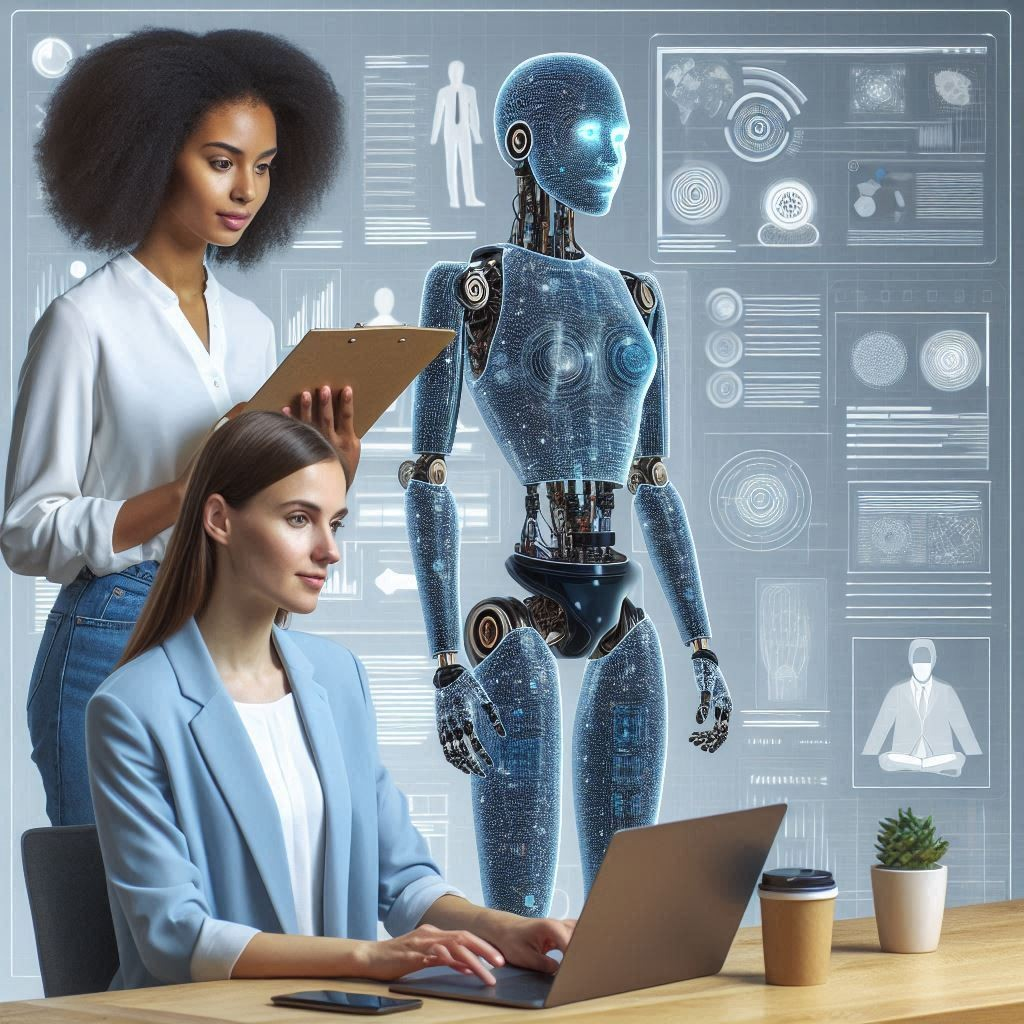

In recent years, the fashion industry has witnessed a significant transformation with the advent of immersive fashion. This innovative approach leverages virtual try-ons, augmented reality (AR), virtual reality (VR) experiences, and interactive design to create a more engaging and personalized shopping experience. Svegea of Sweden is leading this revolution, advancing the fashion industry with its cutting-edge textile machines.

The Rise of Virtual Try-Ons

Virtual try-ons have become a game-changer in the fashion industry. Advanced technology now allows customers to try on clothes virtually, enhancing the shopping experience and reducing returns. Virtual try-on uses AR to overlay digital images of clothing onto a live video feed of the customer, allowing them to see how different outfits look on them in real-time.

Augmented Reality (AR) and Virtual Reality (VR) Experiences

AR and VR technologies have opened up new possibilities for the fashion industry. AR allows customers to see how clothes, accessories, and even makeup will look on them without physically trying them on. This technology is especially helpful for online shopping, allowing customers to make informed decisions based on virtual product displays.

VR, on the other hand, offers immersive fashion experiences that transport customers to virtual fashion shows, fitting rooms, and even designer studios. These experiences provide a unique and engaging way for customers to interact with brands and explore new collections.

Interactive Design: A New Era of Customization

Interactive design is another key aspect of immersive fashion. This approach allows customers to personalize their clothing and accessories, creating unique pieces that reflect their style. Through interactive design platforms, customers can choose fabrics, colors, and patterns, and even add custom details to their garments.

