Driven by technological progression and the need for efficiency, the advanced apparel manufacturing industry has undergone significant transformations over the years. One of the most notable developments is the integration of automated processes and precision cutting techniques. These innovations have not only enhanced productivity but also improved the quality of garments produced. In this blog, we will explore the impact of these technologies and how they are shaping the future of apparel manufacturing.

The Rise of Automated Processes

Automation has become a cornerstone of modern apparel manufacturing. By incorporating advanced machinery and software, manufacturers can streamline various stages of production, from fabric cutting to sewing and assembly. Automated processes reduce the reliance on manual labor, minimize errors, and increase production speed.

One of the key benefits of automation is consistency. Machines can perform repetitive tasks with high precision, ensuring that each garment meets the same quality standards. This consistency is vital in large-scale production, where minor variations can lead to significant quality issues.

Moreover, automation allows for better resource management. By optimizing the use of materials and reducing waste, manufacturers can achieve cost savings and contribute to sustainability efforts. Integrating automated systems also enables real-time monitoring and data analysis, providing valuable insights for continuous improvement.

Precision Cutting Techniques

Precision cutting is a critical aspect of apparel manufacturing, as it directly impacts the fit and finish of garments. Traditional cutting methods often involve manual labor, which can be time-consuming and prone to errors. However, with the advent of precision cutting machines, manufacturers can achieve unparalleled accuracy and efficiency.

These machines utilize advanced technologies such as laser cutting, computer numerical control (CNC), and automated pattern recognition. Laser cutting, for instance, offers precise and clean cuts, even on intricate designs. CNC machines, on the other hand, can execute complex cutting patterns with high precision, ensuring minimal fabric wastage.

Automated pattern recognition systems further enhance precision by accurately identifying and aligning fabric patterns before cutting. This technology is particularly useful for patterned fabrics, where precise alignment is crucial to maintaining design integrity.

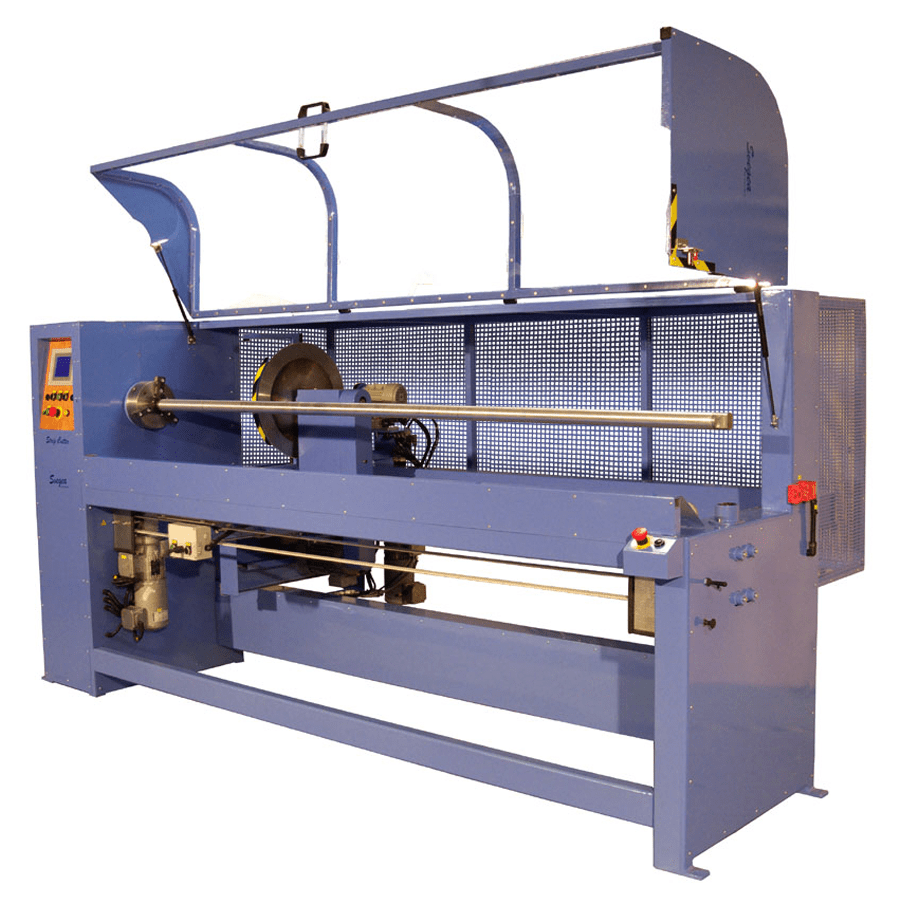

Svegea’s Roll/Slitting Machines: A Game Changer

Among the various precision cutting machines available, Svegea’s Roll/Slitting Machines stand out for their exceptional performance and versatility. These machines are designed to handle a wide range of materials, from delicate fabrics to heavy-duty textiles, making them ideal for diverse apparel manufacturing needs.

Svegea’s Roll/Slitting Machines are equipped with state-of-the-art sensors and smart controls, allowing them to adapt to different material thicknesses and cutting requirements in real time. This adaptability minimizes downtime and maximizes efficiency, making them a valuable asset for manufacturers aiming for operational excellence.

Integration with Industry 4.0

The integration of advanced apparel manufacturing machines with Industry 4.0 principles further enhances their capabilities. These machines are equipped with connectivity features and data analytics tools, enabling real-time insights and data-driven decision-making. This integration not only improves efficiency but also contributes to smarter and more sustainable manufacturing practices.

By leveraging data analytics, manufacturers can monitor machine performance, predict maintenance needs, and optimize production schedules. This proactive approach reduces downtime, extends the lifespan of machinery, and ensures consistent production quality.

Embracing Advanced Technologies

As the apparel manufacturing industry continues to evolve, embracing advanced technologies like automated processes and precision cutting techniques is essential for staying competitive. Svegea’s Roll/Slitting Machines exemplify the potential of these innovations, offering manufacturers the tools they need to achieve excellence.

If you’re looking to enhance your apparel manufacturing operations, consider integrating cutting-edge machines into your production line. Visit Svegea’s website to learn more about their innovative solutions and how they can help you achieve your manufacturing goals.