In a world where sustainability is becoming more than a buzzword, the fashion industry is undergoing a significant transformation. One of the most innovative and impactful changes is the adoption of zero waste pattern cutting. This method not only revolutionizes the way garments are produced but also addresses the environmental concerns associated with traditional fashion practices.

Understanding Zero Waste Pattern Cutting

Zero waste pattern cutting is a design technique that aims to eliminate fabric waste in the creation of garments. Traditional garment production often results in approximately 15-20% of fabric waste due to the inefficient placement of patterns on the fabric. This discarded material often ends up in landfills, contributing to environmental pollution.

In contrast, zero waste pattern cutting meticulously plans the layout of each piece of fabric, ensuring that every inch is utilized. This approach can involve intricate designs, geometric shapes, and innovative sewing techniques to fit the pieces together like a puzzle. The result is a garment that uses all the fabric with minimal to no waste.

The Environmental Impact

The fashion industry is notorious for its environmental footprint. From water consumption to carbon emissions, the production of clothing has significant impacts on the planet. Zero waste pattern cutting offers a practical solution to one of these issues: fabric waste.

By reducing fabric waste, this method helps in conserving resources. It means fewer raw materials are needed, reducing the demand for water, energy, and chemicals involved in fabric production. Additionally, less waste means fewer textiles end up in landfills, decreasing environmental pollution.

Economic Benefits

While the environmental benefits of zero waste pattern cutting are clear, the economic advantages are equally compelling. For designers and manufacturers, fabric is a significant cost. By maximizing fabric usage, zero waste techniques can lead to substantial cost savings.

Moreover, as consumers become more conscious of sustainability, there is a growing market for eco-friendly products. Brands that adopt zero waste practices can attract environmentally conscious customers, willing to pay a premium for sustainable fashion. This shift not only helps the planet but also makes good business sense.

Challenges and Innovations

Despite its many benefits, zero waste pattern cutting is not without its challenges. The method requires a high level of skill and creativity. Designers must rethink the way they approach garment construction, often needing to create entirely new patterns and techniques.

However, this challenge has spurred innovation in the industry. Designers are experimenting with modular designs, where pieces can be rearranged and used in multiple ways. Digital tools and software are also being developed to aid in the creation of zero waste patterns, making the process more accessible to a broader range of designers.

Success Stories

Many brands and designers are already making significant strides in zero waste fashion. For instance, designers like Timo Rissanen and Holly McQuillan are pioneers in this field, pushing the boundaries of what is possible with zero waste pattern cutting. Their work not only showcases the potential of this method but also inspires others in the industry to follow suit.

Brands like Tonlé and Daniel Silverstein (Zero Waste Daniel) have built their entire business models around zero waste principles. They demonstrate that sustainability and style can go hand in hand, offering chic and modern designs that do not compromise on environmental values.

The Future of Fashion

As the fashion industry continues to evolve, the importance of sustainable practices cannot be overstated. Zero waste pattern cutting represents a significant step forward in this journey. It challenges the status quo, pushing designers and manufacturers to think creatively and responsibly.

The future of fashion lies in innovation and sustainability. By adopting zero waste techniques, the industry can reduce its environmental footprint, create economic opportunities, and cater to a growing market of eco-conscious consumers. As more brands embrace this method, we can look forward to a fashion industry that not only looks good but does good for the planet.