The Impact on the Fashion Ecosystem

The integration of immersive fashion technologies has far-reaching implications for the fashion ecosystem. Not only does it enhance customer satisfaction with a more engaging and personalized shopping experience, but it also contributes to environmental sustainability by reducing returns and overproduction.

Revolutionizing Fashion

Immersive fashion is revolutionizing the way we shop and interact with fashion brands. Virtual try-ons, AR/VR experiences, and interactive design are transforming the fashion landscape, making it more engaging, personalized, and sustainable. Innovative textile companies are at the forefront of this transformation. And they provide the technology and solutions needed to support this new era of fashion.

As the fashion industry continues to evolve, the role of immersive fashion will only become more prominent. By embracing these technologies, brands can create unique and memorable experiences for their customers. This action will ultimately drive growth and innovation in the fashion ecosystem.

Svegea of Sweden’s contributions to this ecosystem are significant. Their innovative textile machines support the production of high-quality garments that are suitable for virtual try-ons, AR/VR experiences, and interactive design. By enabling the creation of accurate and realistic digital representations of clothing, Svegea helps bridge the gap between the physical and digital worlds.

The textile industry is in the midst of a transformative era, driven by technological advancements and the urgent need for sustainability. Imagine a production line where machines think ahead, predict demand, and cut fabrics with surgical precision—ushering in a new age of efficiency and innovation. This isn’t a distant future; it’s the present reality of smart production planning, powered by artificial intelligence (AI) and exemplified by Svegea’s state-of-the-art machinery. In this article, we explore how AI and Svegea are revolutionizing textile production planning, making it smarter, leaner, and greener.

The Role of AI in Textile Production Planning

Predictive Demand Forecasting

AI algorithms analyze historical data, market trends, and customer behavior to predict future demand accurately. By understanding consumer preferences and market fluctuations, textile manufacturers can fine-tune their production schedules. Svegea’s machinery seamlessly integrates with these predictive models, ensuring just-in-time production to meet customer demands without excess inventory.

Efficient Inventory Management

Managing inventory levels is a delicate balancing act. Excess inventory ties up capital, while insufficient stock disrupts production. AI-driven inventory management optimizes stock levels, minimizing waste and maximizing efficiency. Svegea’s machinery, known for its precision and speed, aligns perfectly with lean inventory practices.

Streamlined Production Scheduling

Production planning involves orchestrating various processes – from spinning and weaving to cutting and finishing. AI algorithms create optimized schedules, considering machine availability, lead times, and resource constraints. Svegea’s machinery, such as the EC 450 XF Collarette Cutting System, fits seamlessly into these schedules, ensuring timely and accurate fabric cutting.

Svegea’s Machinery: A Catalyst for Waste Reduction

Precision Cutting

Svegea’s cutting systems operate with unparalleled precision. Whether it’s collarette cutting or bias cutting, the machinery ensures minimal fabric wastage. AI-driven algorithms enhance this precision by analyzing fabric patterns and suggesting optimal cutting paths.

Just-in-Time Production

The synergy between AI and Svegea’s machinery enables just-in-time production. By cutting fabric precisely when needed, manufacturers reduce excess inventory and minimize waste. The EC 450 XF Collarette Cutting System exemplifies this approach, seamlessly integrating with production schedules.

Sustainable Practices

Textile production planning isn’t just about efficiency; it’s also about sustainability. AI-driven waste reduction aligns with eco-conscious goals. Svegea’s machinery contributes to this by minimizing fabric scraps and ensuring resource-efficient processes.

Case Study: Svegea’s AI-Integrated Production Line

Imagine a textile factory where AI algorithms analyze real-time data from production machines. These algorithms predict machine maintenance needs, optimize production schedules, and minimize downtime. Svegea’s machinery – from fabric cutting to winding – collaborates harmoniously with AI, resulting in a lean, efficient, and sustainable production line.

A Reality Powered by AI

Smart production planning isn’t a distant dream; it’s a reality powered by AI and innovative machinery. As textile manufacturers embrace these advancements, Svegea stands at the forefront, bridging the gap between technology and textile production planning. Let’s weave a future where waste reduction, efficiency, and quality converge seamlessly.

For more information on how Svegea’s machinery can revolutionize your textile production planning, visit Svegea of Sweden’s contact page.

The garment industry, a cornerstone of global manufacturing, has faced numerous challenges and transformations over the years. Despite the rapid advancement of artificial intelligence (AI) and other cutting-edge technologies, garment manufacturing companies continues to thrive. This article explores how the industry adapts and prospers in the face of technological evolution.

