In today’s fast-paced textile industry, precision, speed, and sustainability are no longer optional — they’re essential. That’s why manufacturers around the world are turning to Swedish textile cutting machinery — specifically Svegea, a company that’s been redefining automated cutting solutions since 1952.

Svegea’s Swedish-engineered solutions help manufacturers by focusing on automation, sustainability, and user-friendly design to improve efficiency, reduce waste, and adapt to market demands. Their machines support the creation of smarter, more connected factories through integration with Industry 4.0 principles, making them ideal partners for reshoring efforts and sustainable production goals.

Automation: The Foundation of Competitive Manufacturing

High-Speed Precision Cutting

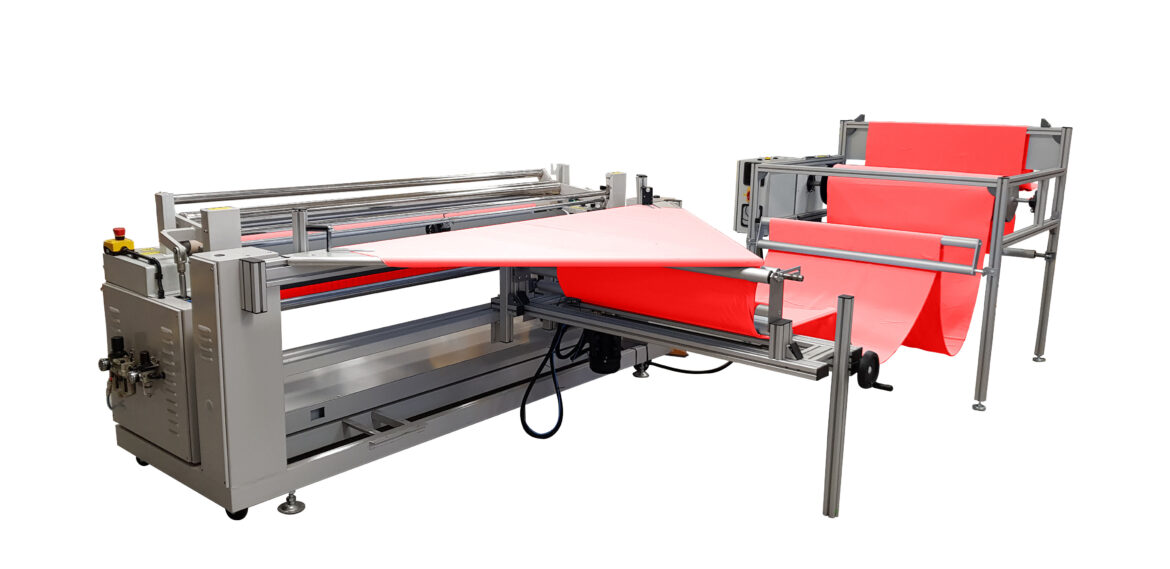

Svegea’s textile cutting machinery from Sweden is engineered for high-speed, precise cutting, which helps produce consistent quality and faster production times. Every machine is designed to maintain exacting standards even at maximum operational speeds, ensuring that manufacturers can scale production without sacrificing quality.

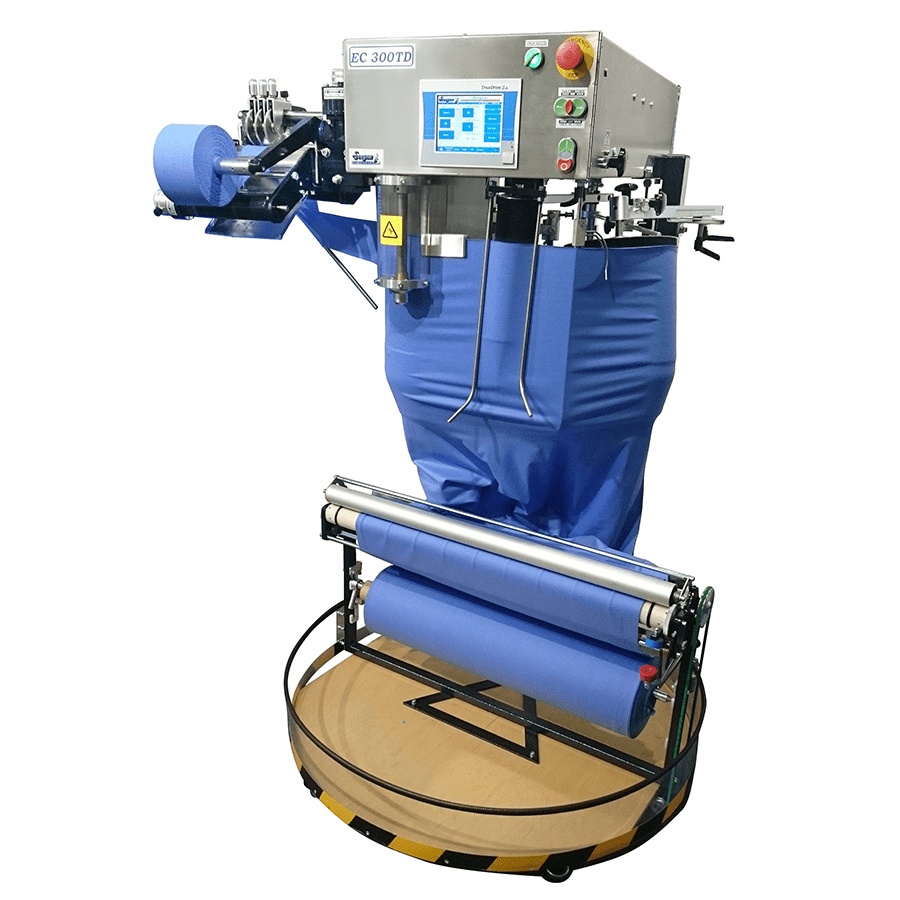

- EC-450XF Collarette Cutting System: Awarded at Texprocess 2023 for its innovation and sustainability, this fully automatic system delivers high-speed, low-waste performance with precision that’s become the industry benchmark.

- Euro-Collarette Fully Automatic Series: These models feature the intuitive E Drive 2 panel and two-step cutting for multiple bands — ideal for high-volume operations requiring consistent output.

Automated Processes That Reduce Labor Dependency

Svegea integrates automatic tube sewing units for creating sewn tubes in rolled or flat-folded forms, reducing the need for operator assistance and minimizing human error.

- TSU 200 A/AF Tube Sewing Unit: Minimal operator input, maximum efficiency. This system exemplifies how automation enables manufacturers to redirect skilled labor to higher-value tasks.

- Bias Cutter / Winder 200: Smooth unwinding and rewinding into single ply rolls with minimal manual intervention.

