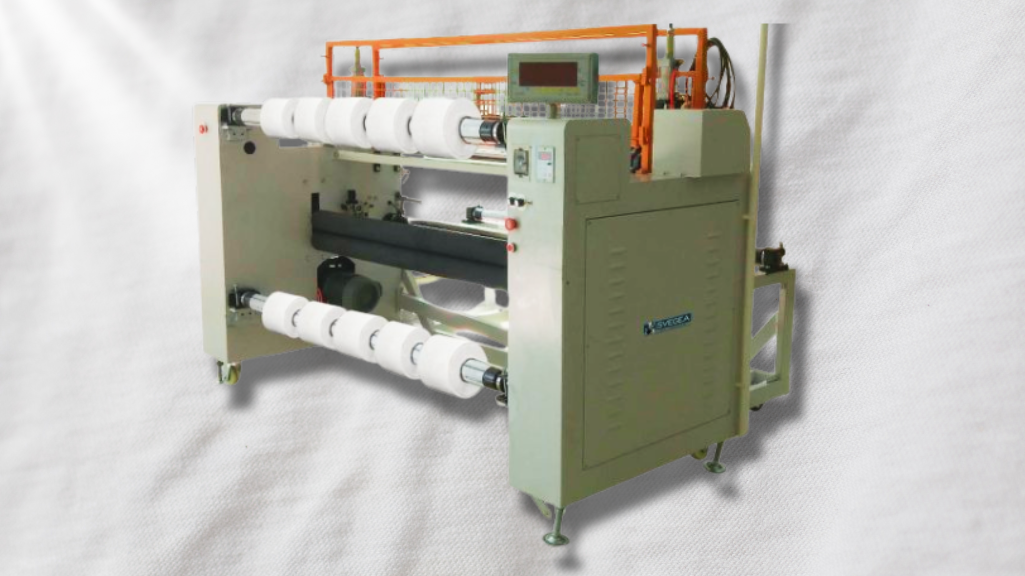

In manufacturing optimization, Svegea’s roll-slitting machines stand out as pioneers, integrating precision and speed to redefine production standards. These advanced machines cater to diverse industries, from textiles to packaging, offering sustainable solutions that maximize output while minimizing waste. Let’s explore how Svegea’s technology contributes to efficient material utilization and supports sustainable manufacturing practices.

Enhancing Efficiency Through Innovation

Svegea’s roll-slitting machines address the inefficiencies of traditional cutting methods by optimizing material usage. Unlike conventional processes that often result in significant leftover materials, Svegea ensures each roll is fully utilized, reducing costs and environmental impact. This commitment to efficiency boosts productivity and supports sustainable production practices.

Seamless Integration and Versatility

One of the key strengths of Svegea’s machines lies in their seamless integration into existing production workflows. Their user-friendly interfaces and intuitive designs empower operators to manage and control operations effortlessly. This versatility allows manufacturers to handle a wide range of materials with precision, adapting swiftly to varying production demands.

Precision and Quality Assurance

Precision is paramount in manufacturing, and Svegea’s roll-slitting machines excel in delivering consistent and accurate cuts. Advanced technology ensures that each slit meets stringent quality standards, minimizing errors and enhancing overall product quality. This precision not only reduces rework but also enhances operational efficiency, making these machines indispensable in high-demand industries.

Contributing to Sustainable Practices

Central to Svegea’s innovation is its commitment to sustainable manufacturing. By minimizing material waste through efficient roll-slitting technology, these machines play a crucial role in reducing environmental footprint. Optimal material utilization not only lowers raw material consumption but also supports eco-friendly production processes, aligning with global sustainability goals.

Shaping the Future of Manufacturing

Looking ahead, Svegea’s roll-slitting machines continue to set benchmarks for efficient and sustainable manufacturing practices. Their ability to maximize output while minimizing waste underscores a paradigm shift towards more responsible industrial practices. As industries evolve towards greater efficiency and environmental consciousness, Svegea remains at the forefront of driving innovation and shaping the future of manufacturing worldwide.

Harnessing the Power of Roll/Slitting Machines

By harnessing the capabilities of Svegea’s Roll/Slitting Machines, industries can achieve significant improvements in production efficiency and sustainability. These machines not only optimize material utilization but also pave the way for a more environmentally conscious approach to manufacturing. Embracing such technology not only benefits businesses economically but also contributes positively to global environmental efforts.

