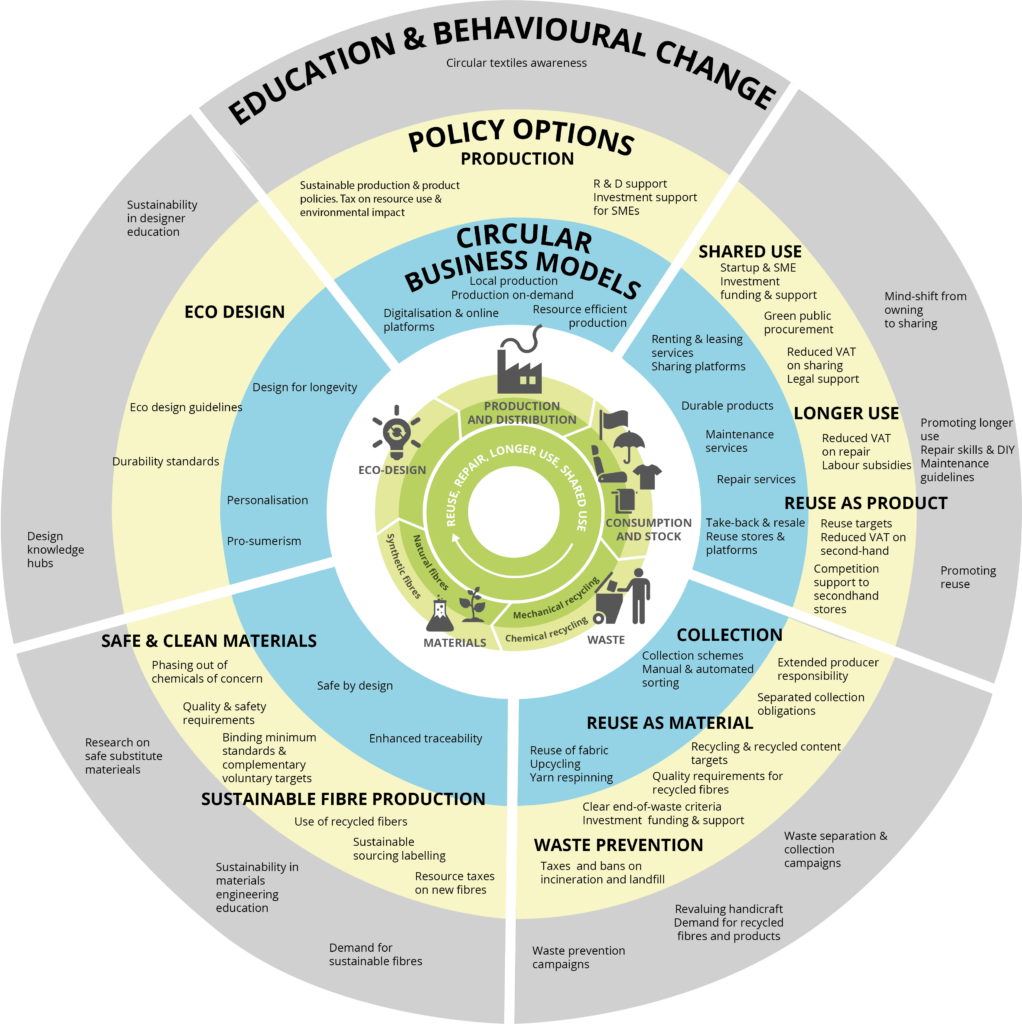

In an era where sustainability is paramount, the circular economy offers a transformative approach to how we produce and consume goods. Central to this concept are closed-loop systems and circular design, both of which aim to minimize waste and make the most of our resources.

Understanding Closed-Loop Systems

Closed-loop systems are designed to create a continuous cycle of use and reuse, effectively reducing waste. In these systems, the output of one process becomes the input for another, ensuring that materials are constantly recycled and repurposed. This approach not only conserves resources but also significantly reduces environmental impact.

The Importance of Circular Design

The circular design is a key element of the circular economy. It involves designing products with their entire lifecycle in mind, from creation to disposal. Circular design focuses on durability, reparability, and recyclability, making products easy to disassemble and reuse. This process reduces the need for new raw materials and minimizes waste.

Strategies for Minimizing Waste

Minimizing waste is a fundamental goal of the circular economy. This process is achievable through various strategies, including:

- Design for Longevity: Creating products that last longer and are easily repairable.

- Material Innovation: Using materials that are easier to recycle and have a lower environmental impact.

- Efficient Manufacturing: Implementing processes that reduce waste and improve resource efficiency.

Real-World Applications

Many companies are now adopting circular principles to enhance sustainability. For instance, in the textile industry, some manufacturers are focusing on producing high-quality trim that aligns with circular design principles. By ensuring that their products are durable and recyclable, these companies contribute to a more sustainable future.

The Benefits of a Circular Economy

The shift towards a circular economy offers numerous benefits:

- Environmental Sustainability: By reducing waste and conserving resources, the circular economy helps protect the environment.