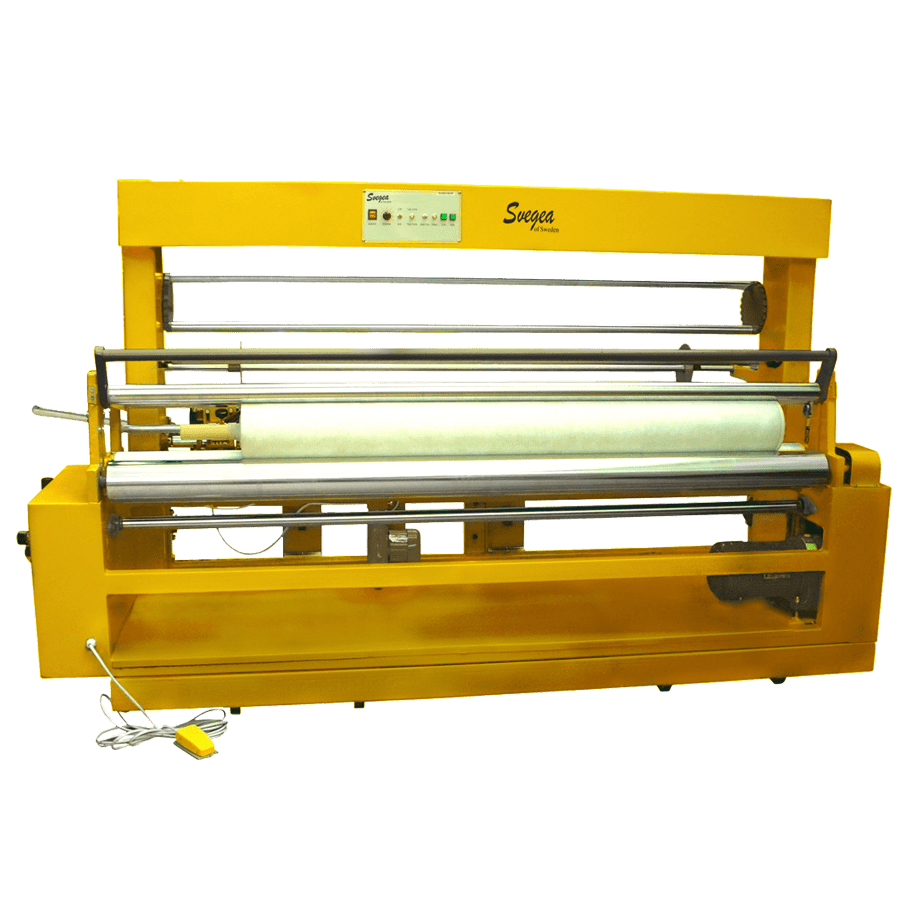

Svegea of Sweden: Revolutionizing Zero Waste with Advanced Technology

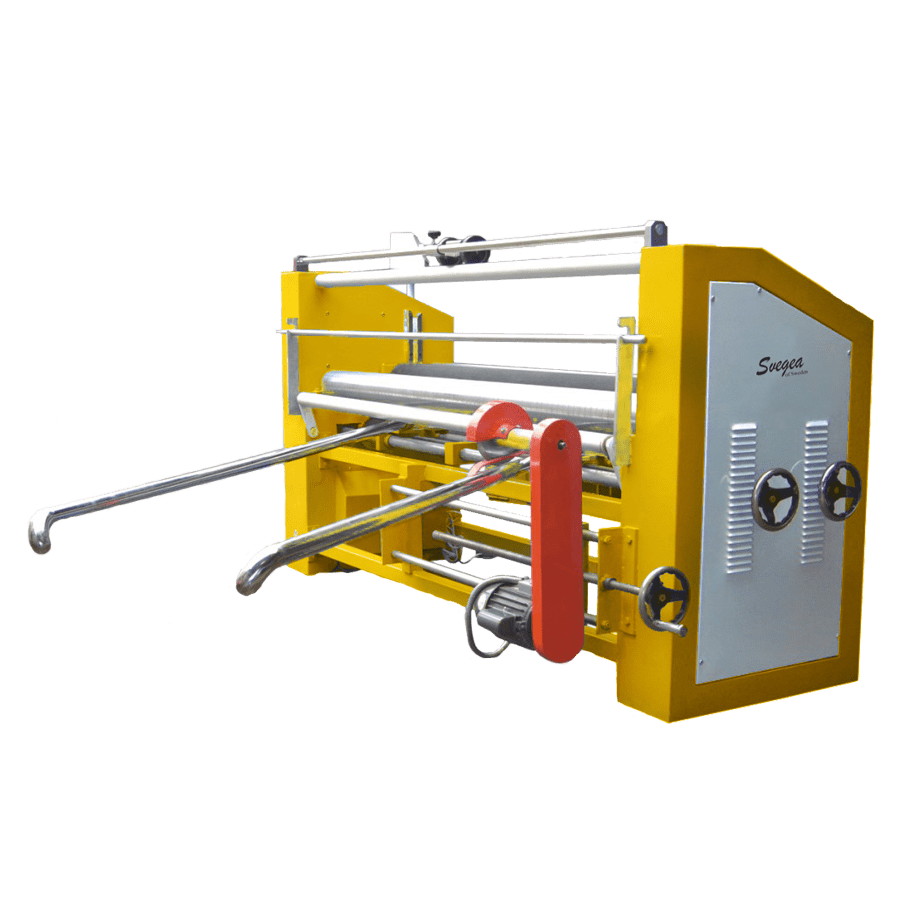

One notable brand making strides in the realm of zero waste pattern cutting is Svegea of Sweden. Known for their advanced cutting machinery, Svegea offers innovative solutions designed to maximize fabric utilization. Their machines not only enhance precision but also significantly reduce waste, aligning perfectly with the zero waste philosophy. By incorporating Svegea’s technology, designers can seamlessly integrate zero waste techniques into their production process.

Curious about how Svegea of Sweden can elevate your zero waste pattern cutting process? Visit our contact page for more information on our cutting-edge machinery and start your journey towards a more sustainable future today.

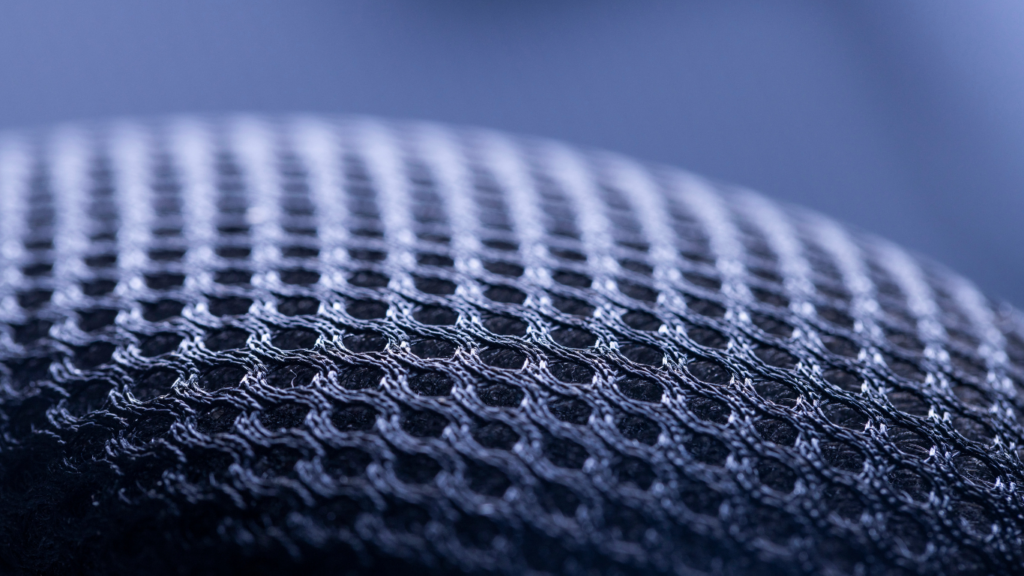

Ever wondered how fabrics impact your mood? The textures of the textiles we surround ourselves with can significantly influence our emotions and behavior. This article delves into the fascinating psychology of fabric textures and how they can shape our daily experiences.

The Power of Fabric Textures

Fabric texture refers to the surface quality of a fabric, which can be smooth, rough, soft, or stiff. Different textures evoke different emotional responses.

Smooth Textures: Fabrics like silk, satin, and cotton have smooth textures. These materials are often associated with luxury and comfort. Wearing smooth fabrics can make you feel more relaxed, elegant, and confident. They’re perfect for special occasions or when you want to pamper yourself.

Rough Textures: Fabrics like wool and raw silk are examples of rough textures. These materials can evoke feelings of ruggedness, durability, and strength. Wearing rough-textured fabrics can make you feel more grounded and resilient. They’re great for casual, everyday wear or outdoor activities.

Soft Textures: Fabrics such as velvet are incredibly soft. These fabrics are associated with warmth, comfort, and nurturing. Wearing soft, textured fabrics can make you feel cozy and secure, making them ideal for relaxing at home or during the colder months.

Stiff Textures: Fabrics like organza have a stiff texture. These fabrics often convey formality and structure. Wearing stiff fabrics can make you feel more disciplined and poised. They’re suitable for formal events or professional settings.

The Influence of Fabric Colors

Colors are powerful psychological tools that can influence our emotions and perceptions. Different colors can have varying effects on our mood.

Red: Red is a bold and stimulating color. It is often associated with passion, energy, and excitement. Wearing red can make you feel more confident and assertive. It’s a great choice for events where you want to stand out and make a strong impression.

Blue: Blue is a calming and soothing color, often linked to feelings of tranquility, trust, and stability. Wearing blue can help you feel more relaxed and at peace. It’s ideal for situations where you need to stay calm and composed, such as job interviews or exams.

