Zero-waste fashion is more than a design trend—it is a revolution reshaping the garment and textile industry. As sustainability shifts from being optional to essential, manufacturers are rethinking how clothing is produced. Traditional cutting methods waste up to 20% of fabric, which often ends up in landfills. By contrast, zero-waste techniques promise efficiency, creativity, and responsibility.

What Is Zero Waste Pattern Cutting?

Zero-waste pattern cutting is a design approach where every piece of fabric is used. Instead of discarding scraps, designers plan layouts meticulously, fitting pieces together like a puzzle. This method requires innovation, geometric thinking, and sometimes unconventional garment shapes. The result is stylish clothing with minimal environmental impact.

Why Fashion Needs Zero Waste

The fashion industry is one of the world’s largest polluters. Consider these facts:

- Fabric waste: Traditional methods waste 15–20% of fabric.

- Water consumption: Producing textiles consumes billions of liters annually.

- Carbon footprint: Clothing production contributes significantly to global emissions.

By adopting zero-waste cutting, manufacturers reduce raw material demand, conserve water, and lower emissions. Less waste also means fewer textiles in landfills. This is why zero-waste fashion is not just a design choice—it is a necessity.

Economic Benefits for Manufacturers

Sustainability is ethical, but it is also profitable. Fabric is a major cost in garment production. By maximizing fabric use, companies save money. Moreover, eco‑conscious consumers are willing to pay more for sustainable fashion. Brands that embrace zero waste gain a competitive edge, appealing to a growing market segment.

For manufacturers, this means higher margins, stronger brand loyalty, and alignment with global sustainability goals.

Challenges and Innovations

Transitioning to zero waste is not simple. Designers must rethink traditional methods, often creating new patterns from scratch. This requires skill, creativity, and sometimes advanced technology.

Fortunately, digital tools are emerging to assist in pattern design. Innovative textile machinery producing companies are leading the way with cutting‑edge machinery that enhances precision and reduces waste. Their automated cutting solutions help manufacturers achieve efficiency without sacrificing quality.

Success Stories in Zero Waste Fashion

Several pioneers are proving that sustainability and style can coexist:

- Timo Rissanen & Holly McQuillan: Academic leaders pushing boundaries in zero-waste design.

- Tonlé: A brand built entirely on zero-waste principles.

- Zero Waste Daniel: Designer Daniel Silverstein creates chic, modern pieces from fabric scraps.

These innovators demonstrate that fashion can be both eco‑friendly and commercially viable. Their work inspires manufacturers to consider how to scale zero-waste fashion globally.

The Role of Technology

Technology is accelerating adoption. CAD software helps designers visualize efficient layouts. Automated cutting machines, like those from Svegea, ensure precision and minimize waste. As digital tools evolve, zero-waste cutting becomes more accessible to mainstream manufacturers.

This integration of design and machinery is critical. Without advanced tools, scaling zero-waste fashion would be difficult. With them, the industry can move faster toward sustainability.

Consumer Demand and Market Trends

Consumers are increasingly aware of sustainability. According to recent studies, demand for eco‑friendly fashion has surged, with “slow fashion” and “circular design” gaining traction. Zero-waste fashion aligns perfectly with these values, offering transparency and responsibility.

Brands that ignore this shift risk losing relevance. Manufacturers who adapt will not only meet consumer expectations but also position themselves as leaders in sustainable innovation.

The Future of Fashion

The future of fashion lies in innovation and sustainability. Zero waste pattern cutting is not just a technique—it is a philosophy. It challenges the industry to rethink efficiency, creativity, and responsibility. As more brands adopt this method, fashion will evolve into a sector that not only looks good but also does good for the planet.

A Revolution That Saves Fabric

Zero-waste fashion is a revolution that saves fabric, reduces costs, and protects the environment. It requires creativity, but the rewards—economic, ecological, and social—are immense. Manufacturers who embrace this approach will thrive in a competitive market while contributing to a sustainable future.

Ready to revolutionize your production?

Zero waste fashion isn’t just a trend—it’s the future. Svegea’s innovative textile machinery empowers manufacturers to cut smarter, save fabric, and boost profits while meeting sustainability goals.

Contact Håkan Steene at h.steene@svegea.se or reach out to us today to explore how we can achieve zero-waste pattern cutting together.

