As we step into 2025, the textile manufacturing industry is poised for significant transformations. Driven by technological advancements and evolving consumer demands, the industry is embracing new trends that promise to reshape the landscape. This blog explores the key textile trends for 2025, highlighting how innovative solutions are leading the charge.

Sustainability Takes Center Stage

Sustainability continues to be a dominant trend in textile manufacturing. Consumers are increasingly demanding eco-friendly products, pushing manufacturers to adopt sustainable practices. In 2025, we will see a rise in the use of organic and recycled materials, such as organic cotton, bamboo, and Tencel. These materials are not only environmentally friendly but also offer superior quality and comfort.

Moreover, manufacturers are focusing on reducing their carbon footprint by optimizing production processes and minimizing waste. Advanced textile machinery, such as cutting-edge collarette cutting systems, exemplifies this commitment to sustainability. These systems reduce fabric waste and enhance production efficiency, aligning with the industry’s green goals.

The Rise of Smart Textiles

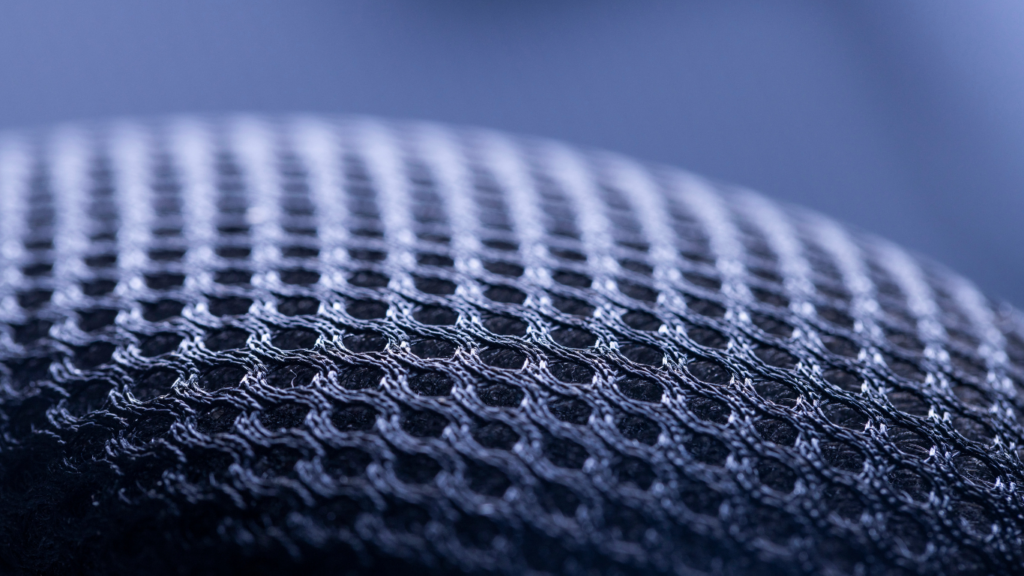

Smart textiles are revolutionizing the industry by integrating advanced technology into fabrics. These textiles can monitor health, regulate temperature, and even change color based on environmental conditions. In 2025, we expect to see more widespread adoption of smart textiles in various applications, from fashion to healthcare.

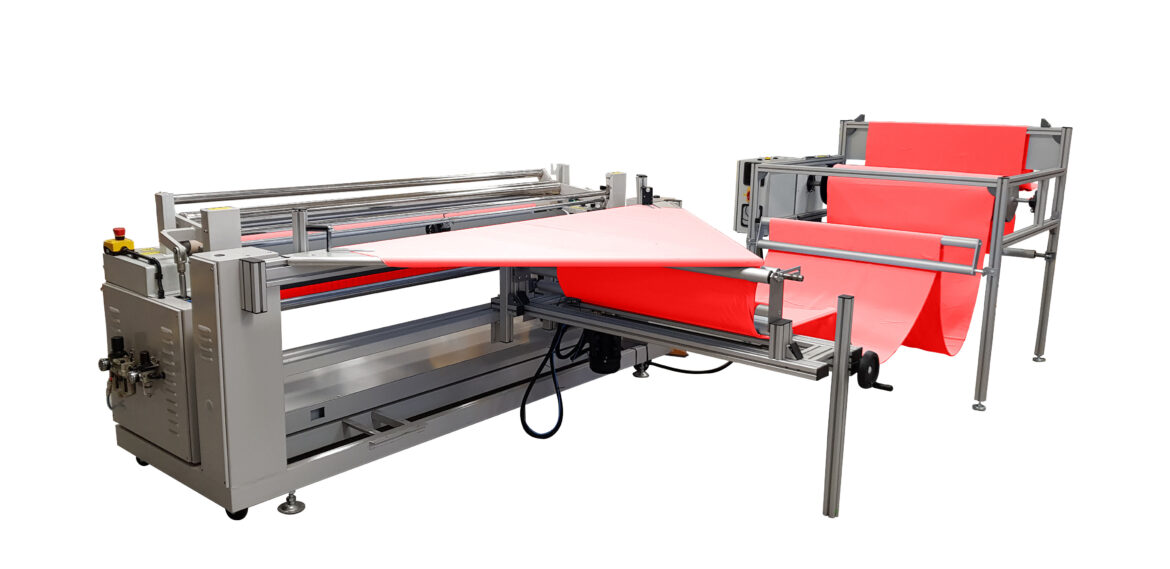

Innovative solutions are at the forefront of this trend. Automated systems, like advanced roll-cutting/slitting machines, incorporate cutting-edge technology to enhance precision and efficiency. These advancements not only improve product quality but also open new possibilities for smart textile applications.

