Cutting Corners (Without Compromising Quality)

In the intricate world of textile cutting, businesses often find themselves at a crossroads. Imagine standing amidst bolts of fabric, scissors poised, pondering the delicate dance between quality and cost. Fear not! Enter Svegea’s Economy Range, where affordability meets excellence. Let’s unravel these affordable cutting solutions, stitch by stitch.

1. The CMS 1800A Strip Cutter: Precision Unleashed

Meet the CMS 1800A, the Gandalf of strip cutters. It trims fabric edges with surgical precision, leaving waste trembling in its wake. Small to medium-sized enterprises (SMEs), rejoice! Your budget just found a reliable sidekick.

2. Fabric Inspection Machines: CSI for Textiles

Enter the CMI 180 and its twin, the CMI 180E. These machines don their detective hats, magnifying glass in hand, scrutinizing fabrics for defects. Quality control? Nailed it. SMEs can now play textile detective without maxing out their credit cards.

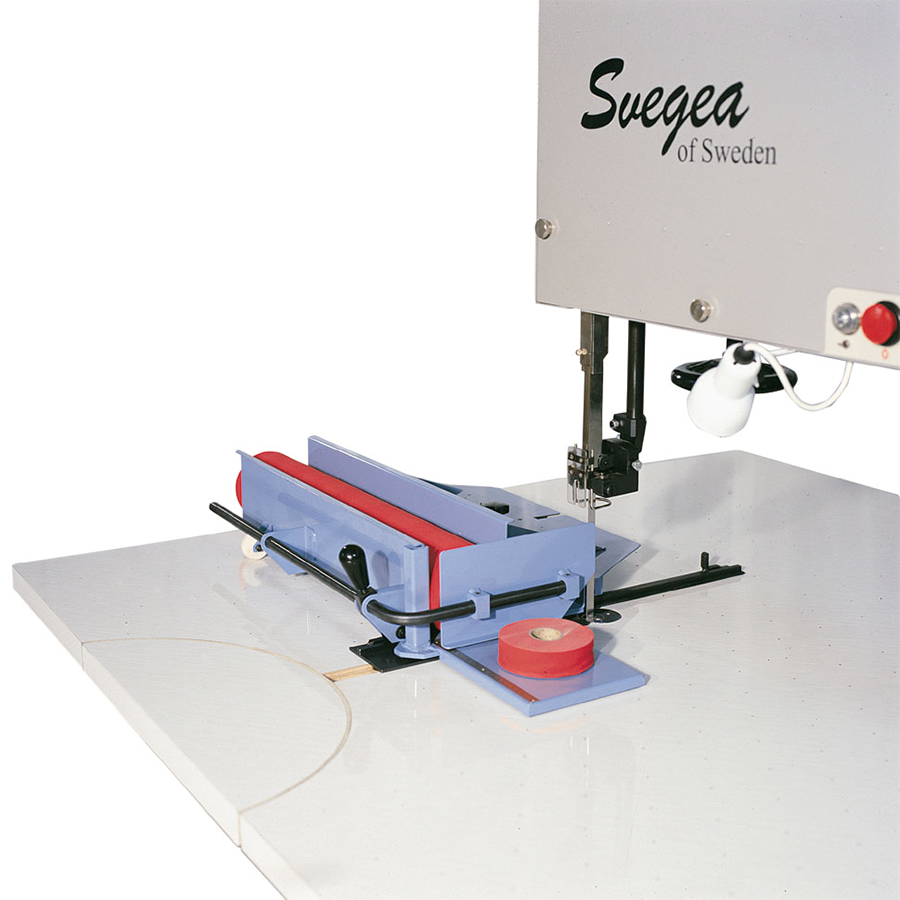

3. Band Knife Machines: Precision, Thy Name Is SV/BK

The SV/BK series slices through textiles like a seasoned sushi chef. From the pocket-sized SV/BK 500 to the burly SV/BK 1250, these machines cater to all cutting cravings. Affordability? Check. Quality? Double-check. It’s like having a Swiss Army knife for fabrics.

