The textile industry is no stranger to innovation. From early mechanization to today’s cutting-edge technologies, it has continually evolved to meet growing demands. In this era, automated textile machines are leading the charge with their state-of-the-art efficiency.

The Role of Automated Textile Machines

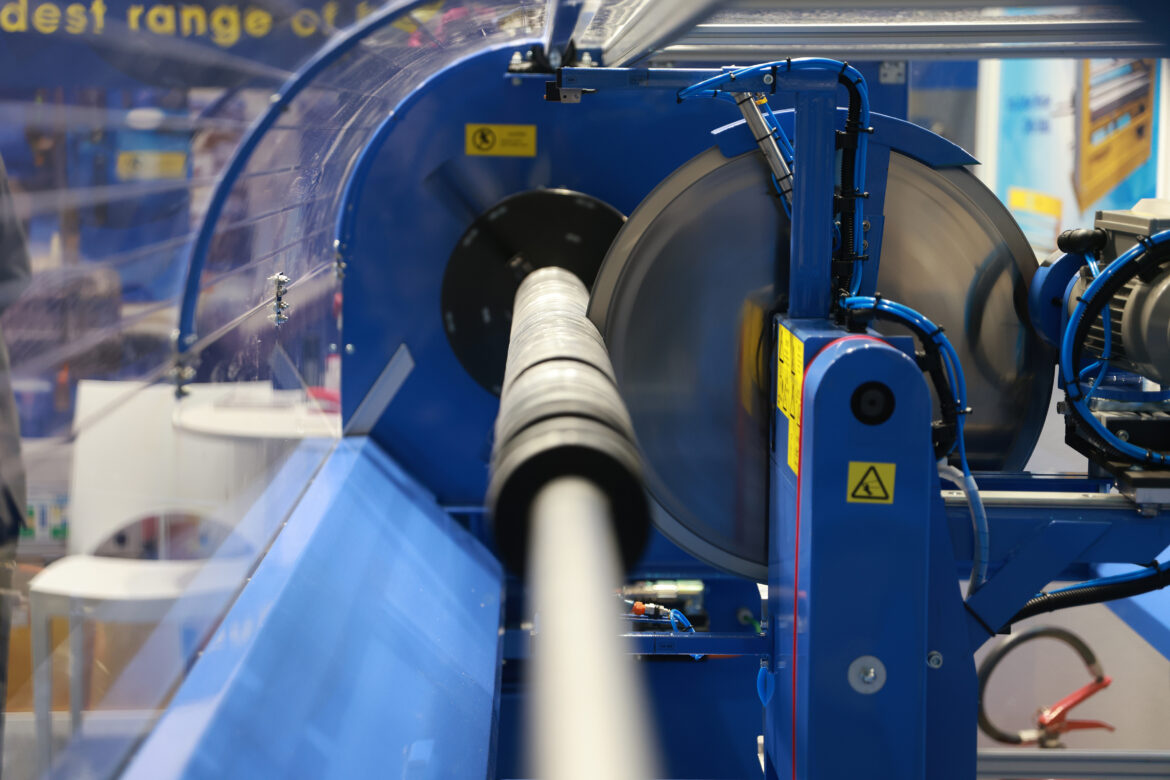

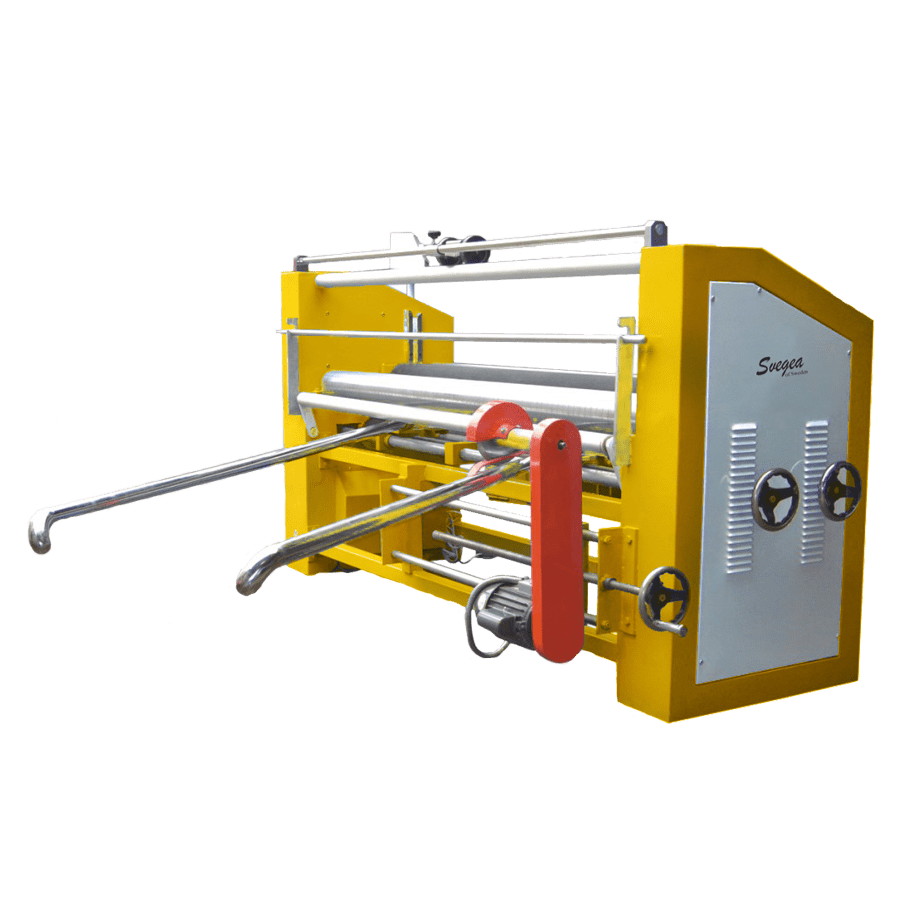

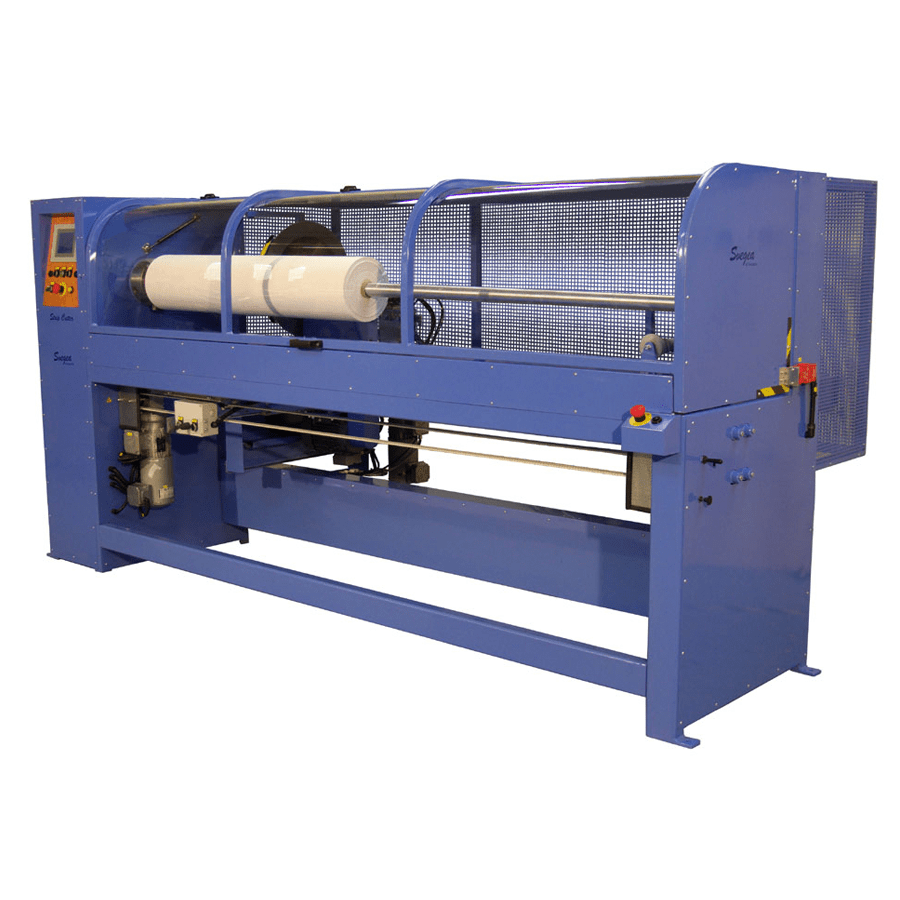

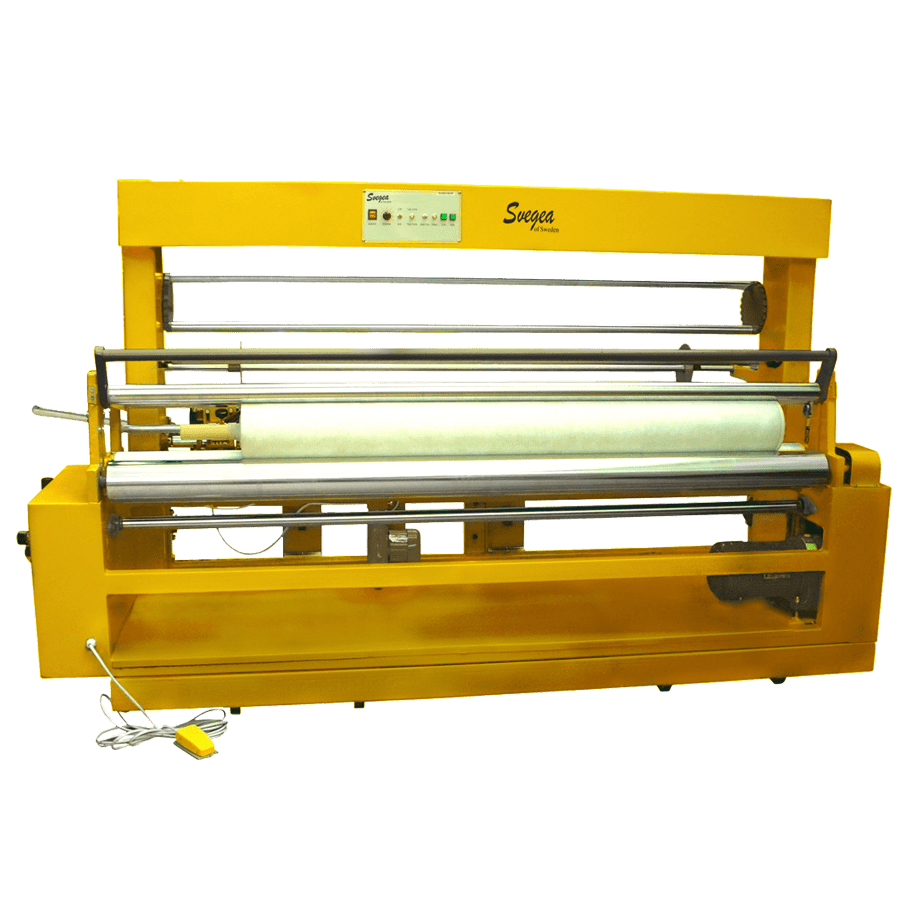

Automation has become a cornerstone of modern textile manufacturing, enabling greater precision and efficiency. Svegea’s automated systems, such as the Fully Automatic Roll Slitting Machine, exemplify how technology can optimize production while maintaining exceptional quality.

Efficiency at Its Core

Automated machines offer unmatched speed and precision. Svegea’s Roll Slitting Machine, for instance, transforms raw materials into finished rolls with minimal waste and maximum consistency. This efficiency helps manufacturers meet tight deadlines without compromising quality.

A Safer Workplace

Safety is critical in any manufacturing environment. Svegea incorporates advanced safety features into its machines, protecting operators and reducing risks. Intuitive controls and built-in safeguards ensure smooth, secure operations while minimizing downtime caused by accidents.

Automation: Transforming the Textile Landscape

1. Faster Production

Automation significantly accelerates production cycles. Machines like Svegea’s are designed to handle large volumes quickly and reliably, helping manufacturers keep pace with market demands.

2. Improved Quality

Automated systems incorporate sensors and monitoring technologies to ensure uniform results. Svegea’s machines deliver consistent, defect-free products, enhancing customer satisfaction and reducing rework.

3. Cost Efficiency

Although automation requires an initial investment, it reduces long-term expenses. Lower labor costs, minimized errors, and reduced material waste translate to significant savings for manufacturers.

4. Flexibility

Modern textile machines are highly adaptable. Svegea’s equipment can be tailored to produce various materials, enabling manufacturers to meet diverse client needs in a competitive market.

The Future of Textile Automation

1. Integration with IoT and AI

As the industry embraces smart manufacturing, technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) will play a pivotal role. IoT-enabled devices can optimize workflows, while AI-driven analytics can predict maintenance needs, enhancing efficiency. Svegea is exploring these innovations to further enhance its product offerings.

2. Sustainability in Focus

Automated machines contribute to greener production by reducing energy use and waste. Svegea is committed to designing sustainable solutions that help manufacturers minimize their environmental impact.