Sustainability as the New Baseline

The textile industry in 2026 is standing at a crossroads. What was once a competitive edge—sustainability—has now become the baseline expectation. Regulators, consumers, and brands are converging on one undeniable truth: fabrics must be eco‑friendly, transparent, and innovative.

According to market analysis, the sustainable fabrics market is projected to reach USD 41.28 billion in 2026, with growth expected to hit USD 115.72 billion by 2035 at a CAGR of 12%.

Regenerative Textiles: Beyond “Do No Harm”

For years, “sustainable” was the buzzword. In 2026, the conversation has shifted toward regenerative textiles—materials that actively restore ecosystems. Cotton grown through regenerative farming improves soil health, while hemp blends reduce water usage. These fabrics don’t just minimize harm; they contribute positively to biodiversity.

This evolution reflects a deeper consumer desire: products that give back to the planet rather than simply take less from it.

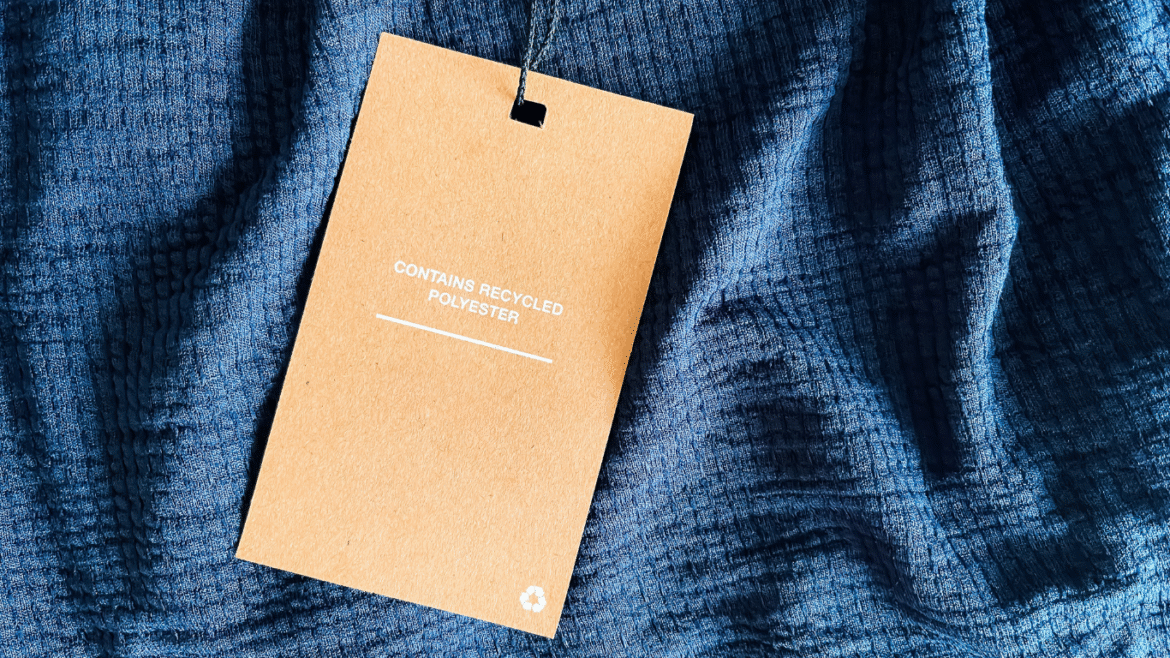

Circular Fashion Moves Center Stage

Circular fashion, once a niche experiment, has gone mainstream. Closed‑loop systems recycle fabrics and reintroduce them into production. Recycled polyester and bio‑cellulosics like Lyocell are now used at scale, proving that sustainability can coexist with performance and aesthetics.

The Global Circular Fashion Forum reports that brands are scaling recycling of post‑industrial textile waste to achieve a just transition.

Innovative textile machinery companies play a supporting role here. By enabling efficient cutting and minimizing waste, they help manufacturers align with circularity goals without compromising productivity.

Smart Fabrics Meet Eco‑Innovation

Another defining trend is the rise of smart fabrics—materials embedded with sensors or responsive weaves that regulate temperature, moisture, or even monitor health. In 2026, innovation is merging with sustainability: smart fabrics are being designed to be biodegradable or recyclable.

