In the ever-evolving tapestry of the textile industry, staying ahead of the curve isn’t just smart—it’s essential. As we thread our way through 2024, let’s unravel the spool of future trends in textile manufacturing that are stitching a new narrative for fabric production.

Smart Textiles: The Brainy Fibers

Imagine a world where your clothes adjust to your body temperature, track your health stats, or even change color to match your mood. No, it’s not science fiction; it’s the magic of smart textiles. These brainy fibers integrate advanced materials to bring intelligence to our wardrobes. It’s like having a personal assistant woven into your jeans!

3D Technologies: Tailoring a New Reality

Gone are the days of one-size-fits-all. With 3D technologies in fashion, custom-fit clothing is becoming the norm, not the exception. This trend is not just about looking good; it’s about precision, efficiency, and reducing waste. So, if you’re tired of clothes that just don’t fit right, the future looks tailor-made for you.

Sustainable Supply Chains: Green Is the New Black

As the industry spins toward sustainability, sustainable supply chains are becoming as crucial as fashion. It’s about creating a cycle of production that respects the planet as much as it does profit. After all, what’s the point of looking good if we don’t have a planet to look good on?

Customization and Personalization: The ‘You’ in Your Clothes

In a world where everyone wants to stand out, customization is king. The future of textiles is personal, with bespoke designs and personalized experiences becoming the new standard. It’s time to wear your personality on your sleeve—literally.

AI and Data Analytics: The Style Algorithm

Data is the new thread in textile manufacturing, with AI and data analytics weaving patterns of efficiency and innovation. These technologies are not just about crunching numbers; they’re about creating fabrics that are smarter, more responsive, and, dare we say, more fashionable.

Engaging the Right Partner

As we embrace these future trends, it’s clear that the right partner can make all the difference. Engage the services of a textile manufacturing company that’s not just keeping up with these trends but is at the forefront of the textile revolution. You want to be in good company. Whether it’s smart textiles or sustainable practices, Svegea is the go-to for any manufacturing needs to cope with the future trends in textiles.

It’s an exciting time to be in the industry, and with companies like Svegea of Sweden leading the charge, the future is not just bright; it’s brilliant. For more insights into these trends, check out the full reports from StartUs Insights and GreyB. And remember, when it comes to the future of textiles, don’t just follow the trends—wear them.

