The Impact of Fast Fashion vs. Slow Fashion

The fashion industry is at a crossroads. On one side, fast fashion dominates with its rapid production cycles, low-cost garments, and ever-changing trends. Conversely, slow fashion is gaining momentum, advocating for sustainability, ethical production, and long-lasting quality. Understanding the differences between these two approaches is crucial for consumers and manufacturers alike.

The Environmental and Social Implications of Fast Fashion

Fast fashion has revolutionized the industry, making trendy clothing accessible. However, this convenience comes at a significant cost.

Environmental Consequences

The fast fashion industry is one of the most significant contributors to pollution worldwid e. It generates excessive textile waste, consumes vast amounts of water, and releases harmful chemicals into the environment. Consider these alarming statistics:

e. It generates excessive textile waste, consumes vast amounts of water, and releases harmful chemicals into the environment. Consider these alarming statistics:

- The fashion industry accounts for 10% of global carbon emissions and produces 20% of global wastewater.

- A single cotton shirt requires 2,700 liters of water—enough to sustain one person for 2.5 years.

- Synthetic fibers used in fast fashion take up to 200 years to decompose.

These figures highlight the urgent need for sustainable alternatives.

Social Consequences

Beyond environmental concerns, fast fashion has severe social implications. Many garment factories operate under challenging conditions, where workers often receive wages that may not fully meet the cost of living. In regions like Bangladesh, where the textile industry is a vital economic driver, efforts continue to improve labor standards and create more sustainable working environments. Supporting ethical production and fair compensation remains essential in shaping a more responsible and equitable fashion industry.

The widespread demand for affordable clothing presents challenges in ensuring ethical labor practices. As the fashion industry evolves, businesses and consumers play a key role in promoting fair wages and responsible sourcing to create a more sustainable and equitable future.

Slow Fashion and Sustainability

Slow fashion prioritizes quality over quantity, focusing on durable, ethically produced garments. This movement is supported by innovative textile machines that enhance sustainability and efficiency.

Tips for Manufacturers Transitioning to Sustainable Practices

For manufacturers looking to embrace slow fashion, adopting sustainable practices is essential. Here are key strategies to facilitate the transition:

1. Optimize Energy Efficiency

Investing in energy-efficient textile machines can significantly reduce operational costs and environmental impact. Technologies such as variable frequency drives and energy recovery systems help minimize energy consumption.

2. Use Sustainable Raw Materials

Choosing organic cotton, recycled fabrics, and biodegradable materials can drastically reduce pollution and resource depletion. Sustainable sourcing ensures ethical production while maintaining high-quality standards.

3. Implement Waste Reduction Strategies

Advanced textile machines, like those from Svegea, help manufacturers cut fabric efficiently, reducing excess material waste. Additionally, adopting zero-waste design techniques can further minimize environmental impact.

4. Reduce Water Usage and Pollution

Traditional textile production consumes vast amounts of water. Modern dyeing machines now recycle water, significantly lowering consumption. Manufacturers should also explore low-impact dyeing techniques to reduce chemical pollution.

5. Promote Supply Chain Sustainability

Partnering with ethical suppliers and ensuring fair labor practices throughout the supply chain is crucial. Transparency in sourcing and production fosters consumer trust and strengthens brand reputation.

6. Foster a Culture of Sustainability

Educating employees and stakeholders about sustainable practices encourages long-term commitment to eco-friendly production. Companies should integrate sustainability goals into their business strategies to drive meaningful change.

Sustainable Textile Production

Svegea of Sweden specializes in innovative textile machinery that supports sustainable and efficient garment production. Their advanced solutions help manufacturers reduce waste and optimize processes by:

- Maximizing fabric usage through precision cutting and automation, minimizing material waste.

- Enhancing energy efficiency, reducing overall consumption and environmental impact.

- Improving garment durability, promoting longevity, and contributing to a circular economy.

By integrating Svegea’s technology, manufacturers can transition to eco-friendly production methods without compromising efficiency or profitability.

More than a Trend

The battle between fast fashion and slow fashion is more than a trend—it’s a movement toward a more sustainable future. While fast fashion continues to dominate, its environmental and social consequences cannot be ignored. Slow fashion, supported by innovative textile machines like those from Svegea of Sweden, offers a viable solution for manufacturers seeking ethical and sustainable production.

By adopting energy-efficient technology, sustainable materials, and waste reduction strategies, manufacturers can contribute to a greener industry while maintaining profitability. The shift toward slow fashion is not just necessary—it’s inevitable.

Let’s embrace sustainability and redefine the future of fashion. If you’re looking to enhance the productivity and sustainability of your garment production processes, reach out to Håkan Steene at h.steene@svegea.se to learn more about Svegea’s advanced textile machinery and solutions.

Image credits: Photo by Alina Bordunova on Unsplash | Photo by Hannah Morgan on Unsplash