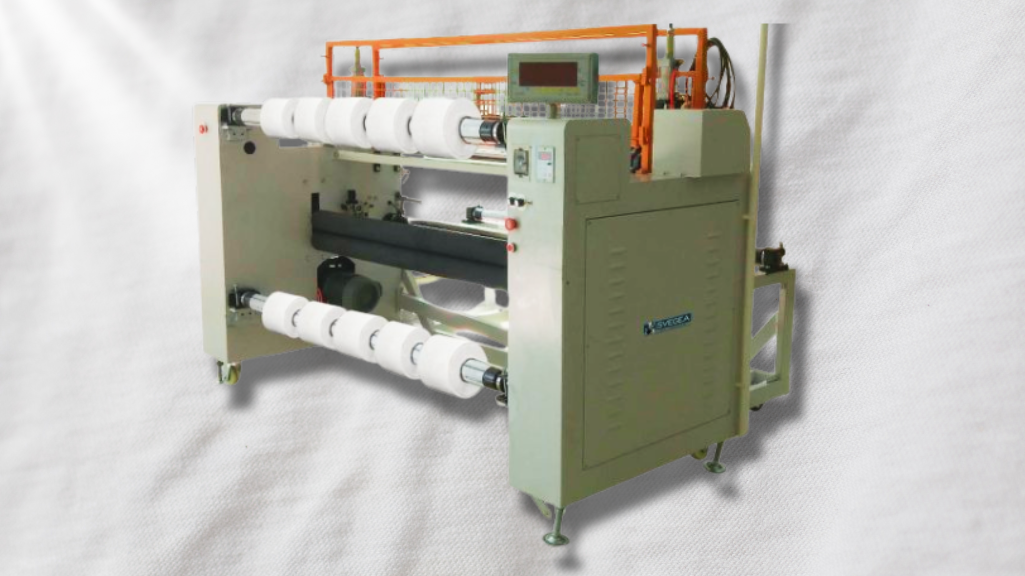

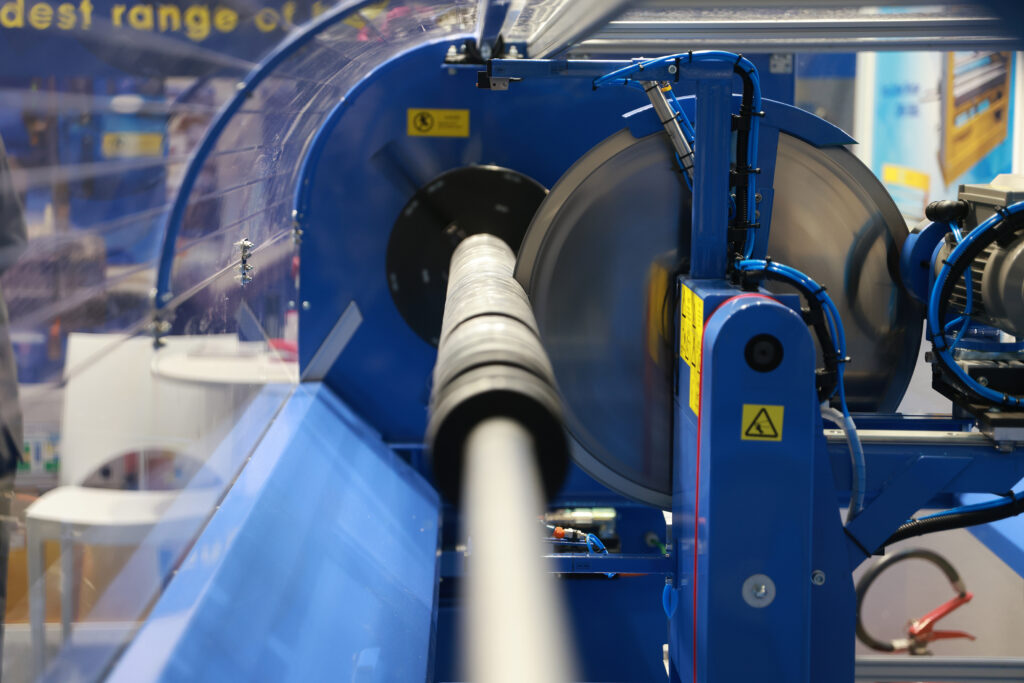

4. Roll to Roll Slitting Machine RRS-800: Unroll the Red Carpet

Textile production needs a red carpet moment. Cue the RRS-800! It slits rolls like a pro, leaving clean, accurate cuts in its wake. Startups and seasoned manufacturers alike can now roll with the big dogs without emptying their wallets.