- Economic Efficiency: Reusing materials and improving efficiency can lead to cost savings for businesses.

- Innovation and Growth: The circular economy encourages innovation, leading to new business opportunities and economic growth.

Representing a Significant Shift

The circular economy represents a significant shift in how we think about production and consumption. By embracing closed-loop systems and circular design, we can minimize waste and make better use of our resources. This approach not only benefits the environment but also offers economic advantages.

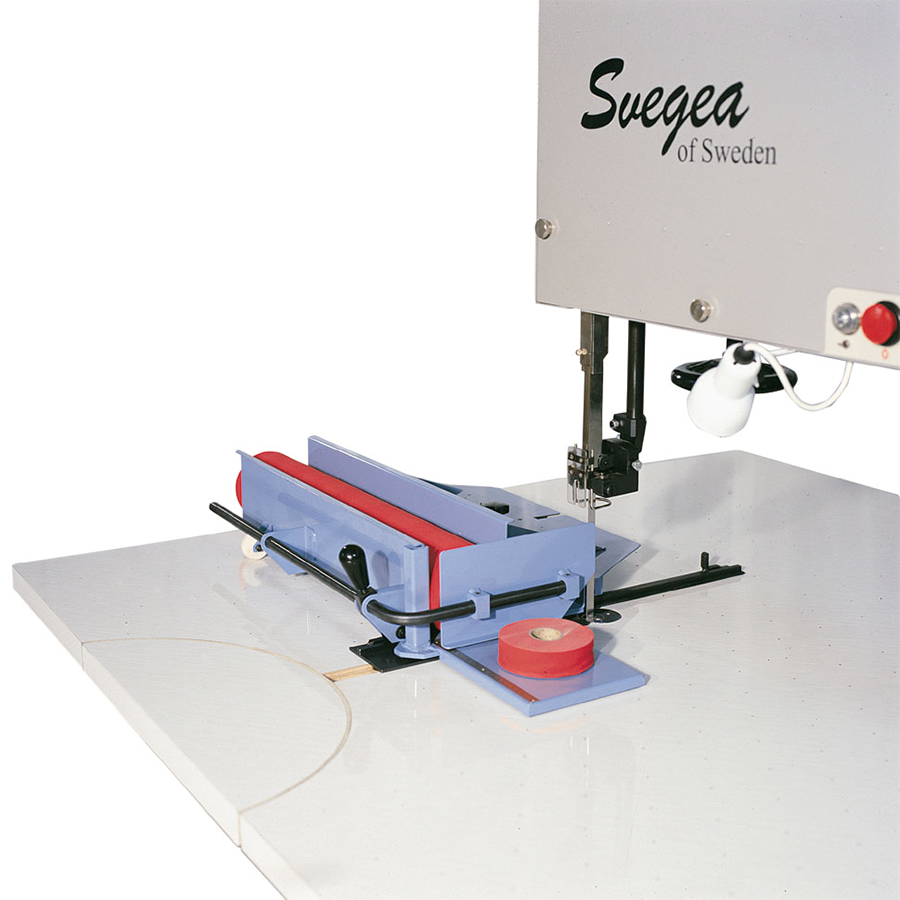

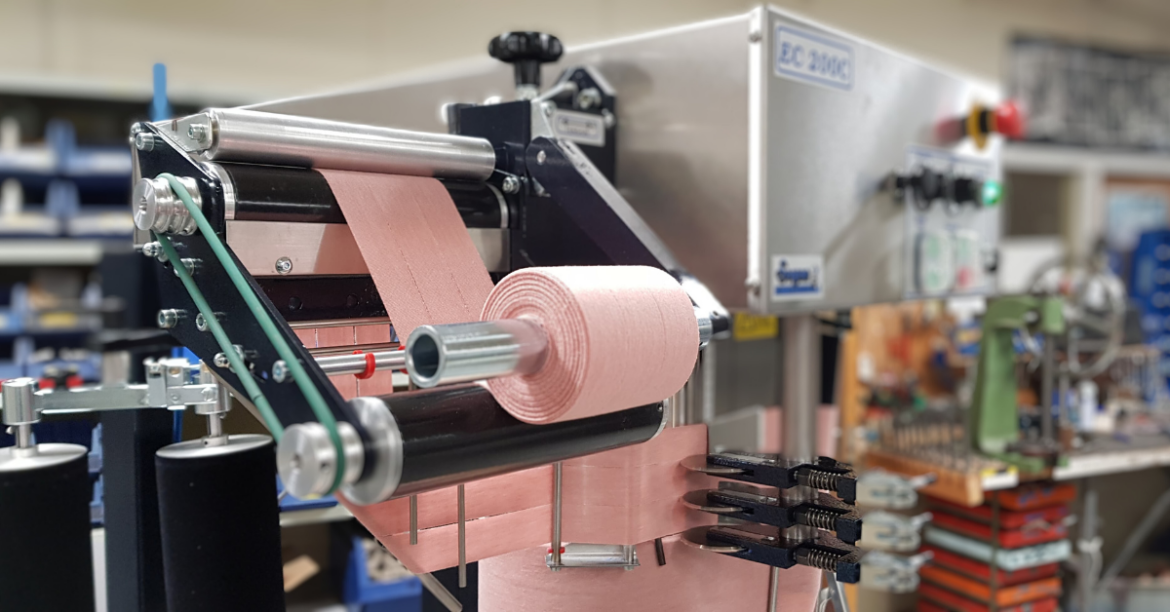

Sustainable Textile Manufacturing

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

To learn more about how quality trim can align with circular principles, visit Svegea’s contact page and discover their commitment to sustainability.