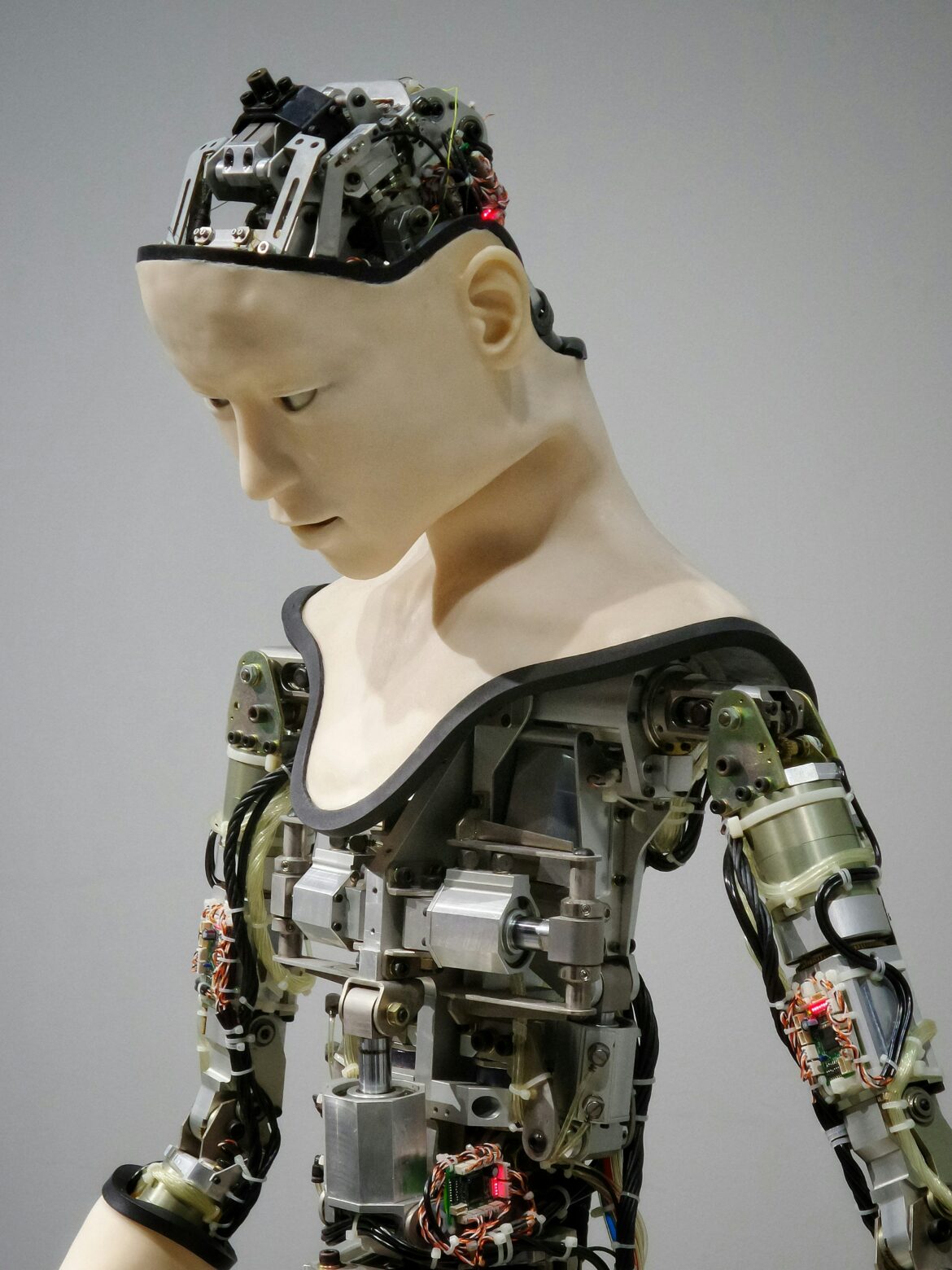

The textile industry is undergoing a remarkable transformation, blending biology with cutting-edge machinery to create sustainable and high-performance fabrics. Biotextiles—materials engineered through biological processes—are redefining not just how fabrics are made but also how they function. As demand for sustainability and efficiency rises, advanced textile machinery, such as Svegea of Sweden’s precision cutting solutions, plays a crucial role in making these innovations commercially viable.

Biology Meets Fabric: A New Era in Textile Manufacturing

Traditional textile production is resource-intensive, consuming vast amounts of water, chemicals, and energy. However, biotextiles offer a revolutionary alternative, leveraging natural fibers, microbial cellulose, and protein-based materials to create fabrics that are both biodegradable and high-performing. Researchers have successfully developed microbial cellulose fabrics that decompose naturally, significantly reducing textile waste. Meanwhile, mycelium-based leather and spider silk proteins engineered from microorganisms provide durable, eco-friendly alternatives to conventional materials.

Medical and Performance Applications of Biotextiles

Biotextiles aren’t just shaping sustainable fashion—they’re also transforming healthcare and high-performance textiles. Bacterial cellulose is now used for wound dressings that promote faster healing, while protein-based tissue scaffolds aid regenerative medicine. These bio-engineered fabrics even adapt to environmental stimuli, paving the way for smart medical textiles that interact with the human body.

For these breakthroughs to transition from labs to large-scale manufacturing, precision equipment is critical. The delicate nature of living fabrics and engineered fibers demands cutting technology that preserves their biological integrity without compromising efficiency.

How Svegea’s Precision Machinery Powers the Biotextile Revolution

The production of biotextiles requires more than just innovation—it demands precise and efficient fabric-handling solutions. Svegea of Sweden, a leader in textile machinery, has developed bias-cutting and band-cutting machines that ensure biotextiles maintain their structural integrity throughout processing.

- Precision cutting for delicate materials: Svegea’s circular cutting technology handles biological fabrics with exceptional accuracy, preventing damage and maximizing material efficiency.

- Automation for consistency: Biotextiles require a controlled, repeatable cutting process, which Svegea’s automated bias-cutting machines deliver, ensuring uniformity in every production run.

- Sustainable processing: Svegea’s machinery optimizes material use, reducing textile waste while supporting sustainable textile production—a key objective of biotextile manufacturers.

Sustainability and Market Growth: The Future of Biotextiles

The biotextile industry is experiencing rapid growth, driven by demand for sustainable fashion, medical textiles, and eco-friendly industrial fabrics. Forward-thinking manufacturers are recognizing that advanced cutting technology bridges the gap between biotextile research and large-scale production. Svegea’s Swedish-made, high-precision textile cutting machines are empowering businesses to adopt these innovations seamlessly, ensuring that the future of textiles is not only biological and sustainable but also efficient and commercially viable.

A Partnership Between Innovation and Precision

Biotextiles represent more than just a shift in fabric composition—they mark a new philosophy in textile production, combining nature’s intelligence with human ingenuity. As this industry evolves, the collaboration between biotechnological advancements and cutting-edge machinery will be crucial to scaling these solutions.

To stay ahead in the future of textile production, partner with Svegea of Sweden—where sustainability, precision, and innovation come together. Contact Håkan Steene at h.steene@svegea.se or visit our website to explore cutting-edge textile solutions that support your sustainable production needs.

Are you ready to witness the latest innovations in textile manufacturing and processing? Mark your calendars for Texprocess Americas 2025, the premier event that brings together industry leaders, innovators, and professionals to explore cutting-edge technologies and trends shaping the future of textiles.

Discover the Latest Innovations

Texprocess Americas 2025 promises an exciting lineup of exhibitors showcasing the newest advancements in textile machinery, software, and materials. This is your chance to see first-hand how industry pioneers are revolutionizing the textile landscape with state-of-the-art solutions designed to enhance efficiency, sustainability, and creativity.

Texprocess Americas, co-produced by SPESA, creates an opportunity for retail, brand, manufacturing executives, and professionals involved in the sewn products industry to meet with leading international manufacturers and distributors of machinery, equipment, parts, supplies, systems, technology, supply chain solutions, and other products and services used for the development of sewn products.

Learn from Industry Experts

The event will feature a series of thought-provoking sessions and workshops led by renowned experts. Attendees will gain invaluable insights into the latest trends, best practices, and strategies to stay ahead in the ever-evolving textile industry. Whether you’re looking to expand your knowledge, network with like-minded professionals, or discover new business opportunities, Texprocess Americas is the place to be.