These fabrics are expected to revolutionize apparel and healthcare applications, merging fashion with function in ways previously unimaginable.

Transparency as a Consumer Demand

Consumers in 2026 are more informed than ever. They demand to know where fabrics come from, how they are produced, and whether they align with ethical standards. Transparency is no longer optional—it is a requirement.

Brands that fail to provide clear information risk losing credibility. Conversely, those that embrace transparency gain loyalty and trust. Machinery that ensures consistent quality and traceability supports manufacturers in meeting these expectations.

Luxury Meets Sustainability

Luxury fashion has embraced sustainability without sacrificing aesthetics. Premium eco‑fabrics are being introduced by high‑end brands, proving that sustainability can be synonymous with elegance. Innovations include silk alternatives made from orange peels and leather substitutes crafted from mushrooms.

Global Market Shifts

Textile trends in 2026 vary across regions. Asia continues to dominate production, Europe leads in sustainability regulations, and the US focuses on innovation‑driven textiles.

The global textile market is projected to grow from USD 660.13 billion in 2025 to USD 919.08 billion in 2030 at a CAGR of 6.9%.

Wellness Woven Into Fabrics

Health and wellness are influencing textile innovation. Fabrics with antimicrobial properties, stress‑reducing textures, and wellness‑enhancing designs are gaining popularity. These textiles are not only functional but also align with the growing demand for holistic lifestyles.

Craft Meets Computation

2026 is witnessing a fascinating blend of artisanal craftsmanship and computational design. Digital tools enhance traditional weaving techniques, creating fabrics that are both culturally rich and technologically advanced.

Pigment Technologies That Dance With Light

Color innovation is another exciting frontier. Pigment technologies that shift with light or angle are redefining aesthetics. Analysts project the textile pigment market will exceed USD 4 billion by 2026.

Upholstery Evolves Into Storytelling

Textiles extend far beyond fashion. Upholstery is evolving into a storytelling medium, with fabrics designed to reflect identity, culture, and emotion. Furniture is becoming a canvas for narratives, and textiles are the brushstrokes.

The Future Is Sustainable

Sustainability, innovation, and adaptability define the textile industry in 2026. From regenerative fabrics to smart textiles, responsibility and creativity weave the future.

Consequently, manufacturers who embrace these trends will not only meet consumer expectations, but also secure long‑term success. The role of advanced textile machinery is strategic—supporting efficiency and precision where sustainability demands it, without overshadowing the broader industry narrative.

Talk to us now and learn how we can help your production cope with the textile trends in 2026!

A Global Stage for Garment Technology

The Garment Technology Bangladesh (GTB) Expo 2026, held from January 14–17 at ICCB in Dhaka, once again proved why it is one of the most influential gatherings in the garment and textile industry. The expo brought together innovators, buyers, and industry leaders from across the globe to showcase the latest machinery, automation, and sustainable solutions.

Attendees experienced:

- Cutting-edge machinery exhibitions range from sewing and embroidery equipment to advanced automation systems.

- Workshops and educational sessions that highlighted sustainability, digital transformation, and efficiency in garment production.

- Networking opportunities that fostered collaborations and strengthened global partnerships.

- The event was not just an exhibition—it became a movement toward smarter, more sustainable garment technology.

A Productive Partnership

Svegea of Sweden participated thanks to an invitation from their partner Tech Cell BT Ltd. This collaboration underscored GTB’s role in building bridges between international companies and local innovators.

Håkan Steene, Managing Director of Svegea of Sweden, along with Svegea’s technical engineer Erik Bernhardsson, attended with enthusiasm and shared his reflections:

“The organizers ran the event with impressive precision. Everything flowed so smoothly that the days passed before we even noticed. We had a wonderful time engaging with textile innovation enthusiasts and guests, all equally curious about how technology is reshaping the garment industry.” – Håkan Steene

His words captured the seamless execution and vibrant energy of GTB 2026, where meaningful connections and groundbreaking showcases made time fly.

Textile Machinery Showcase

Svegea’s booth drew significant attention with demonstrations of their Collarette Cutter and Semi-Automatic EC 50. These machines highlighted:

- Precision cutting technology for garment applications.

- Semi-automation features that balance efficiency with flexibility.