Smart textiles, also known as electronic or e-textiles, represent a groundbreaking fusion of fashion and technology. These textiles go beyond mere wearability; they are programmable, interactive, and functional. In this article, we’ll explore what smart fabrics are, provide real-life examples, and discuss their future implications.

What Are Smart Materials?

Also called intelligent or responsive materials, these types of fabrics automatically respond to external stimuli such as temperature changes, light, pressure, or electric fields. Unlike traditional materials with static properties, interactive materials can adapt and change their properties based on environmental conditions. For instance:

– Piezoelectric materials generate voltage when pressure is applied.

– Shape memory alloys return to their original form after deformation.

– Thermochromic materials change color with temperature variations.

Enter Smart Fabrics

A subset of smart materials, these special fabrics embed digital components directly into textiles. These fabrics can:

- Conduct electricity

- React to environmental changes

- Gather and transmit data

- Incorporate embedded LED lights

Examples of Intelligent Fabrics

1. Thermochromic Fabrics: These fabrics change color in response to temperature variations, finding applications in fashion and safety gear.

2. Conductive Fabrics: Embedded with conductive threads, these fabrics transmit electrical signals and are used in wearable electronics.

3. Self-Healing Fabrics: Developed with materials that repair themselves after being punctured or torn.

Cutting-Edge Innovations

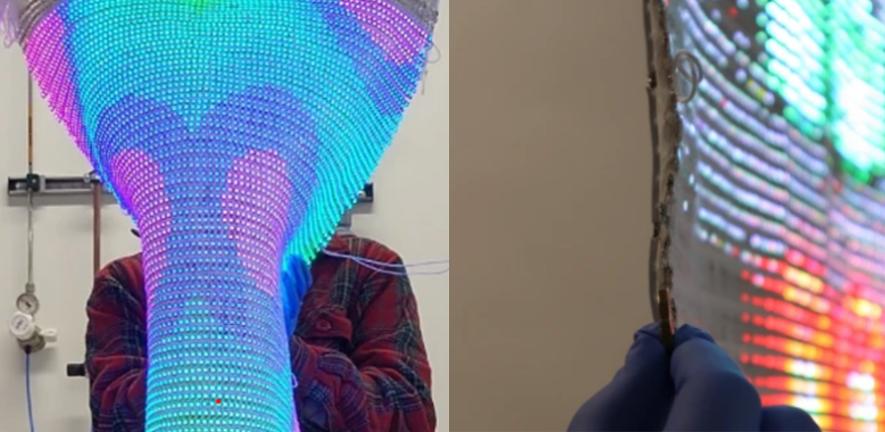

Researchers at Cambridge University have woven a 46-inch textile display loaded with LEDs, sensors, and energy storage. This e-textile can display different images or colors based on input from fiber-based devices like light, touch, and temperature sensors. The textile’s multi-functionality and compatibility with existing industrial manufacturing processes make it truly unique.

Image Source: https://www.cam.ac.uk/research/news/scientists-develop-fully-woven-smart-display

Healthcare and Beyond

Responsive fabrics embedded with sensors could transform everyday clothing into interactive devices. Imagine garments that track health metrics or provide real-time environmental feedback.

Tech textiles are more than just fabrics; they’re a canvas for innovation, bridging the gap between style and functionality. As technology advances, we can expect even more exciting developments in this field.

Remember, the future of fashion isn’t just about what you wear—it’s about what your clothes can do for you!

Luxury has evolved beyond mere opulence and exclusivity. It now tells the story of each design piece, highlighting meticulous craftsmanship and a commitment to ethical and sustainable practices. This article explores the world of high-end textiles, with fabric production as its cornerstone.

The Artisans and Their Craft

At the heart of luxury textiles are talented artisans. These skilled craftsmen and women create exquisite fabrics with unparalleled attention to detail. Every stitch, cut, and curve reflects their dedication, driving the continuous evolution of luxury with highly sought-after designs.

Slow Design and Bespoke Quality

Artisanal textiles are deeply rooted in craftsmanship. Unlike mass-produced goods, these items are created meticulously and thoughtfully. This movement, known as Slow Design, celebrates quality over quantity. Each piece is a unique work of art, reflecting the artisan’s expertise and passion.