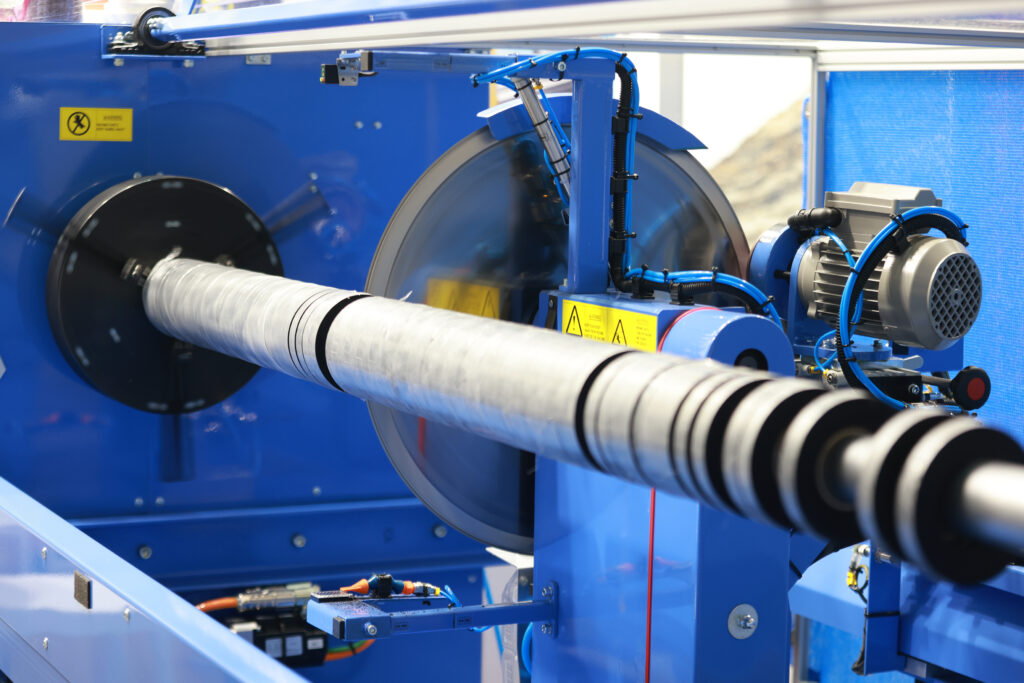

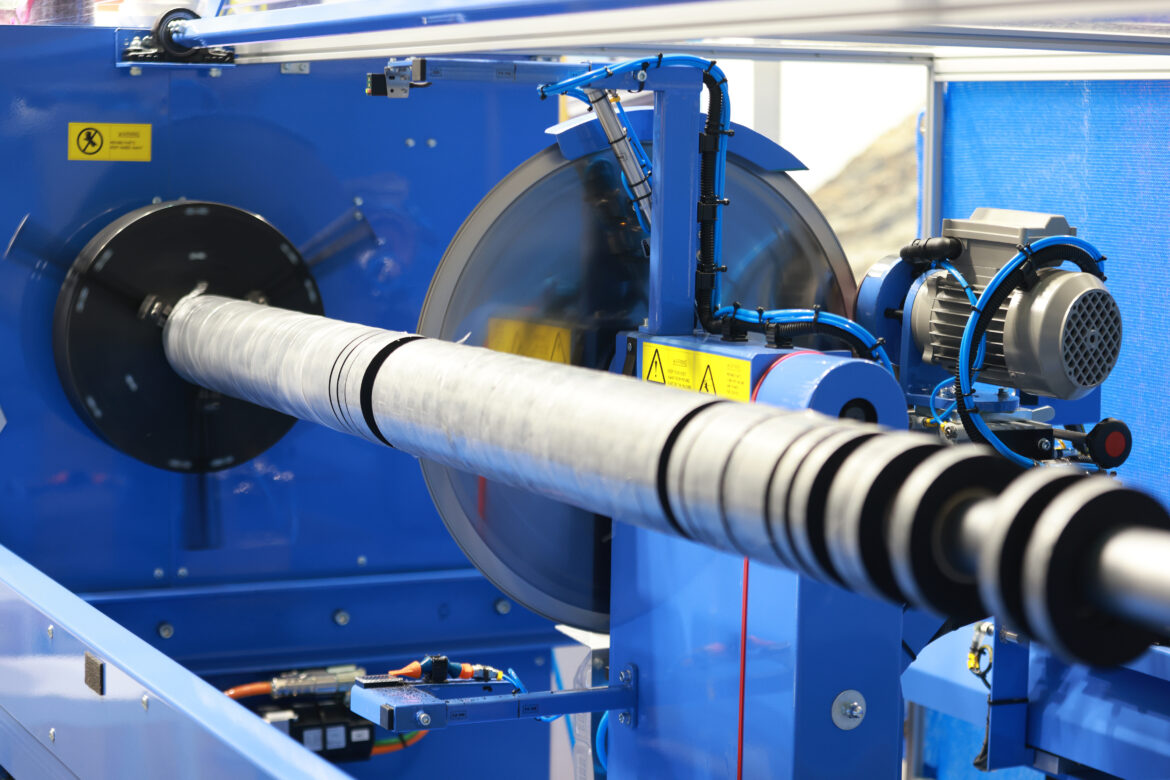

In manufacturing optimization, Svegea’s roll-slitting machines stand out as pioneers, integrating precision and speed to redefine production standards. These advanced machines cater to diverse industries, from textiles to packaging, offering sustainable solutions that maximize output while minimizing waste. Let’s explore how Svegea’s technology contributes to efficient material utilization and supports sustainable manufacturing practices.

Enhancing Efficiency Through Innovation

Svegea’s roll-slitting machines address the inefficiencies of traditional cutting methods by optimizing material usage. Unlike conventional processes that often result in significant leftover materials, Svegea ensures each roll is fully utilized, reducing costs and environmental impact. This commitment to efficiency boosts productivity and supports sustainable production practices.