- Reduced material waste while maintaining accuracy.

By presenting these solutions, Svegea reinforced GTB’s reputation as a launchpad for innovation and practical advancements in garment production.

Sustainable Garment Technology Insights

Reflecting on the event, several insights stood out from Håkan Steene’s perspective:

- Organization matters: The smooth flow of the expo allowed participants to maximize networking and learning.

- Global enthusiasm: Textile technology enthusiasts from all over the world created a dynamic atmosphere.

- Partnerships thrive: Meeting other Tech Cell partners and exhibitors strengthened collaboration and opened new opportunities.

- Innovation inspires: Showcases such as Svegea’s Collarette Cutter and EC 50 demonstrate how technology continues to reshape garment production.

These takeaways highlight GTB’s unique ability to combine education, networking, and innovation in one platform.

Looking Ahead

As GTB 2026 concluded, participants left with renewed inspiration and stronger connections. For Svegea and Tech Cell BT Ltd, the expo was not just about attendance—it was about building bridges, sharing knowledge, and preparing for the next wave of textile innovation. The anticipation for future expos is already growing, with expectations of even greater collaboration and technological breakthroughs.

If you are eager to explore Svegea’s Collarette Cutter or Semi-Automatic EC 50, don’t wait until the next expo. Contact Håkan Steene at h.steene@svegea.se to schedule a product demo and discover how these solutions can transform your production line.

In 2026, fashion is moving away from “looking good” and toward “feeling good.” Experts at trend agencies like WGSN are calling this the era of “Feel Appeal.” For fashionistas, this means wardrobes full of 3D textures and colors that soothe the mind. For manufacturers, it presents a new challenge: how to produce these complex garments without slowing down their production line?

Understanding these trends today allows you to adjust your factory floor before the demand peaks. Here are the three major shifts coming in 2026.

1. The Rise of “Hyper-Haptic” Textures

Minimalism is changing. While “Quiet Luxury” was about smooth, flat fabrics, 2026 introduces Tactile Maximalism. Expect to see heavy bouclé, 3D knits, and fabrics with “puckered” or uneven surfaces. These materials engage the sense of touch.

Consequently, these textures are much harder to cut than standard cotton. Traditional blades can snag or tear these delicate surfaces. To handle these “Hyper-Haptic” fabrics, manufacturers need high-precision band knives and automated tension control. This ensures that the 3D structure of the fabric remains perfect from the roll to the final garment.

2. Modular Design and the Return of the Trim

Sustainability in 2026 focuses on longevity. Fashionistas want “Modular Garments”—clothes that they can change or repair. This includes detachable sleeves, adjustable waistbands, and layered pockets.

In addition, high-quality trims and bindings are becoming a central design feature. A simple shirt becomes a luxury item when it features a perfectly cut collarette or a contrast bias binding. For the manufacturer, this means the demand for specialized trimmings will skyrocket. Using an automated collarette cutter allows you to produce these complex details at high speed with zero errors.

3. Raw Authenticity and “Brut” Materials

The “natural” look is taking a bold turn. “Brut Denim”—which is unwashed, stiff, and raw—is a top trend for 2026. Alongside this, we see earthy pigments like “Transformative Teal” and “Cocoa Powder” dominating the runways.

Furthermore, consumers are looking for “honest” materials. They want to see the weave of the fabric and the quality of the stitch. When the fabric is this raw, there is nowhere to hide mistakes. Precision in every cut is vital. If a manufacturer uses outdated machinery, the raw edges of these heavy materials will fray, resulting in increased waste and lower quality.

How to Prepare Your Factory for 2026

The trends of 2026 require a “quality first” mindset. Manufacturers who invest in precision garment finishing will capture the luxury and technical markets. By upgrading to automated slitting and cutting systems, you can handle 3D textures and modular designs with ease.

Specifically, automation allows you to produce the “hand-crafted” look that fashionistas crave, but at an industrial scale. This balance of craft and technology is the secret to success in the coming year.

Let’s Design the Future Together

We understand that transitioning to new fabric trends can be difficult. Our team is here to help you choose the right machinery to stay ahead of the curve.

Contact Håkan Steene at h.steene@svegea.se or visit our Contact Us page to request a product demo. Let us show you how our Swedish-engineered solutions can make your 2026 collections a reality.