- Bias Cutter CMB 1800: Versatile and adaptable across fabric types, streamlining the entire bias binding process.

Supporting Reshoring with Smart Automation

Automation facilitates reshoring operations by making local manufacturing more competitive and efficient. Sweden’s textile cutting machinery industry leads this transformation, offering manufacturers the tools they need to bring production home without sacrificing cost-effectiveness.

Sustainability: Engineering for a Better Future

Precision That Reduces Waste

Precision cutting and automation help maximize fabric usage, minimizing material waste. Svegea’s machines are engineered to optimize every centimeter of fabric, contributing directly to both profitability and environmental responsibility.

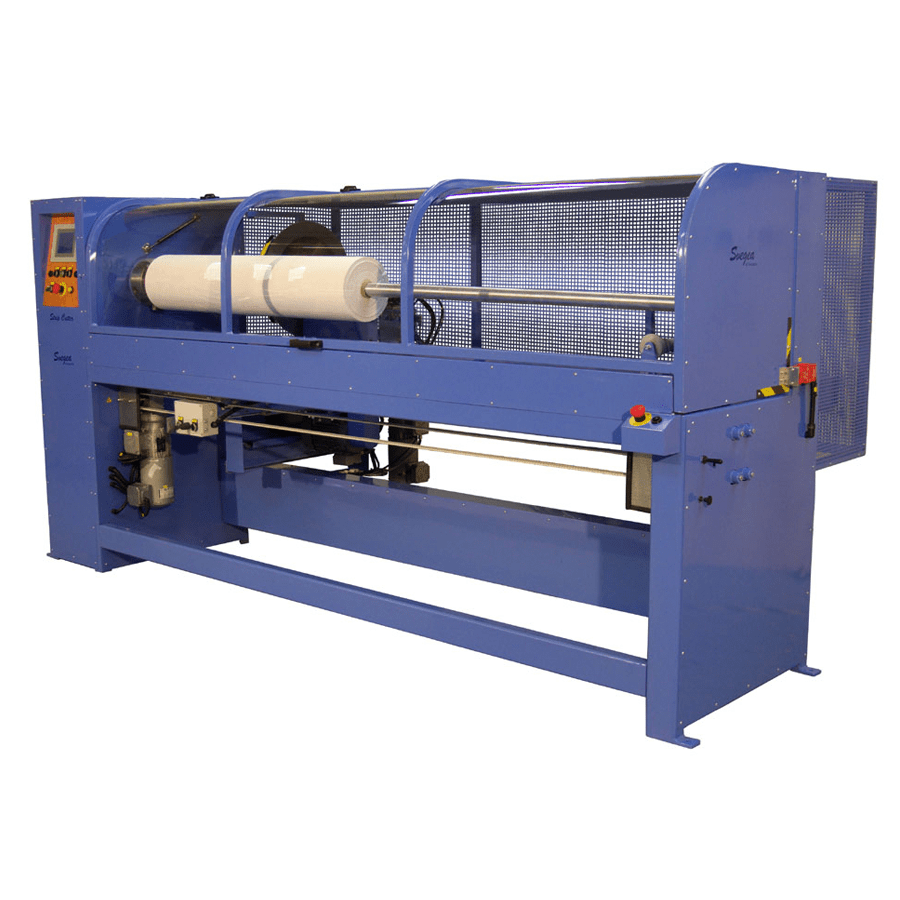

- Strip Cutter CMS 1800A2: High-speed cutting for bias tape, trims, and bindings with advanced nesting algorithms that reduce offcut waste.

- TSO 380 G/GF Tubular Knit Slitter: Reduces waste and improves material yield through intelligent cutting patterns.

Energy-Efficient Engineering

Svegea’s machinery is designed to be energy efficient, lowering consumption and environmental impact. Every system is optimized for minimal power draw without compromising performance, making textile cutting machinery from Sweden a smart choice for manufacturers committed to reducing their carbon footprint.

- RRS-800 Fully Automatic Roll Slitting Machine: Offers motorized knife control and adjustable speed for consistent quality while maintaining low energy consumption throughout extended production runs.

Supporting Circular Economy and Recycled Materials

By improving garment durability and promoting longevity through efficient production, Svegea’s machines contribute to a more circular economy. The advanced technology can support the use of recycled materials in production, accommodating the varied characteristics of reclaimed fabrics without compromising cut quality.

- FIM CMI 210 R / ZR Fabric Inspection Machine: Detects defects and inconsistencies in both virgin and recycled materials before they reach the cutting floor, ensuring quality regardless of source.

User-Friendly Design: Versatility Meets Accessibility

Adaptable Across Material Types

The cutting machines can handle a wide range of materials, from delicate silks to heavy-duty industrial textiles. This versatility makes Swedish textile cutting machinery ideal for manufacturers serving diverse market segments.

- SV/BK Band Knife Series: Precision cutting for everything from delicate silks to heavy-duty fabrics, with easily adjustable settings for quick material transitions.

- Strip Cutter FA 500: Heavy-duty and reliable, perfect for long production cycles with materials ranging from PVC to non-woven fabrics.

Quick Changeovers for Maximum Productivity

User-friendly interfaces and the ability to quickly switch between patterns and materials reduce downtime and enhance productivity. The intuitive E Drive 2 control panel makes complex operations accessible to operators at all skill levels.

- Euro-Collarette Semi-Automatic Series: A semi-automatic option that cuts two bands simultaneously, with widths ranging from 16 to 140 mm — changeable in minutes, not hours.

Customization for Niche Applications

Svegea provides custom-specific machines and units for niche applications like bias cutting, and can adapt to diverse customer preferences. This flexibility ensures that whether you’re producing standard collarettes or specialized technical textiles, there’s a solution engineered specifically for your needs.

- W 2100S Fabric Rewinding Machine: Perfect re-rolls every time, with customizable tension and speed settings for different fabric types.

Industry 4.0 Integration: Building Smarter Factories

Sweden’s textile cutting machinery leads the way in smart manufacturing integration. Designed to connect seamlessly with modern factory management software the Svegea system enables:

- Real-time production monitoring and quality control

- Predictive maintenance scheduling to minimize downtime

- Data-driven optimization of cutting patterns and material usage

- Integration with inventory and supply chain management systems

This connectivity transforms individual machines into components of an intelligent manufacturing ecosystem. The result? Long-term competitiveness in an increasingly digital industry.

The Swedish Advantage: Seven Decades of Innovation

Textile cutting machinery from Sweden represents more than a geographic label — it’s a commitment to quality, innovation, and sustainability. Svegea embodies the best of Swedish engineering: meticulous attention to detail, long-term reliability, and environmental responsibility.