Embracing Technological Advancements

The integration of AI and automation in garment manufacturing has revolutionized the industry. Technologies such as the Internet of Things (IoT), machine learning, and robotics have enhanced production efficiency and precision. AI-driven systems can predict fashion trends, optimize supply chains, and improve quality control. These advancements have allowed manufacturers to meet the growing demand for fast fashion while maintaining high standards of quality.

However, the garment industry has not fully automated its processes. The intricate tasks of cutting, sewing, and assembling garments still require human expertise. This blend of human skill and technological innovation has created a unique synergy, ensuring that the industry remains competitive and resilient.

The Human Touch in Garment Manufacturing

While AI and automation have streamlined many aspects of garment manufacturing, the human touch remains indispensable. Skilled artisans and workers bring creativity, precision, and adaptability to the production process. This human element is particularly crucial in high-end fashion, where bespoke tailoring and intricate designs demand a level of craftsmanship that machines cannot replicate.

Moreover, the collaboration between humans and machines has led to the emergence of Industry 5.0, where technology enhances human capabilities rather than replacing them. This approach fosters a more sustainable and efficient manufacturing process, benefiting both producers and consumers.

Sustainability and Ethical Practices

In recent years, there has been a growing emphasis on sustainability and ethical practices within the garment industry. Advanced technologies have played a significant role in this shift. For example, AI can optimize resource usage, reducing waste and minimizing the environmental impact of garment manufacturing. Additionally, blockchain technology is being used to ensure transparency and traceability in supply chains, promoting fair labor practices and ethical sourcing of materials.

These innovations have not only improved the industry’s sustainability but also enhanced its reputation among consumers who are increasingly conscious of the environmental and social impact of their purchases.

Adapting to Market Demands

The garment industry has shown remarkable adaptability in responding to changing market demands. The rise of e-commerce and the shift towards personalized fashion have driven manufacturers to adopt more flexible and responsive production methods. AI-powered tools enable manufacturers to analyze consumer preferences and tailor their offerings accordingly. This ability to quickly adapt to market trends has been a key factor in the industry’s continued success.

Furthermore, the COVID-19 pandemic accelerated the adoption of digital technologies in garment manufacturing. Virtual fitting rooms, 3D design software, and online collaboration tools have become essential in maintaining operations and meeting customer expectations during times of social distancing and lockdowns.

The Future of Garment Manufacturing

Looking ahead, the garment industry is poised to continue its evolution, leveraging AI and other advanced technologies to drive innovation and growth. The integration of smart textiles, wearable technology, and AI-driven design tools will further enhance the capabilities of garment manufacturers. These advancements will enable the creation of garments that are not only stylish but also functional, offering features such as temperature regulation and health monitoring.

Moreover, the ongoing development of sustainable materials and eco-friendly production methods will ensure that the industry remains aligned with global efforts to combat climate change and promote environmental stewardship.

Remarkable Resilience and Adaptability

The garment industry has demonstrated remarkable resilience and adaptability in the face of rapid technological advancements. By embracing AI and other cutting-edge technologies, while preserving the essential human touch, garment manufacturing continues to thrive. The industry’s commitment to sustainability, ethical practices, and responsiveness to market demands ensures its continued success in the ever-evolving landscape of global manufacturing.

As a testament to the industry’s innovative spirit, companies like Svegea of Sweden are providing state-of-the-art textile machinery that enhances production efficiency and quality. These advancements support garment manufacturers in their quest to stay competitive and meet the demands of a dynamic market.

Discover the future of garment manufacturing with innovative solutions from Svegea of Sweden. Enhance your production efficiency and quality today. Talk to us to learn more!

In the ever-evolving tapestry of the textile industry, staying ahead of the curve isn’t just smart—it’s essential. As we thread our way through 2024, let’s unravel the spool of future trends in textile manufacturing that are stitching a new narrative for fabric production.

Smart Textiles: The Brainy Fibers

Imagine a world where your clothes adjust to your body temperature, track your health stats, or even change color to match your mood. No, it’s not science fiction; it’s the magic of smart textiles. These brainy fibers integrate advanced materials to bring intelligence to our wardrobes. It’s like having a personal assistant woven into your jeans!

3D Technologies: Tailoring a New Reality

Gone are the days of one-size-fits-all. With 3D technologies in fashion, custom-fit clothing is becoming the norm, not the exception. This trend is not just about looking good; it’s about precision, efficiency, and reducing waste. So, if you’re tired of clothes that just don’t fit right, the future looks tailor-made for you.

Sustainable Supply Chains: Green Is the New Black

As the industry spins toward sustainability, sustainable supply chains are becoming as crucial as fashion. It’s about creating a cycle of production that respects the planet as much as it does profit. After all, what’s the point of looking good if we don’t have a planet to look good on?

Customization and Personalization: The ‘You’ in Your Clothes

In a world where everyone wants to stand out, customization is king. The future of textiles is personal, with bespoke designs and personalized experiences becoming the new standard. It’s time to wear your personality on your sleeve—literally.