In recent years, advancements in technology and a growing emphasis on sustainability have fueled the development of novel fabrics. These textiles are engineered to possess unique properties that challenge the boundaries of traditional materials.

Let’s explore some exciting innovations:

1. Algae-Based Fabrics

Keel Labs has introduced Kelsun, an algae-based material that looks and feels like natural fiber. Derived from algae, Kelsun offers a sustainable alternative to petroleum-based synthetics. It has already appeared in collections by designer Stella McCartney.

2. Shrimp Shells and Mushroom Leather

TomTex, another trailblazer, uses shrimp shells and mushrooms to create proprietary materials that mimic leather, suede, and even latex. These alternatives are not only eco-friendly but also versatile. Peter Do’s Spring 2023 faux leather and Dauphinette’s Fall 2024 handbags feature TomTex materials.

3. Pineapple Leaf Fiber Leather

Piñatex is an innovative leather alternative made from pineapple leaf fibers, a byproduct of pineapple harvest. It’s both sustainable and stylish, making it a favorite among eco-conscious designers.

4. Regenerated Nylon (Econyl)

Econyl is a regenerated nylon made from recycled materials, including discarded fishing nets and fabric scraps. It’s a step toward reducing plastic waste and promoting circular fashion.

5. Geotextiles

These specialized fabrics find applications in civil engineering and construction. Geotextiles are used for drainage, soil stabilization, and erosion prevention.

6. Protective Textiles

Designed to shield users from various hazards, protective textiles are crucial in industries such as chemical handling, firefighting, and the military. They protect against chemicals, heat, and even ballistic impact.

7. Industrial Textiles

These textiles serve industrial purposes, including automotive applications. Automobiles utilize them for insulation, upholstery, seat belts, and airbags.

Sustainability and Functionality

Novel textile manufacturers engineer them to repel water, resist flames, or exhibit antibacterial qualities. These features enhance their functionality and sustainability in various applications.

Svegea’s Collarette Cutting Machines

As we delve into the world of novel textiles, we must acknowledge the role of cutting-edge machinery. Svegea, a Swedish company, specializes in Collarette Cutting Machines. These machines efficiently cut fabric collars, cuffs, and other textile components, contributing to sustainable production processes.

The fashion industry’s shift toward novel textiles reflects a commitment to environmental responsibility. As designers and consumers embrace these innovations, we move closer to a more sustainable and functional future.