Why Svegea’s Economy Range Rocks

1. Quality Assurance: Svegea doesn’t do shortcuts. Each machine undergoes rigorous testing – think of it as a textile boot camp. No flimsy recruits here!

2. Cost Savings: Choosing the Economy Range is like finding a hidden treasure chest. You save on upfront costs, leaving room for victory dances and celebratory confetti.

3. Tailored Solutions: One size doesn’t fit all – especially in the textile world. Svegea’s got options galore. Pick your cutting companion, like choosing a wand at Ollivanders (minus the magical mishaps).

Cut Above the Rest

Svegea’s Economy Range isn’t just about numbers; it’s about weaving dreams into reality. Whether you’re a startup producing your first batch of garment materials or a seasoned manufacturer patching up decades of experience, these cutting solutions are your secret weapon. So grab your scissors (or better yet, an SV/BK), and let’s cut through the fabric of limitations. Affordable excellence awaits!

Svegea’s Economy Range isn’t just about numbers; it’s about weaving dreams into reality. Whether you’re a startup producing your first batch of garment materials or a seasoned manufacturer patching up decades of experience, these cutting solutions are your secret weapon. So grab your scissors (or better yet, an SV/BK), and let’s cut through the fabric of limitations. Affordable excellence awaits!

In the fast-paced world of textile manufacturing, precision and efficiency are paramount. The Roll-to-Roll Slitting Machine RRS-800 is a cutting-edge solution that meets these demands, allowing textile producers to optimize their processes and deliver high-quality products. In this article, we’ll explore the key features of this machine, its specifications, and its impact on the industry.

Key Features:

Motorized Knife with Adjustable Speed

The heart of this efficient slitting machine lies in its motorized knife. This advanced feature allows operators to control the cutting speed, ensuring precise slitting without compromising quality. Whether it’s delicate fabrics or heavy-duty materials, the RRS-800 adapts effortlessly.

Adjustable Cutting Widths

Flexibility is essential in textile production. This state-of-the-art textile machine achieves this by allowing operators to adjust cutting widths. By moving the placement of the knives, manufacturers can tailor the machine to their specific needs.

Optional Electronic Meter Counter

Keeping track of material usage is crucial for cost management. It offers an optional electronic meter counter, enabling real-time monitoring. This feature ensures efficient resource allocation and minimizes waste.

Pneumatic Lift Kit for Easy Loading and Start-Up

Loading and starting up a slitting machine can be labor-intensive. The RRS-800 streamlines this process with its pneumatic lift kit. Operators can effortlessly raise the knife shaft, reducing downtime and enhancing productivity.

Re-Rolling Efficiency

After slitting, re-rolling becomes essential. This cost-effective machine excels in this aspect by utilizing two independent air-expanding shafts. These shafts handle the re-rolling of slit rolls, ensuring uniform tension and preventing material distortion.

Three Shafts for Optimal Performance

The RRS-800 boasts a total of three shafts:

- One for the master roll

- Two for re-rolling

This configuration allows seamless transitions between processes, minimizing downtime and maximizing throughput.

Customizable Air-Shaft Sizes

Different materials require different handling. This slitting machine caters to this diversity by offering customizable air-shaft sizes upon request. Garment manufacturers can fine-tune the machine to match their specific textile types and dimensions.

The RRS-800 combines innovation, precision, and adaptability, making it a valuable asset for textile manufacturers worldwide. As the industry continues to evolve, machines like the RRS-800 are pivotal in meeting production demands while maintaining product quality.

In an era where sustainability is not just a choice but a necessity, the story of sustainable natural fibers is a compelling narrative of environmental responsibility and traditional artisanship. This tale begins with the nurturing of seeds and ends with the creation of fabrics that embody both style and ecological consciousness.