The Journey from Fiber to Fabric

1. Fiber Selection: Luxury textiles begin with carefully chosen raw materials. Whether it’s silk, cashmere, or organic cotton, the quality of the fiber sets the foundation for the final product.

2. Spinning and Weaving: Artisans spin the fibers into yarns, which are then woven into fabric. Jacquard looms, guided by intricate patterns, produce complex designs that grace haute couture and high-end interiors.

3. Dyeing and Finishing: Artisans meticulously curate the color palette and apply dyes precisely. Finishing techniques—such as mercerization or calendering—enhance texture and luster.

4. Hand Embellishments: Embroidery, beading, and appliqué add a touch of luxury. Skilled hands transform plain fabric into wearable art.

The Role of Svegea of Sweden

Svegea of Sweden, a renowned textile machinery manufacturer, plays a crucial role in luxury fabric production. Their cutting-edge machines enable precise weaving, intricate patterns, and flawless finishes. From jacquard looms to automated knitting devices, Svegea’s technology empowers artisans to create fabrics that define luxury.

Subscribe to our blog for more insights into the world of luxury textiles, craftsmanship, and sustainable practices. Stay informed and inspired as we unravel the secrets behind high-end fabrics.

In the ever-evolving textile industry, innovation, and sustainability are paramount. One company leading the charge in this space is Svegea of Sweden. Renowned for its state-of-the-art cutting machines, Svegea combines advanced technology with eco-friendly practices to revolutionize textile manufacturing.

The Rise of Eco-Friendly Cutting Machines

As the demand for sustainable solutions in the textile industry grows, Svegea has positioned itself at the forefront. The company’s cutting machines are designed with a strong emphasis on reducing environmental impact. These machines not only enhance efficiency but also minimize waste, setting a new standard for eco-friendly manufacturing.

Svegea’s cutting machines incorporate several features that make them stand out. Firstly, they use energy-efficient motors that consume less power, resulting in lower carbon emissions. Additionally, the precision of these machines ensures that fabric waste is significantly reduced. This is a major concern in traditional textile production methods.

Innovative Technology for a Greener Future

Svegea’s commitment to sustainability goes beyond just reducing waste. Their cutting machines are equipped with advanced technology that supports the use of recycled materials. This capability is crucial for textile manufacturers aiming to meet the increasing consumer demand for eco-friendly products.

One of the key technological advancements in Svegea’s machines is the integration of AI-driven precision cutting. This technology allows for optimal use of fabric, ensuring that every inch of material is utilized effectively. By maximizing fabric use, manufacturers can significantly cut down on waste, contributing to a greener future.

Efficiency Meets Sustainability

Efficiency and sustainability are often seen as two competing goals in manufacturing. However, Svegea has successfully merged these two objectives with their cutting machines. The company’s machines are designed to deliver high-speed cutting without compromising on quality or environmental standards.

Svegea’s machines also feature user-friendly interfaces that allow operators to quickly adapt to new cutting patterns and materials. This adaptability not only enhances productivity but also reduces downtime, leading to more efficient production cycles. By streamlining operations, manufacturers can achieve higher output while maintaining sustainable practices.

Reducing Environmental Impact

The textile industry has long been criticized for its environmental footprint. Traditional cutting methods often result in significant fabric waste, contributing to landfill overflows and environmental degradation. Svegea addresses this issue head-on with their cutting-edge machines.

Svegea engineers their cutting machines to minimize fabric waste using precise cutting technology. This precision not only reduces waste but also maintains the quality of the cut pieces. By producing more usable fabric pieces per roll, Svegea helps manufacturers reduce their material costs and environmental impact.

Commitment to Continuous Improvement

A sustainability-conscious company demonstrates its dedication to innovation through its continuous efforts to improve its cutting machines. The company invests heavily in research and development to stay ahead of industry trends and meet the evolving needs of textile manufacturers.

Svegea regularly updates its machines with the latest technological advancements. This commitment to continuous improvement ensures that their cutting machines remain at the forefront of the industry. They do so while providing manufacturers with the best possible tools for sustainable production.

Customer-Centric Approach

At the heart of Svegea’s success is its customer-centric approach. The company works closely with textile manufacturers to understand their specific needs and challenges. This collaboration enables Svegea to tailor their cutting machines to meet the unique requirements of their clients.

Svegea offers comprehensive support and training to help manufacturers get the most out of their cutting machines. This support extends beyond the initial purchase, with ongoing maintenance and updates to ensure the machines continue to operate at peak efficiency. By prioritizing customer satisfaction, Svegea has built a loyal client base that values its innovative and eco-friendly solutions.

Svegea of Sweden is a pioneer in the textile industry, setting new standards with their eco-friendly cutting machines. By combining advanced technology with sustainable practices, Svegea is helping manufacturers reduce waste, improve efficiency, and meet the growing demand for environmentally responsible products. Its commitment to continuous improvement and customer satisfaction ensures that Svegea will remain a leader in the industry for years to come.