Digital Printing Innovations

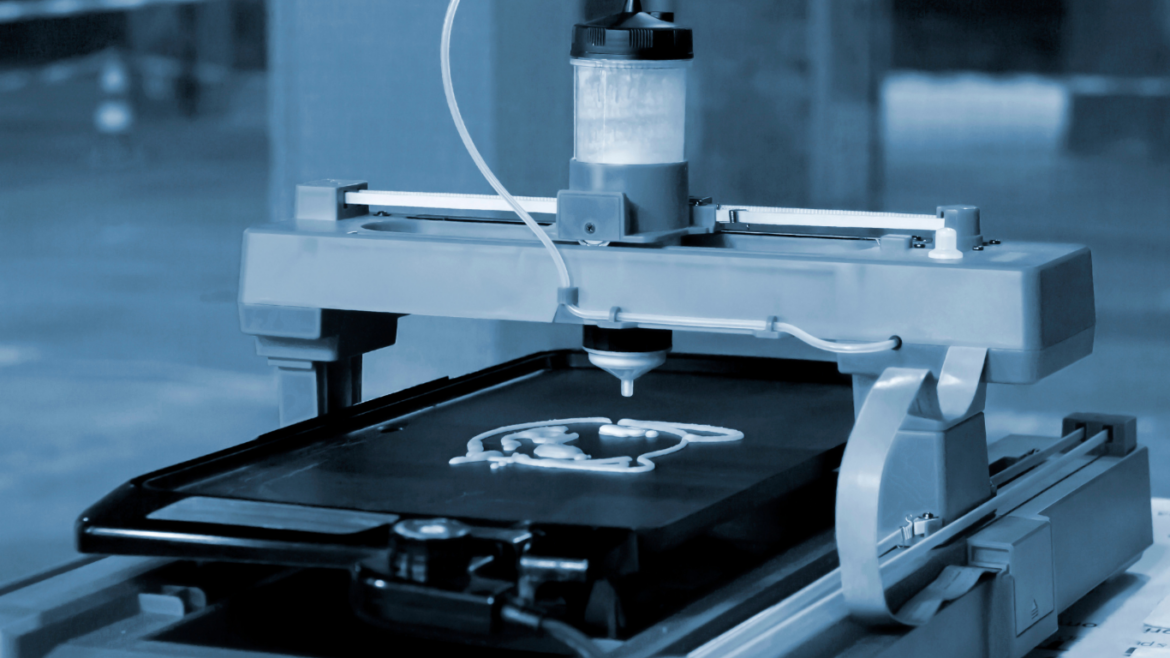

Digital printing is transforming textile design by allowing for greater creativity and customization. Traditional printing methods are being replaced by digital techniques that enable intricate designs and vibrant colors. This trend is expected to grow in 2025, with more manufacturers adopting digital printing to meet consumer demands for unique and personalized products.

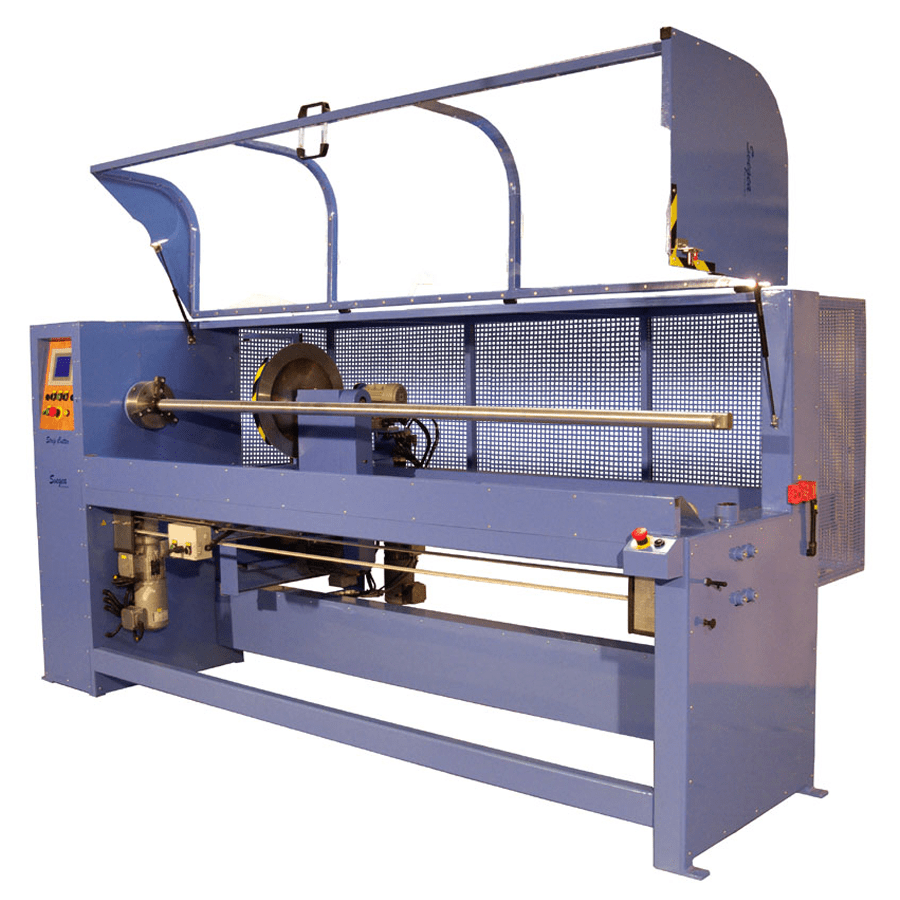

Precise cutting capabilities, offered by advanced strip cutters, ensure that digitally printed fabrics are handled with the utmost care and accuracy. These innovations are integral to maintaining the quality and appeal of digitally printed textiles.

Advanced Apparel Manufacturing

The apparel manufacturing sector is experiencing a shift towards automation and advanced technologies. In 2025, we will see increased use of AI and robotics to streamline production processes and reduce labor costs. These technologies enhance efficiency, improve product quality, and enable manufacturers to respond quickly to market changes.

Automated sewing units simplify the production of bias binding, reducing the need for manual intervention and increasing overall productivity. By leveraging such advanced machinery, manufacturers can stay competitive in a rapidly evolving market.

Customization and Personalization

Consumers are seeking more personalized products, driving the trend toward customization in textile manufacturing. In 2025, manufacturers will leverage AI and data analytics to offer tailored solutions that meet individual preferences. This trend is particularly evident in the fashion industry, where personalized clothing and accessories are becoming increasingly popular.

Innovative textile machinery can be tailored to meet specific production needs, ensuring that manufacturers can deliver unique products that resonate with their customers.

Sustainable Supply Chains

Sustainability extends beyond materials and production processes to encompass the entire supply chain. In 2025, we will see a greater emphasis on creating sustainable supply chains that minimize environmental impact and promote ethical practices. This includes sourcing raw materials responsibly, reducing transportation emissions, and ensuring fair labor practices.

Innovative solutions help manufacturers optimize their supply chains, reducing waste and improving efficiency. By adopting these advanced technologies, companies can enhance their sustainability efforts and meet the growing demand for eco-friendly products.