The Seed of Sustainability

Every fiber’s journey starts with a seed, a sapling, or a fleece. Farmers globally cultivate plants like cotton, flax, or hemp, or rear animals for wool and silk. These sustainable natural fibers are gifts from the earth, renewable and biodegradable, contrasting sharply with synthetic fibers made from petrochemicals.

Cultivation with Care

The art of growing sustainable natural fibers involves a delicate balance between yield and environmental care. Techniques such as crop rotation, organic farming, and integrated pest management minimize ecological damage. Despite challenges like water consumption for cotton or the fragility of silk production, these practices ensure the fibers’ sustainability.

Harvesting with Heritage

Harvesting these fibers often involves age-old traditions, with methods handed down through generations. Whether it’s picking cotton, processing flax, or shearing sheep, these actions are performed with a precision that reflects a deep harmony with nature.

Spinning Stories

Post-harvest, the fibers travel to mills to be cleaned, carded and spun into yarn. This stage is where modern technology meets human expertise. Artisans and workers apply their skills to guarantee the yarn’s quality, influencing the fabric’s eventual texture and strength.

Weaving Worlds

The yarn then transforms into fabric through weaving or knitting. This process can occur on simple handlooms in rural settings or through sophisticated machinery in modern factories. Here, the fabric acquires its unique patterns and characteristics, ready for dyeing, printing, and finishing.

The yarn then transforms into fabric through weaving or knitting. This process can occur on simple handlooms in rural settings or through sophisticated machinery in modern factories. Here, the fabric acquires its unique patterns and characteristics, ready for dyeing, printing, and finishing.

Dyeing with Diligence

The dyeing process adds color to the sustainable natural fibers, with a growing preference for eco-friendly dyes derived from plants and minerals. These methods are not only less polluting but also reconnect us with ancient, earth-friendly practices.

Fashioning Fabrics

The penultimate phase is turning the fabric into garments. Designers and tailors are crucial here, as they convert the fabric into wearable art. The slow fashion movement is fostering an appreciation for the narrative and quality behind each piece.

Challenges and Opportunities

The supply chain for sustainable natural fibers faces challenges like price volatility and competition from synthetics. However, the industry is ripe with opportunities, particularly sustainably and ethically.

The Road Ahead

As awareness grows, so does the demand for sustainable natural fibers. The industry is innovating at every supply chain level, ensuring that the path from farm to fabric remains both sustainable and enriching.

Craft Your Sustainable Legacy

For those inspired by the sustainable journey of natural fibers and seeking precision in their textile projects, Svegea of Sweden is a beacon of excellence. With over 72 years of experience in creating high-quality textile cutting systems, they epitomize the commitment to the enduring value of natural fibers. To discover how their state-of-the-art solutions can enhance the sustainability and quality of your work, visit their contact page. Together, let’s craft a future that respects our planet with every fiber.

In the fast-paced realm of textile manufacturing, precision isn’t just a goal—it’s an essential. Whether you’re crafting intricate patterns or tackling complex shapes, the need for clean, accurate cuts is paramount for producing top-notch textile products. That’s where band knife-cutting machines step in—a versatile solution that marries precision with adaptability, making them indispensable in the industry’s arsenal.

Decoding Band Knife-Cutting Machines

Band knife-cutting machines operate seamlessly with a continuous band blade, slicing through fabric with remarkable precision. Unlike conventional die-cutting methods, which often struggle with intricate designs, these machines excel at effortlessly cutting even the most complex shapes and patterns.

The Anatomy of Precision

At the heart of band knife-cutting machines lies a robust band blade forged from high-grade steel. This blade continuously rotates around two pulleys, meticulously tensioned to ensure optimal cutting performance. The razor-sharp edge, combined with precise computer-controlled movements, guarantees consistently clean and precise cuts with every operation.

Versatility Across Materials

A standout feature of band knife-cutting machines is their versatility across various materials. From delicate silk and chiffon to rugged canvas and denim, these machines effortlessly slice through diverse textiles. Their adaptability extends beyond fabrics, making them suitable for cutting foam, leather, cardboard, and more.