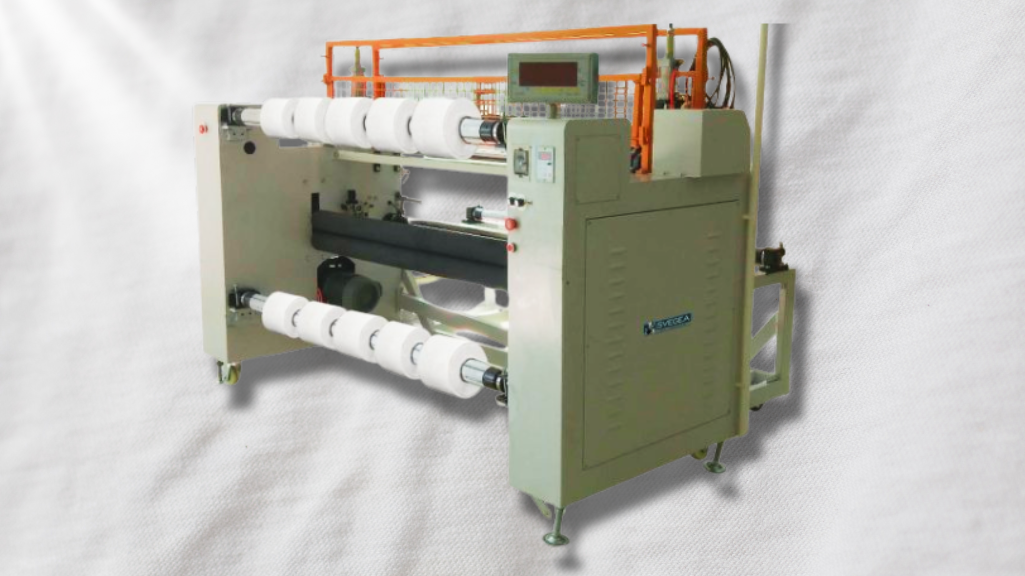

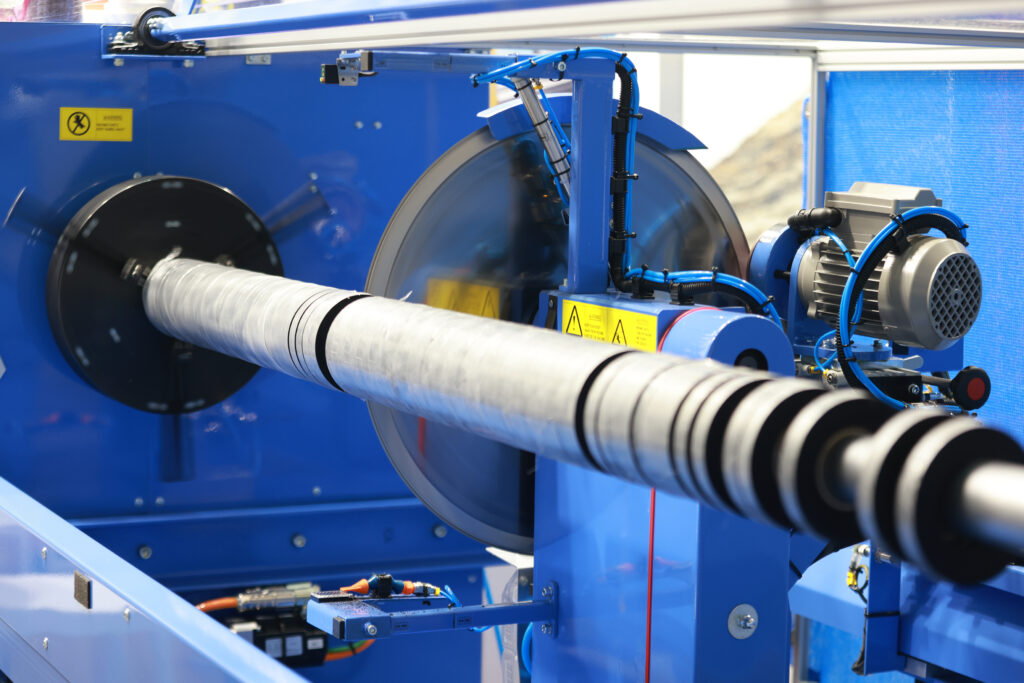

In the fast-paced world of textile manufacturing, precision and efficiency are paramount. The Roll-to-Roll Slitting Machine RRS-800 is a cutting-edge solution that meets these demands, allowing textile producers to optimize their processes and deliver high-quality products. In this article, we’ll explore the key features of this machine, its specifications, and its impact on the industry.

Key Features:

Motorized Knife with Adjustable Speed

The heart of this efficient slitting machine lies in its motorized knife. This advanced feature allows operators to control the cutting speed, ensuring precise slitting without compromising quality. Whether it’s delicate fabrics or heavy-duty materials, the RRS-800 adapts effortlessly.

Adjustable Cutting Widths

Flexibility is essential in textile production. This state-of-the-art textile machine achieves this by allowing operators to adjust cutting widths. By moving the placement of the knives, manufacturers can tailor the machine to their specific needs.

