The dynamic world of textile design and manufacturing is driven by innovation, shaping the industry’s future. From embracing sustainable practices to integrating cutting-edge technology, there’s a profound evolution underway. This shift promises enhanced efficiency and a more environmentally conscious approach to production. It’s an exciting time where creativity meets sustainability in every thread of the textile industry.

Sustainability in Textile Design:

Consumers increasingly demand eco-friendly products, prompting manufacturers to adopt sustainable practices throughout production. Svegea of Sweden, a leader in sustainable textile machinery innovations, champions sustainability with its state-of-the-art equipment designed to reduce waste and energy consumption while maintaining high-quality standards.

Digitalization and Efficiency:

The integration of digital technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) has revolutionized manufacturing processes. Svegea’s advanced machines leverage AI algorithms to optimize production efficiency, ensuring precise cuts and minimizing material wastage.

Customization for Consumer Preferences:

Customization is key as consumers increasingly desire unique and personalized products. Manufacturers are responding by offering customizable solutions tailored to consumer preferences. Svegea of Sweden collaborates with industry leaders to deliver intricate designs and patterns, meeting the growing demand for personalized textiles.

Collaborative Innovation:

Industry players are forging strategic partnerships to leverage collective expertise and resources. Svegea’s collaboration with textile industry leaders fosters innovation and knowledge exchange, driving continuous improvement in design and manufacturing processes.

Automation for Productivity:

Automated systems streamline production, reduce manual labor, and improve overall efficiency. The latest automated textile machines incorporate advanced robotics and AI, ensuring consistent quality across production batches.

Smart Textiles and Future Possibilities:

The adoption of smart textiles embedded with sensors and actuators is revolutionizing wearable technology. Innovative machines play a crucial role in producing smart textiles, paving the way for advancements in functionality and user experiences.

As we embrace sustainability, digitalization, customization, collaboration, automation, and smart textiles, the textile industry is poised for a future defined by innovation and efficiency. Explore Svegea’s innovative solutions to stay ahead in the evolving textile landscape and drive your business toward success.

The textile industry is undergoing transformative changes driven by trends around sustainability, automation, customization, and circularity. Leading machinery manufacturers offer cutting-edge solutions to help textile producers capitalize on these powerful market shifts.

Sustainability Imperative

Environmental consciousness is fueling the demand for eco-friendly textiles, currently, a global textile trend that we cannot ignore. Innovative machinery enables sustainable manufacturing practices like energy efficiency and waste reduction, minimizing environmental impact while maintaining competitive operations.

Automation & Industry 4.0

Principles like robotics, AI, and IoT are optimizing production through automation. Advanced textile machinery seamlessly integrates these technologies to streamline operations, boost productivity, and reduce costs – keeping manufacturers at the forefront of the digital revolution.

Customization & Diversification

Evolving consumer tastes favor personalized products and unique experiences. Flexible machinery allows for customized, diverse offerings tailored to changing market demands.

Circular Economy Transition

Resource efficiency is paramount, with textile circularity reducing waste. Circular knitting machines and recycling technologies enable closed-loop supply chains by repurposing waste into new materials.

As these trends reshape the global landscape, machinery manufacturers position textile producers for success. By adopting innovative solutions for sustainability, automation, customization, and circularity, industry leaders can drive sustainable growth and gain a lasting competitive edge.

For inquiries, brochures, or further information about Svegea of Sweden’s cutting-edge textile machinery, visit our contact page.

In the ever-evolving realm of sewn product manufacturing, optimizing profitability hinges on a delicate balance of precision, efficiency, and cost-effectiveness. This balance is particularly crucial in textile-cutting machines, where every cut impacts material utilization and production output. Svegea of Sweden stands out as a leader in this arena, offering cutting-edge machines tailored to meet the diverse needs of the industry.