3. Robotics and Advanced Automation

Robotic systems are increasingly performing complex tasks with remarkable accuracy. Svegea integrates robotics into its machines, pushing the boundaries of what textile automation can achieve.

Redefining Textile Automation

Automation is redefining textile manufacturing, driving efficiency, safety, and sustainability. Svegea’s innovative solutions empower manufacturers to stay ahead in an ever-evolving industry. As technology advances, Svegea remains dedicated to shaping the future of textile production.

For more information about Svegea’s solutions, reach out to us at info@svegea.se.

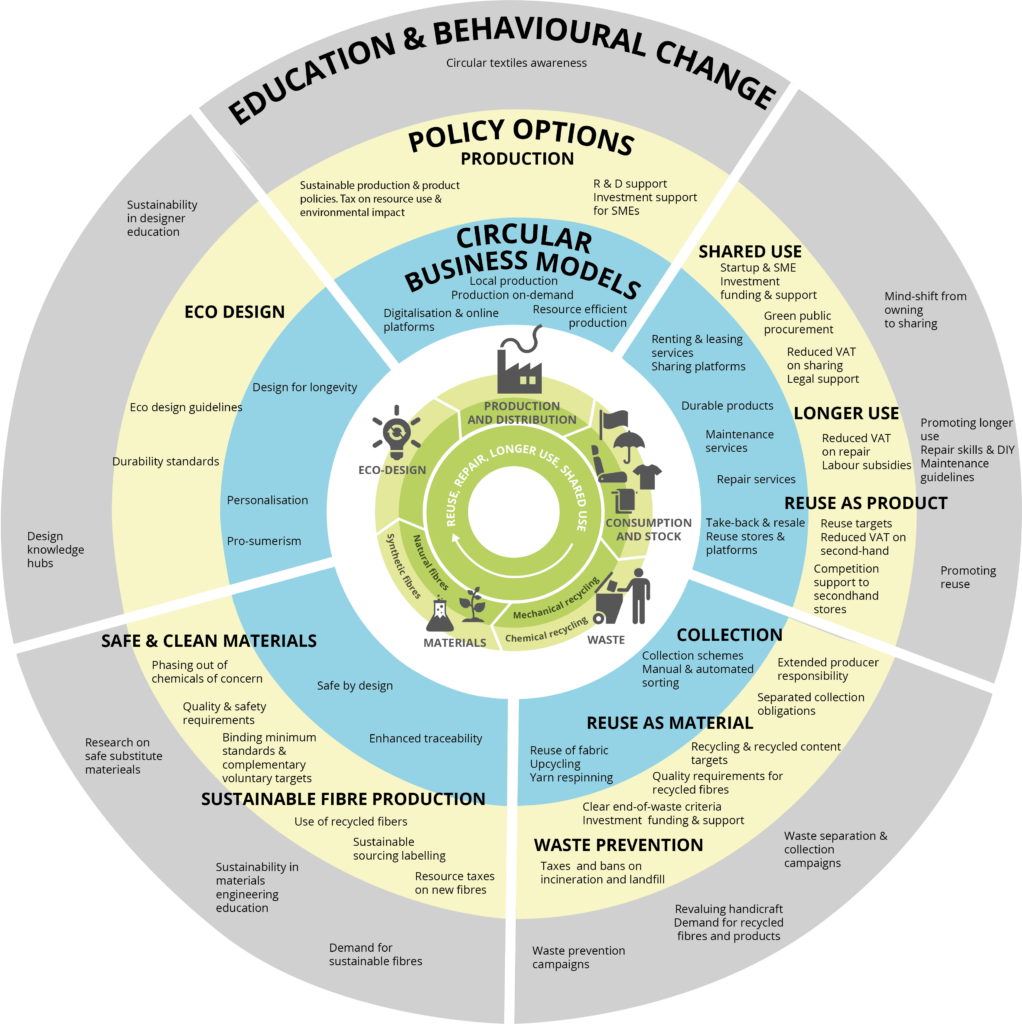

In today’s world, sustainability is more than just a buzzword; it’s necessary. The textile industry, known for its significant environmental impact, is transforming greener practices. Central to this shift is the adoption of sustainable textile production methods. The importance of using the right equipment lies at the heart of these methods. This blog will explore how advanced machinery contributes to a greener future and why choosing the right equipment is crucial for sustainable textile production.

The Environmental Impact of Textile Production

Textile production is one of the most resource-intensive industries globally. It involves the extensive use of water, energy, and chemicals, leading to significant environmental pollution. Traditional textile manufacturing processes often result in high levels of waste and emissions, contributing to water and air pollution. However, with the right equipment, these negative impacts can be significantly reduced.

Advanced Machinery: The Key to Sustainable Textile Production

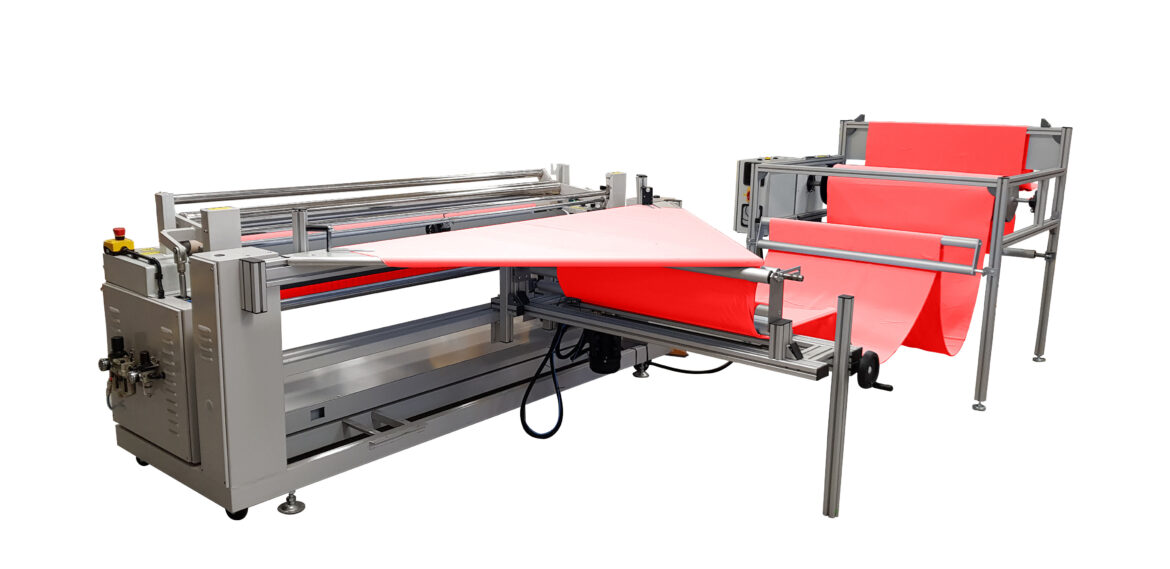

Modern textile machinery is designed with sustainability in mind. These machines are more efficient, consume less energy, and produce less waste. For instance, advanced dyeing machines use less water and chemicals, reducing the environmental footprint of the dyeing process. Similarly, automated cutting machines minimize fabric waste, ensuring that every piece of material is utilized effectively.