AI and Data Analytics: The Style Algorithm

Data is the new thread in textile manufacturing, with AI and data analytics weaving patterns of efficiency and innovation. These technologies are not just about crunching numbers; they’re about creating fabrics that are smarter, more responsive, and, dare we say, more fashionable.

Engaging the Right Partner

As we embrace these future trends, it’s clear that the right partner can make all the difference. Engage the services of a textile manufacturing company that’s not just keeping up with these trends but is at the forefront of the textile revolution. You want to be in good company. Whether it’s smart textiles or sustainable practices, Svegea is the go-to for any manufacturing needs to cope with the future trends in textiles.

It’s an exciting time to be in the industry, and with companies like Svegea of Sweden leading the charge, the future is not just bright; it’s brilliant. For more insights into these trends, check out the full reports from StartUs Insights and GreyB. And remember, when it comes to the future of textiles, don’t just follow the trends—wear them.

Smart textiles, also known as electronic or e-textiles, represent a groundbreaking fusion of fashion and technology. These textiles go beyond mere wearability; they are programmable, interactive, and functional. In this article, we’ll explore what smart fabrics are, provide real-life examples, and discuss their future implications.

What Are Smart Materials?

Also called intelligent or responsive materials, these types of fabrics automatically respond to external stimuli such as temperature changes, light, pressure, or electric fields. Unlike traditional materials with static properties, interactive materials can adapt and change their properties based on environmental conditions. For instance:

– Piezoelectric materials generate voltage when pressure is applied.

– Shape memory alloys return to their original form after deformation.

– Thermochromic materials change color with temperature variations.

Enter Smart Fabrics

A subset of smart materials, these special fabrics embed digital components directly into textiles. These fabrics can:

- Conduct electricity

- React to environmental changes

- Gather and transmit data

- Incorporate embedded LED lights

Examples of Intelligent Fabrics

1. Thermochromic Fabrics: These fabrics change color in response to temperature variations, finding applications in fashion and safety gear.

2. Conductive Fabrics: Embedded with conductive threads, these fabrics transmit electrical signals and are used in wearable electronics.

3. Self-Healing Fabrics: Developed with materials that repair themselves after being punctured or torn.

Cutting-Edge Innovations

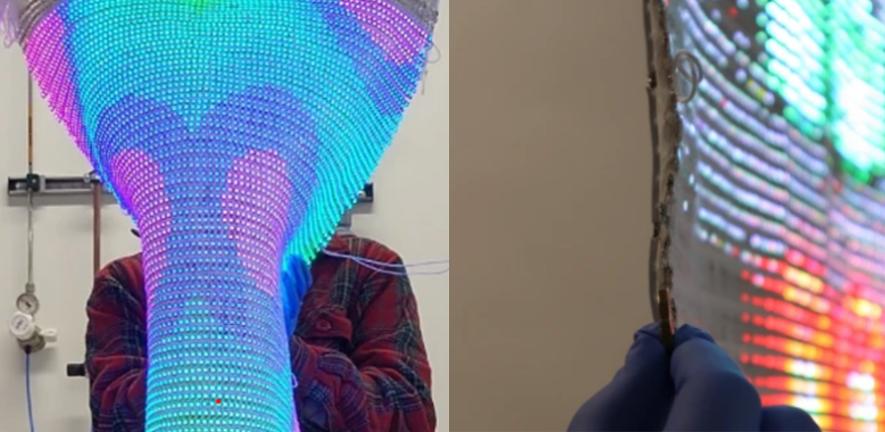

Researchers at Cambridge University have woven a 46-inch textile display loaded with LEDs, sensors, and energy storage. This e-textile can display different images or colors based on input from fiber-based devices like light, touch, and temperature sensors. The textile’s multi-functionality and compatibility with existing industrial manufacturing processes make it truly unique.

Image Source: https://www.cam.ac.uk/research/news/scientists-develop-fully-woven-smart-display

Healthcare and Beyond

Responsive fabrics embedded with sensors could transform everyday clothing into interactive devices. Imagine garments that track health metrics or provide real-time environmental feedback.

Tech textiles are more than just fabrics; they’re a canvas for innovation, bridging the gap between style and functionality. As technology advances, we can expect even more exciting developments in this field.

Remember, the future of fashion isn’t just about what you wear—it’s about what your clothes can do for you!

Cutting Corners (Without Compromising Quality)

In the intricate world of textile cutting, businesses often find themselves at a crossroads. Imagine standing amidst bolts of fabric, scissors poised, pondering the delicate dance between quality and cost. Fear not! Enter Svegea’s Economy Range, where affordability meets excellence. Let’s unravel these affordable cutting solutions, stitch by stitch.