Precision and Efficiency

Svegea’s textile cutting machines epitomize precision and efficiency, crucial elements that directly impact profitability. Engineers design these machines with advanced technology that ensures precise cuts, minimizing material wastage and maximizing resource utilization. Svegea machines excel in handling diverse cutting requirements with unparalleled accuracy, translating into significant cost savings and increased profitability for businesses.

Customization for Unique Manufacturing Needs

Customization for Unique Manufacturing Needs

A defining feature of Svegea machines is their customizable nature, meticulously crafted to address the unique challenges faced by businesses in garment manufacturing. Through collaborative customization processes, Svegea works closely with clients to understand their specific requirements and tailor machines accordingly. This tailored approach results in machines that seamlessly integrate into the client’s production processes, optimizing efficiency, reducing downtime, and ultimately, enhancing ROI.

Enhanced Productivity and Reduced Labor Costs

Svegea’s textile-cutting machines are designed to streamline production processes and enhance overall productivity. The integration of PLC-controlled operations, adjustable cutting speeds, and automatic blade sharpening mechanisms ensures smooth and uninterrupted workflow. This increased productivity not only accelerates production cycles but also reduces labor costs by minimizing the need for manual intervention, freeing up workforce resources for other value-added tasks.

Optimized Material Utilization

Efficient material utilization is paramount in sewn product manufacturing to minimize waste and maximize resource efficiency. Svegea engineers its machines to optimize material usage through precise cutting techniques and customizable settings. This results in minimal material wastage, leading to significant cost savings and improved profitability over time.

Scalability and Future-Readiness

Scalability and future readiness are critical considerations for businesses aiming for sustained success in the competitive landscape of garment manufacturing. Svegea designs its textile-cutting machines with scalability in mind, accommodating varying production volumes and evolving business needs. Ongoing R&D keeps Svegea ahead with future-ready solutions for evolving industry trends and challenges.

Integrating Svegea’s textile cutting machines into sewn product manufacturing processes presents a compelling opportunity for businesses to maximize ROI. Through precision, efficiency, customization, and scalability, Svegea machines offer a comprehensive solution that enhances productivity, reduces costs, and drives profitability. Investing in Svegea tech positions businesses for long-term success in sewn product manufacturing.

Tell us how we can enhance your production’s efficiency and ROI!

In the manufacturing sector, precision and efficiency are paramount. Svegea of Sweden has long been a pioneer in innovation, providing cutting-edge solutions tailored to diverse manufacturing needs. Their standout approach involves customizing machines to precisely match clients’ demands, showcasing the adaptability and versatility of their products.

Understanding Unique Manufacturing Needs

Every manufacturing process poses unique challenges. Material specifications, production volumes, and intricate cutting requirements vary widely. Svegea recognizes the critical importance of grasping these distinct needs to deliver optimal solutions. This understanding begins with an in-depth consultation process, where Svegea’s expert team collaborates closely with clients to gain comprehensive insights into their operations and objectives.

Collaborative Customization Process

The journey toward customized solutions starts with an in-depth assessment of the client’s manufacturing environment. Svegea’s engineers meticulously analyze factors such as material properties, production workflows, and desired outcomes. This collaborative approach ensures that every aspect of the machine’s design and functionality is precisely aligned with the client’s goals.

Flexibility in Design and Functionality

Svegea’s range of cutting machines, including the Strip Cutter CMS series and the Strip Cutter FA 500, offers exceptional flexibility in both design and functionality. This inherent flexibility enables seamless customization to accommodate diverse material types, varying thicknesses, and complex cutting requirements. Svegea’s machines can be fine-tuned to excel in diverse manufacturing environments.

Fully Automatic Collarette Cutter Series: Customizable Excellence

A flagship product in Svegea’s lineup, the Fully Automatic Collarette Cutter series exemplifies the company’s dedication to customization. Meticulously designed to meet the specific needs of garment manufacturers, these state-of-the-art machines certainly boost production. They offer a wide array of customization options tailored to suit varying production specifications. From adjustable cutting speeds to meticulously configured blade setups, Svegea’s Fully Automatic Collarette Cutter series can be finely tuned to optimize garment production processes and elevate overall efficiency.