Optional Electronic Meter Counter

Keeping track of material usage is crucial for cost management. It offers an optional electronic meter counter, enabling real-time monitoring. This feature ensures efficient resource allocation and minimizes waste.

Pneumatic Lift Kit for Easy Loading and Start-Up

Loading and starting up a slitting machine can be labor-intensive. The RRS-800 streamlines this process with its pneumatic lift kit. Operators can effortlessly raise the knife shaft, reducing downtime and enhancing productivity.

Re-Rolling Efficiency

After slitting, re-rolling becomes essential. This cost-effective machine excels in this aspect by utilizing two independent air-expanding shafts. These shafts handle the re-rolling of slit rolls, ensuring uniform tension and preventing material distortion.

Three Shafts for Optimal Performance

The RRS-800 boasts a total of three shafts:

- One for the master roll

- Two for re-rolling

This configuration allows seamless transitions between processes, minimizing downtime and maximizing throughput.

Customizable Air-Shaft Sizes

Different materials require different handling. This slitting machine caters to this diversity by offering customizable air-shaft sizes upon request. Garment manufacturers can fine-tune the machine to match their specific textile types and dimensions.

The RRS-800 combines innovation, precision, and adaptability, making it a valuable asset for textile manufacturers worldwide. As the industry continues to evolve, machines like the RRS-800 are pivotal in meeting production demands while maintaining product quality.

The dynamic world of textile design and manufacturing is driven by innovation, shaping the industry’s future. From embracing sustainable practices to integrating cutting-edge technology, there’s a profound evolution underway. This shift promises enhanced efficiency and a more environmentally conscious approach to production. It’s an exciting time where creativity meets sustainability in every thread of the textile industry.

Sustainability in Textile Design:

Consumers increasingly demand eco-friendly products, prompting manufacturers to adopt sustainable practices throughout production. Svegea of Sweden, a leader in sustainable textile machinery innovations, champions sustainability with its state-of-the-art equipment designed to reduce waste and energy consumption while maintaining high-quality standards.

Digitalization and Efficiency:

The integration of digital technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) has revolutionized manufacturing processes. Svegea’s advanced machines leverage AI algorithms to optimize production efficiency, ensuring precise cuts and minimizing material wastage.

Customization for Consumer Preferences:

Customization is key as consumers increasingly desire unique and personalized products. Manufacturers are responding by offering customizable solutions tailored to consumer preferences. Svegea of Sweden collaborates with industry leaders to deliver intricate designs and patterns, meeting the growing demand for personalized textiles.

Collaborative Innovation:

Industry players are forging strategic partnerships to leverage collective expertise and resources. Svegea’s collaboration with textile industry leaders fosters innovation and knowledge exchange, driving continuous improvement in design and manufacturing processes.

Automation for Productivity:

Automated systems streamline production, reduce manual labor, and improve overall efficiency. The latest automated textile machines incorporate advanced robotics and AI, ensuring consistent quality across production batches.

Smart Textiles and Future Possibilities:

The adoption of smart textiles embedded with sensors and actuators is revolutionizing wearable technology. Innovative machines play a crucial role in producing smart textiles, paving the way for advancements in functionality and user experiences.

As we embrace sustainability, digitalization, customization, collaboration, automation, and smart textiles, the textile industry is poised for a future defined by innovation and efficiency. Explore Svegea’s innovative solutions to stay ahead in the evolving textile landscape and drive your business toward success.

The textile industry is undergoing transformative changes driven by trends around sustainability, automation, customization, and circularity. Leading machinery manufacturers offer cutting-edge solutions to help textile producers capitalize on these powerful market shifts.

Sustainability Imperative

Environmental consciousness is fueling the demand for eco-friendly textiles, currently, a global textile trend that we cannot ignore. Innovative machinery enables sustainable manufacturing practices like energy efficiency and waste reduction, minimizing environmental impact while maintaining competitive operations.

Automation & Industry 4.0

Principles like robotics, AI, and IoT are optimizing production through automation. Advanced textile machinery seamlessly integrates these technologies to streamline operations, boost productivity, and reduce costs – keeping manufacturers at the forefront of the digital revolution.

Customization & Diversification

Evolving consumer tastes favor personalized products and unique experiences. Flexible machinery allows for customized, diverse offerings tailored to changing market demands.

Circular Economy Transition

Resource efficiency is paramount, with textile circularity reducing waste. Circular knitting machines and recycling technologies enable closed-loop supply chains by repurposing waste into new materials.

As these trends reshape the global landscape, machinery manufacturers position textile producers for success. By adopting innovative solutions for sustainability, automation, customization, and circularity, industry leaders can drive sustainable growth and gain a lasting competitive edge.

For inquiries, brochures, or further information about Svegea of Sweden’s cutting-edge textile machinery, visit our contact page.