Photo by Egor Myznik on Unsplash

Modern car design relies on much more than just metal and glass. Today, engineers use high-performance fabrics to make vehicles safer, lighter, and more comfortable. By 2026, experts expect the global market for technical textiles in the automotive industry to exceed $34 billion.

Why Engineers Choose Fabric Over Metal

The rise of Electric Vehicles (EVs) is the primary driver of this trend. As a result, manufacturers must find ways to reduce vehicle weight to improve battery range. Technical textiles in the automotive industry provide a perfect solution because they deliver strength without the heavy weight of traditional materials.

In addition to weight savings, textiles play a critical role in safety. Manufacturers use specialized fibers like Nylon 6,6 to create airbags and seatbelts. These materials must withstand extreme heat and pressure without failing.

Solving the Challenges of Precision Slitting

Working with technical materials requires a different approach than working with fashion fabrics. Many automotive materials feature multiple layers, such as foam backings or protective coatings. Cutting these materials often presents a challenge. Because synthetic fibers are sensitive to heat, traditional blades can sometimes melt the edges. To solve this, manufacturers use specialized slitting machines that offer:

- Cold-Cutting Technology: Clean edges without fusing layers.

- High Dimensional Tolerance: Exact measurements for safety-critical parts.

Automated systems eliminate human error, leading to higher quality and lower costs.

Meeting New Environmental Regulations

Looking ahead to 2026, global governments are introducing the Waste Framework Directive. This means car manufacturers must take more responsibility for the waste they create during production. By using precision slitting, a factory maximizes raw materials and complies with new laws. This ensures that technical textiles in the automotive industry continue to support sustainability goals.

Invest in Machinery that Powers the Next Generation of Automotive Interiors

At Svegea, we provide the machinery that powers the next generation of automotive interiors. We invite you to learn more about our high-precision solutions. Contact Håkan Steene at h.steene@svegea.se or visit our Contact Us page for more details and a product demo. Let us know how we can help you meet the strict demands of automotive manufacturing.

Photo by Altered Vision on Unsplash

In the global garment industry, the word “waste” no longer just describes an environmental concern. Today, it represents a major economic challenge for manufacturers, driving interest in textile waste reduction technology. Recent data indicate that the fashion sector generates approximately 92 million tons of waste annually. For factory owners, a significant portion of this loss happens long before a garment reaches a customer.

The True Cost of Fabric Scraps

Traditionally, garment cutting involves a certain amount of “expected” loss. However, rising material costs mean that factories can no longer ignore these scraps. Industry research suggests that between 15% and 25% of all fabric ends up on the cutting room floor. These “off-cuts” represent a massive loss in potential profit.

Furthermore, many countries are now introducing stricter waste disposal fees. Consequently, manufacturers pay twice for waste: first when they buy the fabric, and again when they dispose of it.

How Precision Engineering Saves Money

To combat these rising costs, smart factories are investing in technologies that reduce textile waste. These modern machines improve fabric utilization in garment manufacturing by focusing on two main areas:

- Automated Alignment: Advanced sensors ensure that fabric rolls stay perfectly straight during the slitting process. Even a tiny shift in alignment creates unusable edges.

- Tension Control: When a machine pulls too hard on a knit fabric, it distorts the shape. Precision systems maintain the natural state of the cloth, ensuring every cut remains exact.

Specifically, moving away from manual cutting allows a factory to achieve sustainable fabric savings. This efficiency directly protects the company’s profit margins.

Transitioning to a Circular Economy

The industry is currently moving toward a circular economy. In this model, manufacturers treat waste as a valuable resource. In addition, new laws in Europe will soon require factories to report their waste levels. Precision machines make it easier to collect high-quality, uniform scraps that recyclers can turn back into new yarn.

Let Us Help You Optimize Your Production

We want to help you reduce waste and increase your efficiency. If you want to see how precision cutting can transform your factory, please reach out to us. Contact Håkan Steene directly at h.steene@svegea.se or visit our Contact Us page to book a product demo. Let us know how we can help you streamline your production today.

The textile and garment industry is evolving rapidly in 2026. While new fabrics and fashion trends capture headlines, manufacturers face a bigger challenge: how to boost garment production efficiency. Rising costs, sustainability demands, and global competition mean factories must rethink their processes. This article explores practical strategies for textile and garment manufacturers to streamline production, reduce waste, and stay competitive.