Seamless Integration and Versatility

One of the key strengths of Svegea’s machines lies in their seamless integration into existing production workflows. Their user-friendly interfaces and intuitive designs empower operators to manage and control operations effortlessly. This versatility allows manufacturers to handle a wide range of materials with precision, adapting swiftly to varying production demands.

Precision and Quality Assurance

Precision is paramount in manufacturing, and Svegea’s roll-slitting machines excel in delivering consistent and accurate cuts. Advanced technology ensures that each slit meets stringent quality standards, minimizing errors and enhancing overall product quality. This precision not only reduces rework but also enhances operational efficiency, making these machines indispensable in high-demand industries.

Contributing to Sustainable Practices

Central to Svegea’s innovation is its commitment to sustainable manufacturing. By minimizing material waste through efficient roll-slitting technology, these machines play a crucial role in reducing environmental footprint. Optimal material utilization not only lowers raw material consumption but also supports eco-friendly production processes, aligning with global sustainability goals.

Shaping the Future of Manufacturing

Looking ahead, Svegea’s roll-slitting machines continue to set benchmarks for efficient and sustainable manufacturing practices. Their ability to maximize output while minimizing waste underscores a paradigm shift towards more responsible industrial practices. As industries evolve towards greater efficiency and environmental consciousness, Svegea remains at the forefront of driving innovation and shaping the future of manufacturing worldwide.

Harnessing the Power of Roll/Slitting Machines

By harnessing the capabilities of Svegea’s Roll/Slitting Machines, industries can achieve significant improvements in production efficiency and sustainability. These machines not only optimize material utilization but also pave the way for a more environmentally conscious approach to manufacturing. Embracing such technology not only benefits businesses economically but also contributes positively to global environmental efforts.

The textile industry is undergoing transformative changes driven by trends around sustainability, automation, customization, and circularity. Leading machinery manufacturers offer cutting-edge solutions to help textile producers capitalize on these powerful market shifts.

Sustainability Imperative

Environmental consciousness is fueling the demand for eco-friendly textiles, currently, a global textile trend that we cannot ignore. Innovative machinery enables sustainable manufacturing practices like energy efficiency and waste reduction, minimizing environmental impact while maintaining competitive operations.

Automation & Industry 4.0

Principles like robotics, AI, and IoT are optimizing production through automation. Advanced textile machinery seamlessly integrates these technologies to streamline operations, boost productivity, and reduce costs – keeping manufacturers at the forefront of the digital revolution.

Customization & Diversification

Evolving consumer tastes favor personalized products and unique experiences. Flexible machinery allows for customized, diverse offerings tailored to changing market demands.

Circular Economy Transition

Resource efficiency is paramount, with textile circularity reducing waste. Circular knitting machines and recycling technologies enable closed-loop supply chains by repurposing waste into new materials.

As these trends reshape the global landscape, machinery manufacturers position textile producers for success. By adopting innovative solutions for sustainability, automation, customization, and circularity, industry leaders can drive sustainable growth and gain a lasting competitive edge.

For inquiries, brochures, or further information about Svegea of Sweden’s cutting-edge textile machinery, visit our contact page.

In the fast-paced world of textile manufacturing, the key to seamless operations and consistent quality lies in the proper maintenance of production machinery. Whether it’s cutting-edge equipment like Svegea’s innovative solutions or industry-standard machines, regular upkeep is essential to ensure optimal performance and longevity. Let’s dive into some expert tips on maintaining textile production machinery for peak efficiency.

Follow Manufacturer Guidelines

First and foremost, it’s crucial to follow the manufacturer’s guidelines for maintenance. This includes adhering to recommended maintenance schedules, using approved cleaning agents and lubricants, and following specific calibration and part replacement procedures. By following these guidelines diligently, you can prevent premature wear and tear and ensure the machinery operates at its best.

Regular Cleaning and Inspection

Keeping the machinery clean and well-maintained is key to preventing breakdowns and ensuring smooth operation. Regularly clean all components to remove dust, debris, and buildup that can affect performance. Conduct thorough inspections to identify any signs of wear, damage, or loose parts that may require attention. Addressing minor issues early can prevent them from escalating into major problems later on.