Svegea has been serving global textile manufacturers since 1952, continuously innovating to meet the evolving demands of modern production. This heritage of excellence makes Swedish textile cutting machinery a global benchmark for quality, sustainability, and technological advancement.

Ready to Transform Your Production Line?

Experience how premium Swedish textile cutting machinery can revolutionize your operations. Whether you’re looking to reshore production, reduce waste, improve efficiency, or build an Industry 4.0-ready factory, Svegea has the solutions you need.

Explore Svegea’s full range of automated textile solutions at svegea.se. For a personalized product demo and consultation, contact Håkan Steene at h.steene@svegea.se.

Let’s build the future of sustainable, efficient textile manufacturing — together.

Fashion is changing—and fast. Today, being eco-friendly isn’t just a trend. It’s a smart move. People care more about the planet, and they want clothes made responsibly. That’s where fabric innovation comes in. It’s helping fashion brands create better materials and use smarter machines to make clothes in cleaner ways.

Let’s explore how new fabrics and modern machines are working together to build a more sustainable fashion industry.

New Materials, New Possibilities

For years, most clothes were made from cotton or polyester. These materials use a lot of water, chemicals, and energy. But now, designers are using things like fruit peels, mushrooms, and even carbon from the air to make fabric.

Here are a few examples:

- Mylo: A soft, leather-like material made from mushroom roots. It feels like real leather but is biodegradable and doesn’t harm animals.

- Orange Fiber: Made from leftover citrus peels. It’s silky and smooth, perfect for dresses and scarves.

- Piñatex: Created from pineapple leaves. It’s strong and flexible, often used in shoes and bags.

These new fabrics are stylish, durable, and better for the environment. They break down naturally and don’t need as many resources to produce. People want to know where their clothes come from, and brands are responding with cleaner, smarter choices.

Machines That Make It Happen

These cool new fabrics wouldn’t exist without the right machines. Today’s textile machines are smarter and greener than ever. They use less water, less energy, and fewer chemicals.

Let’s break down what these machines do:

- Dyeing machines with closed-loop systems: These machines clean and reuse water during the dyeing process. That means less pollution and lower water bills.

- Spinning machines with smart sensors: These sensors adjust the yarn tension automatically. This helps reduce waste and keeps the fabric smooth and strong.

- Aluminum extrusion frames: These lightweight frames make machines faster and easier to maintain. They also use less energy during production.

This is where fabric innovation meets smart engineering. By using better materials and better machines, factories can make high-quality clothes while protecting the planet.

Why Going Green Is Good for Business

Being sustainable isn’t just good for the Earth—it’s good for business too. Brands that use fabric innovation often save money and attract more customers.

Here’s how:

- Lower energy costs: Machines that use less electricity help reduce monthly bills.

- Fewer labor expenses: Automated systems do more work with fewer people, saving time and money.

- Longer-lasting products: Strong, recyclable fabrics mean fewer returns and happier customers.

Also, governments are starting to set stricter rules about waste and pollution. Companies that switch to cleaner methods now will be ready for the future—and avoid fines or delays.

Recycling Clothes: The Circular Fashion Idea

One of the coolest parts of fabric innovation is how it helps with recycling. Instead of throwing old clothes away, companies can now turn them into new fabric.

Here are some exciting developments:

- Fiber-to-fiber recycling: This process breaks down old clothes and spins them into fresh yarn. It keeps materials in use and out of landfills.

- Carbon capture polyester: Some companies are turning carbon dioxide from factory smoke into polyester fabric. It’s a smart way to clean the air and make clothes.

- Lab-grown cotton: Scientists are growing cotton in labs without using farmland or pesticides. It’s clean, safe, and doesn’t harm the soil.

These ideas are already being tested in places like Europe and Asia. They help reduce trash, save resources, and even create new jobs.

Working Together to Make It Work

To make all this happen, people across the fashion world need to team up. Garment manufacturers, fabric developers, and clothing brands must share ideas and work together.

Here’s what that looks like:

- Engineers designing new machines: These machines can handle unusual fabrics like mushroom leather or pineapple fiber.

- Designers experimenting with new styles: They’re testing how these new materials feel, look, and move.

- Factory owners rethinking production: They’re changing how they plan, cut, and ship products to reduce waste and save money.

This teamwork is what makes fabric innovation so powerful. It’s not just about one product—it’s about changing the whole system.

Fashion Innovation is Growing Every Day

If you’re a garment maker, designer, or business owner, this is your moment. The tools are ready. The materials are here. And the demand for sustainable fashion is growing every day.

“At Svegea, we believe fabric innovation is the heartbeat of modern fashion. That’s why we’re constantly evolving our machinery—making it smarter, cleaner, and more adaptable—so garment and textile manufacturers can stay ahead in a fast-changing industry.” — Hakan Steene, Managing Director of Svegea of Sweden

Reach out to Hakan Steene at h.steene@svegea.se to explore how Svegea’s textile machinery can help you lead the way. Whether you’re upgrading your factory or starting fresh, Svegea offers smart solutions that fit your goals—and your budget.