Why Efficiency Is the Key Trend in 2026

Efficiency is no longer just about speed—it’s about smart resource use. Manufacturers who optimize production benefit from:

- Lower material and energy costs

- Higher quality garments with fewer defects

- Faster turnaround times for global buyers

- Improved sustainability credentials

Core Strategies to Boost Garment Production

1. Lean Manufacturing Principles

Lean methods eliminate waste and streamline workflows. By mapping processes and removing non‑value steps, factories can cut production time by up to 30%.

2. Smart Factory Automation

AI‑driven scheduling, robotics, and digital monitoring systems are becoming mainstream in 2026. These tools reduce human error and allow managers to adjust production in real time.

3. Workforce Upskilling

Training operators to handle advanced machinery ensures fewer mistakes and higher productivity. Continuous learning programs also improve employee retention.

4. Preventive Maintenance

Downtime is one of the biggest drains on efficiency. Regular machine checks and predictive maintenance systems keep production lines running smoothly.

5. Sustainable Resource Management

Efficient factories use less water, energy, and chemicals. This not only lowers costs but also meets growing buyer demands for eco‑friendly production.

Textile Trends That Shape Efficiency in 2026

| Trend (2026) | Efficiency Impact | Manufacturer Action |

| Regenerative fabrics | Higher costs initially | Invest in supplier partnerships |

| Smart textiles | Complex QC needs | Train staff, upgrade testing tools |

| Circular economy models | Requires recycling systems | Adopt waste-sorting technology |

| Digital automation | Upfront investment | Long-term savings, higher output |

Practical Steps for Manufacturers

- Audit current workflows: Identify bottlenecks and wasted motion.

- Adopt modular production lines: Flexible setups allow quick adaptation to new orders.

- Integrate digital dashboards: Real‑time visibility improves decision‑making.

- Collaborate with suppliers: Secure reliable sources of sustainable fabrics to avoid delays.

- Benchmark against leaders: Study efficiency models from top factories worldwide.

Efficiency and Sustainability Go Hand in Hand

Boosting garment production efficiency is not just about profit. It’s about aligning with global sustainability goals. Factories that reduce waste, energy use, and water consumption will gain a competitive edge in 2026 while meeting consumer expectations for responsible fashion.

Innovation and Sustainability

Textile trends in 2026 highlight innovation and sustainability, but the real opportunity lies in boosting garment production efficiency. By embracing lean manufacturing, smart automation, workforce training, and sustainable resource management, garment and textile manufacturers can thrive in a competitive global market.

Ready to Boost Garment Production?

If you’re looking to boost garment production efficiency in 2026, Svegea of Sweden offers advanced textile machinery designed to streamline operations and reduce waste.

Contact Håkan Steene at h.steene@svegea.se to discuss how their solutions can transform your production line. Or browse the full range of textile machinery and discover how innovation meets efficiency.

As 2025 comes to a close, the textile industry has shown us remarkable shifts. Textile Industry Trends 2025 were not just headlines; they were practical lessons for garment manufacturers worldwide. The key takeaway? What worked in 2025 must be refined and scaled in 2026 to achieve even greater efficiency and sustainability.

Sustainability Was the Foundation

In 2025, sustainable textile production became non‑negotiable. Factories that reduced water use, chemicals, and energy gained stronger reputations and long‑term buyers.

➡️ 2026 Lesson: Double down on eco‑friendly garment production. Integrate smarter resource management and circular economy in fashion models to meet rising consumer expectations.

Smart Textiles Became Mainstream

Smart textiles in 2025 introduced fabrics with sensors and adaptive properties. These innovations demanded workforce upskilling and advanced testing tools.

➡️ 2026 Lesson: Continue investing in workforce training. Precision in garment manufacturing efficiency will be critical as smart textiles expand into everyday fashion.

Circular Economy Took Root

Circular economy in fashion gained traction, with recycling and reuse shaping production strategies. Factories that adopted modular production lines reduced waste and improved flexibility.

➡️ 2026 Lesson: Scale recycling systems and modular setups further. This ensures eco‑friendly garment production while keeping costs under control.