One of the leading companies in this field is Svegea of Sweden. Their innovative machines are at the forefront of sustainable textile production. By integrating advanced technology and sustainable practices, Svegea’s equipment helps manufacturers reduce their environmental impact while maintaining high production standards. For more information on sustainable textile and leather production standards, you can visit the OEKO-TEX® STeP certification page.

Benefits of Using Sustainable Textile Machinery

1. Reduced Energy Consumption: Modern textile machines are designed to be energy-efficient. They use advanced technologies such as variable frequency drives and energy recovery systems to minimize energy usage. This not only reduces the carbon footprint but also lowers operational costs.

2. Water Conservation: Traditional textile production processes are notorious for their high water consumption. Advanced machines, however, use water more efficiently. For example, modern dyeing machines can recycle water, significantly reducing the amount needed for each cycle.

3. Minimized Chemical Use: Sustainable textile machinery is designed to use fewer chemicals. This is achieved through precise control systems that ensure optimal use of dyes and other chemicals, reducing waste and environmental contamination.

4. Waste Reduction: Automated cutting and sewing machines are programmed to maximize fabric usage, reducing waste. This not only conserves resources but also lowers disposal costs.

5. Improved Product Quality: Sustainable machines often produce higher-quality textiles. This is because they operate with greater precision and consistency, leading to fewer defects and higher overall product quality.

The Future of Textile Production

The future of textile production lies in sustainability. As consumers become more environmentally conscious, the demand for sustainably produced textiles will continue to grow. Manufacturers who invest in the right equipment will be better positioned to meet this demand and stay competitive in the market.

Moreover, regulatory pressures are increasing, with governments around the world implementing stricter environmental standards. By adopting sustainable textile production practices now, manufacturers can stay ahead of these regulations and avoid potential penalties. For a deeper dive into sustainable textiles, you can read this blog post on eco-friendly fabric production.

Starting with the Right Equipment

Sustainable textile production starts with the right equipment. Advanced machinery not only reduces the environmental impact of textile manufacturing but also offers numerous benefits such as lower energy consumption, water conservation, minimized chemical use, waste reduction, and improved product quality. Companies like Svegea of Sweden are leading the way with their innovative and sustainable machines.

At Svegea of Sweden, we pride ourselves on leading the way in sustainable textile production. Our machines are designed to be both efficient and environmentally friendly. For instance, our automatic collarette cutting machines are renowned for their precision and minimal waste production. By investing in such advanced equipment, we help textile manufacturers significantly reduce their environmental impact.

Our commitment to sustainability extends beyond our products. We also focus on sustainable practices within our operations, such as using renewable energy sources and implementing waste reduction programs. This holistic approach ensures that our contribution to a greener future is comprehensive and impactful. To learn more about how advanced textiles are being developed to improve performance and sustainability, check out this article from Textile World.

If you’re looking to make your textile production more sustainable, consider investing in advanced machinery from Svegea of Sweden. Their commitment to sustainability and cutting-edge technology can help you achieve your environmental goals while maintaining high production standards.

Contact Svegea of Sweden today to learn more about how their machines can contribute to a greener future for your textile production.

Preserving history, one fabric at a time! Discover why textile conservation is crucial to safeguarding the past for future generations.

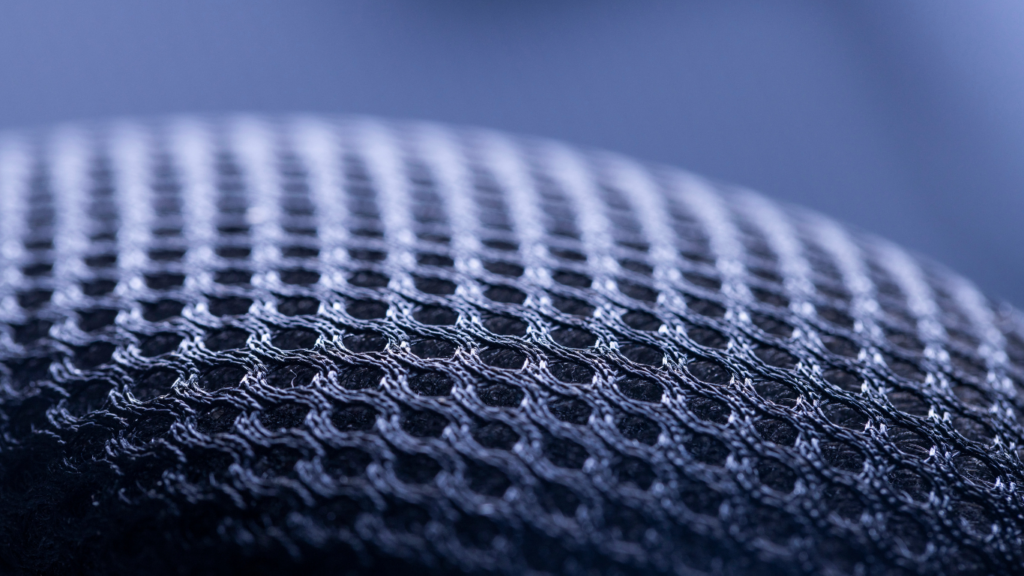

Textile conservation is a specialized field dedicated to preserving historical fabrics that offer a tangible connection to our past. These textiles aren’t just pieces of cloth; they tell stories of cultures, traditions, and technological advancements. This blog will explore the significance of textile conservation, the techniques involved, and how modern textile machines contribute to this delicate preservation process.

The Importance of Textile Conservation

Historical fabrics offer invaluable insights into social, economic, and cultural histories. Without proper conservation, these artifacts would deteriorate, erasing important chapters of human history. Textile conservation ensures that future generations can continue studying and appreciating these pieces of the past.

Cultural Significance

Textiles often hold deep cultural importance. Traditional garments showcase unique weaving techniques and patterns, offering glimpses into the identities of diverse communities. Preserving these fabrics helps protect cultural heritage, ensuring it remains intact for future generations to learn from.

Educational Value

Historical fabrics serve as powerful educational tools. Researchers and students can study ancient techniques, materials, and designs that have shaped modern innovations in textiles. By conserving these textiles, we preserve this knowledge for future generations to explore.

Techniques in Textile Conservation

Preserving delicate fabrics requires specialized techniques tailored to the fabric’s age, condition, and historical value.