Advanced Technology for Tailored Solutions

Central to Svegea’s ability to deliver tailored solutions is its substantial investment in advanced technology. The seamless integration of PLC-controlled operations, adjustable cutting speeds, and automatic blade sharpening mechanisms ensures that customized machines not only meet but surpass client expectations. Heightened productivity, reduced material wastage, and enhanced overall efficiency result from this.

Real-World Applications

The success stories of Svegea’s customized solutions resonate across various industries. Clients in the textile sector have reaped substantial benefits from machines that flawlessly handle intricate patterns and multiple fabric layers, thereby optimizing production processes and curbing labor costs.

Future-Ready Solutions

As manufacturing landscapes evolve and technologies continue to advance, Svegea remains steadfast in its commitment to delivering future-ready solutions. This includes ongoing research and development efforts aimed at integrating AI-driven optimizations, predictive maintenance capabilities, and connectivity features. These innovations enable remote monitoring and control, ensuring that Svegea machines not only meet current needs but also adapt seamlessly to emerging challenges and opportunities.

In the ever-evolving realm of manufacturing, customization stands as a pivotal pillar for staying competitive and meeting dynamic demands. The company’s unwavering commitment to tailored solutions underscores its dedication to empowering clients with cutting-edge technology precisely tailored to their unique manufacturing needs. They continue to be a trusted partner for industries seeking optimized and efficient manufacturing solutions. Svegea does the process by seamlessly blending expertise, collaboration, and advanced engineering.

Drop us a line and share how we can assist you! Connect with us via email at info@svegea.se. We’re eager to hear from you!

In the fast-paced world of textile manufacturing, the key to seamless operations and consistent quality lies in the proper maintenance of production machinery. Whether it’s cutting-edge equipment like Svegea’s innovative solutions or industry-standard machines, regular upkeep is essential to ensure optimal performance and longevity. Let’s dive into some expert tips on maintaining textile production machinery for peak efficiency.

Follow Manufacturer Guidelines

First and foremost, it’s crucial to follow the manufacturer’s guidelines for maintenance. This includes adhering to recommended maintenance schedules, using approved cleaning agents and lubricants, and following specific calibration and part replacement procedures. By following these guidelines diligently, you can prevent premature wear and tear and ensure the machinery operates at its best.

Regular Cleaning and Inspection

Keeping the machinery clean and well-maintained is key to preventing breakdowns and ensuring smooth operation. Regularly clean all components to remove dust, debris, and buildup that can affect performance. Conduct thorough inspections to identify any signs of wear, damage, or loose parts that may require attention. Addressing minor issues early can prevent them from escalating into major problems later on.

Lubrication and Calibration

Proper lubrication is essential for reducing friction, preventing overheating, and prolonging the life of moving parts. Follow the recommended lubrication schedule and use the correct type and amount of lubricant for each component. Additionally, ensure that the machinery is calibrated regularly to maintain accuracy and consistency in performance, especially for cutting and sewing machines.

Training and Monitoring

Invest in training for machine operators to ensure they understand how to use the machinery correctly, follow maintenance procedures, and identify early signs of issues. Encourage them to monitor the machinery’s performance regularly, including production output, efficiency metrics, and any abnormal sounds or vibrations. Promptly addressing any anomalies can prevent downtime and costly repairs.

Implement Preventive Maintenance

Establish a proactive approach to maintenance by implementing a preventive maintenance schedule. This should include routine inspections, cleaning, lubrication, and minor adjustments as needed. Keep detailed records of maintenance activities to track maintenance history, identify recurring issues, and plan for future maintenance needs effectively.

Professional Assistance from Svegea

Don’t hesitate to seek professional assistance from Svegea’s team of experts for complex maintenance tasks or troubleshooting. They have the knowledge, experience, and resources to handle maintenance and repairs efficiently, ensuring your textile production machinery operates optimally. Contact Svegea’s team today to discuss your maintenance needs and maximize the performance of your machinery.