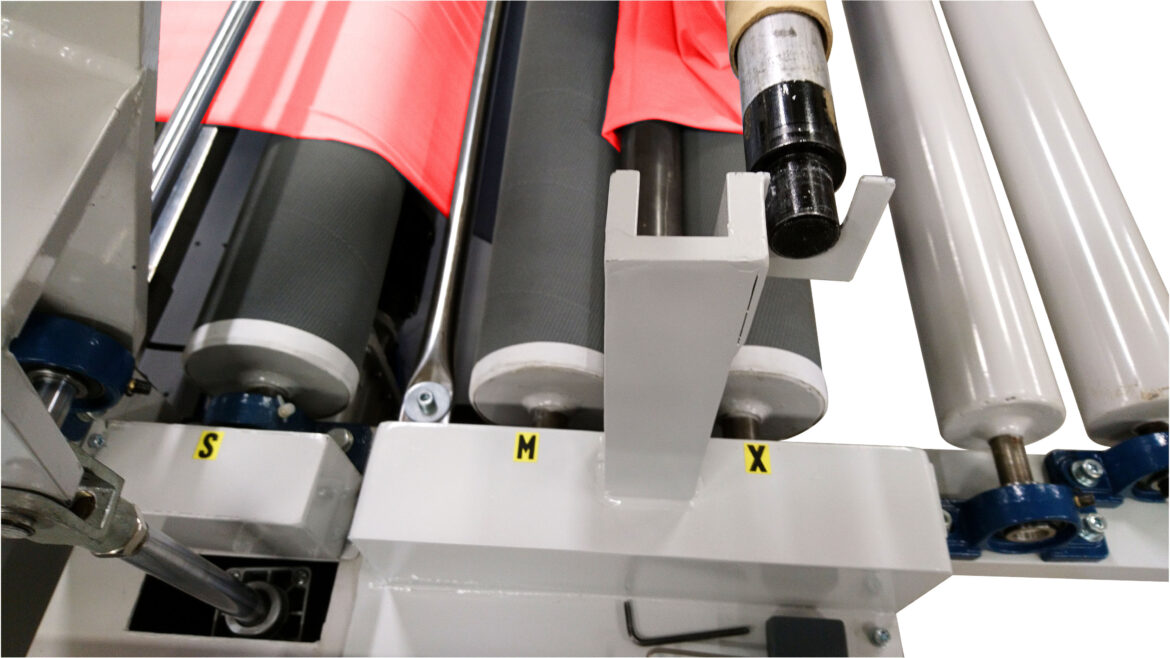

1. The CMS 1800A Strip Cutter: Precision Unleashed

Meet the CMS 1800A, the Gandalf of strip cutters. It trims fabric edges with surgical precision, leaving waste trembling in its wake. Small to medium-sized enterprises (SMEs), rejoice! Your budget just found a reliable sidekick.

2. Fabric Inspection Machines: CSI for Textiles

Enter the CMI 180 and its twin, the CMI 180E. These machines don their detective hats, magnifying glass in hand, scrutinizing fabrics for defects. Quality control? Nailed it. SMEs can now play textile detective without maxing out their credit cards.

3. Band Knife Machines: Precision, Thy Name Is SV/BK

The SV/BK series slices through textiles like a seasoned sushi chef. From the pocket-sized SV/BK 500 to the burly SV/BK 1250, these machines cater to all cutting cravings. Affordability? Check. Quality? Double-check. It’s like having a Swiss Army knife for fabrics.

4. Roll to Roll Slitting Machine RRS-800: Unroll the Red Carpet

Textile production needs a red carpet moment. Cue the RRS-800! It slits rolls like a pro, leaving clean, accurate cuts in its wake. Startups and seasoned manufacturers alike can now roll with the big dogs without emptying their wallets.

Why Svegea’s Economy Range Rocks

1. Quality Assurance: Svegea doesn’t do shortcuts. Each machine undergoes rigorous testing – think of it as a textile boot camp. No flimsy recruits here!

2. Cost Savings: Choosing the Economy Range is like finding a hidden treasure chest. You save on upfront costs, leaving room for victory dances and celebratory confetti.

3. Tailored Solutions: One size doesn’t fit all – especially in the textile world. Svegea’s got options galore. Pick your cutting companion, like choosing a wand at Ollivanders (minus the magical mishaps).

Cut Above the Rest

Svegea’s Economy Range isn’t just about numbers; it’s about weaving dreams into reality. Whether you’re a startup producing your first batch of garment materials or a seasoned manufacturer patching up decades of experience, these cutting solutions are your secret weapon. So grab your scissors (or better yet, an SV/BK), and let’s cut through the fabric of limitations. Affordable excellence awaits!