Yellow: Yellow is a bright and cheerful color. It is associated with happiness, optimism, and creativity. Wearing yellow can lift your spirits and make you feel more joyful and energetic. It’s perfect for social gatherings or creative endeavors.

Green: Green is a refreshing and harmonious color. It represents nature, balance, and growth. Wearing green can make you feel more refreshed and rejuvenated.

Combining Textures and Colors

The combination of textures and colors can create a powerful impact on your mood and behavior. For instance, a smooth, blue silk dress can make you feel both elegant and calm, while a rough, red wool sweater can evoke feelings of strength and confidence. Understanding how these elements work together can help you make more informed choices about your wardrobe and home decor.

Svegea of Sweden: Innovating Textile Machinery

Svegea of Sweden is at the forefront of textile machinery innovation. Their advanced fabric-cutting machines ensure precision and efficiency, making it easier for designers to create garments that not only look good but also feel good. By investing in high-quality machinery from Svegea, manufacturers can produce textiles that meet the psychological needs of their customers.

Svegea leads the textile industry with its quality and innovation. Their machines cut various fabrics with utmost precision. This attention to detail helps create garments that provide the desired emotional and psychological benefits to the wearer.

A Fascinating Field

The psychology of fabric is a fascinating field that highlights the significant impact that textures and colors can have on our moods and behavior. By understanding these effects, we can make more informed choices about the fabrics we wear and surround ourselves with. Whether you’re looking to feel more confident, relaxed, or joyful, the right fabric can make all the difference.

For manufacturers and designers, investing in high-quality textile machinery from Svegea of Sweden can help ensure that your products meet the psychological needs of your customers. To learn more about Svegea’s innovative solutions, visit their contact page.

Explore the world of fabrics and discover how the textures and colors you choose can transform your mood and behavior. Make informed choices and experience the psychological benefits of the right textiles today!

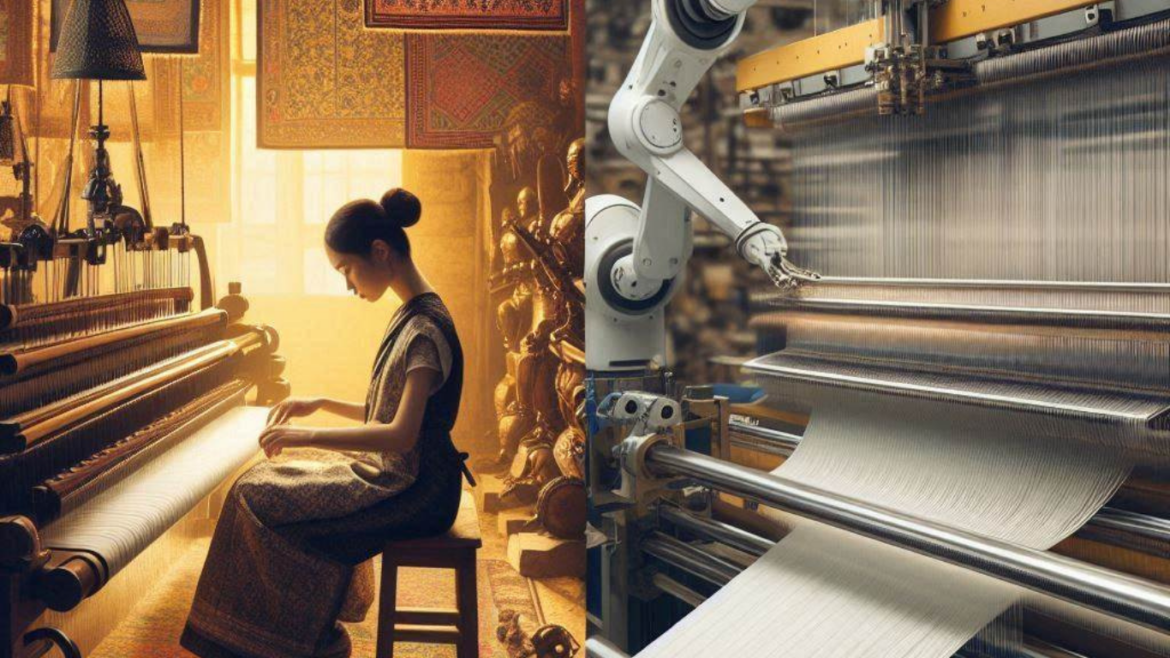

In the dynamic world of textile manufacturing, automation is a cornerstone of innovation, driving unprecedented efficiency, precision, and sustainability. As an expert with over two decades of experience in textile automation, we have witnessed firsthand the transformative power of these technologies. Today, we’ll explore how automation is reshaping the fabric of our industry.

The Evolution of Textile Automation

The journey from hand-spun fibers to today’s high-tech production lines tells a story of relentless innovation. Early mechanization during the Industrial Revolution laid the groundwork, but modern automation has catapulted us into a new era of manufacturing excellence.

Key milestones include:

1. 1960s-1970s: Introduction of computer-controlled looms

2. 1980s-1990s: Development of robotic systems for material handling

3. 2000s-2010s: Integration of AI and machine learning in quality control

4. 2020s and beyond: Emergence of fully automated, smart textile factories

Core Areas Transformed by Automation

Spinning: Precision at Lightning Speeds

Modern spinning systems, such as rotor and air-jet technologies, have revolutionized yarn production. These systems can produce yarn up to 20 times faster than traditional ring spinning, with unparalleled consistency.

Weaving: Intelligent Looms for Flawless Fabrics

Today’s computerized looms are marvels of engineering. There are machines for example that use real-time adaptive tension control to adjust warp tension on the fly, ensuring fabric quality remains consistent even as conditions change during production. This level of precision was unthinkable just a decade ago.

Dyeing and Finishing: Sustainability Meets Efficiency

Automated dyeing and finishing processes have dramatically reduced water and energy consumption while improving color consistency. Digital textile printing, exemplified by machines can print complex designs directly onto fabric at up to 1,000 m²/hour, revolutionizing small-batch and customized production.

Spotlight on Innovation: Svegea’s EC 450 XF Collarette Cutting System

The EC 450 XF Collarette Cutting System by Svegea represents the cutting edge of textile automation. As the winner of the Texprocess Americas 2023 Innovation Award, this system exemplifies how targeted automation can solve specific industry challenges.