Proactive maintenance is the cornerstone of efficient and reliable textile production machinery. By following these tips and working with trusted professionals like Svegea, you can prolong the lifespan of your equipment, minimize downtime, and achieve consistent quality in your manufacturing processes. Schedule regular maintenance, train your operators, and partner with experts for a seamless production experience.

In the realm of cutting-edge technology, Svegea of Sweden emerges as a trailblazer, reshaping the cutting machine landscape. This article explores Svegea’s cutting technology, delving into advanced features and technological innovations that redefine precision, efficiency, and innovation.

Precision Engineering Excellence:

At the core of Svegea of Sweden’s cutting technology lies a dedication to precision engineering. These cutting machines, meticulously crafted with cutting-edge technology, guarantee accuracy in every cut. Whether handling intricate textile patterns or precise angles in industrial materials, Svegea’s cutting machines, born in Sweden, deliver unmatched precision, instilling confidence for seamless execution.

Adaptive Intelligent Automation:

Svegea of Sweden’s cutting machines go beyond automation; they embody intelligent automation. Armed with state-of-the-art sensors and smart controls, these machines adapt to varying materials and thicknesses, adjusting parameters in real time. This adaptability minimizes downtime, boosts efficiency, and optimizes the overall cutting process, positioning Svegea’s technology as a valuable asset for operational excellence.

Versatility Crafted in Sweden:

A standout feature of Svegea of Sweden’s cutting technology is its unparalleled versatility. Designed to handle diverse materials and applications, from textiles to industrial composites, these machines streamline operations and maximize return on investment, offering a single-cutting solution crafted in Sweden that caters to multiple needs.

Tailored Customization Capabilities:

Recognizing unique business requirements, Svegea of Sweden’s cutting technology provides extensive customization capabilities. Whether adjusting cutting speeds, configuring blade angles, or implementing specific cutting patterns, businesses gain the flexibility to tailor the machine to exact specifications. This customization, rooted in Swedish commitment to quality, empowers businesses to address challenges and optimize cutting processes.

Integration with Industry 4.0 – The Swedish Way:

Svegea of Sweden’s cutting-edge technology seamlessly integrates with Industry 4.0 principles, ushering in a smart manufacturing era. With connectivity features and data analytics, these machines offer real-time insights, enabling data-driven decisions. This Swedish-inspired integration enhances efficiency, reduces waste, and contributes to smarter, sustainable manufacturing.

Energy-Efficient Design – Swedish Sustainability:

In an era prioritizing sustainability, Svegea of Sweden’s cutting technology excels with its energy-efficient design. Engineered to optimize power consumption without compromising performance, this eco-friendly approach aligns with global sustainability goals, translating into long-term cost savings for businesses.

User-Friendly Interface – Swedish Simplicity:

While boasting advanced features, Svegea of Sweden’s cutting-edge technology remains accessible through a user-friendly interface. Intuitive controls and a user-friendly interface, influenced by Swedish design principles, simplify system navigation for operators. This focus on user experience ensures seamless integration into workflows without extensive training.

Svegea of Sweden’s cutting technology transcends the ordinary, offering businesses advanced features that redefine cutting machine possibilities. From precision engineering and intelligent automation to versatility, customization, and sustainability, Svegea of Sweden’s commitment to innovation shines in every facet. For businesses aspiring to lead their industries, Svegea of Sweden’s advanced cutting solutions presents a transformative force propelling them into a future of unparalleled efficiency and innovation.

Discover Svegea of Sweden’s precision cutting technology today. Elevate operations with the Swedish touch. Contact us for a consultation and experience the difference.

In the dynamic world of textile machinery, Svegea of Sweden shines as a beacon of innovation. Our dedication to “Quality Beyond Speed” is more than a tagline; it’s the force driving the design of our cutting-edge machines. Let’s explore some of our standout products that have set new benchmarks in the industry.