Svegea’s Economy Range isn’t just about numbers; it’s about weaving dreams into reality. Whether you’re a startup producing your first batch of garment materials or a seasoned manufacturer patching up decades of experience, these cutting solutions are your secret weapon. So grab your scissors (or better yet, an SV/BK), and let’s cut through the fabric of limitations. Affordable excellence awaits!

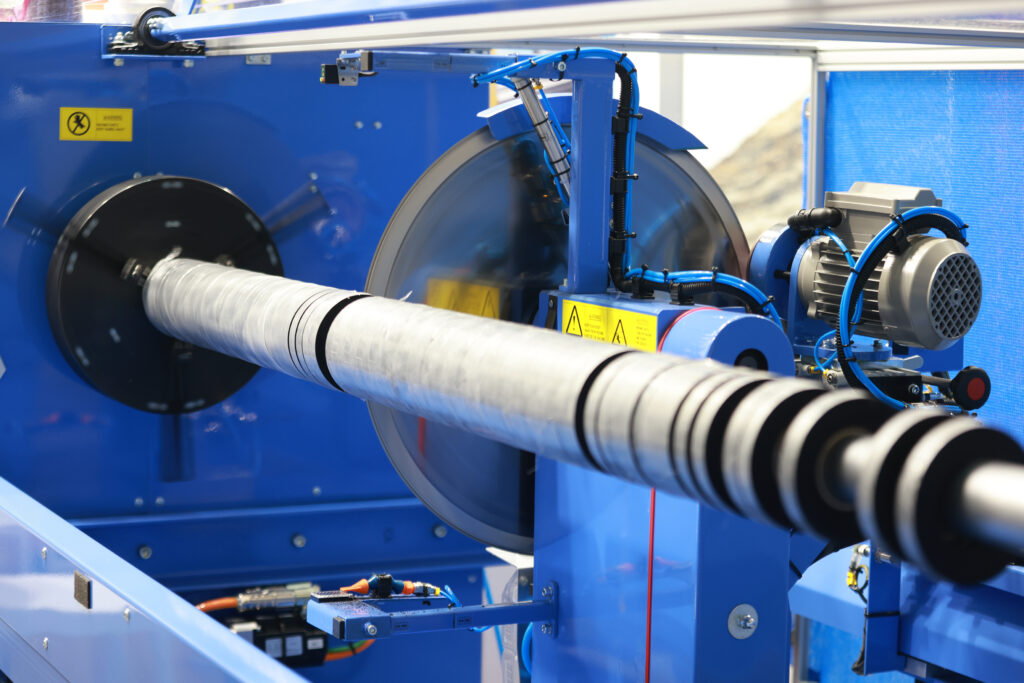

In manufacturing optimization, Svegea’s roll-slitting machines stand out as pioneers, integrating precision and speed to redefine production standards. These advanced machines cater to diverse industries, from textiles to packaging, offering sustainable solutions that maximize output while minimizing waste. Let’s explore how Svegea’s technology contributes to efficient material utilization and supports sustainable manufacturing practices.

Enhancing Efficiency Through Innovation

Svegea’s roll-slitting machines address the inefficiencies of traditional cutting methods by optimizing material usage. Unlike conventional processes that often result in significant leftover materials, Svegea ensures each roll is fully utilized, reducing costs and environmental impact. This commitment to efficiency boosts productivity and supports sustainable production practices.

Seamless Integration and Versatility

One of the key strengths of Svegea’s machines lies in their seamless integration into existing production workflows. Their user-friendly interfaces and intuitive designs empower operators to manage and control operations effortlessly. This versatility allows manufacturers to handle a wide range of materials with precision, adapting swiftly to varying production demands.

Precision and Quality Assurance

Precision is paramount in manufacturing, and Svegea’s roll-slitting machines excel in delivering consistent and accurate cuts. Advanced technology ensures that each slit meets stringent quality standards, minimizing errors and enhancing overall product quality. This precision not only reduces rework but also enhances operational efficiency, making these machines indispensable in high-demand industries.

Contributing to Sustainable Practices

Central to Svegea’s innovation is its commitment to sustainable manufacturing. By minimizing material waste through efficient roll-slitting technology, these machines play a crucial role in reducing environmental footprint. Optimal material utilization not only lowers raw material consumption but also supports eco-friendly production processes, aligning with global sustainability goals.

Shaping the Future of Manufacturing

Looking ahead, Svegea’s roll-slitting machines continue to set benchmarks for efficient and sustainable manufacturing practices. Their ability to maximize output while minimizing waste underscores a paradigm shift towards more responsible industrial practices. As industries evolve towards greater efficiency and environmental consciousness, Svegea remains at the forefront of driving innovation and shaping the future of manufacturing worldwide.