- Cleaning and Stabilization – One of the first steps in textile conservation is gentle cleaning to remove dirt and contaminants. Stabilization follows, reinforcing fragile areas to prevent further damage while maintaining the fabric’s integrity.

- Repair and Restoration – In some cases, conservators repair damaged textiles, ensuring that repairs are as discreet as possible. Restoration work aims to return the fabric to its original appearance, allowing it to tell its full story while maintaining authenticity.

The Role of Textile Machines

Modern textile machines play a pivotal role in helping conservators perform these intricate tasks with precision.

- Advanced Weaving Machines – These machines can replicate historical weaving techniques, making it easier to create seamless patches that blend with the original fabric. This ensures that repairs remain nearly invisible, preserving the authenticity of the textile.

- Cleaning and Drying Equipment – Specialized cleaning and drying machines help protect fragile fabrics by providing a controlled environment. These machines ensure that delicate textiles are handled with care during every step of the cleaning process.

Svegea of Sweden: Precision Machines for Conservation

Svegea of Sweden provides advanced textile machines that play a vital role in modern textile manufacturing and quality control. Their equipment, including the Fabric Inspection Machine CMI 180, is designed for precision and delicate handling, ensuring high-quality fabrics. While primarily used for quality control, these machines support the broader textile industry, which includes conservation efforts by ensuring that only the best materials are used in preservation projects.

Case Studies in Textile Conservation

Several high-profile conservation projects highlight the importance and success of textile conservation:

- The Bayeux Tapestry: An 11th-century masterpiece, the Bayeux Tapestry underwent meticulous cleaning and stabilization, preserving it for generations to come.

- The Shroud of Turin: This significant religious artifact benefited from advanced textile conservation techniques, ensuring its continued preservation.

Challenges in Textile Conservation

Textile conservation faces several challenges, including the fragility of fabrics and environmental threats such as humidity, light, and temperature.

Fabric Fragility

Handling fragile textiles requires expert knowledge and specialized equipment to avoid causing further damage during the conservation process.

Environmental Factors

Conservators must constantly manage factors such as humidity and light exposure, which can accelerate the deterioration of historical fabrics. Controlled environments are essential for long-term preservation.

The Future of Textile Conservation

Technological advancements and growing awareness promise a bright future for textile conservation.

Technological Innovations

Cutting-edge technologies like 3D scanning and digital imaging allow conservators to analyze fabrics in unprecedented detail. These innovations are transforming preservation techniques, enabling conservators to develop more effective methods.

Increased Awareness

Growing public and institutional awareness of the importance of textile conservation has led to increased funding and support for preservation projects. As more people understand the value of preserving these historical fabrics, the future of textile conservation looks bright.

Preserving Cultural Heritage

Textile conservation is essential for preserving our cultural heritage and ensuring future generations have access to these invaluable artifacts. By using advanced techniques and modern machines like those from Svegea of Sweden, conservators can safeguard these fabrics for years to come. As we continue to innovate and raise awareness, textile conservation will thrive, preserving history—one fabric at a time.

For expert textile machines, contact Svegea of Sweden for precision solutions tailored to your conservation needs.

Choosing the right textile machinery can be a daunting task, especially with the plethora of options available in the market. The decision impacts your production efficiency, product quality, and overall business profitability. Here are some key tips to help you navigate this critical process.

1. Understand Your Production Needs

Before investing in textile machinery, it’s crucial to understand your specific production needs. Different types of machinery serve various purposes, from weaving and knitting to dyeing and finishing. Determine the scale of your operations, the types of textiles you produce, and your production goals. This understanding will guide your choice of machinery that best suits your requirements.

2. Evaluate Technology and Features

Modern textile machinery comes with a range of advanced technologies and features designed to enhance productivity and quality. Look for machines that offer automation, precision control, and energy efficiency. For instance, Svegea of Sweden offers cutting-edge machinery equipped with the latest technology, ensuring high efficiency and minimal waste. Our products are known for their durability and innovative features.

3. Consider Quality and Reliability

Quality and reliability are paramount when choosing textile machinery. Investing in high-quality machines may come with a higher initial cost, but it ensures long-term performance and fewer breakdowns. Research and compare different brands, read reviews, and consider the manufacturer’s reputation. Modesty aside, our brand has a proven track record of producing reliable and high-quality textile machinery.

4. Assess After-Sales Support and Maintenance

After-sales support and maintenance services are crucial for the smooth operation of textile machinery. Ensure that the manufacturer offers comprehensive support, including installation, training, and regular maintenance services. We provide excellent customer support and maintenance services, ensuring that your machinery operates optimally.

5. Analyze Cost and Return on Investment (ROI)

While the cost of textile machinery is a significant factor, it’s essential to consider the return on investment (ROI). A more expensive machine with advanced features and higher efficiency can lead to cost savings in the long run. Calculate the total cost of ownership, including maintenance and operational costs, and compare it with the expected benefits. Opt for machines that offer the best value for money.

6. Environmental Considerations

Sustainability is a growing concern in the textile industry. Choose machinery that is energy-efficient and environmentally friendly. Machines that reduce water and chemical usage, minimize waste, and consume less energy are ideal. This Swedish textile company is known for producing sustainable textile machinery that aligns with eco-friendly production practices.

7. Compatibility with Existing Systems

Ensure that the new machinery is compatible with your existing systems and processes. Incompatibility can lead to production delays and additional costs. Consult with the manufacturer or a technical expert to evaluate the integration process. A company that offers flexible machinery solutions that can be seamlessly integrated into various production setups, should be the right choice.

Explore Svegea of Sweden’s Textile Machinery

Choosing the right textile machinery is a critical decision that impacts your production efficiency and product quality. By considering factors such as your production needs, technology and features, quality, after-sales support, cost, environmental impact, and compatibility, you can make an informed choice. Svegea of Sweden’s innovative machinery solutions are designed to meet diverse production requirements while ensuring high efficiency and sustainability.

Curious about how we can elevate your textile production process? Visit our product page for more information and start your journey towards optimal textile production today.

In a world where sustainability is becoming more than a buzzword, the fashion industry is undergoing a significant transformation. One of the most innovative and impactful changes is the adoption of zero waste pattern cutting. This method not only revolutionizes the way garments are produced but also addresses the environmental concerns associated with traditional fashion practices.

Understanding Zero Waste Pattern Cutting

Zero waste pattern cutting is a design technique that aims to eliminate fabric waste in the creation of garments. Traditional garment production often results in approximately 15-20% of fabric waste due to the inefficient placement of patterns on the fabric. This discarded material often ends up in landfills, contributing to environmental pollution.