In the ever-evolving realm of sewn product manufacturing, optimizing profitability hinges on a delicate balance of precision, efficiency, and cost-effectiveness. This balance is particularly crucial in textile-cutting machines, where every cut impacts material utilization and production output. Svegea of Sweden stands out as a leader in this arena, offering cutting-edge machines tailored to meet the diverse needs of the industry.

Precision and Efficiency

Svegea’s textile cutting machines epitomize precision and efficiency, crucial elements that directly impact profitability. Engineers design these machines with advanced technology that ensures precise cuts, minimizing material wastage and maximizing resource utilization. Svegea machines excel in handling diverse cutting requirements with unparalleled accuracy, translating into significant cost savings and increased profitability for businesses.

Customization for Unique Manufacturing Needs

Customization for Unique Manufacturing Needs

A defining feature of Svegea machines is their customizable nature, meticulously crafted to address the unique challenges faced by businesses in garment manufacturing. Through collaborative customization processes, Svegea works closely with clients to understand their specific requirements and tailor machines accordingly. This tailored approach results in machines that seamlessly integrate into the client’s production processes, optimizing efficiency, reducing downtime, and ultimately, enhancing ROI.

Enhanced Productivity and Reduced Labor Costs

Svegea’s textile-cutting machines are designed to streamline production processes and enhance overall productivity. The integration of PLC-controlled operations, adjustable cutting speeds, and automatic blade sharpening mechanisms ensures smooth and uninterrupted workflow. This increased productivity not only accelerates production cycles but also reduces labor costs by minimizing the need for manual intervention, freeing up workforce resources for other value-added tasks.

Optimized Material Utilization

Efficient material utilization is paramount in sewn product manufacturing to minimize waste and maximize resource efficiency. Svegea engineers its machines to optimize material usage through precise cutting techniques and customizable settings. This results in minimal material wastage, leading to significant cost savings and improved profitability over time.

Scalability and Future-Readiness

Scalability and future readiness are critical considerations for businesses aiming for sustained success in the competitive landscape of garment manufacturing. Svegea designs its textile-cutting machines with scalability in mind, accommodating varying production volumes and evolving business needs. Ongoing R&D keeps Svegea ahead with future-ready solutions for evolving industry trends and challenges.

Integrating Svegea’s textile cutting machines into sewn product manufacturing processes presents a compelling opportunity for businesses to maximize ROI. Through precision, efficiency, customization, and scalability, Svegea machines offer a comprehensive solution that enhances productivity, reduces costs, and drives profitability. Investing in Svegea tech positions businesses for long-term success in sewn product manufacturing.

Tell us how we can enhance your production’s efficiency and ROI!

In the manufacturing sector, precision and efficiency are paramount. Svegea of Sweden has long been a pioneer in innovation, providing cutting-edge solutions tailored to diverse manufacturing needs. Their standout approach involves customizing machines to precisely match clients’ demands, showcasing the adaptability and versatility of their products.

Understanding Unique Manufacturing Needs

Every manufacturing process poses unique challenges. Material specifications, production volumes, and intricate cutting requirements vary widely. Svegea recognizes the critical importance of grasping these distinct needs to deliver optimal solutions. This understanding begins with an in-depth consultation process, where Svegea’s expert team collaborates closely with clients to gain comprehensive insights into their operations and objectives.

Collaborative Customization Process

The journey toward customized solutions starts with an in-depth assessment of the client’s manufacturing environment. Svegea’s engineers meticulously analyze factors such as material properties, production workflows, and desired outcomes. This collaborative approach ensures that every aspect of the machine’s design and functionality is precisely aligned with the client’s goals.

Flexibility in Design and Functionality

Svegea’s range of cutting machines, including the Strip Cutter CMS series and the Strip Cutter FA 500, offers exceptional flexibility in both design and functionality. This inherent flexibility enables seamless customization to accommodate diverse material types, varying thicknesses, and complex cutting requirements. Svegea’s machines can be fine-tuned to excel in diverse manufacturing environments.