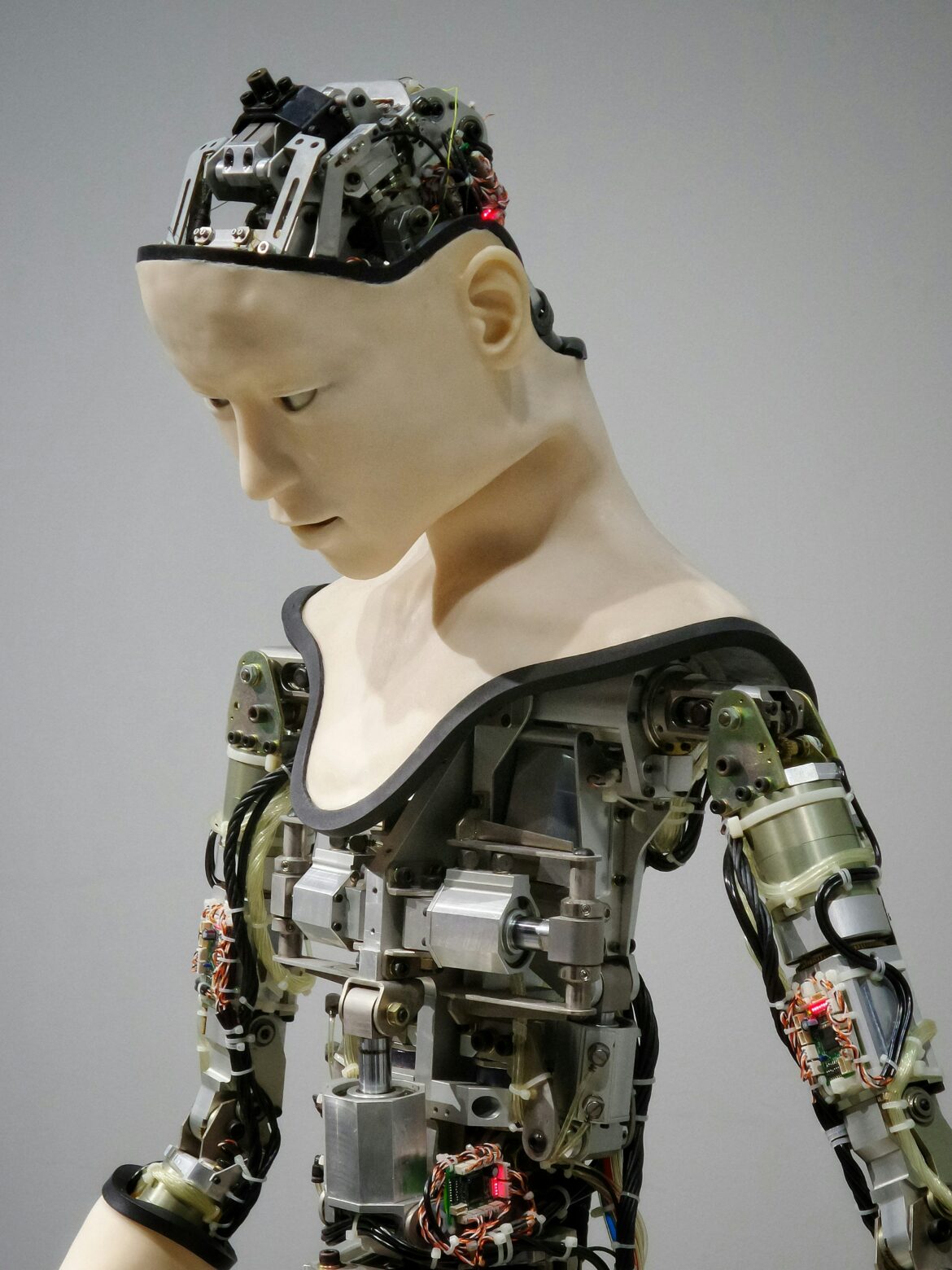

The textile industry is undergoing a digital revolution, and AI in textile manufacturing is at the forefront of this transformation. Artificial intelligence reshapes how textiles are created, manufactured, and distributed, from optimizing design processes to enhancing production efficiency.

AI in Textile Design: Innovation Meets Creativity

AI is revolutionizing textile design by enabling faster, smarter, and more efficient pattern-making. Designers now use AI-powered tools to generate intricate patterns, predict fashion trends, and customize designs based on consumer preferences.

How AI Enhances Textile Design:

-

- Automated Pattern Generation: AI algorithms analyze vast datasets to create unique textile patterns.

- Trend Prediction: Machine learning models forecast upcoming fashion trends, helping designers stay ahead.

- Customization: AI-driven tools allow brands to personalize designs based on customer preferences.

AI in Textile Production: Efficiency and Precision

AI is streamlining textile production by automating processes, reducing waste, and improving quality control. Manufacturers are integrating AI into machinery to optimize operations and enhance productivity.

Key AI Applications in Textile Production:

AI is transforming textile production through targeted, high-impact applications. Automated  fabric inspection systems now use advanced vision technology to identify defects with precision, ensuring only high-quality materials move forward in the process. On the factory floor, smart manufacturing machines continuously adjust their settings in real time, maximizing efficiency and minimizing downtime. Meanwhile, AI-driven supply chain tools analyze demand patterns and guide resource allocation, keeping operations agile and responsive.

fabric inspection systems now use advanced vision technology to identify defects with precision, ensuring only high-quality materials move forward in the process. On the factory floor, smart manufacturing machines continuously adjust their settings in real time, maximizing efficiency and minimizing downtime. Meanwhile, AI-driven supply chain tools analyze demand patterns and guide resource allocation, keeping operations agile and responsive.

AI-Driven Innovations in the Textile Industry

AI is not just improving efficiency—it’s driving groundbreaking innovations in textile production.

Examples of AI-Driven Innovations:

-

- AI-Powered Smart Textiles: Fabrics embedded with AI sensors for enhanced functionality.

- Predictive Maintenance: AI anticipates machine failures, reducing downtime.

- Eco-Friendly AI Solutions: AI optimizes dyeing processes to minimize environmental impact.

The Future of AI in Textile

AI is transforming the textile industry, making design and production more efficient, sustainable, and innovative. As AI continues to evolve, manufacturers and designers must embrace these advancements to stay competitive.

For more information on AI in textile manufacturing and product demos, contact Hakan Steene at h.steene@svegea.se.

In the competitive garment and textile manufacturing world, efficiency and precision are paramount. Svegea of Sweden, a leader in textile machinery, offers cutting-edge solutions that transform production processes, ensuring higher ROI and safer operations.

Efficiency Meets Innovation

Svegea’s machines are designed to streamline operations and reduce waste. The EC300, known for its precision, ensures consistent quality and faster production times. The Tube Sewing Unit 200A simplifies the creation of bias binding by sewing open fabric into continuous tubular pieces. This innovation minimizes operator assistance while maintaining high productivity.

Adding to their achievements, Svegea received the prestigious New Technology Innovation Award at Texprocess 2023, recognizing the innovative and sustainable design of their textile machinery. Their solutions, such as the award-winning EC-450XF Collarette Cutting System, set benchmarks for precision, efficiency, and eco-friendly manufacturing practices.

Versatility in Production

Svegea’s Bias-Cutting Systems are ideal for slitting, sewing, and rolling bias-cut fabrics. These systems handle various fabric types, ensuring strong and stretchable materials for diverse applications. Roll Slitting Machines, such as the FA600, offer fully automated solutions for cutting materials like PVC, polyester, and non-wovens.

Customized Solutions for Your Unique Needs

Every garment manufacturer has unique production requirements, and Svegea understands that one size doesn’t fit all. Their ability to customize textile machines to suit your specific needs ensures smarter, more efficient operations. Whether it’s tailoring machinery to fit fabric types, production volumes, or unique manufacturing goals, Svegea provides solutions that seamlessly integrate into your existing workflows. This flexibility makes their machines a smart investment for companies looking to maximize efficiency and adaptability.

Safety and Sustainability

Modern textile machinery prioritizes operator safety and environmental sustainability. Svegea’s machines incorporate intelligent sensors and energy-efficient designs, reducing workplace hazards and supporting eco-friendly practices.