In contrast, zero waste pattern cutting meticulously plans the layout of each piece of fabric, ensuring that every inch is utilized. This approach can involve intricate designs, geometric shapes, and innovative sewing techniques to fit the pieces together like a puzzle. The result is a garment that uses all the fabric with minimal to no waste.

The Environmental Impact

The fashion industry is notorious for its environmental footprint. From water consumption to carbon emissions, the production of clothing has significant impacts on the planet. Zero waste pattern cutting offers a practical solution to one of these issues: fabric waste.

By reducing fabric waste, this method helps in conserving resources. It means fewer raw materials are needed, reducing the demand for water, energy, and chemicals involved in fabric production. Additionally, less waste means fewer textiles end up in landfills, decreasing environmental pollution.

Economic Benefits

While the environmental benefits of zero waste pattern cutting are clear, the economic advantages are equally compelling. For designers and manufacturers, fabric is a significant cost. By maximizing fabric usage, zero waste techniques can lead to substantial cost savings.

Moreover, as consumers become more conscious of sustainability, there is a growing market for eco-friendly products. Brands that adopt zero waste practices can attract environmentally conscious customers, willing to pay a premium for sustainable fashion. This shift not only helps the planet but also makes good business sense.

Challenges and Innovations

Despite its many benefits, zero waste pattern cutting is not without its challenges. The method requires a high level of skill and creativity. Designers must rethink the way they approach garment construction, often needing to create entirely new patterns and techniques.

However, this challenge has spurred innovation in the industry. Designers are experimenting with modular designs, where pieces can be rearranged and used in multiple ways. Digital tools and software are also being developed to aid in the creation of zero waste patterns, making the process more accessible to a broader range of designers.

Success Stories

Many brands and designers are already making significant strides in zero waste fashion. For instance, designers like Timo Rissanen and Holly McQuillan are pioneers in this field, pushing the boundaries of what is possible with zero waste pattern cutting. Their work not only showcases the potential of this method but also inspires others in the industry to follow suit.

Brands like Tonlé and Daniel Silverstein (Zero Waste Daniel) have built their entire business models around zero waste principles. They demonstrate that sustainability and style can go hand in hand, offering chic and modern designs that do not compromise on environmental values.

The Future of Fashion

As the fashion industry continues to evolve, the importance of sustainable practices cannot be overstated. Zero waste pattern cutting represents a significant step forward in this journey. It challenges the status quo, pushing designers and manufacturers to think creatively and responsibly.

The future of fashion lies in innovation and sustainability. By adopting zero waste techniques, the industry can reduce its environmental footprint, create economic opportunities, and cater to a growing market of eco-conscious consumers. As more brands embrace this method, we can look forward to a fashion industry that not only looks good but does good for the planet.

Svegea of Sweden: Revolutionizing Zero Waste with Advanced Technology

One notable brand making strides in the realm of zero waste pattern cutting is Svegea of Sweden. Known for their advanced cutting machinery, Svegea offers innovative solutions designed to maximize fabric utilization. Their machines not only enhance precision but also significantly reduce waste, aligning perfectly with the zero waste philosophy. By incorporating Svegea’s technology, designers can seamlessly integrate zero waste techniques into their production process.

Curious about how Svegea of Sweden can elevate your zero waste pattern cutting process? Visit our contact page for more information on our cutting-edge machinery and start your journey towards a more sustainable future today.

In the dynamic world of textile manufacturing, automation is a cornerstone of innovation, driving unprecedented efficiency, precision, and sustainability. As an expert with over two decades of experience in textile automation, we have witnessed firsthand the transformative power of these technologies. Today, we’ll explore how automation is reshaping the fabric of our industry.

The Evolution of Textile Automation

The journey from hand-spun fibers to today’s high-tech production lines tells a story of relentless innovation. Early mechanization during the Industrial Revolution laid the groundwork, but modern automation has catapulted us into a new era of manufacturing excellence.

Key milestones include:

1. 1960s-1970s: Introduction of computer-controlled looms

2. 1980s-1990s: Development of robotic systems for material handling

3. 2000s-2010s: Integration of AI and machine learning in quality control

4. 2020s and beyond: Emergence of fully automated, smart textile factories

Core Areas Transformed by Automation

Spinning: Precision at Lightning Speeds

Modern spinning systems, such as rotor and air-jet technologies, have revolutionized yarn production. These systems can produce yarn up to 20 times faster than traditional ring spinning, with unparalleled consistency.

Weaving: Intelligent Looms for Flawless Fabrics

Today’s computerized looms are marvels of engineering. There are machines for example that use real-time adaptive tension control to adjust warp tension on the fly, ensuring fabric quality remains consistent even as conditions change during production. This level of precision was unthinkable just a decade ago.

Dyeing and Finishing: Sustainability Meets Efficiency

Automated dyeing and finishing processes have dramatically reduced water and energy consumption while improving color consistency. Digital textile printing, exemplified by machines can print complex designs directly onto fabric at up to 1,000 m²/hour, revolutionizing small-batch and customized production.

Spotlight on Innovation: Svegea’s EC 450 XF Collarette Cutting System

The EC 450 XF Collarette Cutting System by Svegea represents the cutting edge of textile automation. As the winner of the Texprocess Americas 2023 Innovation Award, this system exemplifies how targeted automation can solve specific industry challenges.

Key features include:

– Multi-material compatibility for unparalleled versatility

– Precision cutting with minimal waste

– Rapid changeover times, boosting overall productivity

The EC 450 XF doesn’t just cut fabric; it redefines efficiency in garment manufacturing. For manufacturers looking to stay competitive, systems like this are not just beneficial—they’re essential.

The Tangible Benefits of Automation

1. Quality Assurance: Automated systems consistently produce high-quality textiles, reducing defects by up to 90% compared to manual processes.

2. Increased Productivity: Modern automated lines can operate 24/7, increasing output by 200-300% over traditional methods.

3. Cost Reduction: While initial investment is significant, automated systems can reduce labor costs by 40-60% and material waste by 20-30% over their lifetime.

4. Customization at Scale: Automation enables quick changeovers, making small-batch and customized production economically viable.

5. Enhanced Safety: Automation minimizes human exposure to hazardous processes, reducing workplace accidents by up to 80% in some facilities.

Overcoming Implementation Challenges

While the benefits of automation are clear, implementation comes with challenges:

1. Initial Investment: The upfront cost of automation can be substantial. However, ROI typically occurs within 2-5 years, depending on the scale of implementation.

2. Workforce Transition: Shifting to automated systems requires retraining staff. Forward-thinking companies are investing in upskilling programs to transition workers into higher-value roles.

3. System Integration: Ensuring new automated systems work seamlessly with existing processes is crucial. Careful planning and phased implementation can mitigate disruptions.