Harnessing the Power of Roll/Slitting Machines

By harnessing the capabilities of Svegea’s Roll/Slitting Machines, industries can achieve significant improvements in production efficiency and sustainability. These machines not only optimize material utilization but also pave the way for a more environmentally conscious approach to manufacturing. Embracing such technology not only benefits businesses economically but also contributes positively to global environmental efforts.

In recent years, advancements in technology and a growing emphasis on sustainability have fueled the development of novel fabrics. These textiles are engineered to possess unique properties that challenge the boundaries of traditional materials.

Let’s explore some exciting innovations:

1. Algae-Based Fabrics

Keel Labs has introduced Kelsun, an algae-based material that looks and feels like natural fiber. Derived from algae, Kelsun offers a sustainable alternative to petroleum-based synthetics. It has already appeared in collections by designer Stella McCartney.

2. Shrimp Shells and Mushroom Leather

TomTex, another trailblazer, uses shrimp shells and mushrooms to create proprietary materials that mimic leather, suede, and even latex. These alternatives are not only eco-friendly but also versatile. Peter Do’s Spring 2023 faux leather and Dauphinette’s Fall 2024 handbags feature TomTex materials.

3. Pineapple Leaf Fiber Leather

Piñatex is an innovative leather alternative made from pineapple leaf fibers, a byproduct of pineapple harvest. It’s both sustainable and stylish, making it a favorite among eco-conscious designers.

4. Regenerated Nylon (Econyl)

Econyl is a regenerated nylon made from recycled materials, including discarded fishing nets and fabric scraps. It’s a step toward reducing plastic waste and promoting circular fashion.

5. Geotextiles

These specialized fabrics find applications in civil engineering and construction. Geotextiles are used for drainage, soil stabilization, and erosion prevention.

6. Protective Textiles

Designed to shield users from various hazards, protective textiles are crucial in industries such as chemical handling, firefighting, and the military. They protect against chemicals, heat, and even ballistic impact.

7. Industrial Textiles

These textiles serve industrial purposes, including automotive applications. Automobiles utilize them for insulation, upholstery, seat belts, and airbags.

Sustainability and Functionality

Novel textile manufacturers engineer them to repel water, resist flames, or exhibit antibacterial qualities. These features enhance their functionality and sustainability in various applications.

Svegea’s Collarette Cutting Machines

As we delve into the world of novel textiles, we must acknowledge the role of cutting-edge machinery. Svegea, a Swedish company, specializes in Collarette Cutting Machines. These machines efficiently cut fabric collars, cuffs, and other textile components, contributing to sustainable production processes.

The fashion industry’s shift toward novel textiles reflects a commitment to environmental responsibility. As designers and consumers embrace these innovations, we move closer to a more sustainable and functional future.

In the fast-paced realm of textile manufacturing, precision and innovation reign supreme, shaping industry standards and pushing boundaries. Svegea of Sweden AB emerges as a beacon of cutting-edge technology, offering various products and services that redefine the textile landscape. A standout in their lineup is the Tubular Knit Slitter, a product that epitomizes Svegea’s commitment to excellence and efficiency in textile production.

Cutting-Edge Technology

A steadfast commitment to cutting-edge technology lies at the core of Svegea’s success. The EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, epitomizes this dedication. This advanced system achieves unparalleled precision and efficiency, setting new benchmarks in production excellence. From automatic roll-cutting/slitting machines to the Strip Cutter CMS-1800A, Svegea’s lineup showcases technological prowess.

Global Presence and Bespoke Services

With a global presence across continents, Svegea delivers innovative solutions and bespoke services to clients worldwide. Whether it’s fabric inspection machines such as the CMI 210 R or the Complete Bias System, Svegea’s commitment to meeting client needs remains steadfast. Their tailored approach ensures that each solution addresses specific requirements, ensuring customer satisfaction and success.

Award-Winning Innovation

Svegea’s relentless pursuit of excellence has earned them recognition and accolades in the textile industry. Their award-winning innovation is evident in every product, from the Tube Sewing Unit 200 A/AF to the Euro Collarette range. This dedication to pushing boundaries positions Svegea as a leader in innovation and customer satisfaction.