Why Invest in Textile Machinery?

Acquiring advanced machinery is not just an expense—it’s a strategic investment. Svegea’s equipment enhances production efficiency, reduces operational costs, and boosts workforce productivity. With minimal maintenance and optimized resource utilization, these machines guarantee a robust ROI.

Explore Svegea’s Best-Selling Machines

Explore Svegea’s Best-Selling Machines

Svegea’s portfolio includes:

- Collarette Cutters: Precision-driven textile cutting

- Tube Sewing Unit 200A: Seamless bias binding creation

- Bias Cutting Systems: High-speed slitting and rolling

- Roll Slitting Machines: Automated material cutting

Take the Next Step

Ready to elevate your textile manufacturing? Contact Håkan Steene (h.steene@svegea.se) today for a product demo and discover how Svegea’s innovative machinery can revolutionize your operations.

For more details, visit www.svegea.se.

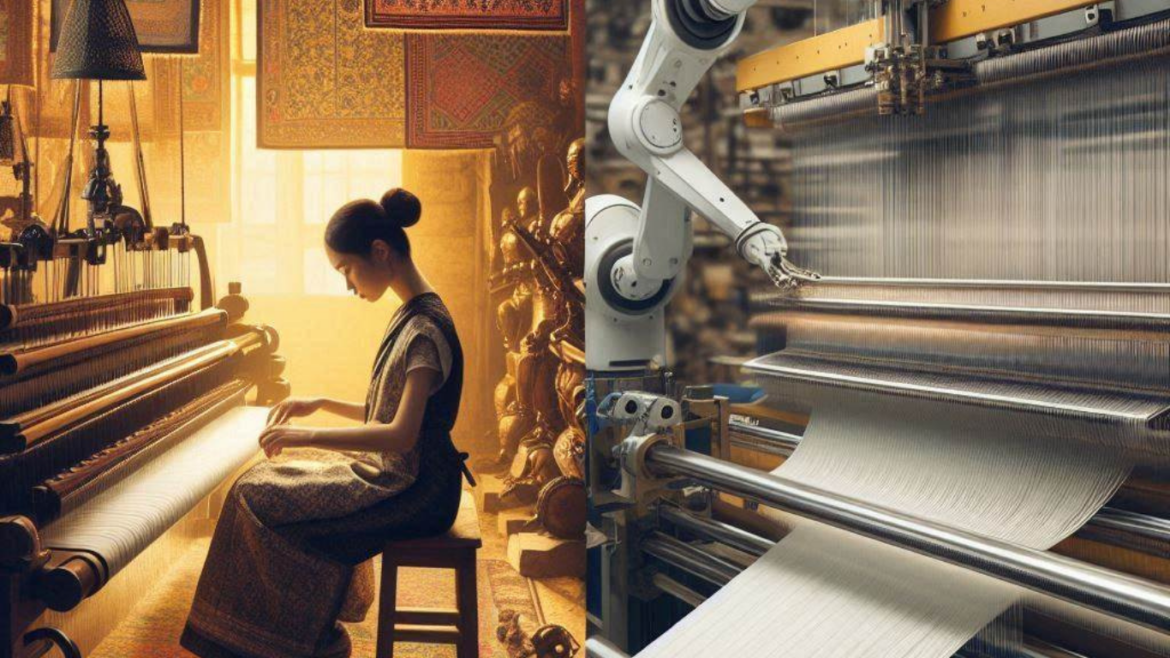

In an era where OOTD (Outfit of the Day) reigns supreme on social media, our relationship with clothing has become increasingly complicated. The fashion industry stands at a crossroads. Fast fashion pulls us one way—slow, sustainable production beckons from another direction. Let’s unzip the truth about these contrasting approaches and explore how quality textile production could be the thread that weaves a more sustainable future.

The True Cost of Fast Fashion: More Than Just a Price Tag

Remember that $5 t-shirt you couldn’t resist? While your wallet might have thanked you, our planet tells a different story. According to the United Nations Environment Programme, the fashion industry accounts for 10% of global carbon emissions and generates 20% of global wastewater. Stop and think about that. It’s more than all international flights and maritime shipping combined! The numbers are staggering. The implications are worse.

Fast fashion’s environmental impact reads like a horror story:

- One cotton shirt requires 2,700 liters of water – enough to keep one person hydrated for 2.5 years

- Synthetic fibers take up to 200 years to decompose

- The industry produces 92 million tons of textile waste annually

But environmental concerns are just the beginning. The human cost of fast fashion includes poor working conditions, minimal wages, and unsafe environments. A 2021 report by the Business & Human Rights Resource Centre revealed over 100 cases of worker exploitation in major fashion brands’ supply chains. These aren’t just statistics. They’re real people’s lives.

The Slow Fashion Revolution: Quality Over Quantity

Think of slow fashion as the farm-to-table movement of the textile world. It’s about creating garments that last. Simple as that. This approach emphasizes quality over quantity, craftsmanship over mass production, and sustainability over quick profits.

Quality Materials and Craftsmanship

High-quality textile production isn’t just about using better materials. Every thread counts. Manufacturers who invest in quality control and precise cutting techniques create garments that maintain their shape and durability through countless washes. It’s an investment in the future.

Innovation in Sustainable Manufacturing

Small and medium-sized enterprises (SMEs) often lead the way in sustainable innovation. Take Svegea of Sweden, for instance. This family-owned SME has spent decades perfecting bias-cutting technology that significantly reduces fabric waste. Their commitment to quality and sustainability shows how smaller companies can make a big impact. Through continuous innovation and unwavering dedication to quality, such companies prove that sustainable manufacturing isn’t just possible – it’s profitable.

Sustainable Production Methods

Modern textile manufacturing doesn’t have to choose between efficiency and sustainability. Advanced bias cutting machines can reduce fabric waste by up to 15% compared to traditional methods, while maintaining precise, high-quality cuts. Technology and sustainability can work hand in hand. They must.

Fair Labor Practices

Slow fashion emphasizes fair wages and safe working conditions. No compromises. When workers aren’t rushed to meet impossible quotas, they can focus on craftsmanship and quality control. The result? Superior products that last longer.

Making the Transition: A Guide for Manufacturers

Transitioning to sustainable practices isn’t just good for the planet – it’s good for business. A recent McKinsey survey found that 67% of consumers consider the use of sustainable materials an important purchasing factor. The message is clear. The time is now.