3D Technologies

3D technologies are making waves in textile manufacturing by enabling the creation of complex designs and prototypes. In 2025, we will see more manufacturers adopting 3D printing and other advanced techniques to push the boundaries of textile design. These technologies allow for greater experimentation and innovation, resulting in unique and high-quality products.

Cutting-edge machinery supports the integration of 3D technologies into textile production. These machines precisely cut and slit 3D-printed fabrics, handling them with care and accuracy.

Immersive Fashion

Immersive fashion is an emerging trend that combines technology and design to create interactive and engaging experiences. In 2025, we will see more brands exploring immersive fashion through augmented reality (AR) and virtual reality (VR) technologies. These innovations allow consumers to visualize and interact with products in new and exciting ways.

Advanced textile machinery supports the production of immersive fashion by enabling precise and efficient manufacturing processes. These innovations ensure that manufacturers can stay ahead of the curve and deliver cutting-edge products to their customers.

A Transformative Era

The textile manufacturing industry is on the cusp of a transformative era, driven by technological advancements and changing consumer demands. Trends such as sustainability, smart textiles, digital printing, and advanced manufacturing are reshaping the landscape, offering new opportunities for innovation and growth.

Innovative textile machinery is setting new standards in the industry. As we move into 2025, manufacturers must embrace these trends to stay competitive and meet the evolving needs of their customers.

For more information on how advanced solutions can help your business thrive, contact Håkan Steene at h.steene@svegea.se today!

Artificial Intelligence (AI) is emerging as a game-changer in the ever-evolving landscape of textile manufacturing. From design to production, AI is revolutionizing the industry, enhancing efficiency, reducing waste, and driving innovation. This blog delves into how AI is transforming textile manufacturing, spotlighting Svegea’s innovative solutions.

The Role of AI in Textile Manufacturing

AI is making significant strides in various aspects of textile manufacturing. One of the most notable areas is automated design and pattern-making. AI tools like Adobe’s Textile Designer analyze vast amounts of trend data from fashion shows, online retail platforms, and consumer behavior studies. This analysis helps predict future trends in patterns, colors, and materials with high accuracy, enabling designers to create collections that align closely with market demands.

Moreover, AI is enhancing the fabric inspection process. Advanced systems equipped with high-resolution cameras and sophisticated AI software, such as the Uster Quantum 4.0, conduct real-time textile analysis. These systems meticulously scan for defects like misweaves, pattern irregularities, and color deviations, ensuring only top-quality fabrics move forward in the production line. This precision significantly reduces waste and elevates product quality.

Enhancing Manufacturing Efficiency

AI-driven automation is streamlining textile manufacturing processes. Predictive maintenance, for instance, uses AI to foresee equipment failures before they happen, minimizing downtime and repair costs. Advanced AI-powered robotics and automation streamline tasks such as fabric cutting, sewing, and quality inspection, leading to faster production cycles and reduced labor costs.

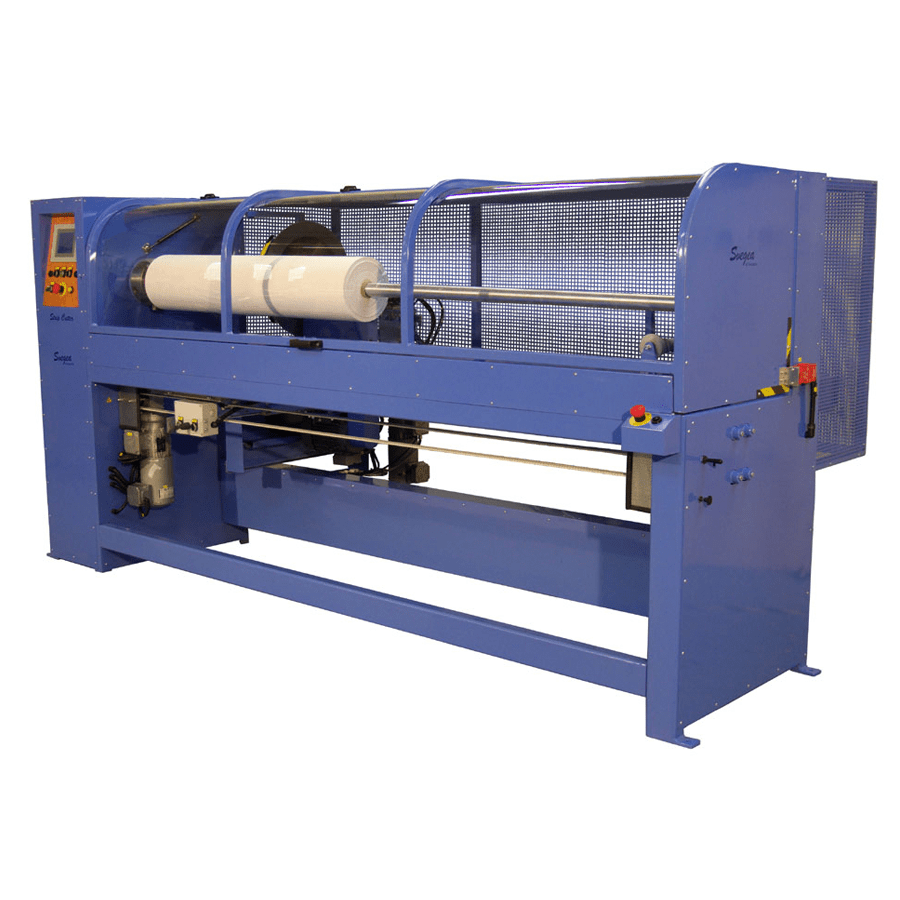

Svegea, a leader in textile manufacturing solutions, exemplifies the integration of AI in production. Their EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, achieves unparalleled precision and efficiency. This system, along with other advanced machines like the SWS automatic roll cutting/slitting machines and the Strip Cutter CMS-1800A3, showcases Svegea’s commitment to cutting-edge technology.

Optimizing Supply Chains

AI plays a crucial role in optimizing supply chains within the textile industry. Machine learning models predict demand patterns, allowing manufacturers to adjust production schedules and inventory levels accordingly. AI-driven analytics also help identify the most efficient routes for shipping and logistics, reducing transportation costs and carbon footprint. This level of optimization ensures that products reach consumers promptly, enhancing customer satisfaction.