Beyond Cutting: Added Advantages

Aside from their cutting prowess, band knife-cutting machines offer several other benefits:

1. Automated Material Handling: Many models come with automated material handling systems, streamlining the cutting process and ensuring consistent quality.

2. Programmability: Manufacturers can input and modify cutting patterns easily. Quick changeovers between different designs minimize downtime, boosting overall productivity.

Staying Ahead with Innovation

As technology progresses, so do band knife-cutting machines. Newer models boast enhanced blade life, quicker cutting speeds, and heightened precision. These advancements ensure that these machines remain at the forefront of cutting-edge technology.

Precision Redefined

In the fiercely competitive textile manufacturing landscape, precision and efficiency are the cornerstones of success. Band knife-cutting machines, with their prowess in handling intricate shapes and patterns, empower producers to create top-quality products without compromising accuracy. As the industry continues to evolve, these machines are set to play a pivotal role in shaping the future of textile production.

Ready to explore the precision of band knife-cutting machines? Contact Svegea of Sweden for more details and elevate your manufacturing capabilities today!

The textile industry is undergoing transformative changes driven by trends around sustainability, automation, customization, and circularity. Leading machinery manufacturers offer cutting-edge solutions to help textile producers capitalize on these powerful market shifts.

Sustainability Imperative

Environmental consciousness is fueling the demand for eco-friendly textiles, currently, a global textile trend that we cannot ignore. Innovative machinery enables sustainable manufacturing practices like energy efficiency and waste reduction, minimizing environmental impact while maintaining competitive operations.

Automation & Industry 4.0

Principles like robotics, AI, and IoT are optimizing production through automation. Advanced textile machinery seamlessly integrates these technologies to streamline operations, boost productivity, and reduce costs – keeping manufacturers at the forefront of the digital revolution.

Customization & Diversification

Evolving consumer tastes favor personalized products and unique experiences. Flexible machinery allows for customized, diverse offerings tailored to changing market demands.

Circular Economy Transition

Resource efficiency is paramount, with textile circularity reducing waste. Circular knitting machines and recycling technologies enable closed-loop supply chains by repurposing waste into new materials.

As these trends reshape the global landscape, machinery manufacturers position textile producers for success. By adopting innovative solutions for sustainability, automation, customization, and circularity, industry leaders can drive sustainable growth and gain a lasting competitive edge.

For inquiries, brochures, or further information about Svegea of Sweden’s cutting-edge textile machinery, visit our contact page.

In the fast-paced world of textile manufacturing, the key to seamless operations and consistent quality lies in the proper maintenance of production machinery. Whether it’s cutting-edge equipment like Svegea’s innovative solutions or industry-standard machines, regular upkeep is essential to ensure optimal performance and longevity. Let’s dive into some expert tips on maintaining textile production machinery for peak efficiency.

Follow Manufacturer Guidelines

First and foremost, it’s crucial to follow the manufacturer’s guidelines for maintenance. This includes adhering to recommended maintenance schedules, using approved cleaning agents and lubricants, and following specific calibration and part replacement procedures. By following these guidelines diligently, you can prevent premature wear and tear and ensure the machinery operates at its best.

Regular Cleaning and Inspection

Keeping the machinery clean and well-maintained is key to preventing breakdowns and ensuring smooth operation. Regularly clean all components to remove dust, debris, and buildup that can affect performance. Conduct thorough inspections to identify any signs of wear, damage, or loose parts that may require attention. Addressing minor issues early can prevent them from escalating into major problems later on.

Lubrication and Calibration

Proper lubrication is essential for reducing friction, preventing overheating, and prolonging the life of moving parts. Follow the recommended lubrication schedule and use the correct type and amount of lubricant for each component. Additionally, ensure that the machinery is calibrated regularly to maintain accuracy and consistency in performance, especially for cutting and sewing machines.

Training and Monitoring

Invest in training for machine operators to ensure they understand how to use the machinery correctly, follow maintenance procedures, and identify early signs of issues. Encourage them to monitor the machinery’s performance regularly, including production output, efficiency metrics, and any abnormal sounds or vibrations. Promptly addressing any anomalies can prevent downtime and costly repairs.