Start Small, Think Big

1. Audit your current waste levels and identify areas for improvement

2. Invest in precision cutting technology to reduce fabric waste

3. Train staff in sustainable practices and quality control

4. Consider implementing a circular production model

Embrace Technology Wisely

Modern machinery isn’t just about speed. It’s about precision and efficiency. The right equipment can help reduce waste, improve quality, and maintain consistency while reducing overall production costs. Smart choices lead to better results.

Build Transparency

Document your sustainability journey and share it with customers. Today’s consumers want to know the story behind their clothes. Transparency builds trust. Trust builds loyalty. Loyalty builds success.

The Future is in Our Hands

The fashion industry’s future doesn’t have to be a choice between profitability and sustainability. By focusing on quality textile production, manufacturers can create products that benefit everyone – from workers to consumers to the planet itself. The choice is ours. The time is now.

Want to learn more about sustainable textile production methods or see how modern technology can support your sustainability goals? Visit www.svegea.se to explore innovative solutions for quality textile production. For personalized guidance on implementing sustainable practices in your manufacturing process, reach out to our sustainability expert at h.steene@svegea.se.

*Author’s Note: This article was crafted with care to provide accurate information about sustainable fashion practices. All statistics and facts have been sourced from reputable industry reports and research papers. While specific solutions mentioned may vary in effectiveness depending on individual circumstances, the principles of sustainable production remain universal.*

The textile industry is experiencing a significant transformation, with Artificial Intelligence (AI) at its core. AI is revolutionizing textile design by automating processes, predicting trends, and promoting sustainability. This technological advancement is reshaping how designers and manufacturers approach creativity and production.

What is Textile Design AI?

Textile design AI involves utilizing artificial intelligence to enhance and automate the creation of textile patterns and designs. By analyzing extensive datasets, AI can generate unique designs and forecast consumer preferences. For instance, AI can blend historical patterns with current trends to produce innovative designs, expediting the creative process and fostering unprecedented innovation.

How AI is Transforming Textile Design

1. Automating Repetitive Tasks – AI streamlines tasks such as pattern creation and color adjustments, allowing designers to focus on creativity. Tools like Adobe’s Sensei automate pattern generation and color matching, enhancing efficiency.

2. Predicting Trends – By analyzing data from social media and fashion platforms, AI predicts upcoming trends. Platforms like Heuritech scan millions of images to identify emerging patterns, helping brands stay ahead.

3. Personalization at Scale – AI enables mass customization, allowing consumers to personalize products without hindering production. Companies like Unmade offer personalized knitwear, letting customers select colors and patterns.

4. Sustainable Design Solutions – AI optimizes material usage and reduces waste by calculating efficient fabric-cutting methods and suggesting eco-friendly materials, aiding brands in adopting sustainable practices.

Real-World Applications of Textile Design AI

- Fashion Brands Leading the Way – Brands like Stitch Fix use AI to analyze customer preferences and recommend personalized clothing. Similarly, Zara employs AI to monitor real-time sales data and adjust designs accordingly.

- Textile Machinery and AI Integration – Companies are integrating AI into textile machinery to optimize production, ensuring high-quality results with minimal waste. For example, advanced systems use AI to adjust settings based on fabric types automatically, reducing errors and improving efficiency.

Why Textile Design AI Matters

- For Designers – AI empowers designers to experiment with new ideas and streamline workflows, bringing visions to life faster. By automating routine tasks, designers can focus more on creativity and innovation.

- For Consumers – AI-driven design offers consumers more options, including personalized clothing and eco-friendly fabrics, meeting individual preferences and reducing wait times for new collections.

- For the Planet – The textile industry is a significant polluter. AI helps reduce environmental impact by optimizing resource usage and promoting sustainable practices, contributing to a more sustainable future.

Challenges and Opportunities

While AI offers numerous benefits, challenges include potential job displacement due to automation and the need for high-quality data for effective AI systems. However, AI can create new roles focusing on creativity and strategy, and as technology advances, data collection barriers are likely to decrease.

Challenges

-

Job Displacement & Workforce Adaptation

One of the biggest concerns with AI automation is job displacement. Tasks that were once done manually, such as pattern-making, color matching, and quality control, are now being automated, reducing the demand for traditional roles. However, this shift doesn’t necessarily mean mass unemployment. Instead, the workforce needs to adapt by acquiring new skills in AI-assisted design, data analysis, and machine operation.

-

Need for High-Quality Data

AI relies on vast amounts of high-quality data to function effectively. In textile design, this means collecting and organizing fabric patterns, color schemes, consumer preferences, and trend data. Poor data quality—such as incomplete, outdated, or biased datasets—can lead to inaccurate predictions and ineffective designs.

-

Implementation Costs & Infrastructure

Small and mid-sized textile businesses may struggle with the high cost of AI implementation, which includes purchasing software, integrating AI with existing production lines, and training employees. Companies need to balance initial investments with long-term gains in efficiency and productivity.

-

Creativity vs. Standardization

While AI can generate unique patterns and automate design processes, it still lacks human intuition and artistic expression. Over-reliance on AI might lead to standardized, repetitive designs, reducing originality in fashion and textile production.

Opportunities

-

New Job Roles & Upskilling

- As AI automates repetitive tasks, new roles will emerge that require human expertise in:

- AI-driven textile design

- Digital trend forecasting

- AI model training and management

- Sustainable material innovation

- This shift creates opportunities for upskilling and cross-functional roles, blending AI knowledge with traditional design expertise.

- As AI automates repetitive tasks, new roles will emerge that require human expertise in:

-

Improved Efficiency & Cost Savings

- AI streamlines design, manufacturing, and inventory management, reducing waste and increasing efficiency.

- Brands can cut production costs by optimizing material usage and minimizing trial-and-error design iterations.

-

Enhanced Personalization & Sustainability

- AI allows for mass customization, where consumers can personalize clothing designs at scale.

- AI-driven sustainability solutions, such as fabric waste reduction algorithms and eco-friendly material selection, are helping the industry move towards a greener future.

-

Data-Driven Design & Trend Forecasting

- AI tools can analyze social media, runway trends, and past consumer behavior to predict upcoming fashion trends.

- This helps brands stay ahead of the curve, reducing the risk of overproduction and unsold inventory.

The Future of Textile Design AI

The future holds endless possibilities for AI in textile design, including creating adaptive fabrics and designs that change based on user preferences. Continued innovation and sustainability efforts will drive the industry forward.

Join the Textile AI Revolution!

Don’t miss out on the future of textile design powered by AI. Embrace innovation, sustainability, and personalization in your textile creations. For more details on how AI can transform your designs and production processes, contact h.steene@svegea.se.

Choosing the right textile machinery can be a daunting task, especially with the plethora of options available in the market. The decision impacts your production efficiency, product quality, and overall business profitability. Here are some key tips to help you navigate this critical process.