The Future of Textile Automation

Looking ahead, several trends will shape the future of textile automation:

1. AI and Machine Learning: These technologies will enable predictive maintenance and real-time quality control, further improving efficiency and reducing downtime.

2. Internet of Things (IoT): Connected devices will create smart factories where every aspect of production is monitored and optimized in real-time.

3. Sustainable Automation: Future systems will focus even more on reducing environmental impact, with closed-loop water systems and energy-efficient processes.

4. Collaborative Robotics: Cobots will work alongside humans, handling repetitive tasks while allowing human workers to focus on high-value activities.

Embracing the Automated Future

Automation in textile manufacturing isn’t just about replacing human labor—it’s about augmenting human capabilities, driving innovation, and creating a more sustainable, efficient industry. As we look to the future, it’s clear that automation will play an increasingly central role in shaping the textiles of tomorrow.

For manufacturers, the message is clear: embrace automation or risk being left behind. The future of textiles is automated, and that future is now.

To explore cutting-edge automation solutions like Svegea’s EC 450 XF Collarette Cutting System, contact us now! For those ready to take the next step in their automation journey, now is the time to act.

The textile manufacturing industry is undergoing a significant transformation. As we move into 2025, several trends are shaping the future of this dynamic sector. From sustainable practices to advanced technologies, the landscape is evolving rapidly. Let’s explore the top trends in textile manufacturing for 2024 and 2025.

1. Sustainable Practices

Sustainability is no longer a buzzword; it’s a necessity. Textile manufacturers are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes using organic materials, recycling waste, and implementing energy-efficient processes. According to the World Economic Forum, sustainable practices in textile manufacturing can significantly reduce carbon emissions and water usage.

2. Advanced Technologies

The integration of advanced technologies is revolutionizing textile manufacturing. Automation, artificial intelligence (AI), and the Internet of Things (IoT) are enhancing efficiency and productivity. For instance, AI-driven machines can predict maintenance needs, reducing downtime and increasing output. The International Textile Manufacturers Federation highlights that these technologies are crucial for staying competitive in the global market.

3. Customization and Personalization

Consumers today demand unique and personalized products. Textile manufacturers are leveraging digital printing and other technologies to offer customized solutions. This trend is particularly evident in the fashion industry, where personalized clothing is gaining popularity. A report by McKinsey & Company suggests that customization will be a key driver of growth in the textile sector.

4. Smart Textiles

Smart textiles, also known as e-textiles, are gaining traction. These textiles have embedded sensors and electronics that can monitor health, track fitness, and even change color. The potential applications are vast, ranging from healthcare to sportswear. According to TechCrunch, the smart textiles market is expected to grow exponentially in the coming years.

5. Ethical Labor Practices

Consumers are becoming more conscious of the ethical implications of their purchases. As a result, textile manufacturers are focusing on fair labor practices and ensuring safe working conditions. This shift is not only ethical but also beneficial for brand reputation. The Fair Labor Association provides guidelines and resources for companies aiming to improve their labor practices.

Spotlight on Svegea of Sweden

Svegea of Sweden is a notable player in the textile manufacturing industry. Known for their innovative solutions, Svegea offers advanced slitting and cutting machines that enhance efficiency and precision. Their commitment to quality and sustainability sets them apart in the market. While not overtly promotional, it’s worth noting how companies like Svegea are contributing to the industry’s evolution.

Exciting Changes

The textile manufacturing industry is poised for exciting changes in 2025. From sustainable practices to advanced technologies, the trends shaping this sector are both innovative and impactful. By staying informed and adapting to these trends, manufacturers can thrive in a competitive landscape.

For innovative and sustainable textile machinery, contact Svegea of Sweden. Our advanced solutions can help you stay ahead in the evolving textile industry.

The textile industry has always been a hub of innovation. Each technological leap has transformed production processes from the spinning jenny to modern automated systems. Today, textile-cutting machines stand at the forefront of this revolution, offering unparalleled precision, speed, and efficiency. This article delves into how automated cutting machines reshape the textile industry and highlights a cutting-edge product from Svegea.

The Evolution of Textile Cutting Machines

From Manual to Automated

Historically, textile cutting was a labor-intensive task. Workers relied on manual tools like scissors and rotary cutters, which were time-consuming and prone to errors. The advent of semi-automated machines marked a significant improvement, yet they still required considerable human intervention. Today, fully automated textile-cutting machines have revolutionized the industry, enabling manufacturers to produce high-quality products swiftly and cost-effectively.

Key Features of Modern Textile Cutting Machines

Modern textile cutting machines boast advanced features that significantly enhance their performance:

– Computer-Aided Design (CAD) Integration: This allows for precise pattern creation and modification.

– Laser Cutting Technology: Ensures clean, accurate cuts with minimal fabric wastage.

– Automated Material Handling: Reduces the need for manual labor and speeds up the production process.

– Multi-Layer Cutting Capability: Enables the cutting of multiple fabric layers simultaneously, boosting productivity.

Benefits of Automated Textile Cutting Machines

- Enhanced Precision and Accuracy

One of the most significant advantages of automated textile-cutting machines is their precision. These machines use advanced software and laser technology to cut fabric with incredible accuracy, ensuring that each piece meets exact specifications. This level of precision is particularly important in industries like fashion and automotive, where even minor deviations can lead to significant issues.

- Increased Production Speed

Automated cutting machines can operate at much higher speeds than manual or semi-automated methods. This increased speed translates to higher production rates, allowing manufacturers to meet tight deadlines and respond quickly to market demands. For example, a textile cutting machine can cut hundreds of fabric pieces in the time it would take a human worker to cut just a few.

- Cost Savings

While the initial investment in automated cutting machines can be substantial, the long-term cost savings are significant. These machines reduce labor costs by minimizing the need for manual intervention. Additionally, their precision reduces fabric wastage, leading to lower material costs. Over time, these savings can offset the initial investment and lead to increased profitability.

- Versatility and Flexibility

Modern textile cutting machines are incredibly versatile. They can handle a wide range of fabrics, from delicate silks to heavy-duty industrial textiles. This versatility allows manufacturers to diversify their product offerings and cater to different market segments. Moreover, the ability to quickly switch between different cutting patterns and materials enhances production flexibility.

Real-World Applications

Fashion Industry

In the fashion industry, precision and speed are paramount. Automated textile cutting machines enable designers to bring their visions to life with unparalleled accuracy. These machines can cut intricate patterns and delicate fabrics with ease, ensuring that each garment meets the highest quality standards. Additionally, the ability to quickly produce samples and prototypes allows designers to experiment with new ideas and stay ahead of trends.