Join the Celebration of Innovation

In 2023, Svegea of Sweden had the honor of being recognized at the TPA Innovation Awards for our groundbreaking Svegea EC-450XF Collarette Cutting System. This advanced system is celebrated for its unparalleled precision, efficiency, and versatility in textile manufacturing. The Svegea EC-450XF features rapid start and stop capabilities. It is also equipped with swift adjustability of bandwidths and a unique guide system that ensures seamless operations. Crafted from high-quality Swedish steel, it emphasizes durability and longevity, making it a true game-changer in the industry.

Register Now and Be Part of the Future

Don’t miss this opportunity to be at the forefront of the textile revolution. Register now for Texprocess Americas 2025 and secure your spot at the event where innovation meets inspiration. Visit the official website to sign up and stay updated on the latest event news and announcements.

As Svegea of Sweden won’t be physically present, our US counterpart, SewnProducts, will have a booth showcasing their innovative solutions.

Join us at Texprocess Americas 2025 and experience the future of textiles. Let’s innovate, connect, and thrive together!

The fashion industry is in the midst of a seismic shift. Consumers no longer settle for mass-produced garments—they crave unique, customized pieces that reflect their individuality. This surging demand is reshaping brand strategies, revolutionizing production, and redefining how we express ourselves through fashion.

The Rise of Personalized Fashion

Personalization isn’t a new concept—bespoke tailoring has been around for centuries. But thanks to groundbreaking technology, what was once an exclusive luxury is now accessible to the masses.

According to McKinsey’s The State of Fashion 2023 report, 71% of consumers expect brands to deliver personalized experiences, and 76% become frustrated when those expectations aren’t met. () This consumer-driven revolution is forcing the fashion industry to rethink everything, from design to production and delivery.

The Tech Behind the Transformation

Innovation is fueling the personalization boom. Here’s how cutting-edge technology is turning made-to-order fashion into a scalable, profitable reality:

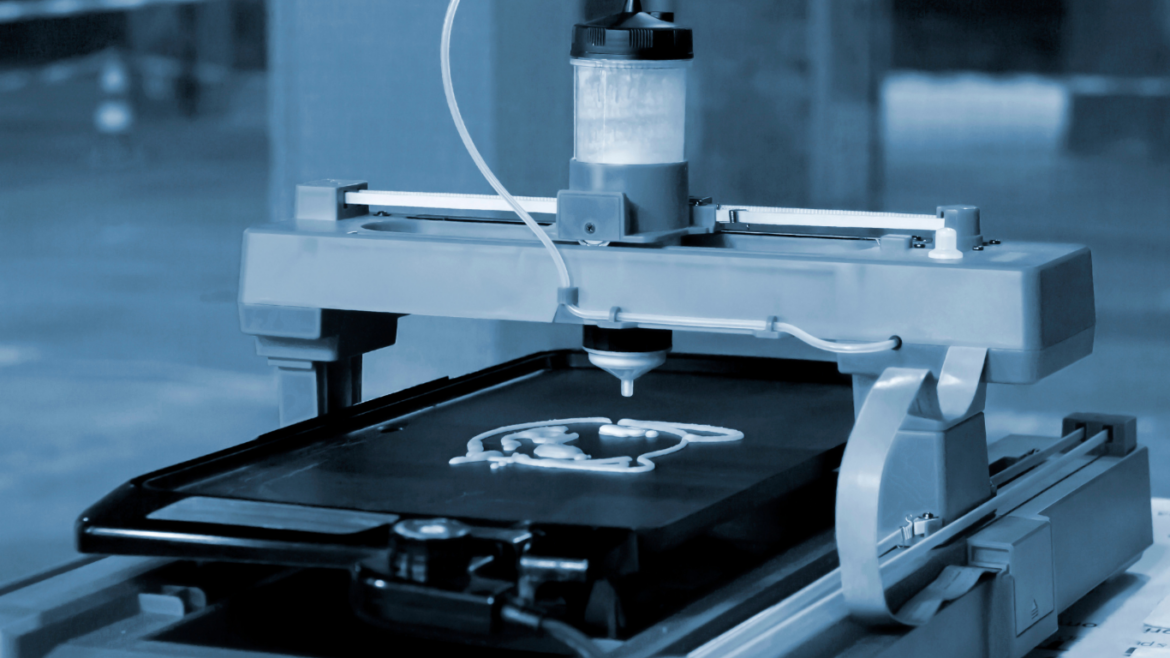

3D Printing: Reinventing Manufacturing

Adidas is a pioneer in this space, integrating 3D printing into their Futurecraft line. Their custom midsoles adapt to individual foot pressure points and gait, providing unparalleled comfort and performance. But the potential extends beyond footwear—startups are now 3D-printing entire garment components, minimizing waste and unlocking design possibilities previously unimaginable.

AI & Machine Learning: Next-Level Personalization

Brands like Stitch Fix blend human stylists with AI-driven algorithms to curate hyper-personalized fashion recommendations. With over 4 million active users, Stitch Fix exemplifies how AI can decode individual style preferences with incredible accuracy.

Body Scanning: Precision Fit, Every Time

Uniqlo has introduced body scanning technology in select stores, allowing customers to create digital avatars for accurate sizing recommendations. This technology eliminates guesswork, reduces returns, and ensures a flawless fit.

The Machinery Powering Personalization

While digital advancements steal the spotlight, specialized machinery is the backbone of small-batch, custom production. One standout player in this arena is Svegea of Sweden.

Svegea’s Role in Personalized Fashion

Svegea, a leader in textile machinery manufacturing, develops precision bias-cutting machines that enable small-batch production without sacrificing quality. Their collarette cutting machines, crucial for trim and binding production, make detailed customization viable at scale.

Automation: The Secret to Scalable Customization

Contrary to popular belief, automation isn’t the enemy of personalization—it’s the key to making it efficient.

Smart Factories: Rapid, Flexible Production

Advanced robotics and computer-controlled cutting systems can switch between personalized designs seamlessly, drastically cutting lead times. What once took weeks can now be produced in days, meeting consumer expectations for speed and exclusivity.

On-Demand Manufacturing: Redefining Fashion’s Business Model

The traditional model of mass-producing inventory is fading. Instead, agile, on-demand production is emerging as the future.

- Made-to-Order Success Stories: Companies like Proper Cloth create perfectly tailored shirts based on individual measurements, eliminating inventory waste and boosting customer satisfaction.

- Microfactories for Localized Production: The concept of small, tech-powered production hubs is gaining traction. According to Fashion for Good, micro-factories can reduce carbon emissions by up to 35% compared to traditional supply chains.