1. Understand Your Production Needs

Before investing in textile machinery, it’s crucial to understand your specific production needs. Different types of machinery serve various purposes, from weaving and knitting to dyeing and finishing. Determine the scale of your operations, the types of textiles you produce, and your production goals. This understanding will guide your choice of machinery that best suits your requirements.

2. Evaluate Technology and Features

Modern textile machinery comes with a range of advanced technologies and features designed to enhance productivity and quality. Look for machines that offer automation, precision control, and energy efficiency. For instance, Svegea of Sweden offers cutting-edge machinery equipped with the latest technology, ensuring high efficiency and minimal waste. Our products are known for their durability and innovative features.

3. Consider Quality and Reliability

Quality and reliability are paramount when choosing textile machinery. Investing in high-quality machines may come with a higher initial cost, but it ensures long-term performance and fewer breakdowns. Research and compare different brands, read reviews, and consider the manufacturer’s reputation. Modesty aside, our brand has a proven track record of producing reliable and high-quality textile machinery.

4. Assess After-Sales Support and Maintenance

After-sales support and maintenance services are crucial for the smooth operation of textile machinery. Ensure that the manufacturer offers comprehensive support, including installation, training, and regular maintenance services. We provide excellent customer support and maintenance services, ensuring that your machinery operates optimally.

5. Analyze Cost and Return on Investment (ROI)

While the cost of textile machinery is a significant factor, it’s essential to consider the return on investment (ROI). A more expensive machine with advanced features and higher efficiency can lead to cost savings in the long run. Calculate the total cost of ownership, including maintenance and operational costs, and compare it with the expected benefits. Opt for machines that offer the best value for money.

6. Environmental Considerations

Sustainability is a growing concern in the textile industry. Choose machinery that is energy-efficient and environmentally friendly. Machines that reduce water and chemical usage, minimize waste, and consume less energy are ideal. This Swedish textile company is known for producing sustainable textile machinery that aligns with eco-friendly production practices.

7. Compatibility with Existing Systems

Ensure that the new machinery is compatible with your existing systems and processes. Incompatibility can lead to production delays and additional costs. Consult with the manufacturer or a technical expert to evaluate the integration process. A company that offers flexible machinery solutions that can be seamlessly integrated into various production setups, should be the right choice.

Explore Svegea of Sweden’s Textile Machinery

Choosing the right textile machinery is a critical decision that impacts your production efficiency and product quality. By considering factors such as your production needs, technology and features, quality, after-sales support, cost, environmental impact, and compatibility, you can make an informed choice. Svegea of Sweden’s innovative machinery solutions are designed to meet diverse production requirements while ensuring high efficiency and sustainability.

Curious about how we can elevate your textile production process? Visit our product page for more information and start your journey towards optimal textile production today.

In the quest for sustainable fashion, choosing the right fabrics is crucial. Eco-friendly fabric choices not only reduce environmental impact but also promote ethical production practices. This guide explores some of the best sustainable fabrics and their benefits.

Understanding Eco-Friendly Fabrics

Eco-friendly fabrics are made from natural, renewable, or recycled materials that have a lower environmental footprint compared to conventional fabrics. These fabrics are produced using methods that minimize water usage, chemical treatments, and energy consumption.

Popular Eco-Friendly Fabrics

- Organic Cotton: Grown without harmful pesticides and synthetic fertilizers, organic cotton is a popular choice for sustainable fashion. It is soft, breathable, and biodegradable.

- Bamboo: Bamboo fabric is made from the pulp of bamboo grass, which grows quickly and requires minimal water and pesticides. It is naturally antibacterial and moisture-wicking.

- Hemp: Hemp is a highly sustainable crop that requires little water and no pesticides. It produces a durable and versatile fabric that is perfect for various types of clothing.

- Recycled Polyester: Made from recycled plastic bottles, recycled polyester reduces waste and conserves resources. It is often used in activewear due to its durability and moisture-wicking properties.

- Tencel (Lyocell): Tencel is a sustainable fabric made from wood pulp sourced from responsibly managed forests. It is biodegradable, soft, and has a silky feel.

The Environmental Impact

The Environmental Impact

Choosing eco-friendly fabrics significantly reduces the environmental impact of fashion production. These fabrics require fewer resources, produce less waste, and are often biodegradable or recyclable. By opting for sustainable fabrics, designers and consumers can contribute to a greener planet.

Economic Benefits

Sustainable fabrics are not only good for the environment but also for business. As consumers become more environmentally conscious, there is a growing demand for eco-friendly products. Brands that use sustainable fabrics can attract a loyal customer base willing to pay a premium for ethical and eco-friendly fashion.

Challenges and Innovations

While eco-friendly fabrics offer many benefits, there are challenges in their production and adoption. The cost of sustainable materials can be higher, and the supply chain may be less established compared to conventional fabrics. However, innovations in textile technology and increased consumer awareness are helping to overcome these challenges.

Success Stories

Many brands are leading the way in sustainable fashion by using eco-friendly fabrics. For example, Patagonia uses recycled polyester in its clothing, and Stella McCartney incorporates organic cotton and Tencel in her designs. These brands demonstrate that sustainability and style can coexist.

The Future of Fashion

The future of fashion lies in sustainability. By choosing eco-friendly fabrics, the industry can reduce its environmental footprint and create a more ethical production process. As more brands and consumers embrace sustainable practices, we can look forward to a fashion industry that is both stylish and environmentally responsible.

Cutting Edge Technology

Svegea of Sweden provides cutting-edge technology that complements the zero waste cutting process, enabling manufacturers to take their sustainability initiatives to the next level. With the Euro Collarette Cutter, Svegea offers a solution that not only minimizes fabric waste but also boosts production efficiency and cost-effectiveness. Euro Collarette Cutters are designed to optimize fabric cutting processes, providing highly efficient solutions that align with zero waste cutting principles. These machines are integral for manufacturers aiming to reduce fabric waste, streamline production, and meet sustainability goals.

Key Features of Svegea’s Euro Collarette Cutters:

- Precision Cutting: Euro Collarette Cutters are renowned for their precise, consistent cutting ability, reducing the amount of fabric waste that typically results from inefficient manual cutting techniques.

- Flexibility in Fabric Handling: These machines are capable of handling various fabric types and thicknesses, making them versatile for different garment production needs. This flexibility ensures minimal waste regardless of the fabric used, supporting zero waste pattern cutting.

- Automation and Efficiency: The advanced automation technology integrated into Svegea’s cutters allows for higher production speeds while maintaining precision. Automation reduces the likelihood of human error, further minimizing material waste.