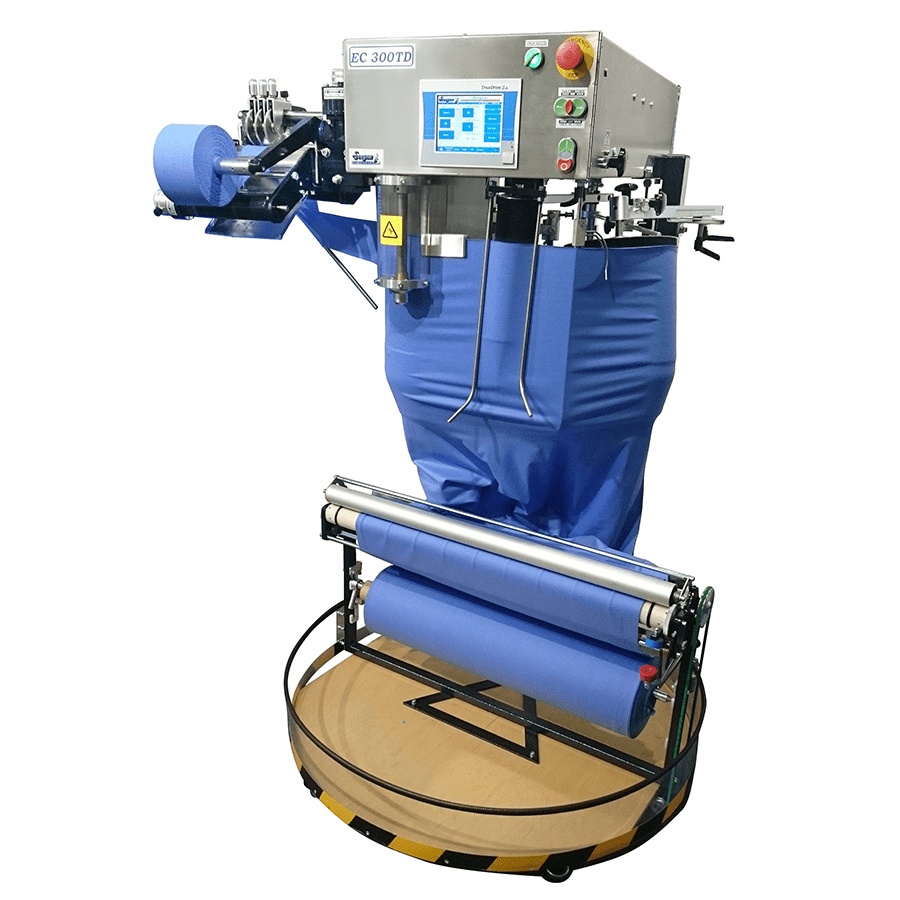

Tubular Knit Slitter TSO 380

In essence, Svegea’s Tubular Knit Slitter is a remarkable machine that converts tubular knit fabric from its tube form into a single-width roll of material, ready to be slit into tape. This innovative approach brings huge fabric savings compared to the traditional method of producing two rolls of open-knit fabric from tubular knit for tape or binding production.

Experience Excellence

Svegea of Sweden AB stands as a testament to innovation, quality, and customer-centricity in the textile industry. They continue to redefine standards and shape the future of textile manufacturing with cutting-edge technology and a diverse product portfolio. Their global presence, bespoke services, and award-winning innovation set them apart. Experience excellence with Svegea – where innovation meets precision, and possibilities are limitless.

If you want to elevate your textile production, consider the Tubular Knit Slitter from Svegea. Let us know by pressing the contact button!

Luxury has evolved beyond mere opulence and exclusivity. It now tells the story of each design piece, highlighting meticulous craftsmanship and a commitment to ethical and sustainable practices. This article explores the world of high-end textiles, with fabric production as its cornerstone.

The Artisans and Their Craft

At the heart of luxury textiles are talented artisans. These skilled craftsmen and women create exquisite fabrics with unparalleled attention to detail. Every stitch, cut, and curve reflects their dedication, driving the continuous evolution of luxury with highly sought-after designs.

Slow Design and Bespoke Quality

Artisanal textiles are deeply rooted in craftsmanship. Unlike mass-produced goods, these items are created meticulously and thoughtfully. This movement, known as Slow Design, celebrates quality over quantity. Each piece is a unique work of art, reflecting the artisan’s expertise and passion.

The Journey from Fiber to Fabric

1. Fiber Selection: Luxury textiles begin with carefully chosen raw materials. Whether it’s silk, cashmere, or organic cotton, the quality of the fiber sets the foundation for the final product.

2. Spinning and Weaving: Artisans spin the fibers into yarns, which are then woven into fabric. Jacquard looms, guided by intricate patterns, produce complex designs that grace haute couture and high-end interiors.

3. Dyeing and Finishing: Artisans meticulously curate the color palette and apply dyes precisely. Finishing techniques—such as mercerization or calendering—enhance texture and luster.

4. Hand Embellishments: Embroidery, beading, and appliqué add a touch of luxury. Skilled hands transform plain fabric into wearable art.

The Role of Svegea of Sweden

Svegea of Sweden, a renowned textile machinery manufacturer, plays a crucial role in luxury fabric production. Their cutting-edge machines enable precise weaving, intricate patterns, and flawless finishes. From jacquard looms to automated knitting devices, Svegea’s technology empowers artisans to create fabrics that define luxury.

Subscribe to our blog for more insights into the world of luxury textiles, craftsmanship, and sustainable practices. Stay informed and inspired as we unravel the secrets behind high-end fabrics.