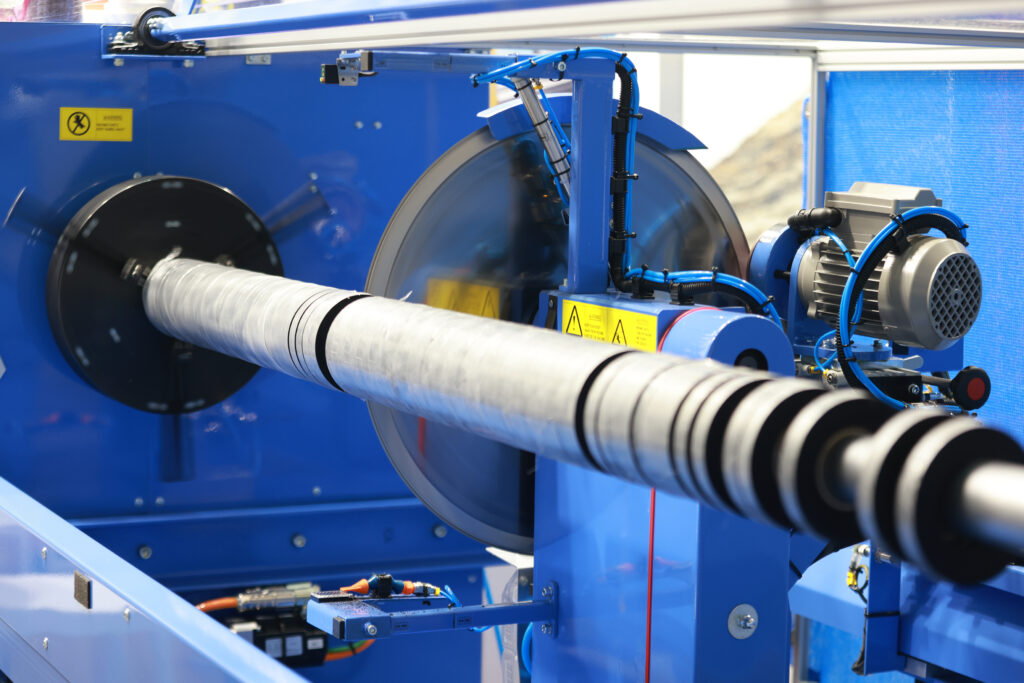

In the fast-paced realm of textile manufacturing, precision and innovation reign supreme, shaping industry standards and pushing boundaries. Svegea of Sweden AB emerges as a beacon of cutting-edge technology, offering various products and services that redefine the textile landscape. A standout in their lineup is the Tubular Knit Slitter, a product that epitomizes Svegea’s commitment to excellence and efficiency in textile production.

Cutting-Edge Technology

A steadfast commitment to cutting-edge technology lies at the core of Svegea’s success. The EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, epitomizes this dedication. This advanced system achieves unparalleled precision and efficiency, setting new benchmarks in production excellence. From automatic roll-cutting/slitting machines to the Strip Cutter CMS-1800A, Svegea’s lineup showcases technological prowess.

Global Presence and Bespoke Services

With a global presence across continents, Svegea delivers innovative solutions and bespoke services to clients worldwide. Whether it’s fabric inspection machines such as the CMI 210 R or the Complete Bias System, Svegea’s commitment to meeting client needs remains steadfast. Their tailored approach ensures that each solution addresses specific requirements, ensuring customer satisfaction and success.

Award-Winning Innovation

Svegea’s relentless pursuit of excellence has earned them recognition and accolades in the textile industry. Their award-winning innovation is evident in every product, from the Tube Sewing Unit 200 A/AF to the Euro Collarette range. This dedication to pushing boundaries positions Svegea as a leader in innovation and customer satisfaction.

Tubular Knit Slitter TSO 380

In essence, Svegea’s Tubular Knit Slitter is a remarkable machine that converts tubular knit fabric from its tube form into a single-width roll of material, ready to be slit into tape. This innovative approach brings huge fabric savings compared to the traditional method of producing two rolls of open-knit fabric from tubular knit for tape or binding production.

Experience Excellence

Svegea of Sweden AB stands as a testament to innovation, quality, and customer-centricity in the textile industry. They continue to redefine standards and shape the future of textile manufacturing with cutting-edge technology and a diverse product portfolio. Their global presence, bespoke services, and award-winning innovation set them apart. Experience excellence with Svegea – where innovation meets precision, and possibilities are limitless.

If you want to elevate your textile production, consider the Tubular Knit Slitter from Svegea. Let us know by pressing the contact button!

Luxury has evolved beyond mere opulence and exclusivity. It now tells the story of each design piece, highlighting meticulous craftsmanship and a commitment to ethical and sustainable practices. This article explores the world of high-end textiles, with fabric production as its cornerstone.

The Artisans and Their Craft

At the heart of luxury textiles are talented artisans. These skilled craftsmen and women create exquisite fabrics with unparalleled attention to detail. Every stitch, cut, and curve reflects their dedication, driving the continuous evolution of luxury with highly sought-after designs.

Slow Design and Bespoke Quality

Artisanal textiles are deeply rooted in craftsmanship. Unlike mass-produced goods, these items are created meticulously and thoughtfully. This movement, known as Slow Design, celebrates quality over quantity. Each piece is a unique work of art, reflecting the artisan’s expertise and passion.

The Journey from Fiber to Fabric

1. Fiber Selection: Luxury textiles begin with carefully chosen raw materials. Whether it’s silk, cashmere, or organic cotton, the quality of the fiber sets the foundation for the final product.

2. Spinning and Weaving: Artisans spin the fibers into yarns, which are then woven into fabric. Jacquard looms, guided by intricate patterns, produce complex designs that grace haute couture and high-end interiors.

3. Dyeing and Finishing: Artisans meticulously curate the color palette and apply dyes precisely. Finishing techniques—such as mercerization or calendering—enhance texture and luster.

4. Hand Embellishments: Embroidery, beading, and appliqué add a touch of luxury. Skilled hands transform plain fabric into wearable art.

The Role of Svegea of Sweden

Svegea of Sweden, a renowned textile machinery manufacturer, plays a crucial role in luxury fabric production. Their cutting-edge machines enable precise weaving, intricate patterns, and flawless finishes. From jacquard looms to automated knitting devices, Svegea’s technology empowers artisans to create fabrics that define luxury.