Automotive Industry

The automotive industry relies heavily on textile materials for interior components like seats, carpets, and headliners. Automated cutting machines ensure that these components are cut to exact specifications, enhancing the overall quality and durability of the final product. The ability to cut multiple layers of fabric simultaneously also speeds up production, allowing manufacturers to meet the high demands of the automotive market.

Home Furnishings

From curtains to upholstery, the home furnishings industry requires precise and efficient fabric cutting. Automated cutting machines enable manufacturers to produce high-quality home textiles quickly and cost-effectively. The versatility of these machines also allows for the production of custom designs, catering to the growing demand for personalized home decor.

The Future of Textile Manufacturing

Integration with Industry 4.0

The future of textile manufacturing lies in the integration of automated cutting machines with Industry 4.0 technologies. This includes the use of IoT (Internet of Things) devices, AI (Artificial Intelligence), and big data analytics to optimize production processes. For example, IoT-enabled cutting machines can communicate with other devices in the production line, ensuring seamless coordination and reducing downtime.

Sustainable Manufacturing

Sustainability is becoming increasingly important in the textile industry. Automated cutting machines contribute to sustainable manufacturing by reducing fabric wastage and energy consumption. Additionally, the precision of these machines minimizes the need for rework, further reducing resource usage. As the industry continues to prioritize sustainability, the adoption of automated cutting machines is likely to increase.

Continuous Innovation

The field of automated textile cutting is constantly evolving. Manufacturers are continually developing new technologies and features to enhance the performance of cutting machines. For example, advancements in laser technology and AI are expected to further improve the precision and efficiency of these machines. As these innovations continue to emerge, the capabilities of automated cutting machines will expand, opening up new possibilities for textile manufacturers.

Featured Product: Svegea’s EC 450 XF Collarette Cutting System

Svegea of Sweden is a leader in textile cutting technology, known for its innovative solutions that enhance productivity and reduce waste. One of their standout products is the EC 450 XF Collarette Cutting System. This system is designed for high-speed, precision cutting of collarettes, making it ideal for manufacturers looking to improve efficiency and product quality. The EC 450 XF features advanced automation and user-friendly controls, ensuring seamless integration into any production line.

For more information on cutting-edge textile-cutting machines, visit Svegea of Sweden

In today’s fast-paced world, consumers are increasingly seeking unique and personalized fashion experiences. This shift is reshaping the fashion industry, pushing brands to innovate and offer more customized products and services. One key player in this transformation is Svegea, whose Fabric Inspection tools are making a significant impact.

The Demand for Personalization

Personalized fashion experiences are no longer a luxury but a necessity for many consumers. According to recent studies, a significant majority of shoppers prefer brands that offer personalized options. This trend is driven by the desire for individuality and the need to stand out in a crowded market. Personalized fashion experiences allow consumers to express their unique style and preferences, creating a deeper connection with the brand.

How Technology is Enabling Customization

Advancements in technology have made it easier for fashion brands to offer personalized experiences. From AI-powered virtual fitting rooms to customized recommendations based on browsing history, technology is at the forefront of this revolution. Svegea’s Fabric Inspection tools play a crucial role in this process by ensuring the quality and precision of customized garments.

The Benefits of Fabric Inspection

Fabric inspection is a critical step in the production of personalized garments. It ensures that each piece meets the quality standards expected by consumers. Svegea’s Fabric Inspection tools are designed to detect even the smallest imperfections, allowing brands to address issues before they reach the customer. This not only enhances the overall quality of the product but also builds trust and loyalty among consumers.

Customization Beyond Fabric Inspection

Customization Beyond Fabric Inspection

While fabric inspection is vital, Svegea’s capabilities extend beyond this. The company can customize its machines to fit the specific production needs of its clients. This flexibility allows fashion brands to optimize their production processes and offer truly unique products. Whether it’s adjusting the machine settings for different fabric types or integrating new technologies, Svegea’s customized solutions ensure that brands can meet the growing demand for personalized fashion experiences.

The Future of Personalized Fashion

The trend towards personalized fashion experiences shows no signs of slowing down. As consumers continue to seek unique and customized products, brands must adapt to stay competitive. Svegea’s innovative solutions, including its Fabric Inspection tools, will play a crucial role in this evolution. By ensuring quality and enabling customization, Svegea is helping to shape the future of the fashion industry.

Transforming the Industry

Personalized fashion experiences are transforming the industry, driven by consumer demand for uniqueness and individuality. Technology, including Svegea’s Fabric Inspection tools, is enabling this shift by ensuring quality and precision in customized garments. As the trend towards personalization continues to grow, Svegea’s innovative solutions will remain at the forefront, helping brands meet the evolving needs of their customers.

In an era where sustainability is paramount, the circular economy offers a transformative approach to how we produce and consume goods. Central to this concept are closed-loop systems and circular design, both of which aim to minimize waste and make the most of our resources.

Understanding Closed-Loop Systems

Closed-loop systems are designed to create a continuous cycle of use and reuse, effectively reducing waste. In these systems, the output of one process becomes the input for another, ensuring that materials are constantly recycled and repurposed. This approach not only conserves resources but also significantly reduces environmental impact.

The Importance of Circular Design

The circular design is a key element of the circular economy. It involves designing products with their entire lifecycle in mind, from creation to disposal. Circular design focuses on durability, reparability, and recyclability, making products easy to disassemble and reuse. This process reduces the need for new raw materials and minimizes waste.

Strategies for Minimizing Waste

Minimizing waste is a fundamental goal of the circular economy. This process is achievable through various strategies, including:

- Design for Longevity: Creating products that last longer and are easily repairable.

- Material Innovation: Using materials that are easier to recycle and have a lower environmental impact.

- Efficient Manufacturing: Implementing processes that reduce waste and improve resource efficiency.

Real-World Applications

Many companies are now adopting circular principles to enhance sustainability. For instance, in the textile industry, some manufacturers are focusing on producing high-quality trim that aligns with circular design principles. By ensuring that their products are durable and recyclable, these companies contribute to a more sustainable future.

The Benefits of a Circular Economy

The shift towards a circular economy offers numerous benefits:

- Environmental Sustainability: By reducing waste and conserving resources, the circular economy helps protect the environment.

- Economic Efficiency: Reusing materials and improving efficiency can lead to cost savings for businesses.

- Innovation and Growth: The circular economy encourages innovation, leading to new business opportunities and economic growth.

Representing a Significant Shift

The circular economy represents a significant shift in how we think about production and consumption. By embracing closed-loop systems and circular design, we can minimize waste and make better use of our resources. This approach not only benefits the environment but also offers economic advantages.

Sustainable Textile Manufacturing

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

To learn more about how quality trim can align with circular principles, visit Svegea’s contact page and discover their commitment to sustainability.