Why Consumers Love Customization

Beyond the cool factor, there are deeper reasons why personalized fashion is taking over:

1. A Unique Identity

In a world of fast fashion, standing out is more important than ever. Studies show that 80% of consumers are more likely to buy from brands that offer personalized experiences.

2. The Perfect Fit

Sizing inconsistencies have plagued shoppers for decades. Custom-fitted clothing eliminates this issue, reducing costly returns—an issue that costs the fashion industry $300 billion annually.

3. Sustainability at Its Core

Personalized fashion isn’t just stylish—it’s eco-friendly.

- Less Waste: On-demand production slashes overproduction and reduces landfill-bound inventory.

- Longer Wear: Research suggests personalized items stay in a consumer’s wardrobe up to 50% longer than mass-produced alternatives.

Brands Leading the Charge

Several fashion giants are proving that personalization isn’t just a gimmick—it’s a game-changer.

- Nike By You (formerly NIKEiD) allows customers to customize every element of their sneakers, adding over $1 billion in direct-to-consumer revenue.

- Ministry of Supply offers 3D-printed knit blazers, tailored to individual measurements in under 90 minutes.

- Unspun uses body scanning to create zero-inventory, custom-fit jeans, reducing carbon emissions by up to 40%.

Challenges & The Future of Personalized Fashion

Despite its rapid growth, personalized fashion isn’t without obstacles:

- Cost & Scaling: Custom production is still pricier than mass manufacturing, but as technology advances, costs are dropping—Deloitte reports a 30% decrease in price premiums for personalized products over the past decade.

- Consumer Awareness: Many shoppers still see personalization as a luxury. Brands must invest in educating consumers on its accessibility and long-term value.

The Future: Customization as the New Norm

Fashion’s transformation is just beginning. As technology evolves, personalized fashion will become an everyday expectation rather than an exclusive option. Brands that embrace this shift will benefit from stronger customer loyalty, reduced waste, and a more sustainable future.

The era of mass-produced fashion is fading. In its place? A world where every piece of clothing tells a unique story—your story.

Photo by Malicki M Beser on Unsplash

In an era where OOTD (Outfit of the Day) reigns supreme on social media, our relationship with clothing has become increasingly complicated. The fashion industry stands at a crossroads. Fast fashion pulls us one way—slow, sustainable production beckons from another direction. Let’s unzip the truth about these contrasting approaches and explore how quality textile production could be the thread that weaves a more sustainable future.

The True Cost of Fast Fashion: More Than Just a Price Tag

Remember that $5 t-shirt you couldn’t resist? While your wallet might have thanked you, our planet tells a different story. According to the United Nations Environment Programme, the fashion industry accounts for 10% of global carbon emissions and generates 20% of global wastewater. Stop and think about that. It’s more than all international flights and maritime shipping combined! The numbers are staggering. The implications are worse.

Fast fashion’s environmental impact reads like a horror story:

- One cotton shirt requires 2,700 liters of water – enough to keep one person hydrated for 2.5 years

- Synthetic fibers take up to 200 years to decompose

- The industry produces 92 million tons of textile waste annually

But environmental concerns are just the beginning. The human cost of fast fashion includes poor working conditions, minimal wages, and unsafe environments. A 2021 report by the Business & Human Rights Resource Centre revealed over 100 cases of worker exploitation in major fashion brands’ supply chains. These aren’t just statistics. They’re real people’s lives.

The Slow Fashion Revolution: Quality Over Quantity

Think of slow fashion as the farm-to-table movement of the textile world. It’s about creating garments that last. Simple as that. This approach emphasizes quality over quantity, craftsmanship over mass production, and sustainability over quick profits.

Quality Materials and Craftsmanship

High-quality textile production isn’t just about using better materials. Every thread counts. Manufacturers who invest in quality control and precise cutting techniques create garments that maintain their shape and durability through countless washes. It’s an investment in the future.

Innovation in Sustainable Manufacturing

Small and medium-sized enterprises (SMEs) often lead the way in sustainable innovation. Take Svegea of Sweden, for instance. This family-owned SME has spent decades perfecting bias-cutting technology that significantly reduces fabric waste. Their commitment to quality and sustainability shows how smaller companies can make a big impact. Through continuous innovation and unwavering dedication to quality, such companies prove that sustainable manufacturing isn’t just possible – it’s profitable.

Sustainable Production Methods

Modern textile manufacturing doesn’t have to choose between efficiency and sustainability. Advanced bias cutting machines can reduce fabric waste by up to 15% compared to traditional methods, while maintaining precise, high-quality cuts. Technology and sustainability can work hand in hand. They must.

Fair Labor Practices

Slow fashion emphasizes fair wages and safe working conditions. No compromises. When workers aren’t rushed to meet impossible quotas, they can focus on craftsmanship and quality control. The result? Superior products that last longer.

Making the Transition: A Guide for Manufacturers

Transitioning to sustainable practices isn’t just good for the planet – it’s good for business. A recent McKinsey survey found that 67% of consumers consider the use of sustainable materials an important purchasing factor. The message is clear. The time is now.

Start Small, Think Big

1. Audit your current waste levels and identify areas for improvement

2. Invest in precision cutting technology to reduce fabric waste

3. Train staff in sustainable practices and quality control

4. Consider implementing a circular production model

Embrace Technology Wisely

Modern machinery isn’t just about speed. It’s about precision and efficiency. The right equipment can help reduce waste, improve quality, and maintain consistency while reducing overall production costs. Smart choices lead to better results.

Build Transparency

Document your sustainability journey and share it with customers. Today’s consumers want to know the story behind their clothes. Transparency builds trust. Trust builds loyalty. Loyalty builds success.

The Future is in Our Hands

The fashion industry’s future doesn’t have to be a choice between profitability and sustainability. By focusing on quality textile production, manufacturers can create products that benefit everyone – from workers to consumers to the planet itself. The choice is ours. The time is now.

Want to learn more about sustainable textile production methods or see how modern technology can support your sustainability goals? Visit www.svegea.se to explore innovative solutions for quality textile production. For personalized guidance on implementing sustainable practices in your manufacturing process, reach out to our sustainability expert at h.steene@svegea.se.

*Author’s Note: This article was crafted with care to provide accurate information about sustainable fashion practices. All statistics and facts have been sourced from reputable industry reports and research papers. While specific solutions mentioned may vary in effectiveness depending on individual circumstances, the principles of sustainable production remain universal.*

The textile industry is experiencing a significant transformation, with Artificial Intelligence (AI) at its core. AI is revolutionizing textile design by automating processes, predicting trends, and promoting sustainability. This technological advancement is reshaping how designers and manufacturers approach creativity and production.