Key features include:

– Multi-material compatibility for unparalleled versatility

– Precision cutting with minimal waste

– Rapid changeover times, boosting overall productivity

The EC 450 XF doesn’t just cut fabric; it redefines efficiency in garment manufacturing. For manufacturers looking to stay competitive, systems like this are not just beneficial—they’re essential.

The Tangible Benefits of Automation

1. Quality Assurance: Automated systems consistently produce high-quality textiles, reducing defects by up to 90% compared to manual processes.

2. Increased Productivity: Modern automated lines can operate 24/7, increasing output by 200-300% over traditional methods.

3. Cost Reduction: While initial investment is significant, automated systems can reduce labor costs by 40-60% and material waste by 20-30% over their lifetime.

4. Customization at Scale: Automation enables quick changeovers, making small-batch and customized production economically viable.

5. Enhanced Safety: Automation minimizes human exposure to hazardous processes, reducing workplace accidents by up to 80% in some facilities.

Overcoming Implementation Challenges

While the benefits of automation are clear, implementation comes with challenges:

1. Initial Investment: The upfront cost of automation can be substantial. However, ROI typically occurs within 2-5 years, depending on the scale of implementation.

2. Workforce Transition: Shifting to automated systems requires retraining staff. Forward-thinking companies are investing in upskilling programs to transition workers into higher-value roles.

3. System Integration: Ensuring new automated systems work seamlessly with existing processes is crucial. Careful planning and phased implementation can mitigate disruptions.

The Future of Textile Automation

Looking ahead, several trends will shape the future of textile automation:

1. AI and Machine Learning: These technologies will enable predictive maintenance and real-time quality control, further improving efficiency and reducing downtime.

2. Internet of Things (IoT): Connected devices will create smart factories where every aspect of production is monitored and optimized in real-time.

3. Sustainable Automation: Future systems will focus even more on reducing environmental impact, with closed-loop water systems and energy-efficient processes.

4. Collaborative Robotics: Cobots will work alongside humans, handling repetitive tasks while allowing human workers to focus on high-value activities.

Embracing the Automated Future

Automation in textile manufacturing isn’t just about replacing human labor—it’s about augmenting human capabilities, driving innovation, and creating a more sustainable, efficient industry. As we look to the future, it’s clear that automation will play an increasingly central role in shaping the textiles of tomorrow.

For manufacturers, the message is clear: embrace automation or risk being left behind. The future of textiles is automated, and that future is now.

To explore cutting-edge automation solutions like Svegea’s EC 450 XF Collarette Cutting System, contact us now! For those ready to take the next step in their automation journey, now is the time to act.

The textile manufacturing industry is undergoing a significant transformation. As we move into 2025, several trends are shaping the future of this dynamic sector. From sustainable practices to advanced technologies, the landscape is evolving rapidly. Let’s explore the top trends in textile manufacturing for 2024 and 2025.

1. Sustainable Practices

Sustainability is no longer a buzzword; it’s a necessity. Textile manufacturers are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes using organic materials, recycling waste, and implementing energy-efficient processes. According to the World Economic Forum, sustainable practices in textile manufacturing can significantly reduce carbon emissions and water usage.

2. Advanced Technologies

The integration of advanced technologies is revolutionizing textile manufacturing. Automation, artificial intelligence (AI), and the Internet of Things (IoT) are enhancing efficiency and productivity. For instance, AI-driven machines can predict maintenance needs, reducing downtime and increasing output. The International Textile Manufacturers Federation highlights that these technologies are crucial for staying competitive in the global market.

3. Customization and Personalization

Consumers today demand unique and personalized products. Textile manufacturers are leveraging digital printing and other technologies to offer customized solutions. This trend is particularly evident in the fashion industry, where personalized clothing is gaining popularity. A report by McKinsey & Company suggests that customization will be a key driver of growth in the textile sector.

4. Smart Textiles

Smart textiles, also known as e-textiles, are gaining traction. These textiles have embedded sensors and electronics that can monitor health, track fitness, and even change color. The potential applications are vast, ranging from healthcare to sportswear. According to TechCrunch, the smart textiles market is expected to grow exponentially in the coming years.

5. Ethical Labor Practices

Consumers are becoming more conscious of the ethical implications of their purchases. As a result, textile manufacturers are focusing on fair labor practices and ensuring safe working conditions. This shift is not only ethical but also beneficial for brand reputation. The Fair Labor Association provides guidelines and resources for companies aiming to improve their labor practices.

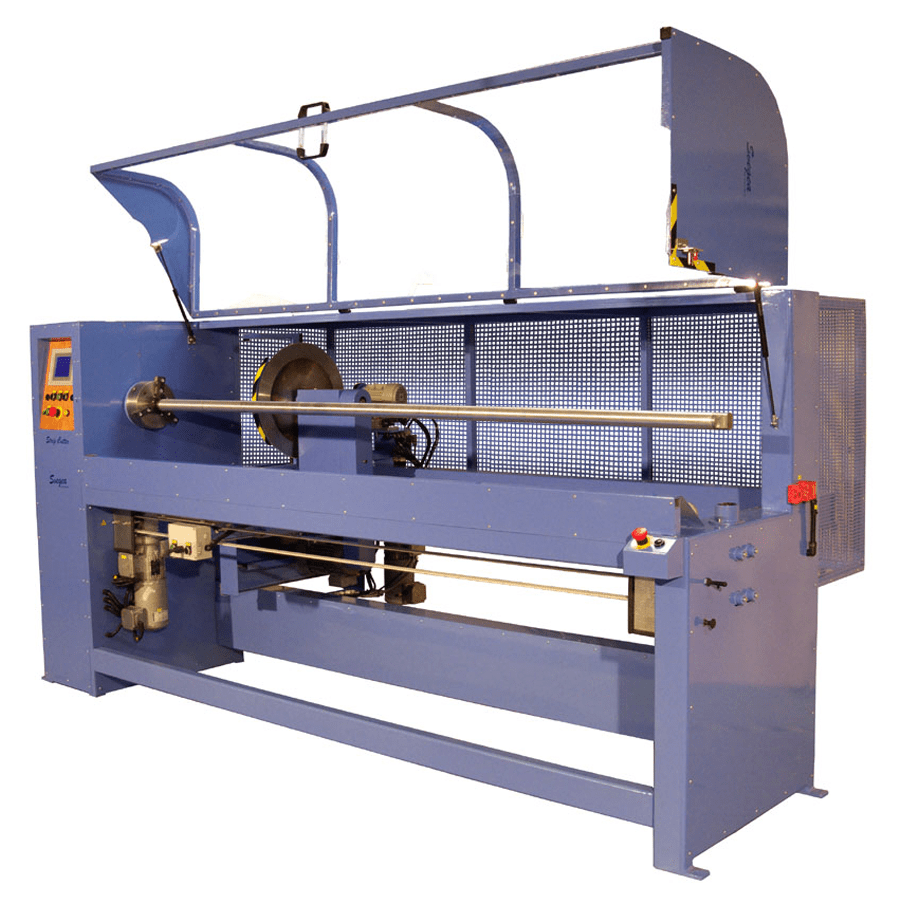

Spotlight on Svegea of Sweden

Svegea of Sweden is a notable player in the textile manufacturing industry. Known for their innovative solutions, Svegea offers advanced slitting and cutting machines that enhance efficiency and precision. Their commitment to quality and sustainability sets them apart in the market. While not overtly promotional, it’s worth noting how companies like Svegea are contributing to the industry’s evolution.

