintaining the quality and appeal of digitally printed textiles.

Advanced Apparel Manufacturing

The apparel manufacturing sector is experiencing a shift towards automation and advanced technologies. In 2025, we will see increased use of AI and robotics to streamline production processes and reduce labor costs. These technologies enhance efficiency, improve product quality, and enable manufacturers to respond quickly to market changes.

Automated sewing units simplify the production of bias binding, reducing the need for manual intervention and increasing overall productivity. By leveraging such advanced machinery, manufacturers can stay competitive in a rapidly evolving market.

Customization and Personalization

Consumers are seeking more personalized products, driving the trend toward customization in textile manufacturing. In 2025, manufacturers will leverage AI and data analytics to offer tailored solutions that meet individual preferences. This trend is particularly evident in the fashion industry, where personalized clothing and accessories are becoming increasingly popular.

Innovative textile machinery can be tailored to meet specific production needs, ensuring that manufacturers can deliver unique products that resonate with their customers.

Sustainable Supply Chains

Sustainability extends beyond materials and production processes to encompass the entire supply chain. In 2025, we will see a greater emphasis on creating sustainable supply chains that minimize environmental impact and promote ethical practices. This includes sourcing raw materials responsibly, reducing transportation emissions, and ensuring fair labor practices.

Innovative solutions help manufacturers optimize their supply chains, reducing waste and improving efficiency. By adopting these advanced technologies, companies can enhance their sustainability efforts and meet the growing demand for eco-friendly products.

3D Technologies

3D technologies are making waves in textile manufacturing by enabling the creation of complex designs and prototypes. In 2025, we will see more manufacturers adopting 3D printing and other advanced techniques to push the boundaries of textile design. These technologies allow for greater experimentation and innovation, resulting in unique and high-quality products.

Cutting-edge machinery supports the integration of 3D technologies into textile production. These machines precisely cut and slit 3D-printed fabrics, handling them with care and accuracy.

Immersive Fashion

Immersive fashion is an emerging trend that combines technology and design to create interactive and engaging experiences. In 2025, we will see more brands exploring immersive fashion through augmented reality (AR) and virtual reality (VR) technologies. These innovations allow consumers to visualize and interact with products in new and exciting ways.

Advanced textile machinery supports the production of immersive fashion by enabling precise and efficient manufacturing processes. These innovations ensure that manufacturers can stay ahead of the curve and deliver cutting-edge products to their customers.

A Transformative Era

The textile manufacturing industry is on the cusp of a transformative era, driven by technological advancements and changing consumer demands. Trends such as sustainability, smart textiles, digital printing, and advanced manufacturing are reshaping the landscape, offering new opportunities for innovation and growth.

Innovative textile machinery is setting new standards in the industry. As we move into 2025, manufacturers must embrace these trends to stay competitive and meet the evolving needs of their customers.

For more information on how advanced solutions can help your business thrive, contact Håkan Steene at h.steene@svegea.se today!

Artificial Intelligence (AI) is emerging as a game-changer in the ever-evolving landscape of textile manufacturing. From design to production, AI is revolutionizing the industry, enhancing efficiency, reducing waste, and driving innovation. This blog delves into how AI is transforming textile manufacturing, spotlighting Svegea’s innovative solutions.

The Role of AI in Textile Manufacturing

AI is making significant strides in various aspects of textile manufacturing. One of the most notable areas is automated design and pattern-making. AI tools like Adobe’s Textile Designer analyze vast amounts of trend data from fashion shows, online retail platforms, and consumer behavior studies. This analysis helps predict future trends in patterns, colors, and materials with high accuracy, enabling designers to create collections that align closely with market demands.

Moreover, AI is enhancing the fabric inspection process. Advanced systems equipped with high-resolution cameras and sophisticated AI software, such as the Uster Quantum 4.0, conduct real-time textile analysis. These systems meticulously scan for defects like misweaves, pattern irregularities, and color deviations, ensuring only top-quality fabrics move forward in the production line. This precision significantly reduces waste and elevates product quality.

Enhancing Manufacturing Efficiency

AI-driven automation is streamlining textile manufacturing processes. Predictive maintenance, for instance, uses AI to foresee equipment failures before they happen, minimizing downtime and repair costs. Advanced AI-powered robotics and automation streamline tasks such as fabric cutting, sewing, and quality inspection, leading to faster production cycles and reduced labor costs.

Svegea, a leader in textile manufacturing solutions, exemplifies the integration of AI in production. Their EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, achieves unparalleled precision and efficiency. This system, along with other advanced machines like the SWS automatic roll cutting/slitting machines and the Strip Cutter CMS-1800A3, showcases Svegea’s commitment to cutting-edge technology.

Optimizing Supply Chains

AI plays a crucial role in optimizing supply chains within the textile industry. Machine learning models predict demand patterns, allowing manufacturers to adjust production schedules and inventory levels accordingly. AI-driven analytics also help identify the most efficient routes for shipping and logistics, reducing transportation costs and carbon footprint. This level of optimization ensures that products reach consumers promptly, enhancing customer satisfaction.

Revolutionizing Quality Control

Quality control is a critical aspect of textile production, and AI is enhancing this process through advanced inspection technologies. Computer vision systems equipped with AI algorithms can detect defects and inconsistencies in fabrics with high precision. These systems analyze images of textiles in real time, identifying issues such as color variations, weave irregularities, and fabric flaws that might be missed by human inspectors. This results in higher quality products and fewer returns.

Personalizing Consumer Experiences

AI is transforming how brands interact with consumers by enabling personalized shopping experiences. AI-powered recommendation engines analyze user behavior, purchase history, and preferences to offer tailored product suggestions. Virtual fitting rooms, driven by AI, allow customers to try on clothes virtually, enhancing the online shopping experience and reducing the likelihood of returns.

Svegea’s Innovative Solutions

Svegea of Sweden AB stands out as a beacon of innovation in textile manufacturing. With over 72 years of experience, Svegea offers a wide array of products and services that redefine the textile landscape. Their product portfolio includes the Tube Sewing Unit 200A, Roll to Roll Slitter RRS 800, and Strip Cutter FA 600, all designed for exceptional performance and efficiency.

Svegea’s commitment to cutting-edge technology is evident in its award-winning products. The EC-450XF Collarette Cutting System, for example, sets new benchmarks in production excellence. Svegea’s global presence and bespoke services ensure that each solution addresses specific client needs, ensuring customer satisfaction and success.

The Future of AI in Textile Manufacturing

The integration of AI in textile manufacturing is just beginning. As technology continues to advance, we can expect even greater efficiencies and innovations. AI will likely play an increasingly important role in areas such as sustainable production, where it can help reduce waste and optimize resource use.

AI is revolutionizing textile manufacturing, driving efficiencies, and fostering innovation. Companies like Svegea are leading this transformation, offering advanced solutions that set new industry standards. As AI continues to evolve, the future of textile manufacturing looks brighter than ever. To learn more about how Svegea can help your business stay ahead of the curve, contact Håkan Steene at h.steene@svegea.se today!