What is Textile Design AI?

Textile design AI involves utilizing artificial intelligence to enhance and automate the creation of textile patterns and designs. By analyzing extensive datasets, AI can generate unique designs and forecast consumer preferences. For instance, AI can blend historical patterns with current trends to produce innovative designs, expediting the creative process and fostering unprecedented innovation.

How AI is Transforming Textile Design

1. Automating Repetitive Tasks – AI streamlines tasks such as pattern creation and color adjustments, allowing designers to focus on creativity. Tools like Adobe’s Sensei automate pattern generation and color matching, enhancing efficiency.

2. Predicting Trends – By analyzing data from social media and fashion platforms, AI predicts upcoming trends. Platforms like Heuritech scan millions of images to identify emerging patterns, helping brands stay ahead.

3. Personalization at Scale – AI enables mass customization, allowing consumers to personalize products without hindering production. Companies like Unmade offer personalized knitwear, letting customers select colors and patterns.

4. Sustainable Design Solutions – AI optimizes material usage and reduces waste by calculating efficient fabric-cutting methods and suggesting eco-friendly materials, aiding brands in adopting sustainable practices.

Real-World Applications of Textile Design AI

- Fashion Brands Leading the Way – Brands like Stitch Fix use AI to analyze customer preferences and recommend personalized clothing. Similarly, Zara employs AI to monitor real-time sales data and adjust designs accordingly.

- Textile Machinery and AI Integration – Companies are integrating AI into textile machinery to optimize production, ensuring high-quality results with minimal waste. For example, advanced systems use AI to adjust settings based on fabric types automatically, reducing errors and improving efficiency.

Why Textile Design AI Matters

- For Designers – AI empowers designers to experiment with new ideas and streamline workflows, bringing visions to life faster. By automating routine tasks, designers can focus more on creativity and innovation.

- For Consumers – AI-driven design offers consumers more options, including personalized clothing and eco-friendly fabrics, meeting individual preferences and reducing wait times for new collections.

- For the Planet – The textile industry is a significant polluter. AI helps reduce environmental impact by optimizing resource usage and promoting sustainable practices, contributing to a more sustainable future.

Challenges and Opportunities

While AI offers numerous benefits, challenges include potential job displacement due to automation and the need for high-quality data for effective AI systems. However, AI can create new roles focusing on creativity and strategy, and as technology advances, data collection barriers are likely to decrease.

Challenges

-

Job Displacement & Workforce Adaptation

One of the biggest concerns with AI automation is job displacement. Tasks that were once done manually, such as pattern-making, color matching, and quality control, are now being automated, reducing the demand for traditional roles. However, this shift doesn’t necessarily mean mass unemployment. Instead, the workforce needs to adapt by acquiring new skills in AI-assisted design, data analysis, and machine operation.

-

Need for High-Quality Data

AI relies on vast amounts of high-quality data to function effectively. In textile design, this means collecting and organizing fabric patterns, color schemes, consumer preferences, and trend data. Poor data quality—such as incomplete, outdated, or biased datasets—can lead to inaccurate predictions and ineffective designs.

-

Implementation Costs & Infrastructure

Small and mid-sized textile businesses may struggle with the high cost of AI implementation, which includes purchasing software, integrating AI with existing production lines, and training employees. Companies need to balance initial investments with long-term gains in efficiency and productivity.

-

Creativity vs. Standardization

While AI can generate unique patterns and automate design processes, it still lacks human intuition and artistic expression. Over-reliance on AI might lead to standardized, repetitive designs, reducing originality in fashion and textile production.

Opportunities

-

New Job Roles & Upskilling

- As AI automates repetitive tasks, new roles will emerge that require human expertise in:

- AI-driven textile design

- Digital trend forecasting

- AI model training and management

- Sustainable material innovation

- This shift creates opportunities for upskilling and cross-functional roles, blending AI knowledge with traditional design expertise.

- As AI automates repetitive tasks, new roles will emerge that require human expertise in:

-

Improved Efficiency & Cost Savings

- AI streamlines design, manufacturing, and inventory management, reducing waste and increasing efficiency.

- Brands can cut production costs by optimizing material usage and minimizing trial-and-error design iterations.

-

Enhanced Personalization & Sustainability

- AI allows for mass customization, where consumers can personalize clothing designs at scale.

- AI-driven sustainability solutions, such as fabric waste reduction algorithms and eco-friendly material selection, are helping the industry move towards a greener future.

-

Data-Driven Design & Trend Forecasting

- AI tools can analyze social media, runway trends, and past consumer behavior to predict upcoming fashion trends.

- This helps brands stay ahead of the curve, reducing the risk of overproduction and unsold inventory.

The Future of Textile Design AI

The future holds endless possibilities for AI in textile design, including creating adaptive fabrics and designs that change based on user preferences. Continued innovation and sustainability efforts will drive the industry forward.

Join the Textile AI Revolution!

Don’t miss out on the future of textile design powered by AI. Embrace innovation, sustainability, and personalization in your textile creations. For more details on how AI can transform your designs and production processes, contact h.steene@svegea.se.

As we step into 2025, the textile manufacturing industry is poised for significant transformations. Driven by technological advancements and evolving consumer demands, the industry is embracing new trends that promise to reshape the landscape. This blog explores the key textile trends for 2025, highlighting how innovative solutions are leading the charge.

Sustainability Takes Center Stage

Sustainability continues to be a dominant trend in textile manufacturing. Consumers are increasingly demanding eco-friendly products, pushing manufacturers to adopt sustainable practices. In 2025, we will see a rise in the use of organic and recycled materials, such as organic cotton, bamboo, and Tencel. These materials are not only environmentally friendly but also offer superior quality and comfort.

Moreover, manufacturers are focusing on reducing their carbon footprint by optimizing production processes and minimizing waste. Advanced textile machinery, such as cutting-edge collarette cutting systems, exemplifies this commitment to sustainability. These systems reduce fabric waste and enhance production efficiency, aligning with the industry’s green goals.