Exciting Changes

The textile manufacturing industry is poised for exciting changes in 2025. From sustainable practices to advanced technologies, the trends shaping this sector are both innovative and impactful. By staying informed and adapting to these trends, manufacturers can thrive in a competitive landscape.

For innovative and sustainable textile machinery, contact Svegea of Sweden. Our advanced solutions can help you stay ahead in the evolving textile industry.

Textile innovation is a fascinating journey that transforms raw ideas into tangible fabrics. This process involves creativity, technology, and a deep understanding of materials. In this blog, we will explore the stages of textile innovation, highlight the role of Svegea of Sweden, and provide insights into how modern machinery is revolutionizing the industry.

The Birth of an Idea

Every textile innovation begins with a concept. Designers and engineers brainstorm to create new fabrics that meet specific needs. Whether it’s for fashion, sports, or industrial use, the initial idea is crucial. This stage involves extensive research and development to ensure the concept is viable.

Research and Development

Research and development (R&D) are at the heart of textile innovation. Scientists and engineers work together to test new materials and techniques. They experiment with different fibers, dyes, and weaving methods to create fabrics that are not only functional but also aesthetically pleasing. This phase is critical as it lays the foundation for the entire process.

Prototyping and Testing

Once the concept is solidified, the next step is prototyping. This involves creating a small batch of the fabric to test its properties. Prototyping allows designers to see how the fabric performs in real-world conditions. They can make adjustments to improve durability, comfort, and appearance.

Importance of Testing

Testing is an essential part of the innovation process. Fabrics are subjected to various tests to ensure they meet industry standards. These tests include checking for strength, flexibility, and resistance to wear and tear. By rigorously testing prototypes, manufacturers can guarantee the quality of the final product.

Production and Manufacturing

After successful prototyping and testing, the fabric moves to the production phase. This is where innovative machinery plays a significant role. Companies like Svegea of Sweden provide state-of-the-art textile machinery that enhances efficiency and precision in manufacturing.

Role of Svegea of Sweden

Svegea of Sweden is a leader in textile machinery innovation. Their machines are designed to handle complex weaving and knitting processes with ease. By incorporating advanced technology, Svegea ensures that fabrics are produced with the highest quality standards. Their machinery is known for its reliability and efficiency, making them a preferred choice for many textile manufacturers.

Sustainability in Textile Innovation

In today’s world, sustainability is a key consideration in textile innovation. Manufacturers are increasingly focusing on eco-friendly materials and processes. This includes using organic fibers, reducing water consumption, and minimizing waste. Sustainable practices not only benefit the environment but also appeal to conscious consumers.

Eco-Friendly Materials

The use of eco-friendly materials is a growing trend in the textile industry. Organic cotton, bamboo, and recycled polyester are some sustainable fibers. These materials are not only environmentally friendly but also offer excellent performance characteristics. By choosing sustainable options, manufacturers can reduce their environmental footprint.

The Future of Textile Innovation

The future of textile innovation looks promising with continuous advancements in technology. Smart fabrics, which can monitor health or change color, are becoming a reality. Additionally, 3D printing is opening new possibilities for custom-made textiles. As technology evolves, the potential for innovation in textiles is limitless.

Embracing New Technologies

Embracing new technologies is essential for staying competitive in the textile industry. Companies that invest in advanced machinery and innovative processes are better positioned to meet the demands of modern consumers. Svegea of Sweden, with its cutting-edge textile machinery, is at the forefront of this technological revolution.

An Exciting Process

From concept to fabric, the journey of textile innovation is a complex and exciting process. It involves creativity, rigorous testing, and the use of advanced machinery. Companies like Svegea of Sweden play a crucial role in this journey by providing innovative solutions that enhance production efficiency and quality.

If you want to learn more about how innovative textile machinery can transform your production process, contact Svegea of Sweden today. Their expertise and state-of-the-art machines can help you stay ahead in the competitive textile industry.

The textile industry has always been a pioneer in technological advancements. From the spinning jenny to modern automated looms, the sector has continually evolved. Today, the integration of Artificial Intelligence (AI) into textile machines marks the latest leap forward, offering unparalleled efficiency, precision, and productivity. This article delves into how AI textile machines are revolutionizing the industry and highlights a cutting-edge product from Svegea of Sweden.

The Rise of AI in Textile Manufacturing

AI is no longer a futuristic concept; it is now a vital component of the manufacturing sector, especially in textiles. The industry is swiftly adopting AI technologies to enhance production processes, improve product quality, and reduce waste. AI-powered machines can analyze vast amounts of data in real time, enabling more informed decision-making and streamlined operations.

AI’s ability to learn from data and make real-time adjustments has transformed textile manufacturing. These machines can predict when a process needs adjustment, reducing downtime and boosting overall efficiency. For instance, AI can optimize machine settings based on the fabric type, ensuring each material is handled with utmost care and precision.

Reducing Waste and Enhancing Sustainability

One of the most significant benefits of AI-integrated textile machines is their ability to minimize waste. Traditional manufacturing often results in excess material being discarded, increasing costs and environmental impact. AI can significantly reduce this waste by optimizing cutting and sewing processes.

AI algorithms can analyze fabric patterns to determine the most efficient cutting method, minimizing leftover scraps. This not only reduces waste but also lowers costs for manufacturers. Additionally, AI can monitor fabric quality throughout production, identifying and correcting defects early.

Reducing waste also supports the industry’s sustainability efforts. As demand for eco-friendly products grows, manufacturers face increasing pressure to adopt sustainable practices. AI textile machines play a crucial role in this shift by enabling more efficient resource use and reducing the carbon footprint of textile production.

Enhancing Productivity with AI

Productivity is a key metric in any manufacturing environment, and the textile industry is no exception. AI-integrated machines are designed to maximize output without compromising quality. By automating routine tasks, these machines free up human workers to focus on more complex, value-added activities.