- Sustainability-Driven Design: Svegea develops its cutting machines with a strong focus on sustainability, ensuring that they minimize fabric waste to nearly zero. These solutions seamlessly integrate into eco-conscious production environments, allowing manufacturers to adopt greener practices while enhancing efficiency.

- Cost Savings: By maximizing fabric use, these machines reduce raw material costs, contributing to both economic and environmental benefits for manufacturers adopting zero waste practices.

Contact us to explore how Svegea’s Euro Collarette Cutters can transform your production line for a more sustainable future.

The textile industry has always been a pioneer in technological advancements. From the spinning jenny to modern automated looms, the sector has continually evolved. Today, the integration of Artificial Intelligence (AI) into textile machines marks the latest leap forward, offering unparalleled efficiency, precision, and productivity. This article delves into how AI textile machines are revolutionizing the industry and highlights a cutting-edge product from Svegea of Sweden.

The Rise of AI in Textile Manufacturing

AI is no longer a futuristic concept; it is now a vital component of the manufacturing sector, especially in textiles. The industry is swiftly adopting AI technologies to enhance production processes, improve product quality, and reduce waste. AI-powered machines can analyze vast amounts of data in real time, enabling more informed decision-making and streamlined operations.

AI’s ability to learn from data and make real-time adjustments has transformed textile manufacturing. These machines can predict when a process needs adjustment, reducing downtime and boosting overall efficiency. For instance, AI can optimize machine settings based on the fabric type, ensuring each material is handled with utmost care and precision.

Reducing Waste and Enhancing Sustainability

One of the most significant benefits of AI-integrated textile machines is their ability to minimize waste. Traditional manufacturing often results in excess material being discarded, increasing costs and environmental impact. AI can significantly reduce this waste by optimizing cutting and sewing processes.

AI algorithms can analyze fabric patterns to determine the most efficient cutting method, minimizing leftover scraps. This not only reduces waste but also lowers costs for manufacturers. Additionally, AI can monitor fabric quality throughout production, identifying and correcting defects early.

Reducing waste also supports the industry’s sustainability efforts. As demand for eco-friendly products grows, manufacturers face increasing pressure to adopt sustainable practices. AI textile machines play a crucial role in this shift by enabling more efficient resource use and reducing the carbon footprint of textile production.

Enhancing Productivity with AI

Productivity is a key metric in any manufacturing environment, and the textile industry is no exception. AI-integrated machines are designed to maximize output without compromising quality. By automating routine tasks, these machines free up human workers to focus on more complex, value-added activities.

For example, AI can automate the inspection process, quickly identifying defects that human inspectors might miss. This speeds up the production line and ensures only the highest-quality products reach the market. Additionally, AI can predict machine failures, allowing for preventative maintenance that minimizes downtime.

AI also excels in predictive analytics. By analyzing historical data, AI can forecast demand for specific products, enabling manufacturers to adjust production schedules accordingly. This ensures they can meet customer demand without overproducing, further reducing waste and costs.

Spotlight on Svegea’s AI-Integrated Textile Machines

Svegea of Sweden is a leading innovator in the textile machinery industry, known for its commitment to quality and efficiency. One standout product is the EC 300 Collarette Cutter, an AI-integrated machine that exemplifies the benefits of modern technology in textile manufacturing.

The EC 300 optimizes the cutting process, ensuring precision and consistency with every cut. With AI at its core, the machine can analyze fabric and make real-time adjustments to cutting parameters, reducing waste and enhancing efficiency. The result is a product that meets and exceeds the high standards expected by today’s manufacturers.

Svegea’s commitment to innovation extends beyond this. The company continuously invests in research and development, ensuring its machines remain at the cutting edge of technology. By integrating AI into its products, Svegea leads the charge toward a more efficient, sustainable, and productive textile industry.

To learn more about Svegea’s AI-integrated textile machines, talk to us now!

Cutting Corners (Without Compromising Quality)

In the intricate world of textile cutting, businesses often find themselves at a crossroads. Imagine standing amidst bolts of fabric, scissors poised, pondering the delicate dance between quality and cost. Fear not! Enter Svegea’s Economy Range, where affordability meets excellence. Let’s unravel these affordable cutting solutions, stitch by stitch.

1. The CMS 1800A Strip Cutter: Precision Unleashed

Meet the CMS 1800A, the Gandalf of strip cutters. It trims fabric edges with surgical precision, leaving waste trembling in its wake. Small to medium-sized enterprises (SMEs), rejoice! Your budget just found a reliable sidekick.

2. Fabric Inspection Machines: CSI for Textiles

Enter the CMI 180 and its twin, the CMI 180E. These machines don their detective hats, magnifying glass in hand, scrutinizing fabrics for defects. Quality control? Nailed it. SMEs can now play textile detective without maxing out their credit cards.

3. Band Knife Machines: Precision, Thy Name Is SV/BK

The SV/BK series slices through textiles like a seasoned sushi chef. From the pocket-sized SV/BK 500 to the burly SV/BK 1250, these machines cater to all cutting cravings. Affordability? Check. Quality? Double-check. It’s like having a Swiss Army knife for fabrics.

4. Roll to Roll Slitting Machine RRS-800: Unroll the Red Carpet

Textile production needs a red carpet moment. Cue the RRS-800! It slits rolls like a pro, leaving clean, accurate cuts in its wake. Startups and seasoned manufacturers alike can now roll with the big dogs without emptying their wallets.

Why Svegea’s Economy Range Rocks

1. Quality Assurance: Svegea doesn’t do shortcuts. Each machine undergoes rigorous testing – think of it as a textile boot camp. No flimsy recruits here!

2. Cost Savings: Choosing the Economy Range is like finding a hidden treasure chest. You save on upfront costs, leaving room for victory dances and celebratory confetti.

3. Tailored Solutions: One size doesn’t fit all – especially in the textile world. Svegea’s got options galore. Pick your cutting companion, like choosing a wand at Ollivanders (minus the magical mishaps).

Cut Above the Rest

Svegea’s Economy Range isn’t just about numbers; it’s about weaving dreams into reality. Whether you’re a startup producing your first batch of garment materials or a seasoned manufacturer patching up decades of experience, these cutting solutions are your secret weapon. So grab your scissors (or better yet, an SV/BK), and let’s cut through the fabric of limitations. Affordable excellence awaits!

Svegea’s Economy Range isn’t just about numbers; it’s about weaving dreams into reality. Whether you’re a startup producing your first batch of garment materials or a seasoned manufacturer patching up decades of experience, these cutting solutions are your secret weapon. So grab your scissors (or better yet, an SV/BK), and let’s cut through the fabric of limitations. Affordable excellence awaits!

- 1

- 2