Subscribe to our blog for more insights into the world of luxury textiles, craftsmanship, and sustainable practices. Stay informed and inspired as we unravel the secrets behind high-end fabrics.

The textile industry, known for its dynamism and competitiveness, faces a new set of challenges in the wake of recent trade wars. In this article, we’ll explore the impact of these trade conflicts on textile businesses worldwide and discuss strategies to thrive amidst uncertainty.

The Impact of Trade Wars

Trade wars, characterized by tariff escalations and retaliatory measures, have disrupted global supply chains. Here’s how they affect the textile industry:

1. Tariffs and Costs: Increased tariffs on textile imports directly impact profit margins. Businesses must find innovative ways to absorb or mitigate these costs while remaining competitive.

2. Supply Chain Disruptions: Trade tensions create uncertainty in supply chains. Raw material availability, transportation, and production schedules are all at risk. Manufacturers need to build resilience and diversify suppliers.

3. Market Access: Some markets become less accessible due to trade restrictions. Textile exporters must explore alternative markets to sustain growth.

Opportunities Amidst Challenges

Despite the hurdles, textile businesses can seize opportunities:

1. Diversification: Exploring new markets and diversifying the customer base reduces reliance on a single market. Businesses can adapt to changing demand patterns.

2. Innovation: Research and development efforts can yield breakthroughs in materials, sustainable practices, and cost-effective solutions. Staying ahead of the curve is crucial.

3. Digitalization: Leveraging technology streamlines supply chain management, enhances marketing efforts, and facilitates e-commerce. Embracing digital tools boosts competitiveness.

Strategies for Success

To navigate these challenges effectively, textile companies should adopt the following strategies:

1. Risk Assessment: Regularly assess geopolitical risks and their impact on your business. Stay informed about policy changes and anticipate potential disruptions.

2. Supply Chain Resilience: Diversify suppliers geographically and build redundancy. Collaborate with suppliers to ensure continuity.

3. Collaboration: Partner with industry associations, government bodies, and other stakeholders. Advocate for fair trade policies and share best practices.

4. Market Intelligence: Understand consumer preferences, monitor trends, and adapt swiftly. Market research is essential for informed decision-making.

Take Action Today!

Ready to navigate the textile trade wars? Start by assessing your supply chain, exploring new markets, and embracing innovation. Remember, resilience and collaboration are key. Let’s shape the future of textiles together!

In the ever-evolving textile industry, innovation, and sustainability are paramount. One company leading the charge in this space is Svegea of Sweden. Renowned for its state-of-the-art cutting machines, Svegea combines advanced technology with eco-friendly practices to revolutionize textile manufacturing.

The Rise of Eco-Friendly Cutting Machines

As the demand for sustainable solutions in the textile industry grows, Svegea has positioned itself at the forefront. The company’s cutting machines are designed with a strong emphasis on reducing environmental impact. These machines not only enhance efficiency but also minimize waste, setting a new standard for eco-friendly manufacturing.

Svegea’s cutting machines incorporate several features that make them stand out. Firstly, they use energy-efficient motors that consume less power, resulting in lower carbon emissions. Additionally, the precision of these machines ensures that fabric waste is significantly reduced. This is a major concern in traditional textile production methods.

Innovative Technology for a Greener Future

Svegea’s commitment to sustainability goes beyond just reducing waste. Their cutting machines are equipped with advanced technology that supports the use of recycled materials. This capability is crucial for textile manufacturers aiming to meet the increasing consumer demand for eco-friendly products.

One of the key technological advancements in Svegea’s machines is the integration of AI-driven precision cutting. This technology allows for optimal use of fabric, ensuring that every inch of material is utilized effectively. By maximizing fabric use, manufacturers can significantly cut down on waste, contributing to a greener future.

Efficiency Meets Sustainability

Efficiency and sustainability are often seen as two competing goals in manufacturing. However, Svegea has successfully merged these two objectives with their cutting machines. The company’s machines are designed to deliver high-speed cutting without compromising on quality or environmental standards.

Svegea’s machines also feature user-friendly interfaces that allow operators to quickly adapt to new cutting patterns and materials. This adaptability not only enhances productivity but also reduces downtime, leading to more efficient production cycles. By streamlining operations, manufacturers can achieve higher output while maintaining sustainable practices.