Revolutionizing Quality Control

Quality control is a critical aspect of textile production, and AI is enhancing this process through advanced inspection technologies. Computer vision systems equipped with AI algorithms can detect defects and inconsistencies in fabrics with high precision. These systems analyze images of textiles in real time, identifying issues such as color variations, weave irregularities, and fabric flaws that might be missed by human inspectors. This results in higher quality products and fewer returns.

Personalizing Consumer Experiences

AI is transforming how brands interact with consumers by enabling personalized shopping experiences. AI-powered recommendation engines analyze user behavior, purchase history, and preferences to offer tailored product suggestions. Virtual fitting rooms, driven by AI, allow customers to try on clothes virtually, enhancing the online shopping experience and reducing the likelihood of returns.

Svegea’s Innovative Solutions

Svegea of Sweden AB stands out as a beacon of innovation in textile manufacturing. With over 72 years of experience, Svegea offers a wide array of products and services that redefine the textile landscape. Their product portfolio includes the Tube Sewing Unit 200A, Roll to Roll Slitter RRS 800, and Strip Cutter FA 600, all designed for exceptional performance and efficiency.

Svegea’s commitment to cutting-edge technology is evident in its award-winning products. The EC-450XF Collarette Cutting System, for example, sets new benchmarks in production excellence. Svegea’s global presence and bespoke services ensure that each solution addresses specific client needs, ensuring customer satisfaction and success.

The Future of AI in Textile Manufacturing

The integration of AI in textile manufacturing is just beginning. As technology continues to advance, we can expect even greater efficiencies and innovations. AI will likely play an increasingly important role in areas such as sustainable production, where it can help reduce waste and optimize resource use.

AI is revolutionizing textile manufacturing, driving efficiencies, and fostering innovation. Companies like Svegea are leading this transformation, offering advanced solutions that set new industry standards. As AI continues to evolve, the future of textile manufacturing looks brighter than ever. To learn more about how Svegea can help your business stay ahead of the curve, contact Håkan Steene at h.steene@svegea.se today!

Have you ever wondered what goes into creating the luxurious fabrics that grace high-end fashion runways and premium home textiles? The journey from raw material to finished fabric is a fascinating process that combines traditional craftsmanship with cutting-edge technology. In this blog, we’ll uncover the secrets behind high-end fabric production, featuring insights from industry leaders like Svegea of Sweden.

The Foundation: Selecting the Finest Fibers

The first step in fabric production is selecting the highest quality fibers. Whether it’s natural fibers like cotton, silk, and wool, or synthetic fibers such as polyester and nylon, the choice of raw material significantly impacts the final product’s quality. Choose only the finest fibers to craft luxury fabrics that exude durability, softness, and a premium feel.

Spinning Magic: Transforming Fibers into Yarn

Once the fibers are selected, they undergo a spinning process to be transformed into yarn. This step involves drawing out and twisting the fibers to create a continuous thread. Advanced spinning techniques ensure that the yarn is strong and uniform, which is crucial for producing high-quality fabric. Modern spinning machines, like those used by leading manufacturers, offer precision and efficiency, resulting in superior yarn quality.

Weaving Wonders: Crafting the Fabric

Weaving is where the magic truly happens. This process involves interlacing two sets of yarns—the warp and the weft—to create a fabric. The type of weave pattern used can vary, from simple plain weaves to intricate jacquard designs. High-end fabric production often employs state-of-the-art weaving machines that can produce complex patterns with remarkable precision. Companies like Vandewiele Sweden are renowned for their advanced weaving technology, which ensures high-quality fabric production.

Dyeing and Finishing: Adding Color and Texture

After weaving, the fabric undergoes dyeing and finishing processes to achieve the desired color and texture. Dyeing involves immersing the fabric in dye solutions while finishing treatments can include processes like brushing, calendaring, and coating to enhance the fabric’s appearance and performance. Sustainable dyeing practices are becoming increasingly important, with many manufacturers adopting eco-friendly methods to reduce environmental impact.

Cutting-Edge Technology: Svegea of Sweden’s Innovations

Svegea of Sweden is a pioneer in the textile machinery industry, known for its innovative solutions that enhance fabric production efficiency and quality. One of their standout products is the Tubular Knit Slitter TSO 380. This machine revolutionizes the way tubular knit fabrics are processed, offering massive fabric savings and precision cutting. With features like advanced tension control and semi-automatic blade sharpening, the TSO 380 ensures perfect cuts every time, making it an invaluable asset for garment manufacturers.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of high-end fabric production. Each piece of fabric undergoes rigorous inspection to ensure it meets the highest standards. This includes checking for defects, measuring fabric weight and thickness, and testing for colorfastness and durability. Advanced fabric inspection machines, like those from Svegea, play a crucial role in maintaining quality by detecting even the smallest imperfections.

Sustainable Practices: The Future of Fabric Production

Sustainability is at the forefront of modern fabric production. Manufacturers are increasingly adopting eco-friendly practices to minimize their environmental footprint. This includes using organic fibers, reducing water and energy consumption, and recycling waste materials. Svegea of Sweden commits to sustainability by offering machinery that supports greener production methods. Their advanced textile-cutting systems reduce waste, increase efficiency, and contribute to a more sustainable textile industry.

The Role of Innovation in High-End Fabric Production

Innovation is key to staying ahead in the competitive world of high-end fabric production. From automated cutting machines to smart weaving technology, continuous advancements are driving the industry forward. Companies like Svegea are leading the way with their cutting-edge machinery that combines precision, efficiency, and sustainability. By investing in innovative solutions, manufacturers can produce superior fabrics that meet the demands of discerning customers.

Embracing the Future of Fabric Production

The secrets behind high-end fabric production lie in the meticulous selection of fibers, advanced spinning and weaving techniques, and cutting-edge technology. Companies like Svegea of Sweden are at the forefront of this industry, offering innovative solutions that enhance quality and efficiency while promoting sustainability. As the textile industry evolves, embracing these advancements will be crucial for producing the luxurious fabrics that define high-end fashion and home textiles.

Ready to learn more about the latest innovations in fabric production? Contact us to learn more about the range of advanced textile machinery designed to revolutionize your production process.