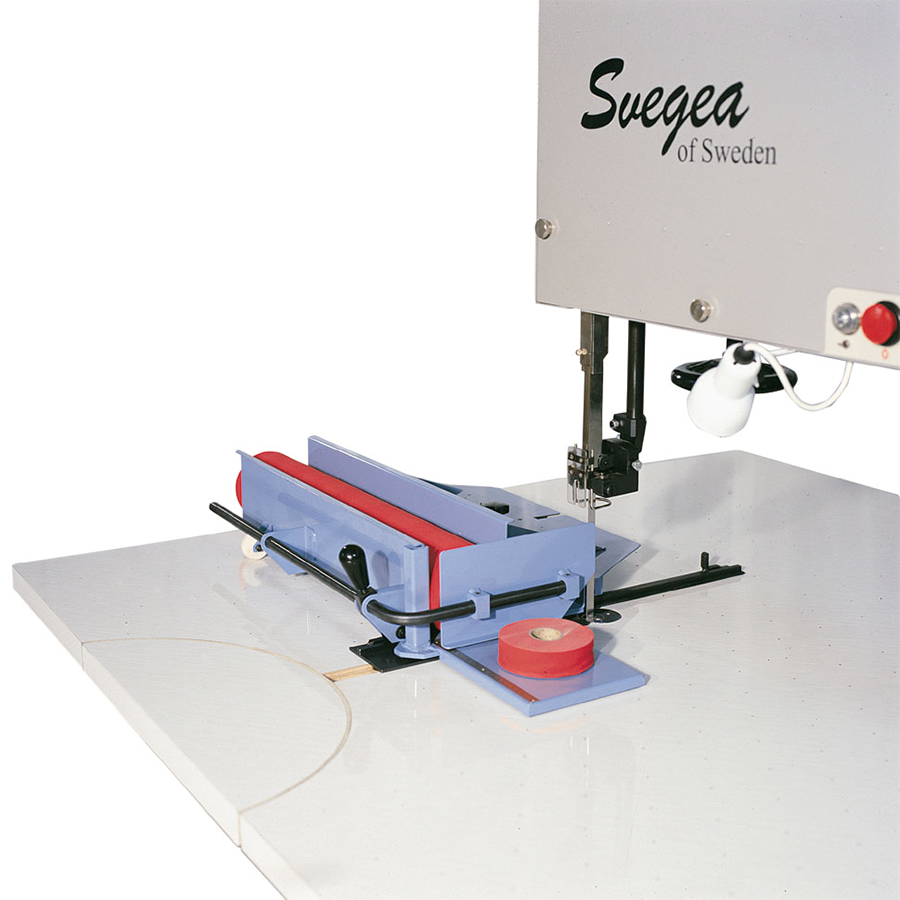

Collarette Cutters: Precision Redefined

Enter the realm of precision with Svegea’s Collarette Cutter. This ingenious machine is tailored to cut collarettes with unmatched precision, ensuring each piece meets the highest quality standards. The advanced cutting mechanisms embody Svegea’s commitment to pushing the boundaries in textile production. Seamlessly combining speed and accuracy, this machinery is a game-changer for companies pursuing perfection in every product detail.