Reducing Environmental Impact

The textile industry has long been criticized for its environmental footprint. Traditional cutting methods often result in significant fabric waste, contributing to landfill overflows and environmental degradation. Svegea addresses this issue head-on with their cutting-edge machines.

Svegea engineers their cutting machines to minimize fabric waste using precise cutting technology. This precision not only reduces waste but also maintains the quality of the cut pieces. By producing more usable fabric pieces per roll, Svegea helps manufacturers reduce their material costs and environmental impact.

Commitment to Continuous Improvement

A sustainability-conscious company demonstrates its dedication to innovation through its continuous efforts to improve its cutting machines. The company invests heavily in research and development to stay ahead of industry trends and meet the evolving needs of textile manufacturers.

Svegea regularly updates its machines with the latest technological advancements. This commitment to continuous improvement ensures that their cutting machines remain at the forefront of the industry. They do so while providing manufacturers with the best possible tools for sustainable production.

Customer-Centric Approach

At the heart of Svegea’s success is its customer-centric approach. The company works closely with textile manufacturers to understand their specific needs and challenges. This collaboration enables Svegea to tailor their cutting machines to meet the unique requirements of their clients.

Svegea offers comprehensive support and training to help manufacturers get the most out of their cutting machines. This support extends beyond the initial purchase, with ongoing maintenance and updates to ensure the machines continue to operate at peak efficiency. By prioritizing customer satisfaction, Svegea has built a loyal client base that values its innovative and eco-friendly solutions.

Svegea of Sweden is a pioneer in the textile industry, setting new standards with their eco-friendly cutting machines. By combining advanced technology with sustainable practices, Svegea is helping manufacturers reduce waste, improve efficiency, and meet the growing demand for environmentally responsible products. Its commitment to continuous improvement and customer satisfaction ensures that Svegea will remain a leader in the industry for years to come.

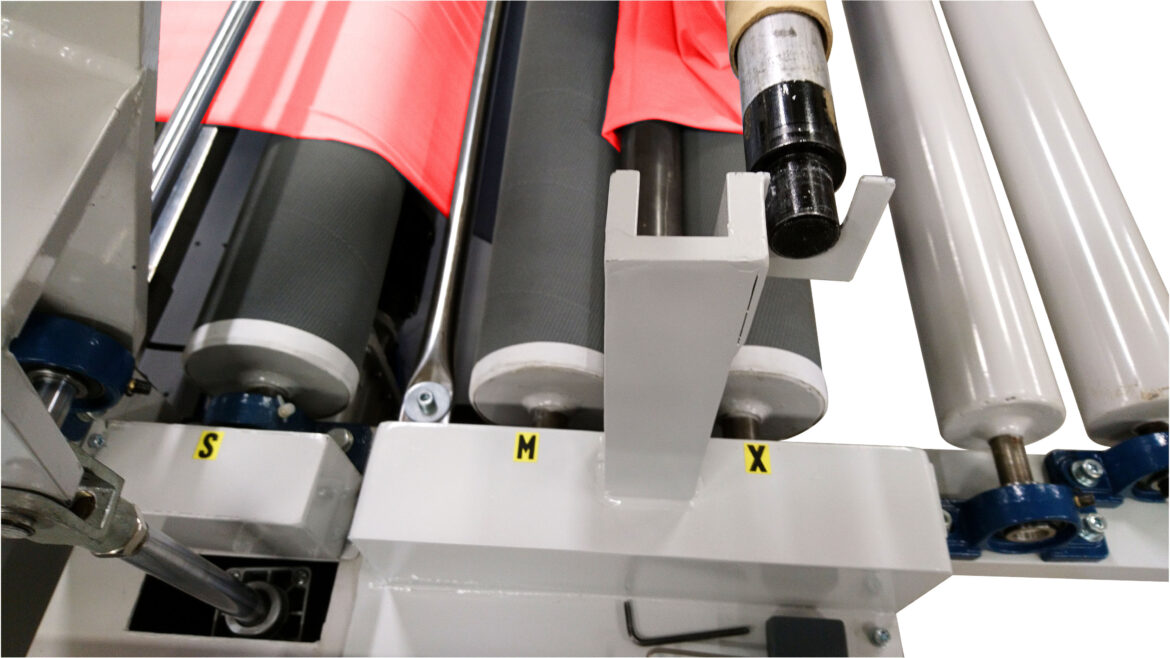

In the fast-paced world of textile manufacturing, precision and efficiency are paramount. The Roll-to-Roll Slitting Machine RRS-800 is a cutting-edge solution that meets these demands, allowing textile producers to optimize their processes and deliver high-quality products. In this article, we’ll explore the key features of this machine, its specifications, and its impact on the industry.