For example, AI can automate the inspection process, quickly identifying defects that human inspectors might miss. This speeds up the production line and ensures only the highest-quality products reach the market. Additionally, AI can predict machine failures, allowing for preventative maintenance that minimizes downtime.

AI also excels in predictive analytics. By analyzing historical data, AI can forecast demand for specific products, enabling manufacturers to adjust production schedules accordingly. This ensures they can meet customer demand without overproducing, further reducing waste and costs.

Spotlight on Svegea’s AI-Integrated Textile Machines

Svegea of Sweden is a leading innovator in the textile machinery industry, known for its commitment to quality and efficiency. One standout product is the EC 300 Collarette Cutter, an AI-integrated machine that exemplifies the benefits of modern technology in textile manufacturing.

The EC 300 optimizes the cutting process, ensuring precision and consistency with every cut. With AI at its core, the machine can analyze fabric and make real-time adjustments to cutting parameters, reducing waste and enhancing efficiency. The result is a product that meets and exceeds the high standards expected by today’s manufacturers.

Svegea’s commitment to innovation extends beyond this. The company continuously invests in research and development, ensuring its machines remain at the cutting edge of technology. By integrating AI into its products, Svegea leads the charge toward a more efficient, sustainable, and productive textile industry.

To learn more about Svegea’s AI-integrated textile machines, talk to us now!

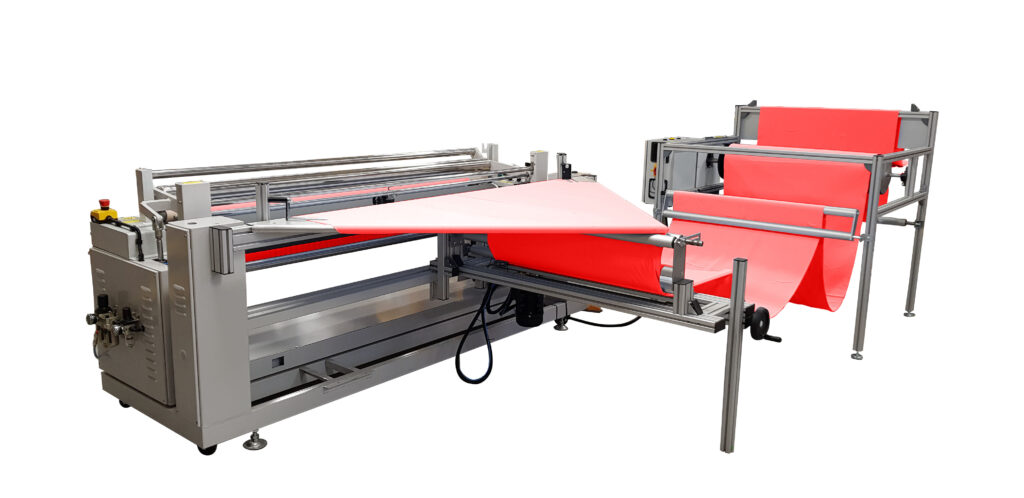

The textile industry has always been a hub of innovation. Each technological leap has transformed production processes from the spinning jenny to modern automated systems. Today, textile-cutting machines stand at the forefront of this revolution, offering unparalleled precision, speed, and efficiency. This article delves into how automated cutting machines reshape the textile industry and highlights a cutting-edge product from Svegea.

The Evolution of Textile Cutting Machines

From Manual to Automated

Historically, textile cutting was a labor-intensive task. Workers relied on manual tools like scissors and rotary cutters, which were time-consuming and prone to errors. The advent of semi-automated machines marked a significant improvement, yet they still required considerable human intervention. Today, fully automated textile-cutting machines have revolutionized the industry, enabling manufacturers to produce high-quality products swiftly and cost-effectively.

Key Features of Modern Textile Cutting Machines

Modern textile cutting machines boast advanced features that significantly enhance their performance:

– Computer-Aided Design (CAD) Integration: This allows for precise pattern creation and modification.

– Laser Cutting Technology: Ensures clean, accurate cuts with minimal fabric wastage.

– Automated Material Handling: Reduces the need for manual labor and speeds up the production process.

– Multi-Layer Cutting Capability: Enables the cutting of multiple fabric layers simultaneously, boosting productivity.

Benefits of Automated Textile Cutting Machines

- Enhanced Precision and Accuracy

One of the most significant advantages of automated textile-cutting machines is their precision. These machines use advanced software and laser technology to cut fabric with incredible accuracy, ensuring that each piece meets exact specifications. This level of precision is particularly important in industries like fashion and automotive, where even minor deviations can lead to significant issues.

- Increased Production Speed

Automated cutting machines can operate at much higher speeds than manual or semi-automated methods. This increased speed translates to higher production rates, allowing manufacturers to meet tight deadlines and respond quickly to market demands. For example, a textile cutting machine can cut hundreds of fabric pieces in the time it would take a human worker to cut just a few.

- Cost Savings

While the initial investment in automated cutting machines can be substantial, the long-term cost savings are significant. These machines reduce labor costs by minimizing the need for manual intervention. Additionally, their precision reduces fabric wastage, leading to lower material costs. Over time, these savings can offset the initial investment and lead to increased profitability.

- Versatility and Flexibility

Modern textile cutting machines are incredibly versatile. They can handle a wide range of fabrics, from delicate silks to heavy-duty industrial textiles. This versatility allows manufacturers to diversify their product offerings and cater to different market segments. Moreover, the ability to quickly switch between different cutting patterns and materials enhances production flexibility.

Real-World Applications

Fashion Industry

In the fashion industry, precision and speed are paramount. Automated textile cutting machines enable designers to bring their visions to life with unparalleled accuracy. These machines can cut intricate patterns and delicate fabrics with ease, ensuring that each garment meets the highest quality standards. Additionally, the ability to quickly produce samples and prototypes allows designers to experiment with new ideas and stay ahead of trends.

Automotive Industry

The automotive industry relies heavily on textile materials for interior components like seats, carpets, and headliners. Automated cutting machines ensure that these components are cut to exact specifications, enhancing the overall quality and durability of the final product. The ability to cut multiple layers of fabric simultaneously also speeds up production, allowing manufacturers to meet the high demands of the automotive market.

Home Furnishings

From curtains to upholstery, the home furnishings industry requires precise and efficient fabric cutting. Automated cutting machines enable manufacturers to produce high-quality home textiles quickly and cost-effectively. The versatility of these machines also allows for the production of custom designs, catering to the growing demand for personalized home decor.