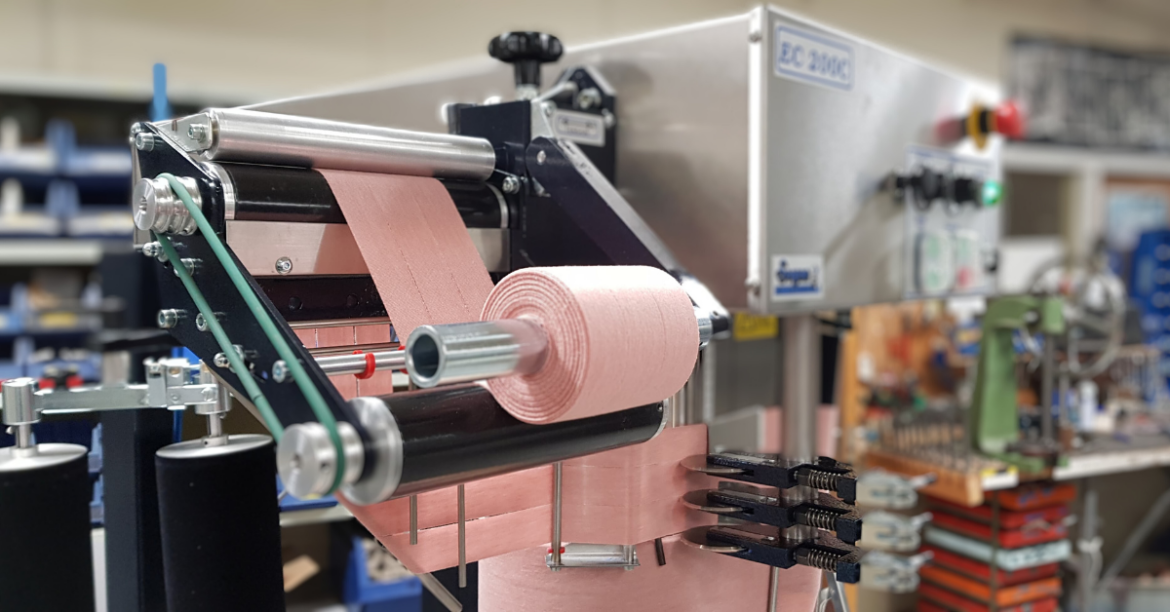

Bias Cutting System: Where Innovation Meets Efficiency

Another jewel in our crown is the Bias Cutting System. Engineered for efficiency and consistency, it produces bias strips that stand second to none. The innovative design showcases our commitment to staying at the forefront of technological advancements in the textile industry. In the challenge of maintaining quality and meeting tight deadlines, Svegea’s Bias Cutting System emerges as a reliable solution, delivering on both fronts.