Key Features:

Motorized Knife with Adjustable Speed

The heart of this efficient slitting machine lies in its motorized knife. This advanced feature allows operators to control the cutting speed, ensuring precise slitting without compromising quality. Whether it’s delicate fabrics or heavy-duty materials, the RRS-800 adapts effortlessly.

Adjustable Cutting Widths

Flexibility is essential in textile production. This state-of-the-art textile machine achieves this by allowing operators to adjust cutting widths. By moving the placement of the knives, manufacturers can tailor the machine to their specific needs.

Optional Electronic Meter Counter

Keeping track of material usage is crucial for cost management. It offers an optional electronic meter counter, enabling real-time monitoring. This feature ensures efficient resource allocation and minimizes waste.

Pneumatic Lift Kit for Easy Loading and Start-Up

Loading and starting up a slitting machine can be labor-intensive. The RRS-800 streamlines this process with its pneumatic lift kit. Operators can effortlessly raise the knife shaft, reducing downtime and enhancing productivity.

Re-Rolling Efficiency

After slitting, re-rolling becomes essential. This cost-effective machine excels in this aspect by utilizing two independent air-expanding shafts. These shafts handle the re-rolling of slit rolls, ensuring uniform tension and preventing material distortion.

Three Shafts for Optimal Performance

The RRS-800 boasts a total of three shafts:

- One for the master roll

- Two for re-rolling

This configuration allows seamless transitions between processes, minimizing downtime and maximizing throughput.

Customizable Air-Shaft Sizes

Different materials require different handling. This slitting machine caters to this diversity by offering customizable air-shaft sizes upon request. Garment manufacturers can fine-tune the machine to match their specific textile types and dimensions.

The RRS-800 combines innovation, precision, and adaptability, making it a valuable asset for textile manufacturers worldwide. As the industry continues to evolve, machines like the RRS-800 are pivotal in meeting production demands while maintaining product quality.

The textile industry is undergoing a profound transformation, propelled by Artificial Intelligence (AI). Gone are the days dominated by manual labor; now, precision and efficiency reign supreme. Let’s explore the dynamic shift of AI in textile manufacturing:

1. AI Empowers Precision and Quality

AI-driven systems detect defects in fabrics, patterns, and colors before they escalate, ensuring top-notch quality and minimizing waste. These systems streamline production, guaranteeing consistency and excellence across products.

Moreover, AI algorithms analyze intricate designs with unmatched precision, ensuring every detail meets specifications. This meticulous scrutiny extends to color matching, maintaining uniformity and visual appeal throughout production.

2. The Rise of Smart Apparel

Welcome to the era of smart apparel, where AI and IoT converge to create functional and stylish clothing. Imagine garments that not only look good but also monitor vital signs seamlessly. Unlike conventional wearables, smart clothing provides continuous health monitoring for a holistic user experience.

3. Sustainable AI with Ultra-Low-Power Technologies

To harness AI sustainably, ultra-low-power (ULP) technologies are crucial. These energy-efficient solutions enable smart textiles to operate seamlessly without compromising resources. They are the backbone of a sustainable AI revolution in textile manufacturing.

Embracing a New Era

The fusion of AI and textiles heralds a new era of innovation and sustainability. It’s a future where precision, quality, and environmental consciousness drive progress. Embrace this transformative journey and stay ahead in the dynamic world of textile manufacturing.

Discover how Svegea, a leader in textile machinery from Sweden, leverages AI to revolutionize production. Their innovative solutions embrace AI’s potential, making manufacturing smarter, efficient, and eco-friendly.

Svegea of Sweden offers cutting-edge textile machinery that leverages AI to optimize production efficiency. Explore our pages more to dive into AI-driven textile solutions and be part of the transformative journey.

In recent years, the textile and clothing sector has undergone a significant transformation. The shift towards sustainability is driven by increasing awareness of environmental issues and the urgent need for change. This article explores the fascinating world of sustainable textiles, delving into eco-friendly materials, circular fashion, responsible manufacturing practices, and leading brands in the sustainable fashion movement.