The Future of Textile Manufacturing

Integration with Industry 4.0

The future of textile manufacturing lies in the integration of automated cutting machines with Industry 4.0 technologies. This includes the use of IoT (Internet of Things) devices, AI (Artificial Intelligence), and big data analytics to optimize production processes. For example, IoT-enabled cutting machines can communicate with other devices in the production line, ensuring seamless coordination and reducing downtime.

Sustainable Manufacturing

Sustainability is becoming increasingly important in the textile industry. Automated cutting machines contribute to sustainable manufacturing by reducing fabric wastage and energy consumption. Additionally, the precision of these machines minimizes the need for rework, further reducing resource usage. As the industry continues to prioritize sustainability, the adoption of automated cutting machines is likely to increase.

Continuous Innovation

The field of automated textile cutting is constantly evolving. Manufacturers are continually developing new technologies and features to enhance the performance of cutting machines. For example, advancements in laser technology and AI are expected to further improve the precision and efficiency of these machines. As these innovations continue to emerge, the capabilities of automated cutting machines will expand, opening up new possibilities for textile manufacturers.

Featured Product: Svegea’s EC 450 XF Collarette Cutting System

Svegea of Sweden is a leader in textile cutting technology, known for its innovative solutions that enhance productivity and reduce waste. One of their standout products is the EC 450 XF Collarette Cutting System. This system is designed for high-speed, precision cutting of collarettes, making it ideal for manufacturers looking to improve efficiency and product quality. The EC 450 XF features advanced automation and user-friendly controls, ensuring seamless integration into any production line.

For more information on cutting-edge textile-cutting machines, visit Svegea of Sweden

In today’s fast-paced world, consumers are increasingly seeking unique and personalized fashion experiences. This shift is reshaping the fashion industry, pushing brands to innovate and offer more customized products and services. One key player in this transformation is Svegea, whose Fabric Inspection tools are making a significant impact.

The Demand for Personalization

Personalized fashion experiences are no longer a luxury but a necessity for many consumers. According to recent studies, a significant majority of shoppers prefer brands that offer personalized options. This trend is driven by the desire for individuality and the need to stand out in a crowded market. Personalized fashion experiences allow consumers to express their unique style and preferences, creating a deeper connection with the brand.

How Technology is Enabling Customization

Advancements in technology have made it easier for fashion brands to offer personalized experiences. From AI-powered virtual fitting rooms to customized recommendations based on browsing history, technology is at the forefront of this revolution. Svegea’s Fabric Inspection tools play a crucial role in this process by ensuring the quality and precision of customized garments.

The Benefits of Fabric Inspection

Fabric inspection is a critical step in the production of personalized garments. It ensures that each piece meets the quality standards expected by consumers. Svegea’s Fabric Inspection tools are designed to detect even the smallest imperfections, allowing brands to address issues before they reach the customer. This not only enhances the overall quality of the product but also builds trust and loyalty among consumers.

Customization Beyond Fabric Inspection

Customization Beyond Fabric Inspection

While fabric inspection is vital, Svegea’s capabilities extend beyond this. The company can customize its machines to fit the specific production needs of its clients. This flexibility allows fashion brands to optimize their production processes and offer truly unique products. Whether it’s adjusting the machine settings for different fabric types or integrating new technologies, Svegea’s customized solutions ensure that brands can meet the growing demand for personalized fashion experiences.

The Future of Personalized Fashion

The trend towards personalized fashion experiences shows no signs of slowing down. As consumers continue to seek unique and customized products, brands must adapt to stay competitive. Svegea’s innovative solutions, including its Fabric Inspection tools, will play a crucial role in this evolution. By ensuring quality and enabling customization, Svegea is helping to shape the future of the fashion industry.

Transforming the Industry

Personalized fashion experiences are transforming the industry, driven by consumer demand for uniqueness and individuality. Technology, including Svegea’s Fabric Inspection tools, is enabling this shift by ensuring quality and precision in customized garments. As the trend towards personalization continues to grow, Svegea’s innovative solutions will remain at the forefront, helping brands meet the evolving needs of their customers.