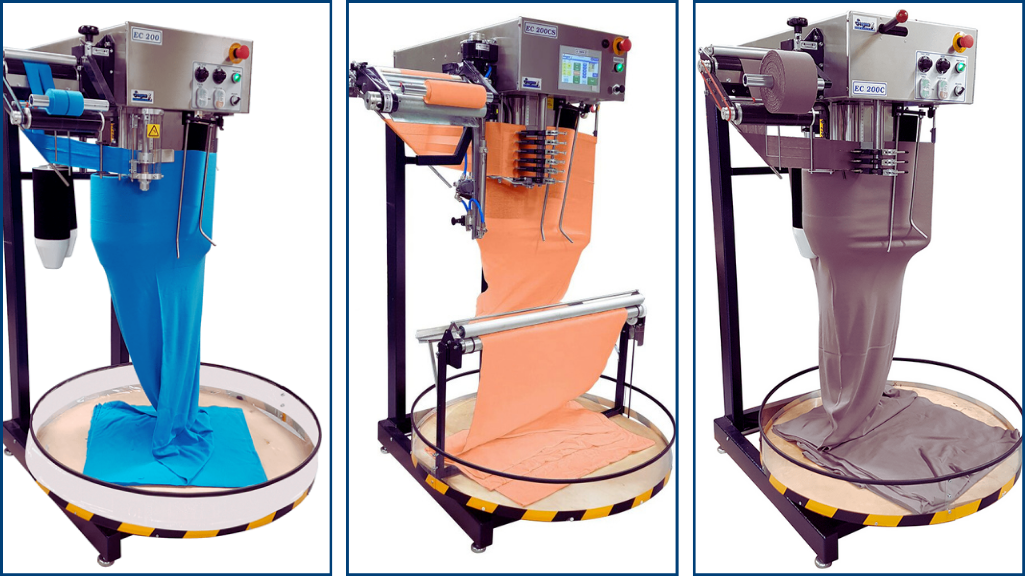

Fully Automatic Collarette Cutter Series: Customizable Excellence

A flagship product in Svegea’s lineup, the Fully Automatic Collarette Cutter series exemplifies the company’s dedication to customization. Meticulously designed to meet the specific needs of garment manufacturers, these state-of-the-art machines certainly boost production. They offer a wide array of customization options tailored to suit varying production specifications. From adjustable cutting speeds to meticulously configured blade setups, Svegea’s Fully Automatic Collarette Cutter series can be finely tuned to optimize garment production processes and elevate overall efficiency.

Advanced Technology for Tailored Solutions

Central to Svegea’s ability to deliver tailored solutions is its substantial investment in advanced technology. The seamless integration of PLC-controlled operations, adjustable cutting speeds, and automatic blade sharpening mechanisms ensures that customized machines not only meet but surpass client expectations. Heightened productivity, reduced material wastage, and enhanced overall efficiency result from this.

Real-World Applications

The success stories of Svegea’s customized solutions resonate across various industries. Clients in the textile sector have reaped substantial benefits from machines that flawlessly handle intricate patterns and multiple fabric layers, thereby optimizing production processes and curbing labor costs.

Future-Ready Solutions

As manufacturing landscapes evolve and technologies continue to advance, Svegea remains steadfast in its commitment to delivering future-ready solutions. This includes ongoing research and development efforts aimed at integrating AI-driven optimizations, predictive maintenance capabilities, and connectivity features. These innovations enable remote monitoring and control, ensuring that Svegea machines not only meet current needs but also adapt seamlessly to emerging challenges and opportunities.

In the ever-evolving realm of manufacturing, customization stands as a pivotal pillar for staying competitive and meeting dynamic demands. The company’s unwavering commitment to tailored solutions underscores its dedication to empowering clients with cutting-edge technology precisely tailored to their unique manufacturing needs. They continue to be a trusted partner for industries seeking optimized and efficient manufacturing solutions. Svegea does the process by seamlessly blending expertise, collaboration, and advanced engineering.

Drop us a line and share how we can assist you! Connect with us via email at info@svegea.se. We’re eager to hear from you!

In the fast-paced realm of textile manufacturing, precision and innovation reign supreme, shaping industry standards and pushing boundaries. Svegea of Sweden AB emerges as a beacon of cutting-edge technology, offering a wide array of products and services that redefine the textile landscape.

Cutting-Edge Technology

A steadfast commitment to cutting-edge technology lies at the core of Svegea’s success. The Svegea EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, epitomizes this dedication. This advanced system achieves unparalleled precision and efficiency, setting new benchmarks in production excellence. From automatic roll cutting/slitting machines like the SWS to the Strip Cutter CMS-1800A3, Svegea’s lineup showcases technological prowess.

Product Portfolio

Diversity and quality define Svegea’s product portfolio. The Tube Sewing Unit 200, Roll to Roll Slitter RRS 800, and Strip Cutter FA 600 are just a glimpse of the diverse offerings tailored to meet the textile industry’s demands. The Euro Collarette range, featuring models like the EC200C and EC200CS, is designed for exceptional performance, ensuring seamless operations and optimal results.

Global Presence and Bespoke Services

With a global presence extending across continents, Svegea delivers innovative solutions and bespoke services to clients worldwide. Whether it’s fabric inspection machines such as the CMI 210 R or the Complete Bias System, Svegea’s commitment to meeting client needs remains steadfast. Their tailored approach ensures that each solution addresses specific requirements, ensuring customer satisfaction and success.

Award-Winning Innovation

Svegea’s relentless pursuit of excellence has earned them recognition and accolades in the textile industry. Their award-winning innovation is evident in every product, from the Tube Sewing Unit 200 A/AF to the Euro Collarette range. This dedication to pushing boundaries positions Svegea as a leader in innovation and customer satisfaction.

Svegea of Sweden AB stands as a testament to innovation, quality, and customer-centricity in the textile industry. With cutting-edge technology, a diverse product portfolio, a global presence, bespoke services, and award-winning innovation, Svegea continues to redefine standards and shape the future of textile manufacturing. Experience excellence with Svegea – where innovation meets precision, and possibilities are limitless.