In the ever-evolving world of textiles, innovation is key to staying ahead. Textile companies that embrace cutting-edge technologies and sustainable practices are leading the way in textile-cutting solutions. Here are ten reasons why these innovative textile companies are at the forefront of the industry.

1. Advanced Cutting Technologies

Innovative textile companies invest in the latest cutting technologies, such as laser cutting and ultrasonic cutting. These methods offer precision and efficiency, reducing waste and improving the quality of the final product. Laser cutting, for example, allows for intricate designs and clean edges, which are essential for high-quality textiles.

2. Automation and Robotics

Automation and robotics have revolutionized the textile industry. Automated cutting machines can work around the clock, increasing productivity and reducing labor costs. Robotics also ensure consistent quality and precision, which is crucial for maintaining high standards in textile production.

3. Sustainable Practices

Sustainability is a major focus for leading textile companies. They adopt eco-friendly cutting methods that minimize waste and reduce energy consumption. For instance, waterjet cutting uses a high-pressure stream of water to cut textiles, which is both efficient and environmentally friendly.

4. Customization and Flexibility

Innovative textile companies offer customization options to meet the specific needs of their clients. Advanced cutting technologies enable these companies to produce bespoke designs and tailor-made solutions. This flexibility is a significant advantage in a competitive market.

5. Integration of Smart Technologies

The integration of smart technologies, such as IoT and AI, has transformed textile cutting solutions. These technologies enable real-time monitoring and optimization of the cutting process, leading to increased efficiency and reduced downtime. Smart sensors can detect and correct errors, ensuring high-quality output.

6. High-Speed Cutting

Speed is a critical factor in textile production. Leading textile companies use high-speed cutting machines that can handle large volumes of fabric quickly and accurately. This capability is essential for meeting tight deadlines and maintaining a competitive edge.

7. Precision and Accuracy

Precision and accuracy are paramount in textile cutting. Innovative companies use advanced software and cutting tools to achieve precise cuts, reducing material waste and ensuring consistent quality. This attention to detail is what sets them apart from the competition.

8. Cost-Effective Solutions

By adopting advanced cutting technologies and automation, textile companies can reduce production costs. These cost savings can be passed on to customers, making high-quality textiles more affordable. Additionally, efficient cutting processes minimize waste, further reducing costs.

9. Enhanced Safety Measures

Safety is a top priority for leading textile companies. They implement advanced safety features in their cutting machines to protect workers and prevent accidents. For example, laser cutting machines are equipped with safety sensors that automatically shut down the machine if a hazard is detected.

10. Continuous Innovation

The most successful textile companies are those that continuously innovate. They invest in research and development to stay ahead of industry trends and adopt new technologies. This commitment to innovation ensures they remain leaders in textile-cutting solutions.

One such example of continuous innovation is the Svegea CMS 1800A2 Strip Cutter. This versatile machine is renowned for its precision in cutting various types of fabrics into strips, making it ideal for producing bias binding, piping, and other narrow fabric applications. The CMS 1800A2 Strip Cutter exemplifies the advanced cutting technologies and efficiency that set leading textile companies apart.

Innovation At Its Finest

Innovative textile companies are leading the way in textile-cutting solutions by embracing advanced technologies, sustainable practices, and continuous innovation. These companies set the standard for quality, efficiency, and customization in the textile industry. If you’re looking for cutting-edge textile solutions, consider exploring the products offered by Svegea of Sweden. Visit our product page to learn more about our innovative textile-cutting solutions.

As we step into 2025, the textile industry is undergoing significant transformations. From sustainability to smart textiles, the trends this year are set to revolutionize both fashion and home decor. Let’s explore the key textile trends for 2025 and how they are shaping the future of the industry.

Sustainability: The Green Revolution

Sustainability continues to be a driving force in the textile industry. Consumers are increasingly demanding eco-friendly and ethically sourced materials. This trend is leading to a rise in the use of organic cotton, bamboo, hemp, and Tencel. Brands are also focusing on traceable supply chains and circular fashion, which includes repairable and biodegradable fabrics. This shift towards sustainability is not just a trend but a necessary evolution for the industry.

Sustainability continues to be a driving force in the textile industry. Consumers are increasingly demanding eco-friendly and ethically sourced materials. This trend is leading to a rise in the use of organic cotton, bamboo, hemp, and Tencel. Brands are also focusing on traceable supply chains and circular fashion, which includes repairable and biodegradable fabrics. This shift towards sustainability is not just a trend but a necessary evolution for the industry.

Smart Textiles: The Future is Now

The integration of advanced technology into fabrics is creating smart textiles that can monitor health metrics and regulate temperature. These innovations are set to revolutionize both fashion and home decor. Imagine clothing that can adjust to your body temperature or fabrics that can track your fitness levels. The possibilities are endless, and the future is now.

Digital Printing: Customization at Its Best

Digital printing technology is allowing for more intricate and customizable designs on textiles. This innovation enables brands to produce unique patterns and reduce waste compared to traditional printing methods. With digital printing, the textile industry can offer more personalized products, catering to the individual tastes of consumers.

Textures and Layers: Creating Visual Appeal

Mixing different textures and layers is becoming increasingly popular in home decor. Combining materials like velvet, linen, and wool can create visually appealing and inviting spaces. This trend is all about creating depth and interest in interior design, making homes feel more cozy and luxurious.

Bold Patterns: Making a Statement

Bold and eye-catching patterns are expected to be a major fashion trend in 2025. These patterns add personality and flair to both fashion and home textiles. Whether it’s a striking geometric design or a vibrant floral print, bold patterns are here to make a statement.

Advanced Apparel Manufacturing: Efficiency and Innovation

The use of 3D technologies and automation in apparel manufacturing is increasing efficiency and allowing for more innovative designs. These advancements are streamlining production processes and enabling the creation of complex and unique garments. The future of apparel manufacturing is bright, with technology leading the way.

Customization and Personalization: Meeting Consumer Demands

Consumers are seeking more personalized and customized textile products. This trend is driving brands to offer bespoke designs and tailored solutions. From custom-fit clothing to personalized home decor, the demand for unique and individualized products is on the rise.

AI and Data Analytics: Optimizing the Industry

Artificial intelligence and data analytics are being used to predict trends, optimize supply chains, and enhance the overall efficiency of textile production. These technologies are providing valuable insights that help brands stay ahead of the curve and meet consumer demands more effectively.