AI and Automation Transformed Factories

AI in textile industry operations and digital automation in garment factories reshaped scheduling, monitoring, and design. Predictive maintenance in textile machinery reduced downtime and improved output.

➡️ 2026 Lesson: Expand automation beyond pilot projects. Lean manufacturing in textiles combined with AI will unlock faster turnaround times and higher quality garments.

Regenerative and Bio‑Based Fabrics Rose

Bio‑based fabrics and regenerative textiles gained popularity despite higher initial costs. Manufacturers who partnered with suppliers for bulk sourcing balanced innovation with affordability.

➡️ 2026 Lesson: Strengthen supplier collaborations. Secure reliable sources of regenerative textiles to meet sustainability goals and consumer demand.

Moving Into 2026

The biggest lesson from Textile Industry Trends 2025 is clear: efficiency and sustainability go hand in hand. Factories that embraced garment manufacturing efficiency, workforce upskilling in factories, and predictive maintenance in textile machinery are already ahead. In 2026, the challenge is to refine these strategies and make them even better.

A Year of Innovation and Change

2025 was a year of innovation and change. For garment and textile manufacturers, the opportunity in 2026 lies in building on what worked—sustainable textile production, smart textiles, AI in garment manufacturing, and circular economy practices. By learning from the past year, factories can thrive in the future.

Ready to Elevate Your Production in 2026?

Take the next step with Svegea of Sweden’s advanced textile machinery—designed to streamline operations, reduce waste, and support sustainable growth.

👉 Contact Svegea directly: https://www.svegea.se/contact

Textile trends in 2026 promise big changes for garment and textile manufacturers in India, the USA, and South America. Manufacturers must adapt to sustainability demands and smart innovations now. These shifts will shape production lines and profits.

Sustainability Leads the Way

Eco-friendly fabrics top textile trends in 2026. Recycled polyester and nylon grow fast, pushed by EU rules for recyclable clothes by 2030. Lyocell markets double to $3.4 billion by 2032 from closed-loop processes. Blends of hemp or recycled cotton appear in activewear. For that reason, factories upgrade to meet global standards.

Bio-based materials surge too. Mycelium leather hits $336 million by 2033, used by brands like Stella McCartney. Banana fiber from waste stems spins into strong cloth. These options cut carbon footprints sharply. Indian exporters eye Europe amid US tariffs, where 29% of $38 billion exports went last year. Portugal’s Porto hub blends craft with tech for high-end textiles. Thus, manufacturers gain an edge in competitive markets.

Smart and Technical Textiles Rise

The technical textiles boom is expected to grow by $481 billion by 2035 at a 6.55% CAGR. Smart fabrics with sensors and energy-harvesting tech lead textile trends in 2026. AI detects defects early, cuts waste. Nano-engineered materials boost performance in autos and medical gear. Demand from construction drives growth.

In the USA and India, wearable tech integrates into apparel. Phase-change fabrics regulate temperature. Portugal firms innovate with full value chains nearby. As a result, production speeds up. Global fiber output nears 160 million tonnes by 2030, but recycled shares must climb. Factories that adopt these stay ahead.

Aesthetic Shifts Reshape Designs

Dots dominate prints with +55% growth in Europe for big dots. Brut denim rises +10%, raw and stiff for authentic looks. Romantic fabrics like lace skirts grow +20% in the EU, +13% in the USA. Checked patterns adapt to summer, zebra prints hit +21%.

Textures return strong. Ruffles and bubble hems trend +20%. Purple hues from lilac to plum add vibrancy. Creamy yellows like vanilla become neutrals. Textile trends in 2026 mix these with sustainability. Manufacturers layer them into versatile lines. Runways from Dior to Zimmerman prove demand.

Regional Impacts for Manufacturers

India faces US tariffs, so exporters cut prices and shift to the EU’s $137 billion trade. Facilities upgrade for ethical sourcing. USA buyers push recycled content amid consumer surveys showing 60% prioritize green. Portugal excels in quality home textiles at events like Intertex 2026.

Challenges persist, like low recycling rates under 1% for textiles. Yet opportunities abound in bio-leathers and cellulosics. Therefore, cross-border partnerships thrive. Technical markets hit $271 billion in 2026. Demographics demand scalable, eco-tech solutions now.