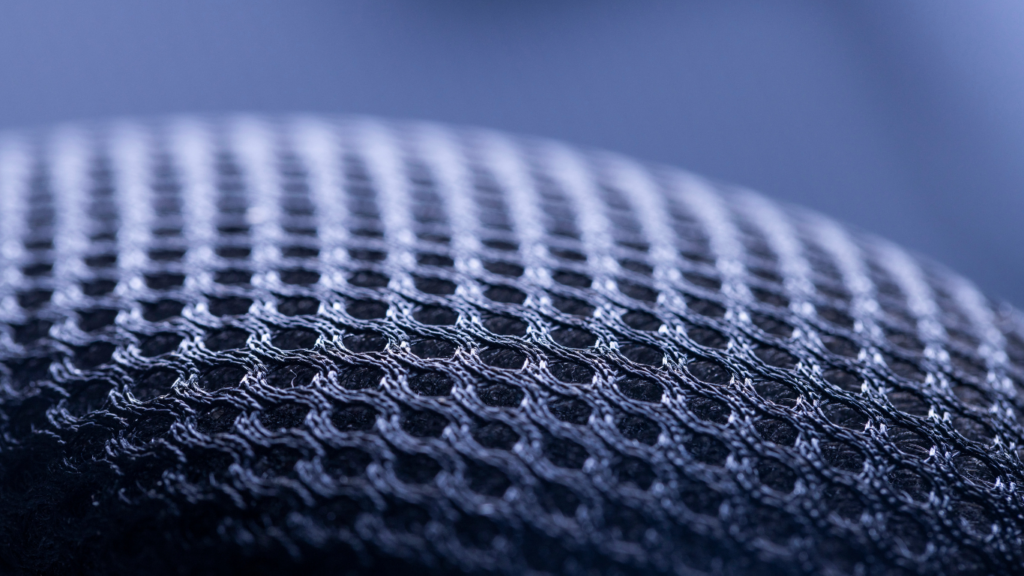

The Rise of Smart Textiles

Smart textiles are revolutionizing the industry by integrating advanced technology into fabrics. These textiles can monitor health, regulate temperature, and even change color based on environmental conditions. In 2025, we expect to see more widespread adoption of smart textiles in various applications, from fashion to healthcare.

Innovative solutions are at the forefront of this trend. Automated systems, like advanced roll-cutting/slitting machines, incorporate cutting-edge technology to enhance precision and efficiency. These advancements not only improve product quality but also open new possibilities for smart textile applications.

Digital Printing Innovations

Digital printing is transforming textile design by allowing for greater creativity and customization. Traditional printing methods are being replaced by digital techniques that enable intricate designs and vibrant colors. This trend is expected to grow in 2025, with more manufacturers adopting digital printing to meet consumer demands for unique and personalized products.

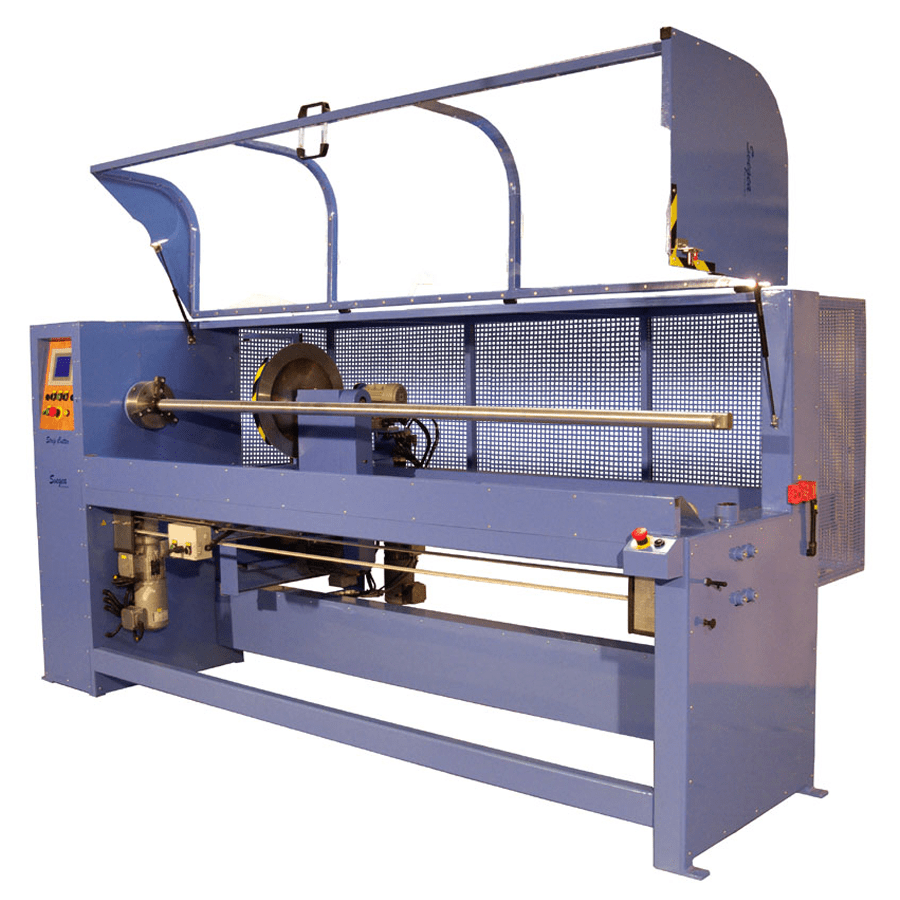

Precise cutting capabilities, offered by advanced strip cutters, ensure that digitally printed fabrics are handled with the utmost care and accuracy. These innovations are integral to maintaining the quality and appeal of digitally printed textiles.

Advanced Apparel Manufacturing

The apparel manufacturing sector is experiencing a shift towards automation and advanced technologies. In 2025, we will see increased use of AI and robotics to streamline production processes and reduce labor costs. These technologies enhance efficiency, improve product quality, and enable manufacturers to respond quickly to market changes.

Automated sewing units simplify the production of bias binding, reducing the need for manual intervention and increasing overall productivity. By leveraging such advanced machinery, manufacturers can stay competitive in a rapidly evolving market.

Customization and Personalization

Consumers are seeking more personalized products, driving the trend toward customization in textile manufacturing. In 2025, manufacturers will leverage AI and data analytics to offer tailored solutions that meet individual preferences. This trend is particularly evident in the fashion industry, where personalized clothing and accessories are becoming increasingly popular.

Innovative textile machinery can be tailored to meet specific production needs, ensuring that manufacturers can deliver unique products that resonate with their customers.

Sustainable Supply Chains

Sustainability extends beyond materials and production processes to encompass the entire supply chain. In 2025, we will see a greater emphasis on creating sustainable supply chains that minimize environmental impact and promote ethical practices. This includes sourcing raw materials responsibly, reducing transportation emissions, and ensuring fair labor practices.

Innovative solutions help manufacturers optimize their supply chains, reducing waste and improving efficiency. By adopting these advanced technologies, companies can enhance their sustainability efforts and meet the growing demand for eco-friendly products.