Innovation with the Right Tools

Having the right machinery is crucial to keeping up with these dynamic trends. For instance, the Svegea EC 450 XF Collarette Cutting System exemplifies how advanced technology can enhance textile production. Known for its precision and efficiency, this machine supports sustainable practices by minimizing material waste and optimizing resource use. Its versatility makes it a valuable addition to any textile manufacturing setup, aligning perfectly with the industry’s move towards automation and smart textiles.

Embrace the Future of Textiles

The textile trends for 2025 highlight the exciting innovations and shifts happening in the industry. From sustainability to smart textiles, these trends are shaping the future of fashion and home decor. As we embrace these changes, staying informed and adapting to the evolving landscape is essential.

Keeping up with these trends requires the right machinery for those in the textile production industry. Contact Svegea of Sweden for all your textile production machinery needs. With its advanced technology and expertise, Svegea can help you stay ahead in this dynamic industry.

Preserving history, one fabric at a time! Discover why textile conservation is crucial to safeguarding the past for future generations.

Textile conservation is a specialized field dedicated to preserving historical fabrics that offer a tangible connection to our past. These textiles aren’t just pieces of cloth; they tell stories of cultures, traditions, and technological advancements. This blog will explore the significance of textile conservation, the techniques involved, and how modern textile machines contribute to this delicate preservation process.

The Importance of Textile Conservation

Historical fabrics offer invaluable insights into social, economic, and cultural histories. Without proper conservation, these artifacts would deteriorate, erasing important chapters of human history. Textile conservation ensures that future generations can continue studying and appreciating these pieces of the past.

Cultural Significance

Textiles often hold deep cultural importance. Traditional garments showcase unique weaving techniques and patterns, offering glimpses into the identities of diverse communities. Preserving these fabrics helps protect cultural heritage, ensuring it remains intact for future generations to learn from.

Educational Value

Historical fabrics serve as powerful educational tools. Researchers and students can study ancient techniques, materials, and designs that have shaped modern innovations in textiles. By conserving these textiles, we preserve this knowledge for future generations to explore.

Techniques in Textile Conservation

Preserving delicate fabrics requires specialized techniques tailored to the fabric’s age, condition, and historical value.

- Cleaning and Stabilization – One of the first steps in textile conservation is gentle cleaning to remove dirt and contaminants. Stabilization follows, reinforcing fragile areas to prevent further damage while maintaining the fabric’s integrity.

- Repair and Restoration – In some cases, conservators repair damaged textiles, ensuring that repairs are as discreet as possible. Restoration work aims to return the fabric to its original appearance, allowing it to tell its full story while maintaining authenticity.

The Role of Textile Machines

Modern textile machines play a pivotal role in helping conservators perform these intricate tasks with precision.

- Advanced Weaving Machines – These machines can replicate historical weaving techniques, making it easier to create seamless patches that blend with the original fabric. This ensures that repairs remain nearly invisible, preserving the authenticity of the textile.

- Cleaning and Drying Equipment – Specialized cleaning and drying machines help protect fragile fabrics by providing a controlled environment. These machines ensure that delicate textiles are handled with care during every step of the cleaning process.

Svegea of Sweden: Precision Machines for Conservation

Svegea of Sweden provides advanced textile machines that play a vital role in modern textile manufacturing and quality control. Their equipment, including the Fabric Inspection Machine CMI 180, is designed for precision and delicate handling, ensuring high-quality fabrics. While primarily used for quality control, these machines support the broader textile industry, which includes conservation efforts by ensuring that only the best materials are used in preservation projects.

Case Studies in Textile Conservation

Several high-profile conservation projects highlight the importance and success of textile conservation:

- The Bayeux Tapestry: An 11th-century masterpiece, the Bayeux Tapestry underwent meticulous cleaning and stabilization, preserving it for generations to come.

- The Shroud of Turin: This significant religious artifact benefited from advanced textile conservation techniques, ensuring its continued preservation.

Challenges in Textile Conservation

Textile conservation faces several challenges, including the fragility of fabrics and environmental threats such as humidity, light, and temperature.

Fabric Fragility

Handling fragile textiles requires expert knowledge and specialized equipment to avoid causing further damage during the conservation process.

Environmental Factors

Conservators must constantly manage factors such as humidity and light exposure, which can accelerate the deterioration of historical fabrics. Controlled environments are essential for long-term preservation.

The Future of Textile Conservation

Technological advancements and growing awareness promise a bright future for textile conservation.

Technological Innovations

Cutting-edge technologies like 3D scanning and digital imaging allow conservators to analyze fabrics in unprecedented detail. These innovations are transforming preservation techniques, enabling conservators to develop more effective methods.

Increased Awareness

Growing public and institutional awareness of the importance of textile conservation has led to increased funding and support for preservation projects. As more people understand the value of preserving these historical fabrics, the future of textile conservation looks bright.

Preserving Cultural Heritage

Textile conservation is essential for preserving our cultural heritage and ensuring future generations have access to these invaluable artifacts. By using advanced techniques and modern machines like those from Svegea of Sweden, conservators can safeguard these fabrics for years to come. As we continue to innovate and raise awareness, textile conservation will thrive, preserving history—one fabric at a time.

For expert textile machines, contact Svegea of Sweden for precision solutions tailored to your conservation needs.

Choosing the right textile machinery can be a daunting task, especially with the plethora of options available in the market. The decision impacts your production efficiency, product quality, and overall business profitability. Here are some key tips to help you navigate this critical process.

1. Understand Your Production Needs

Before investing in textile machinery, it’s crucial to understand your specific production needs. Different types of machinery serve various purposes, from weaving and knitting to dyeing and finishing. Determine the scale of your operations, the types of textiles you produce, and your production goals. This understanding will guide your choice of machinery that best suits your requirements.

2. Evaluate Technology and Features

Modern textile machinery comes with a range of advanced technologies and features designed to enhance productivity and quality. Look for machines that offer automation, precision control, and energy efficiency. For instance, Svegea of Sweden offers cutting-edge machinery equipped with the latest technology, ensuring high efficiency and minimal waste. Our products are known for their durability and innovative features.

3. Consider Quality and Reliability

Quality and reliability are paramount when choosing textile machinery. Investing in high-quality machines may come with a higher initial cost, but it ensures long-term performance and fewer breakdowns. Research and compare different brands, read reviews, and consider the manufacturer’s reputation. Modesty aside, our brand has a proven track record of producing reliable and high-quality textile machinery.