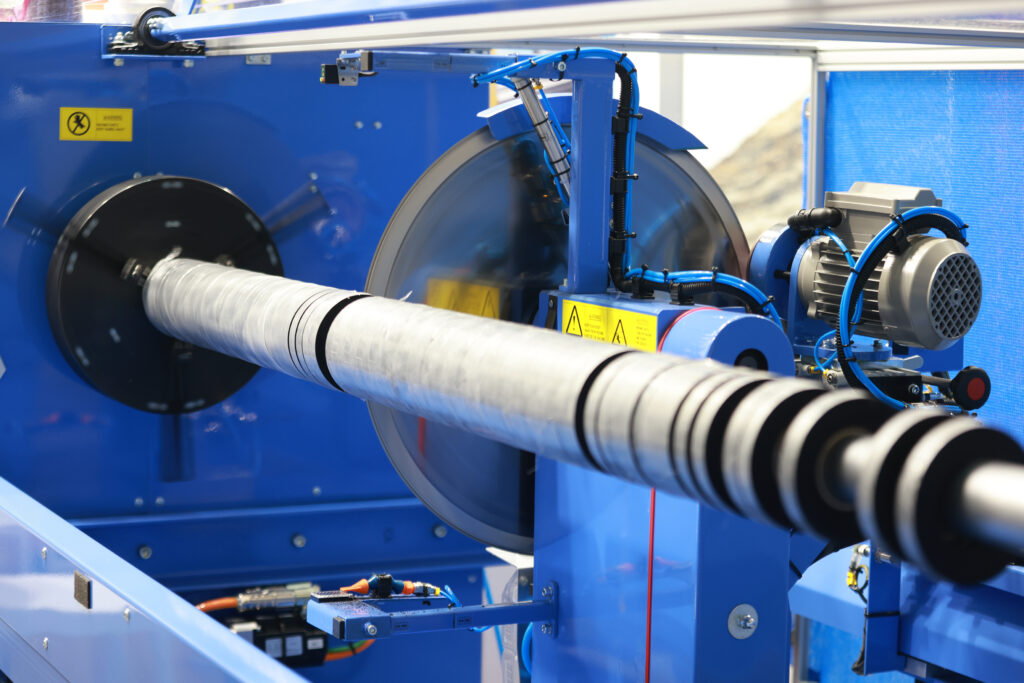

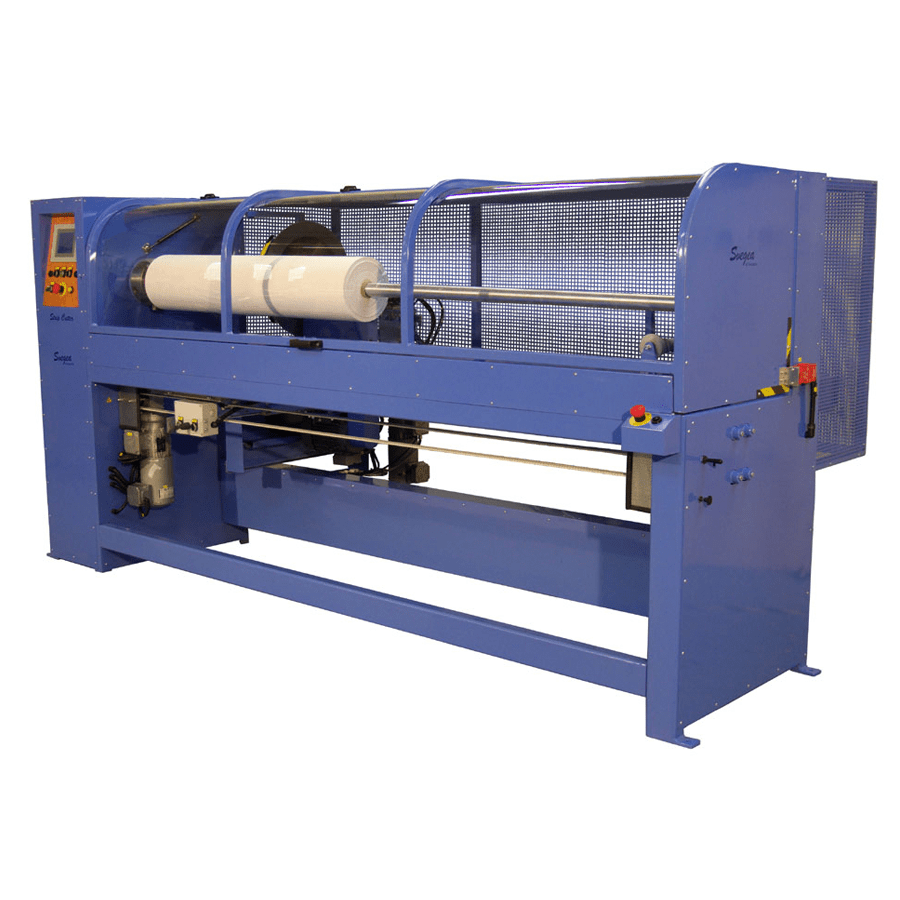

Strip Cutters: Unparalleled Speed, Unrivaled Quality

In the fast-paced world of textile production, speed often battles quality. However, Svegea’s Strip Cutters defy this wisdom by seamlessly blending unparalleled speed with unrivaled quality. Meticulously crafted to handle high demands without compromising precision, these machines exemplify Svegea’s commitment to excellence. It’s not just about keeping up with the pace; it’s about leading the way in efficient and top-notch production processes.

As we reflect on Svegea’s cutting-edge machinery, our commitment to “Quality Beyond Speed” is woven into each machine’s fabric. The textile industry demands solutions that navigate the delicate balance between speed and quality, and Svegea’s machinery rises to the occasion with finesse.

Textile Machinery: Transforming Production Landscapes

“Textile machinery” isn’t just a phrase; it’s a realm where precision meets efficiency. Svegea of Sweden stands as a pioneer in this transformative landscape. Our Collarette Cutters, Bias Cutting System, and Strip Cutters exemplify innovation, contributing to redefining standards in textile production.