3D Technologies

3D technologies are making waves in textile manufacturing by enabling the creation of complex designs and prototypes. In 2025, we will see more manufacturers adopting 3D printing and other advanced techniques to push the boundaries of textile design. These technologies allow for greater experimentation and innovation, resulting in unique and high-quality products.

Cutting-edge machinery supports the integration of 3D technologies into textile production. These machines precisely cut and slit 3D-printed fabrics, handling them with care and accuracy.

Immersive Fashion

Immersive fashion is an emerging trend that combines technology and design to create interactive and engaging experiences. In 2025, we will see more brands exploring immersive fashion through augmented reality (AR) and virtual reality (VR) technologies. These innovations allow consumers to visualize and interact with products in new and exciting ways.

Advanced textile machinery supports the production of immersive fashion by enabling precise and efficient manufacturing processes. These innovations ensure that manufacturers can stay ahead of the curve and deliver cutting-edge products to their customers.

A Transformative Era

The textile manufacturing industry is on the cusp of a transformative era, driven by technological advancements and changing consumer demands. Trends such as sustainability, smart textiles, digital printing, and advanced manufacturing are reshaping the landscape, offering new opportunities for innovation and growth.

Innovative textile machinery is setting new standards in the industry. As we move into 2025, manufacturers must embrace these trends to stay competitive and meet the evolving needs of their customers.

For more information on how advanced solutions can help your business thrive, contact Håkan Steene at h.steene@svegea.se today!

Artificial Intelligence (AI) is emerging as a game-changer in the ever-evolving landscape of textile manufacturing. From design to production, AI is revolutionizing the industry, enhancing efficiency, reducing waste, and driving innovation. This blog delves into how AI is transforming textile manufacturing, spotlighting Svegea’s innovative solutions.

The Role of AI in Textile Manufacturing

AI is making significant strides in various aspects of textile manufacturing. One of the most notable areas is automated design and pattern-making. AI tools like Adobe’s Textile Designer analyze vast amounts of trend data from fashion shows, online retail platforms, and consumer behavior studies. This analysis helps predict future trends in patterns, colors, and materials with high accuracy, enabling designers to create collections that align closely with market demands.

Moreover, AI is enhancing the fabric inspection process. Advanced systems equipped with high-resolution cameras and sophisticated AI software, such as the Uster Quantum 4.0, conduct real-time textile analysis. These systems meticulously scan for defects like misweaves, pattern irregularities, and color deviations, ensuring only top-quality fabrics move forward in the production line. This precision significantly reduces waste and elevates product quality.

Enhancing Manufacturing Efficiency

AI-driven automation is streamlining textile manufacturing processes. Predictive maintenance, for instance, uses AI to foresee equipment failures before they happen, minimizing downtime and repair costs. Advanced AI-powered robotics and automation streamline tasks such as fabric cutting, sewing, and quality inspection, leading to faster production cycles and reduced labor costs.

Svegea, a leader in textile manufacturing solutions, exemplifies the integration of AI in production. Their EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, achieves unparalleled precision and efficiency. This system, along with other advanced machines like the SWS automatic roll cutting/slitting machines and the Strip Cutter CMS-1800A3, showcases Svegea’s commitment to cutting-edge technology.

Optimizing Supply Chains

AI plays a crucial role in optimizing supply chains within the textile industry. Machine learning models predict demand patterns, allowing manufacturers to adjust production schedules and inventory levels accordingly. AI-driven analytics also help identify the most efficient routes for shipping and logistics, reducing transportation costs and carbon footprint. This level of optimization ensures that products reach consumers promptly, enhancing customer satisfaction.

Revolutionizing Quality Control

Quality control is a critical aspect of textile production, and AI is enhancing this process through advanced inspection technologies. Computer vision systems equipped with AI algorithms can detect defects and inconsistencies in fabrics with high precision. These systems analyze images of textiles in real time, identifying issues such as color variations, weave irregularities, and fabric flaws that might be missed by human inspectors. This results in higher quality products and fewer returns.

Personalizing Consumer Experiences

AI is transforming how brands interact with consumers by enabling personalized shopping experiences. AI-powered recommendation engines analyze user behavior, purchase history, and preferences to offer tailored product suggestions. Virtual fitting rooms, driven by AI, allow customers to try on clothes virtually, enhancing the online shopping experience and reducing the likelihood of returns.

Svegea’s Innovative Solutions

Svegea of Sweden AB stands out as a beacon of innovation in textile manufacturing. With over 72 years of experience, Svegea offers a wide array of products and services that redefine the textile landscape. Their product portfolio includes the Tube Sewing Unit 200A, Roll to Roll Slitter RRS 800, and Strip Cutter FA 600, all designed for exceptional performance and efficiency.

Svegea’s commitment to cutting-edge technology is evident in its award-winning products. The EC-450XF Collarette Cutting System, for example, sets new benchmarks in production excellence. Svegea’s global presence and bespoke services ensure that each solution addresses specific client needs, ensuring customer satisfaction and success.

The Future of AI in Textile Manufacturing

The integration of AI in textile manufacturing is just beginning. As technology continues to advance, we can expect even greater efficiencies and innovations. AI will likely play an increasingly important role in areas such as sustainable production, where it can help reduce waste and optimize resource use.

AI is revolutionizing textile manufacturing, driving efficiencies, and fostering innovation. Companies like Svegea are leading this transformation, offering advanced solutions that set new industry standards. As AI continues to evolve, the future of textile manufacturing looks brighter than ever. To learn more about how Svegea can help your business stay ahead of the curve, contact Håkan Steene at h.steene@svegea.se today!

Have you ever wondered what goes into creating the luxurious fabrics that grace high-end fashion runways and premium home textiles? The journey from raw material to finished fabric is a fascinating process that combines traditional craftsmanship with cutting-edge technology. In this blog, we’ll uncover the secrets behind high-end fabric production, featuring insights from industry leaders like Svegea of Sweden.

The Foundation: Selecting the Finest Fibers

The first step in fabric production is selecting the highest quality fibers. Whether it’s natural fibers like cotton, silk, and wool, or synthetic fibers such as polyester and nylon, the choice of raw material significantly impacts the final product’s quality. Choose only the finest fibers to craft luxury fabrics that exude durability, softness, and a premium feel.

Spinning Magic: Transforming Fibers into Yarn

Once the fibers are selected, they undergo a spinning process to be transformed into yarn. This step involves drawing out and twisting the fibers to create a continuous thread. Advanced spinning techniques ensure that the yarn is strong and uniform, which is crucial for producing high-quality fabric. Modern spinning machines, like those used by leading manufacturers, offer precision and efficiency, resulting in superior yarn quality.