Lubrication and Calibration

Proper lubrication is essential for reducing friction, preventing overheating, and prolonging the life of moving parts. Follow the recommended lubrication schedule and use the correct type and amount of lubricant for each component. Additionally, ensure that the machinery is calibrated regularly to maintain accuracy and consistency in performance, especially for cutting and sewing machines.

Training and Monitoring

Invest in training for machine operators to ensure they understand how to use the machinery correctly, follow maintenance procedures, and identify early signs of issues. Encourage them to monitor the machinery’s performance regularly, including production output, efficiency metrics, and any abnormal sounds or vibrations. Promptly addressing any anomalies can prevent downtime and costly repairs.

Implement Preventive Maintenance

Establish a proactive approach to maintenance by implementing a preventive maintenance schedule. This should include routine inspections, cleaning, lubrication, and minor adjustments as needed. Keep detailed records of maintenance activities to track maintenance history, identify recurring issues, and plan for future maintenance needs effectively.

Professional Assistance from Svegea

Don’t hesitate to seek professional assistance from Svegea’s team of experts for complex maintenance tasks or troubleshooting. They have the knowledge, experience, and resources to handle maintenance and repairs efficiently, ensuring your textile production machinery operates optimally. Contact Svegea’s team today to discuss your maintenance needs and maximize the performance of your machinery.

Proactive maintenance is the cornerstone of efficient and reliable textile production machinery. By following these tips and working with trusted professionals like Svegea, you can prolong the lifespan of your equipment, minimize downtime, and achieve consistent quality in your manufacturing processes. Schedule regular maintenance, train your operators, and partner with experts for a seamless production experience.

In the ever-evolving realm of manufacturing optimization, Svegea’s roll-slitting machines emerge as trailblazers, reshaping the production landscape with innovation. These cutting-edge machines seamlessly blend precision and speed, offering a sustainable solution for industries handling various materials.

The Core Commitment: Reducing Waste, Maximizing Efficiency

Svegea’s technology embodies a fundamental commitment to reduce waste and maximize efficiency. Traditional cutting methods often leave significant leftover material, increasing costs and environmental impact. Svegea’s innovation tackles this challenge directly, ensuring each roll reaches its full potential, fostering a more sustainable and cost-effective production process.

Seamless Integration into Workflows: Versatile and Efficient

Roll-slitting machines effortlessly integrate into existing production workflows, providing a versatile and efficient addition to any manufacturing setup. The user-friendly interface and intuitive design empower operators to navigate and control the machine with ease, enhancing overall productivity. This adaptability to various materials makes these machines a valuable asset across diverse industries, from textiles to packaging.

Precision at Every Cut: Enhancing Quality Standards

Precision is a cornerstone of manufacturing, and roll-slitting machines excel in delivering accuracy at every cut. Advanced technology ensures precise slitting, meeting the stringent quality standards demanded by industries. This precision not only enhances overall output quality but also reduces the need for rework, saving both time and resources.

Sustainable Production Practices: Minimizing Environmental Impact

Roll-slitting technology minimizes material waste, contributing to a more eco-friendly production process. By optimizing material utilization and production efficiency, these machines align with the global push for sustainable manufacturing practices. Embracing this technology is not just a strategic move; it’s a commitment to a greener planet and a more sustainable future.

Looking Towards the Future: Shaping Manufacturing Responsibly

As we gaze into the future of manufacturing, Svegea’s roll-slitting machines stand as a testament to innovation. The combination of efficiency, precision, and sustainability sets a new standard for industries worldwide. In a world where maximizing output meets minimizing waste, Svegea’s innovative technology shapes a future where manufacturing is both efficient and environmentally conscious.