Implement Preventive Maintenance

Establish a proactive approach to maintenance by implementing a preventive maintenance schedule. This should include routine inspections, cleaning, lubrication, and minor adjustments as needed. Keep detailed records of maintenance activities to track maintenance history, identify recurring issues, and plan for future maintenance needs effectively.

Professional Assistance from Svegea

Don’t hesitate to seek professional assistance from Svegea’s team of experts for complex maintenance tasks or troubleshooting. They have the knowledge, experience, and resources to handle maintenance and repairs efficiently, ensuring your textile production machinery operates optimally. Contact Svegea’s team today to discuss your maintenance needs and maximize the performance of your machinery.

Proactive maintenance is the cornerstone of efficient and reliable textile production machinery. By following these tips and working with trusted professionals like Svegea, you can prolong the lifespan of your equipment, minimize downtime, and achieve consistent quality in your manufacturing processes. Schedule regular maintenance, train your operators, and partner with experts for a seamless production experience.

In the realm of cutting-edge technology, Svegea of Sweden emerges as a trailblazer, reshaping the cutting machine landscape. This article explores Svegea’s cutting technology, delving into advanced features and technological innovations that redefine precision, efficiency, and innovation.

Precision Engineering Excellence:

At the core of Svegea of Sweden’s cutting technology lies a dedication to precision engineering. These cutting machines, meticulously crafted with cutting-edge technology, guarantee accuracy in every cut. Whether handling intricate textile patterns or precise angles in industrial materials, Svegea’s cutting machines, born in Sweden, deliver unmatched precision, instilling confidence for seamless execution.

Adaptive Intelligent Automation:

Svegea of Sweden’s cutting machines go beyond automation; they embody intelligent automation. Armed with state-of-the-art sensors and smart controls, these machines adapt to varying materials and thicknesses, adjusting parameters in real time. This adaptability minimizes downtime, boosts efficiency, and optimizes the overall cutting process, positioning Svegea’s technology as a valuable asset for operational excellence.

Versatility Crafted in Sweden:

A standout feature of Svegea of Sweden’s cutting technology is its unparalleled versatility. Designed to handle diverse materials and applications, from textiles to industrial composites, these machines streamline operations and maximize return on investment, offering a single-cutting solution crafted in Sweden that caters to multiple needs.

Tailored Customization Capabilities:

Recognizing unique business requirements, Svegea of Sweden’s cutting technology provides extensive customization capabilities. Whether adjusting cutting speeds, configuring blade angles, or implementing specific cutting patterns, businesses gain the flexibility to tailor the machine to exact specifications. This customization, rooted in Swedish commitment to quality, empowers businesses to address challenges and optimize cutting processes.

Integration with Industry 4.0 – The Swedish Way:

Svegea of Sweden’s cutting-edge technology seamlessly integrates with Industry 4.0 principles, ushering in a smart manufacturing era. With connectivity features and data analytics, these machines offer real-time insights, enabling data-driven decisions. This Swedish-inspired integration enhances efficiency, reduces waste, and contributes to smarter, sustainable manufacturing.

Energy-Efficient Design – Swedish Sustainability:

In an era prioritizing sustainability, Svegea of Sweden’s cutting technology excels with its energy-efficient design. Engineered to optimize power consumption without compromising performance, this eco-friendly approach aligns with global sustainability goals, translating into long-term cost savings for businesses.

User-Friendly Interface – Swedish Simplicity:

While boasting advanced features, Svegea of Sweden’s cutting-edge technology remains accessible through a user-friendly interface. Intuitive controls and a user-friendly interface, influenced by Swedish design principles, simplify system navigation for operators. This focus on user experience ensures seamless integration into workflows without extensive training.

Svegea of Sweden’s cutting technology transcends the ordinary, offering businesses advanced features that redefine cutting machine possibilities. From precision engineering and intelligent automation to versatility, customization, and sustainability, Svegea of Sweden’s commitment to innovation shines in every facet. For businesses aspiring to lead their industries, Svegea of Sweden’s advanced cutting solutions presents a transformative force propelling them into a future of unparalleled efficiency and innovation.

Discover Svegea of Sweden’s precision cutting technology today. Elevate operations with the Swedish touch. Contact us for a consultation and experience the difference.