Weaving Wonders: Crafting the Fabric

Weaving is where the magic truly happens. This process involves interlacing two sets of yarns—the warp and the weft—to create a fabric. The type of weave pattern used can vary, from simple plain weaves to intricate jacquard designs. High-end fabric production often employs state-of-the-art weaving machines that can produce complex patterns with remarkable precision. Companies like Vandewiele Sweden are renowned for their advanced weaving technology, which ensures high-quality fabric production.

Dyeing and Finishing: Adding Color and Texture

After weaving, the fabric undergoes dyeing and finishing processes to achieve the desired color and texture. Dyeing involves immersing the fabric in dye solutions while finishing treatments can include processes like brushing, calendaring, and coating to enhance the fabric’s appearance and performance. Sustainable dyeing practices are becoming increasingly important, with many manufacturers adopting eco-friendly methods to reduce environmental impact.

Cutting-Edge Technology: Svegea of Sweden’s Innovations

Svegea of Sweden is a pioneer in the textile machinery industry, known for its innovative solutions that enhance fabric production efficiency and quality. One of their standout products is the Tubular Knit Slitter TSO 380. This machine revolutionizes the way tubular knit fabrics are processed, offering massive fabric savings and precision cutting. With features like advanced tension control and semi-automatic blade sharpening, the TSO 380 ensures perfect cuts every time, making it an invaluable asset for garment manufacturers.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of high-end fabric production. Each piece of fabric undergoes rigorous inspection to ensure it meets the highest standards. This includes checking for defects, measuring fabric weight and thickness, and testing for colorfastness and durability. Advanced fabric inspection machines, like those from Svegea, play a crucial role in maintaining quality by detecting even the smallest imperfections.

Sustainable Practices: The Future of Fabric Production

Sustainability is at the forefront of modern fabric production. Manufacturers are increasingly adopting eco-friendly practices to minimize their environmental footprint. This includes using organic fibers, reducing water and energy consumption, and recycling waste materials. Svegea of Sweden commits to sustainability by offering machinery that supports greener production methods. Their advanced textile-cutting systems reduce waste, increase efficiency, and contribute to a more sustainable textile industry.

The Role of Innovation in High-End Fabric Production

Innovation is key to staying ahead in the competitive world of high-end fabric production. From automated cutting machines to smart weaving technology, continuous advancements are driving the industry forward. Companies like Svegea are leading the way with their cutting-edge machinery that combines precision, efficiency, and sustainability. By investing in innovative solutions, manufacturers can produce superior fabrics that meet the demands of discerning customers.

Embracing the Future of Fabric Production

The secrets behind high-end fabric production lie in the meticulous selection of fibers, advanced spinning and weaving techniques, and cutting-edge technology. Companies like Svegea of Sweden are at the forefront of this industry, offering innovative solutions that enhance quality and efficiency while promoting sustainability. As the textile industry evolves, embracing these advancements will be crucial for producing the luxurious fabrics that define high-end fashion and home textiles.

Ready to learn more about the latest innovations in fabric production? Contact us to learn more about the range of advanced textile machinery designed to revolutionize your production process.

In the ever-evolving world of textiles, innovation is key to staying ahead. Textile companies that embrace cutting-edge technologies and sustainable practices are leading the way in textile-cutting solutions. Here are ten reasons why these innovative textile companies are at the forefront of the industry.

1. Advanced Cutting Technologies

Innovative textile companies invest in the latest cutting technologies, such as laser cutting and ultrasonic cutting. These methods offer precision and efficiency, reducing waste and improving the quality of the final product. Laser cutting, for example, allows for intricate designs and clean edges, which are essential for high-quality textiles.

2. Automation and Robotics

Automation and robotics have revolutionized the textile industry. Automated cutting machines can work around the clock, increasing productivity and reducing labor costs. Robotics also ensure consistent quality and precision, which is crucial for maintaining high standards in textile production.

3. Sustainable Practices

Sustainability is a major focus for leading textile companies. They adopt eco-friendly cutting methods that minimize waste and reduce energy consumption. For instance, waterjet cutting uses a high-pressure stream of water to cut textiles, which is both efficient and environmentally friendly.

4. Customization and Flexibility

Innovative textile companies offer customization options to meet the specific needs of their clients. Advanced cutting technologies enable these companies to produce bespoke designs and tailor-made solutions. This flexibility is a significant advantage in a competitive market.

5. Integration of Smart Technologies

The integration of smart technologies, such as IoT and AI, has transformed textile cutting solutions. These technologies enable real-time monitoring and optimization of the cutting process, leading to increased efficiency and reduced downtime. Smart sensors can detect and correct errors, ensuring high-quality output.

6. High-Speed Cutting

Speed is a critical factor in textile production. Leading textile companies use high-speed cutting machines that can handle large volumes of fabric quickly and accurately. This capability is essential for meeting tight deadlines and maintaining a competitive edge.

7. Precision and Accuracy

Precision and accuracy are paramount in textile cutting. Innovative companies use advanced software and cutting tools to achieve precise cuts, reducing material waste and ensuring consistent quality. This attention to detail is what sets them apart from the competition.

8. Cost-Effective Solutions

By adopting advanced cutting technologies and automation, textile companies can reduce production costs. These cost savings can be passed on to customers, making high-quality textiles more affordable. Additionally, efficient cutting processes minimize waste, further reducing costs.

9. Enhanced Safety Measures

Safety is a top priority for leading textile companies. They implement advanced safety features in their cutting machines to protect workers and prevent accidents. For example, laser cutting machines are equipped with safety sensors that automatically shut down the machine if a hazard is detected.

10. Continuous Innovation

The most successful textile companies are those that continuously innovate. They invest in research and development to stay ahead of industry trends and adopt new technologies. This commitment to innovation ensures they remain leaders in textile-cutting solutions.

One such example of continuous innovation is the Svegea CMS 1800A2 Strip Cutter. This versatile machine is renowned for its precision in cutting various types of fabrics into strips, making it ideal for producing bias binding, piping, and other narrow fabric applications. The CMS 1800A2 Strip Cutter exemplifies the advanced cutting technologies and efficiency that set leading textile companies apart.

Innovation At Its Finest

Innovative textile companies are leading the way in textile-cutting solutions by embracing advanced technologies, sustainable practices, and continuous innovation. These companies set the standard for quality, efficiency, and customization in the textile industry. If you’re looking for cutting-edge textile solutions, consider exploring the products offered by Svegea of Sweden. Visit our product page to learn more about our innovative textile-cutting solutions.