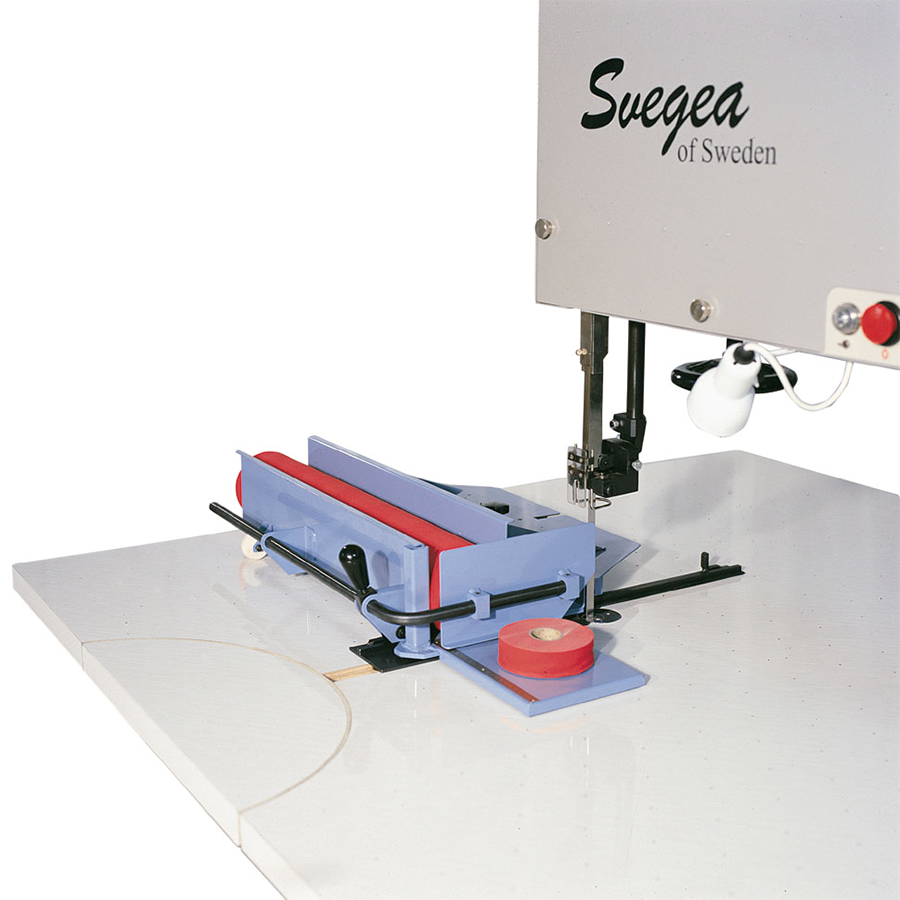

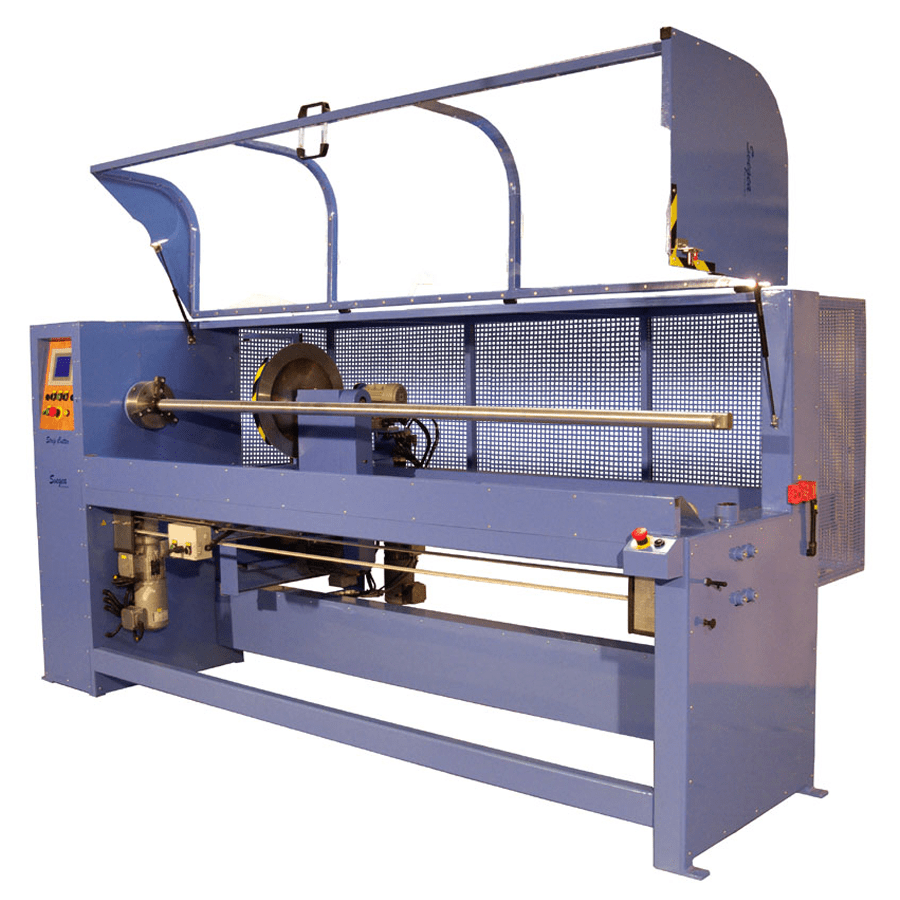

In the world of roll-slitting machines, Svegea’s Strip Cutter FA500 stands tall as a heavy-duty, fully automatic marvel. No frills, just functionality – this is a machine that means business. Let’s dive straight into what makes the FA500 a top pick in its category.

Versatility Redefined

Versatility takes center stage in the FA500’s repertoire. This machine isn’t selective about materials; it effortlessly handles open knits, woven fabric, PVC, Vinyl, Satin, polyester, paper products, and non-wovens. A versatile powerhouse, the FA500 caters to industries dealing with a diverse spectrum of substrates.

Precision Personified

Precision becomes the FA500’s hallmark. With up to three preset cut widths and the capability to determine the number of cuts per cycle, this machine embodies efficiency. It’s not merely about cutting; it’s about cutting with pinpoint accuracy. The inclusion of three standard programs allows operators to tailor cutting operations to specific needs, ensuring a perfect fit for every task.

User-Friendly Operation

Navigating the FA500 is a seamless experience, thanks to its user-friendly touchscreen panel. The intuitive interface enhances the overall user experience, enabling operators to control and monitor the machine with ease. FA500’s design ensures that every operation is not only swift but also seamless.

Safety at the Forefront

Safety takes precedence with the FA500. Operating heavy machinery involves inherent risks, but this machine addresses safety concerns by being entirely enclosed during the cut cycle. Beyond meeting industry standards, this feature instills peace of mind in the workplace, prioritizing the well-being of operators.

Adaptive Blade Control