Eco-Friendly Materials

The cornerstone of sustainable textiles lies in the use of eco-friendly materials. These materials not only reduce environmental impact but also offer innovative solutions for a greener future.

Organic Cotton

Organic cotton is grown without the use of synthetic pesticides or fertilizers. This method reduces soil and water contamination, promoting healthier ecosystems. Moreover, organic cotton farming practices enhance soil fertility and reduce water usage, making it a sustainable choice for textile production.

Tencel (Lyocell)

Tencel, also known as Lyocell, is a fiber derived from sustainably managed eucalyptus trees. The production process of Tencel is notable for its low environmental impact, including reduced water usage and minimal chemical input. Known for its softness and breathability, Tencel is an excellent choice for eco-conscious consumers.

Hemp

Hemp is a versatile plant that requires minimal water and no synthetic pesticides to grow. Its fibers are strong and durable, making hemp an ideal material for various textile applications. Additionally, hemp cultivation improves soil health by preventing soil erosion and enhancing soil structure.

Recycled Polyester

Recycled polyester is made from post-consumer plastic bottles. This process reduces plastic waste and conserves energy compared to producing virgin polyester. Recycled polyester offers a sustainable alternative to traditional synthetic fibers, supporting the reduction of plastic pollution.

Circular Fashion

Circular fashion is a concept that aims to create a closed-loop system in the textile industry. This approach focuses on designing products for longevity, recyclability, and minimal waste.

Closed-Loop Systems

Brands are increasingly adopting closed-loop systems, where products are designed to be easily recycled into new textiles. This approach reduces the need for virgin materials and minimizes waste. By rethinking product life cycles, companies can significantly lessen their environmental footprint.

Take-Back Programs

Many companies now offer take-back programs, encouraging customers to return old garments for recycling or repurposing. These programs extend the life of clothing items and reduce textile waste. Consumers are incentivized to participate through discounts or store credits, promoting a culture of sustainability.

Upcycling

Upcycling involves transforming discarded textiles into new, fashionable pieces. This creative approach reduces waste and adds unique value to otherwise unused materials. Designers and brands are increasingly embracing upcycling to create one-of-a-kind, eco-friendly products.

Responsible Manufacturing Practices

Sustainable textiles extend beyond materials and recycling; they encompass ethical and responsible manufacturing practices that prioritize the well-being of workers and the environment.

Fair Wages and Labor Conditions

Brands committed to sustainability ensure fair wages and safe working conditions for their employees. Ethical treatment of workers is a fundamental aspect of responsible manufacturing, promoting social justice within the industry.

Reducing Water Usage

Innovations in textile production have led to significant reductions in water usage. Techniques such as waterless dyeing and efficient washing processes help conserve this precious resource. By adopting these methods, brands can decrease their environmental impact and support sustainable water management.

Low-Impact Dyeing

The use of natural dyes or low-impact synthetic dyes is gaining traction as a sustainable alternative to traditional dyeing processes. These dyes reduce chemical pollution and lower the environmental footprint of textile production. Brands that prioritize low-impact dyeing contribute to cleaner waterways and healthier ecosystems.

Traceability and Transparency

Transparency in the supply chain allows consumers to make informed choices about the products they purchase. Brands that disclose detailed information about their sourcing, manufacturing processes, and labor practices build customer trust. Traceability ensures accountability and promotes ethical practices within the industry.

Leading Sustainable Brands

Several brands have emerged as leaders in the sustainable fashion movement. These companies set an example by prioritizing environmental and social responsibility.

1. Patagonia

Patagonia is renowned for its commitment to sustainability. The company uses recycled materials, supports fair labor practices, and promotes environmental activism. Patagonia’s dedication to transparency and ethical practices has made it a pioneer in sustainable fashion.

2. Eileen Fisher

Eileen Fisher emphasizes timeless designs, organic materials, and circular practices. The brand’s take-back program encourages customers to return old garments for recycling, promoting a circular economy. Eileen Fisher’s holistic approach to sustainability encompasses both environmental and social aspects.

3. Stella McCartney

Stella McCartney is a trailblazer in luxury sustainable fashion. The brand uses innovative materials such as vegan leather and recycled fabrics, prioritizing animal welfare and environmental impact. Stella McCartney’s designs showcase that sustainability and high fashion can coexist harmoniously.