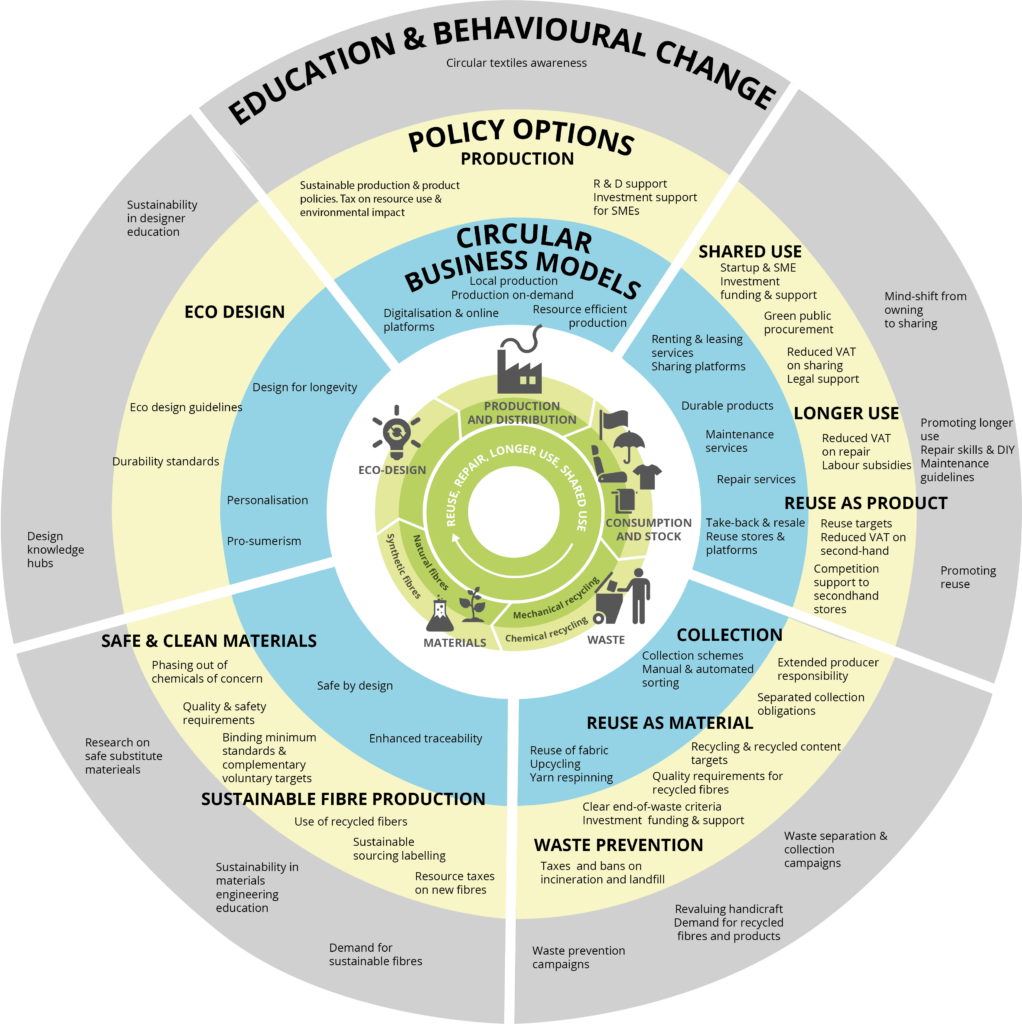

In an era where sustainability is paramount, the circular economy offers a transformative approach to how we produce and consume goods. Central to this concept are closed-loop systems and circular design, both of which aim to minimize waste and make the most of our resources.

Understanding Closed-Loop Systems

Closed-loop systems are designed to create a continuous cycle of use and reuse, effectively reducing waste. In these systems, the output of one process becomes the input for another, ensuring that materials are constantly recycled and repurposed. This approach not only conserves resources but also significantly reduces environmental impact.

The Importance of Circular Design

The circular design is a key element of the circular economy. It involves designing products with their entire lifecycle in mind, from creation to disposal. Circular design focuses on durability, reparability, and recyclability, making products easy to disassemble and reuse. This process reduces the need for new raw materials and minimizes waste.

Strategies for Minimizing Waste

Minimizing waste is a fundamental goal of the circular economy. This process is achievable through various strategies, including:

- Design for Longevity: Creating products that last longer and are easily repairable.

- Material Innovation: Using materials that are easier to recycle and have a lower environmental impact.

- Efficient Manufacturing: Implementing processes that reduce waste and improve resource efficiency.

Real-World Applications

Many companies are now adopting circular principles to enhance sustainability. For instance, in the textile industry, some manufacturers are focusing on producing high-quality trim that aligns with circular design principles. By ensuring that their products are durable and recyclable, these companies contribute to a more sustainable future.

The Benefits of a Circular Economy

The shift towards a circular economy offers numerous benefits:

- Environmental Sustainability: By reducing waste and conserving resources, the circular economy helps protect the environment.

- Economic Efficiency: Reusing materials and improving efficiency can lead to cost savings for businesses.

- Innovation and Growth: The circular economy encourages innovation, leading to new business opportunities and economic growth.

Representing a Significant Shift

The circular economy represents a significant shift in how we think about production and consumption. By embracing closed-loop systems and circular design, we can minimize waste and make better use of our resources. This approach not only benefits the environment but also offers economic advantages.

Sustainable Textile Manufacturing

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

To learn more about how quality trim can align with circular principles, visit Svegea’s contact page and discover their commitment to sustainability.

Driven by technological progression and the need for efficiency, the advanced apparel manufacturing industry has undergone significant transformations over the years. One of the most notable developments is the integration of automated processes and precision cutting techniques. These innovations have not only enhanced productivity but also improved the quality of garments produced. In this blog, we will explore the impact of these technologies and how they are shaping the future of apparel manufacturing.

The Rise of Automated Processes

Automation has become a cornerstone of modern apparel manufacturing. By incorporating advanced machinery and software, manufacturers can streamline various stages of production, from fabric cutting to sewing and assembly. Automated processes reduce the reliance on manual labor, minimize errors, and increase production speed.

One of the key benefits of automation is consistency. Machines can perform repetitive tasks with high precision, ensuring that each garment meets the same quality standards. This consistency is vital in large-scale production, where minor variations can lead to significant quality issues.

Moreover, automation allows for better resource management. By optimizing the use of materials and reducing waste, manufacturers can achieve cost savings and contribute to sustainability efforts. Integrating automated systems also enables real-time monitoring and data analysis, providing valuable insights for continuous improvement.

Precision Cutting Techniques

Precision cutting is a critical aspect of apparel manufacturing, as it directly impacts the fit and finish of garments. Traditional cutting methods often involve manual labor, which can be time-consuming and prone to errors. However, with the advent of precision cutting machines, manufacturers can achieve unparalleled accuracy and efficiency.

These machines utilize advanced technologies such as laser cutting, computer numerical control (CNC), and automated pattern recognition. Laser cutting, for instance, offers precise and clean cuts, even on intricate designs. CNC machines, on the other hand, can execute complex cutting patterns with high precision, ensuring minimal fabric wastage.

Automated pattern recognition systems further enhance precision by accurately identifying and aligning fabric patterns before cutting. This technology is particularly useful for patterned fabrics, where precise alignment is crucial to maintaining design integrity.

Svegea’s Roll/Slitting Machines: A Game Changer

Among the various precision cutting machines available, Svegea’s Roll/Slitting Machines stand out for their exceptional performance and versatility. These machines are designed to handle a wide range of materials, from delicate fabrics to heavy-duty textiles, making them ideal for diverse apparel manufacturing needs.

Svegea’s Roll/Slitting Machines are equipped with state-of-the-art sensors and smart controls, allowing them to adapt to different material thicknesses and cutting requirements in real time. This adaptability minimizes downtime and maximizes efficiency, making them a valuable asset for manufacturers aiming for operational excellence.

Integration with Industry 4.0

The integration of advanced apparel manufacturing machines with Industry 4.0 principles further enhances their capabilities. These machines are equipped with connectivity features and data analytics tools, enabling real-time insights and data-driven decision-making. This integration not only improves efficiency but also contributes to smarter and more sustainable manufacturing practices.

By leveraging data analytics, manufacturers can monitor machine performance, predict maintenance needs, and optimize production schedules. This proactive approach reduces downtime, extends the lifespan of machinery, and ensures consistent production quality.

Embracing Advanced Technologies

As the apparel manufacturing industry continues to evolve, embracing advanced technologies like automated processes and precision cutting techniques is essential for staying competitive. Svegea’s Roll/Slitting Machines exemplify the potential of these innovations, offering manufacturers the tools they need to achieve excellence.

If you’re looking to enhance your apparel manufacturing operations, consider integrating cutting-edge machines into your production line. Visit Svegea’s website to learn more about their innovative solutions and how they can help you achieve your manufacturing goals.