Precision extends beyond width to the very manner in which the cut is executed. The FA500 introduces adjustable variable speed blade penetration, ensuring controlled engagement with the material. This adaptive blade control adds an extra layer of finesse to the cutting process, enhancing overall precision.

Automatic Maintenance

Maintenance is simplified with the FA500’s automatic sharpening feature. Operators can fine-tune the sharpening time, ensuring the blade remains in optimal condition. This proactive approach minimizes downtime and boosts productivity by ensuring consistent, top-notch performance.

Total Control with PLC

PLC provides total control, leaving nothing to chance. All functions are meticulously PLC controlled, streamlining operations and ensuring each cut is executed with unwavering precision. This level of automation not only enhances efficiency but also guarantees consistent results, instilling confidence in the machine’s performance.

Cool and Calm Cutting

For materials requiring extra care during the cutting process, the FA500 offers an optional automatic blade cooling device with variable settings. This innovation is a game-changer, preserving blade longevity and maintaining the quality of each cut.

Support in Every Roll

The pneumatic fabric loading support seamlessly manages to transition between rolls. This innovative feature facilitates a smooth shift from one roll to another, minimizing downtime and, consequently, maximizing overall productivity.

A Testament to Excellence

The Svegea Strip Cutter FA500 isn’t just a machine; it’s a precision tool tailored for industries where accuracy and efficiency reign supreme. With its robust features, user-friendly interface, and unwavering commitment to safety, the FA500 stands as a testament to Svegea’s dedication to excellence in roll-slitting technology.

Choose the FA500, and effortlessly cut through the competition with unparalleled precision, setting a new standard in the world of roll-slitting machines.

- 1

- 2