4. Reformation

Reformation creates stylish clothing from eco-friendly fabrics. The brand’s commitment to sustainability is evident in its use of recycled materials, efficient production processes, and transparent supply chain. Reformation’s trendy designs appeal to fashion-forward consumers who prioritize sustainability.

5. Veja

Veja produces sneakers using sustainable materials such as organic cotton, wild rubber, and recycled plastic. The brand’s dedication to fair trade practices and environmental responsibility has earned it a loyal following. Veja’s innovative approach to sneaker production sets a high standard for sustainable footwear.

Not Just a Trend

Sustainable fashion is not just a trend; it is a crucial step towards a greener and more ethical industry. By embracing eco-friendly materials, circular fashion practices, and responsible manufacturing, the textile sector can significantly reduce its environmental impact. Leading brands like Patagonia, Eileen Fisher, Stella McCartney, Reformation, and Veja demonstrate that sustainability and style can go hand in hand.

Additionally, companies like Svegea of Sweden are making strides in sustainability with innovative textile machinery that supports efficient and eco-friendly production. Supporting these brands and making conscious purchasing decisions contribute to positive change in the industry.

The future of fashion lies in sustainability, and every step towards a greener wardrobe counts.

In an era where sustainability is not just a choice but a necessity, the story of sustainable natural fibers is a compelling narrative of environmental responsibility and traditional artisanship. This tale begins with the nurturing of seeds and ends with the creation of fabrics that embody both style and ecological consciousness.

The Seed of Sustainability

Every fiber’s journey starts with a seed, a sapling, or a fleece. Farmers globally cultivate plants like cotton, flax, or hemp, or rear animals for wool and silk. These sustainable natural fibers are gifts from the earth, renewable and biodegradable, contrasting sharply with synthetic fibers made from petrochemicals.

Cultivation with Care

The art of growing sustainable natural fibers involves a delicate balance between yield and environmental care. Techniques such as crop rotation, organic farming, and integrated pest management minimize ecological damage. Despite challenges like water consumption for cotton or the fragility of silk production, these practices ensure the fibers’ sustainability.

Harvesting with Heritage

Harvesting these fibers often involves age-old traditions, with methods handed down through generations. Whether it’s picking cotton, processing flax, or shearing sheep, these actions are performed with a precision that reflects a deep harmony with nature.

Spinning Stories

Post-harvest, the fibers travel to mills to be cleaned, carded and spun into yarn. This stage is where modern technology meets human expertise. Artisans and workers apply their skills to guarantee the yarn’s quality, influencing the fabric’s eventual texture and strength.

Weaving Worlds

The yarn then transforms into fabric through weaving or knitting. This process can occur on simple handlooms in rural settings or through sophisticated machinery in modern factories. Here, the fabric acquires its unique patterns and characteristics, ready for dyeing, printing, and finishing.

The yarn then transforms into fabric through weaving or knitting. This process can occur on simple handlooms in rural settings or through sophisticated machinery in modern factories. Here, the fabric acquires its unique patterns and characteristics, ready for dyeing, printing, and finishing.

Dyeing with Diligence

The dyeing process adds color to the sustainable natural fibers, with a growing preference for eco-friendly dyes derived from plants and minerals. These methods are not only less polluting but also reconnect us with ancient, earth-friendly practices.

Fashioning Fabrics

The penultimate phase is turning the fabric into garments. Designers and tailors are crucial here, as they convert the fabric into wearable art. The slow fashion movement is fostering an appreciation for the narrative and quality behind each piece.

Challenges and Opportunities

The supply chain for sustainable natural fibers faces challenges like price volatility and competition from synthetics. However, the industry is ripe with opportunities, particularly sustainably and ethically.

The Road Ahead

As awareness grows, so does the demand for sustainable natural fibers. The industry is innovating at every supply chain level, ensuring that the path from farm to fabric remains both sustainable and enriching.

Craft Your Sustainable Legacy

For those inspired by the sustainable journey of natural fibers and seeking precision in their textile projects, Svegea of Sweden is a beacon of excellence. With over 72 years of experience in creating high-quality textile cutting systems, they epitomize the commitment to the enduring value of natural fibers. To discover how their state-of-the-art solutions can enhance the sustainability and quality of your work, visit their contact page. Together, let’s craft a future that respects our planet with every fiber.