Future-Proof Your Production

Textile trends in 2026 demand action from manufacturers. Bold colors, animal prints, and smart hybrids redefine wardrobes. Investments in circular tech pay off long-term. Regulations force shifts, but innovators win big.

Ready to lead? Partner with Svegea of Sweden for precision cutting machines that slash waste and boost efficiency. Our 70-year expertise in sustainable textile production fits India, the USA, and Portugal perfectly. Contact us to upgrade your lines and capture 2026 trends. Act now for greener, faster output.

The fashion world is no longer just about the runway—it’s about revolution. Driven by environmental urgency and consumer demand, the industry must fundamentally transform the way garments are made. This isn’t just a trend; it’s a massive opportunity to build a better, cleaner, and more efficient future. Right at the foundation of this revolution are automated textile cutting machines. These aren’t just faster tools; they are the engines of precision, radically redefining the textile processing industry. For any forward-thinking garment or textile manufacturer, these systems are no longer optional—they are essential for meeting the demands of the modern, responsible market.

The Heartbreak of Manual Cutting: Waste, Inefficiency, and Lost Profit

Let’s face the harsh reality of traditional cutting: it’s messy, costly, and wildly inefficient. Manual processes inevitably lead to jagged edges, misaligned patterns, and an avalanche of unusable offcuts. This isn’t just frustrating—it’s a critical financial and environmental drain.

The numbers are staggering: The fashion industry dumps over 92 million tons of textile waste annually. Poorly executed first cuts simply waste too much material. Manufacturers throw literal profit into a landfill.

The antidote? The uncompromising accuracy of automated fabric cutting machines. These systems are programmed perfectionists. They use every millimetre of material, slashing error rates and transforming mountains of scrap into perfectly optimized components. The result is a leaner, greener, and far more profitable production line.

Where High-Speed Efficiency Meets Deep Environmental Commitment

Investing in automated fabric cutting machines isn’t about compromise; it’s about optimization. It proves that you don’t have to sacrifice speed for sustainability—you can have both.

Here’s the powerful equation:

- Unparalleled Precision: Say goodbye to waste! Automation cuts fabric wastage by up to 30%.

- Power Smart: Modern automated fabric cutting machines are energy-sippers, dramatically lowering your carbon footprint and operational utility costs.

- Speed Without Stress: Achieve lightning-fast throughput while maintaining pristine quality and consistency.

- Elevated Workforce: Free up your skilled workers from repetitive cutting tasks, allowing them to focus on high-value, complex challenges.

These advantages aren’t theoretical—they lead to immediate, quantifiable success: faster market delivery, rock-solid consistency, and simple compliance with global standards like ISO 14001.

Garment Cutting Machinery: Real-World Wins

The shift to automated fabric cutting machines is already creating global success stories:

- A major garment factory in Bangladesh reported a 25% reduction in fabric waste within months of their automation launch.

- A Portuguese knitwear specialist achieved a 40% increase in cutting speed while maintaining a flawless output record.

When global brands demand circular fashion models and net-zero strategies, the use of automated textile cutting machines is the non-negotiable step manufacturers must take. Investing in these solutions doesn’t just keep you current—it positions you as a leader setting the pace for the industry.

The Business Blueprint: Why You Can’t Afford Not to Automate

The business case for advanced fabric handling is irresistible:

-

- Financial Health: Less waste immediately equals lower spending on raw materials.

- Rapid ROI: Increased speed and reduced error rates translate directly into faster cash flow and profitability

- Brand Power: Sustainability is a competitive advantage. Showing commitment enhances your reputation with conscious consumers and key retail partners.

- Future-Proofing: Easily meet rigorous regulatory standards for waste and energy consumption.

In today’s cutthroat market, these efficiencies aren’t luxuries—they are the bedrock of lasting success.

Ready to Transform Your Production Line?

The future of fashion starts with a precise cut. If you are ready to stop calculating waste and start maximizing every yard of fabric, it’s time to explore the best technology available.

Svegea of Sweden offers precision-engineered automated fabric cutting machines trusted globally for their uncompromising reliability, durability, and eco-conscious design.

Take the next step: Contact Håkan Steene at h.steene@svegea.se to schedule a personalized product demo and discover how Svegea can immediately elevate your textile operations.