4. Assess After-Sales Support and Maintenance

After-sales support and maintenance services are crucial for the smooth operation of textile machinery. Ensure that the manufacturer offers comprehensive support, including installation, training, and regular maintenance services. We provide excellent customer support and maintenance services, ensuring that your machinery operates optimally.

5. Analyze Cost and Return on Investment (ROI)

While the cost of textile machinery is a significant factor, it’s essential to consider the return on investment (ROI). A more expensive machine with advanced features and higher efficiency can lead to cost savings in the long run. Calculate the total cost of ownership, including maintenance and operational costs, and compare it with the expected benefits. Opt for machines that offer the best value for money.

6. Environmental Considerations

Sustainability is a growing concern in the textile industry. Choose machinery that is energy-efficient and environmentally friendly. Machines that reduce water and chemical usage, minimize waste, and consume less energy are ideal. This Swedish textile company is known for producing sustainable textile machinery that aligns with eco-friendly production practices.

7. Compatibility with Existing Systems

Ensure that the new machinery is compatible with your existing systems and processes. Incompatibility can lead to production delays and additional costs. Consult with the manufacturer or a technical expert to evaluate the integration process. A company that offers flexible machinery solutions that can be seamlessly integrated into various production setups, should be the right choice.

Explore Svegea of Sweden’s Textile Machinery

Choosing the right textile machinery is a critical decision that impacts your production efficiency and product quality. By considering factors such as your production needs, technology and features, quality, after-sales support, cost, environmental impact, and compatibility, you can make an informed choice. Svegea of Sweden’s innovative machinery solutions are designed to meet diverse production requirements while ensuring high efficiency and sustainability.

Curious about how we can elevate your textile production process? Visit our product page for more information and start your journey towards optimal textile production today.

Ever wondered how fabrics impact your mood? The textures of the textiles we surround ourselves with can significantly influence our emotions and behavior. This article delves into the fascinating psychology of fabric textures and how they can shape our daily experiences.

The Power of Fabric Textures

Fabric texture refers to the surface quality of a fabric, which can be smooth, rough, soft, or stiff. Different textures evoke different emotional responses.

Smooth Textures: Fabrics like silk, satin, and cotton have smooth textures. These materials are often associated with luxury and comfort. Wearing smooth fabrics can make you feel more relaxed, elegant, and confident. They’re perfect for special occasions or when you want to pamper yourself.

Rough Textures: Fabrics like wool and raw silk are examples of rough textures. These materials can evoke feelings of ruggedness, durability, and strength. Wearing rough-textured fabrics can make you feel more grounded and resilient. They’re great for casual, everyday wear or outdoor activities.

Soft Textures: Fabrics such as velvet are incredibly soft. These fabrics are associated with warmth, comfort, and nurturing. Wearing soft, textured fabrics can make you feel cozy and secure, making them ideal for relaxing at home or during the colder months.

Stiff Textures: Fabrics like organza have a stiff texture. These fabrics often convey formality and structure. Wearing stiff fabrics can make you feel more disciplined and poised. They’re suitable for formal events or professional settings.

The Influence of Fabric Colors

Colors are powerful psychological tools that can influence our emotions and perceptions. Different colors can have varying effects on our mood.

Red: Red is a bold and stimulating color. It is often associated with passion, energy, and excitement. Wearing red can make you feel more confident and assertive. It’s a great choice for events where you want to stand out and make a strong impression.

Blue: Blue is a calming and soothing color, often linked to feelings of tranquility, trust, and stability. Wearing blue can help you feel more relaxed and at peace. It’s ideal for situations where you need to stay calm and composed, such as job interviews or exams.

Yellow: Yellow is a bright and cheerful color. It is associated with happiness, optimism, and creativity. Wearing yellow can lift your spirits and make you feel more joyful and energetic. It’s perfect for social gatherings or creative endeavors.

Green: Green is a refreshing and harmonious color. It represents nature, balance, and growth. Wearing green can make you feel more refreshed and rejuvenated.

Combining Textures and Colors

The combination of textures and colors can create a powerful impact on your mood and behavior. For instance, a smooth, blue silk dress can make you feel both elegant and calm, while a rough, red wool sweater can evoke feelings of strength and confidence. Understanding how these elements work together can help you make more informed choices about your wardrobe and home decor.

Svegea of Sweden: Innovating Textile Machinery

Svegea of Sweden is at the forefront of textile machinery innovation. Their advanced fabric-cutting machines ensure precision and efficiency, making it easier for designers to create garments that not only look good but also feel good. By investing in high-quality machinery from Svegea, manufacturers can produce textiles that meet the psychological needs of their customers.

Svegea leads the textile industry with its quality and innovation. Their machines cut various fabrics with utmost precision. This attention to detail helps create garments that provide the desired emotional and psychological benefits to the wearer.

A Fascinating Field

The psychology of fabric is a fascinating field that highlights the significant impact that textures and colors can have on our moods and behavior. By understanding these effects, we can make more informed choices about the fabrics we wear and surround ourselves with. Whether you’re looking to feel more confident, relaxed, or joyful, the right fabric can make all the difference.

For manufacturers and designers, investing in high-quality textile machinery from Svegea of Sweden can help ensure that your products meet the psychological needs of your customers. To learn more about Svegea’s innovative solutions, visit their contact page.

Explore the world of fabrics and discover how the textures and colors you choose can transform your mood and behavior. Make informed choices and experience the psychological benefits of the right textiles today!

In the dynamic world of textile manufacturing, automation is a cornerstone of innovation, driving unprecedented efficiency, precision, and sustainability. As an expert with over two decades of experience in textile automation, we have witnessed firsthand the transformative power of these technologies. Today, we’ll explore how automation is reshaping the fabric of our industry.

The Evolution of Textile Automation

The journey from hand-spun fibers to today’s high-tech production lines tells a story of relentless innovation. Early mechanization during the Industrial Revolution laid the groundwork, but modern automation has catapulted us into a new era of manufacturing excellence.

Key milestones include:

1. 1960s-1970s: Introduction of computer-controlled looms

2. 1980s-1990s: Development of robotic systems for material handling

3. 2000s-2010s: Integration of AI and machine learning in quality control

4. 2020s and beyond: Emergence of fully automated, smart textile factories

Core Areas Transformed by Automation

Spinning: Precision at Lightning Speeds

Modern spinning systems, such as rotor and air-jet technologies, have revolutionized yarn production. These systems can produce yarn up to 20 times faster than traditional ring spinning, with unparalleled consistency.

Weaving: Intelligent Looms for Flawless Fabrics

Today’s computerized looms are marvels of engineering. There are machines for example that use real-time adaptive tension control to adjust warp tension on the fly, ensuring fabric quality remains consistent even as conditions change during production. This level of precision was unthinkable just a decade ago.

Dyeing and Finishing: Sustainability Meets Efficiency

Automated dyeing and finishing processes have dramatically reduced water and energy consumption while improving color consistency. Digital textile printing, exemplified by machines can print complex designs directly onto fabric at up to 1,000 m²/hour, revolutionizing small-batch and customized production.

Spotlight on Innovation: Svegea’s EC 450 XF Collarette Cutting System

The EC 450 XF Collarette Cutting System by Svegea represents the cutting edge of textile automation. As the winner of the Texprocess Americas 2023 Innovation Award, this system exemplifies how targeted automation can solve specific industry challenges.

Key features include:

– Multi-material compatibility for unparalleled versatility

– Precision cutting with minimal waste

– Rapid changeover times, boosting overall productivity

The EC 450 XF doesn’t just cut fabric; it redefines efficiency in garment manufacturing. For manufacturers looking to stay competitive, systems like this are not just beneficial—they’re essential.

The Tangible Benefits of Automation

1. Quality Assurance: Automated systems consistently produce high-quality textiles, reducing defects by up to 90% compared to manual processes.

2. Increased Productivity: Modern automated lines can operate 24/7, increasing output by 200-300% over traditional methods.

3. Cost Reduction: While initial investment is significant, automated systems can reduce labor costs by 40-60% and material waste by 20-30% over their lifetime.

4. Customization at Scale: Automation enables quick changeovers, making small-batch and customized production economically viable.

5. Enhanced Safety: Automation minimizes human exposure to hazardous processes, reducing workplace accidents by up to 80% in some facilities.

Overcoming Implementation Challenges

While the benefits of automation are clear, implementation comes with challenges:

1. Initial Investment: The upfront cost of automation can be substantial. However, ROI typically occurs within 2-5 years, depending on the scale of implementation.

2. Workforce Transition: Shifting to automated systems requires retraining staff. Forward-thinking companies are investing in upskilling programs to transition workers into higher-value roles.

3. System Integration: Ensuring new automated systems work seamlessly with existing processes is crucial. Careful planning and phased implementation can mitigate disruptions.

The Future of Textile Automation

Looking ahead, several trends will shape the future of textile automation:

1. AI and Machine Learning: These technologies will enable predictive maintenance and real-time quality control, further improving efficiency and reducing downtime.

2. Internet of Things (IoT): Connected devices will create smart factories where every aspect of production is monitored and optimized in real-time.

3. Sustainable Automation: Future systems will focus even more on reducing environmental impact, with closed-loop water systems and energy-efficient processes.

4. Collaborative Robotics: Cobots will work alongside humans, handling repetitive tasks while allowing human workers to focus on high-value activities.

Embracing the Automated Future

Automation in textile manufacturing isn’t just about replacing human labor—it’s about augmenting human capabilities, driving innovation, and creating a more sustainable, efficient industry. As we look to the future, it’s clear that automation will play an increasingly central role in shaping the textiles of tomorrow.

For manufacturers, the message is clear: embrace automation or risk being left behind. The future of textiles is automated, and that future is now.

To explore cutting-edge automation solutions like Svegea’s EC 450 XF Collarette Cutting System, contact us now! For those ready to take the next step in their automation journey, now is the time to act.

The textile manufacturing industry is undergoing a significant transformation. As we move into 2025, several trends are shaping the future of this dynamic sector. From sustainable practices to advanced technologies, the landscape is evolving rapidly. Let’s explore the top trends in textile manufacturing for 2024 and 2025.

1. Sustainable Practices

Sustainability is no longer a buzzword; it’s a necessity. Textile manufacturers are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes using organic materials, recycling waste, and implementing energy-efficient processes. According to the World Economic Forum, sustainable practices in textile manufacturing can significantly reduce carbon emissions and water usage.

2. Advanced Technologies

The integration of advanced technologies is revolutionizing textile manufacturing. Automation, artificial intelligence (AI), and the Internet of Things (IoT) are enhancing efficiency and productivity. For instance, AI-driven machines can predict maintenance needs, reducing downtime and increasing output. The International Textile Manufacturers Federation highlights that these technologies are crucial for staying competitive in the global market.

3. Customization and Personalization

Consumers today demand unique and personalized products. Textile manufacturers are leveraging digital printing and other technologies to offer customized solutions. This trend is particularly evident in the fashion industry, where personalized clothing is gaining popularity. A report by McKinsey & Company suggests that customization will be a key driver of growth in the textile sector.

4. Smart Textiles

Smart textiles, also known as e-textiles, are gaining traction. These textiles have embedded sensors and electronics that can monitor health, track fitness, and even change color. The potential applications are vast, ranging from healthcare to sportswear. According to TechCrunch, the smart textiles market is expected to grow exponentially in the coming years.

5. Ethical Labor Practices

Consumers are becoming more conscious of the ethical implications of their purchases. As a result, textile manufacturers are focusing on fair labor practices and ensuring safe working conditions. This shift is not only ethical but also beneficial for brand reputation. The Fair Labor Association provides guidelines and resources for companies aiming to improve their labor practices.

Spotlight on Svegea of Sweden

Svegea of Sweden is a notable player in the textile manufacturing industry. Known for their innovative solutions, Svegea offers advanced slitting and cutting machines that enhance efficiency and precision. Their commitment to quality and sustainability sets them apart in the market. While not overtly promotional, it’s worth noting how companies like Svegea are contributing to the industry’s evolution.

Exciting Changes

The textile manufacturing industry is poised for exciting changes in 2025. From sustainable practices to advanced technologies, the trends shaping this sector are both innovative and impactful. By staying informed and adapting to these trends, manufacturers can thrive in a competitive landscape.

For innovative and sustainable textile machinery, contact Svegea of Sweden. Our advanced solutions can help you stay ahead in the evolving textile industry.