As we envision the future of garment manufacturing, Svegea’s commitment to advancing textile machinery remains unwavering. Innovation, precision, and efficiency drive our mission, not just to meet industry standards but to set new ones.

The journey of Svegea in the world of textile machinery is a testament to visionary engineering. As businesses seek solutions to elevate production, Svegea stands ready to lead the way, providing machinery that surpasses expectations.

Join us on this transformative journey, where the intersection of quality and speed defines the next chapter in textile production.

Revolutionizing Production Capabilities:

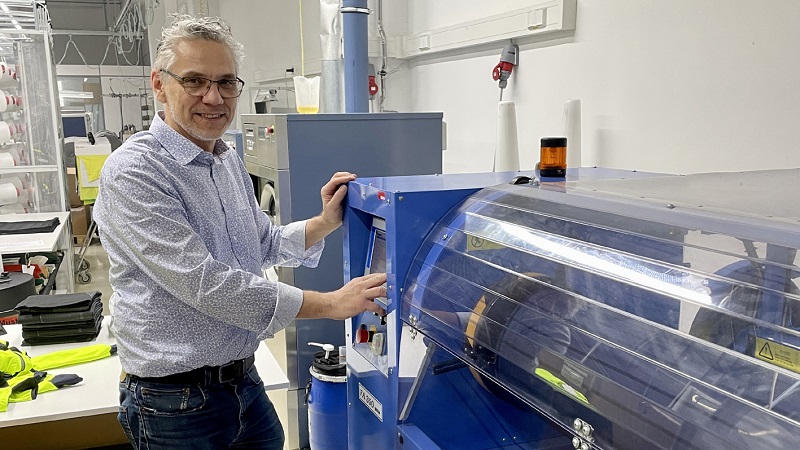

Svegea of Sweden AB, based in Uddevalla, has recently enhanced the production capabilities at Löffler‘s plant with the installation of advanced machinery. Celebrating its 50th anniversary in 2023, Löffler GmbH, a renowned sports and knitwear specialist in Ried im Innkreis, Austria, now boasts the integration of an EC300-S collarette cutter and an FA350 automatic roll slitter.

Innovative Fabric Expertise

Löffler’s plant accommodates 25 circular knitting machines and 3 seamless knitting machines, generating an annual fabric output of approximately 905,000 m². The company is notably recognized for its transtex undergarments. This item pioneered the 2-layer principle, combining hydrophobic polypropylene (PP) with fibers like cotton or merino wool. This ensures moisture absorption by PP, transferring it for evaporation, and keeping the skin dry.

Precision in Tubular Apparel

Demonstrating a commitment to efficiency, Svegea installs the EC300-S collarette cutter, featuring True-Drive II and a high pre-feed device, dedicated to the precision production of tubular apparel components like cuff and neck tapes. Operating at speeds up to 20,000 m/hour, it ensures high-speed and precise manufacturing.

Svegea also incorporates the fully automatic FA350 roll slitter with three separately adjustable settings. This versatile machinery enables the cutting of three different bandwidths within a single cutting cycle, enhancing production flexibility and efficiency. Svegea actively integrates automatic tube sewing units. This process allows for diverse customer preferences and provides options for sewn tubes in either rolled or flat-folded forms.

Strategic Collaboration for Optimization

Collaborating seamlessly with Löffler, Svegea’s cutting-edge technology and automation actively drive the optimization of sewing operations. This alliance actively aligns with the industry’s demand for precision, speed, and flexibility. Svegea’s prowess shapes and refines sewing processes, dynamically exceeding innovation boundaries.

Embrace the future with Svegea’s cutting-edge solutions. Contact us today and revolutionize your sewing operations!

Originally published on February 10th, 2023.

Source: https://www.textiletechnology.net/technology/news/svegea-of-sweden-cutter-for-tubular-apparel-components-for-loeffler-33527

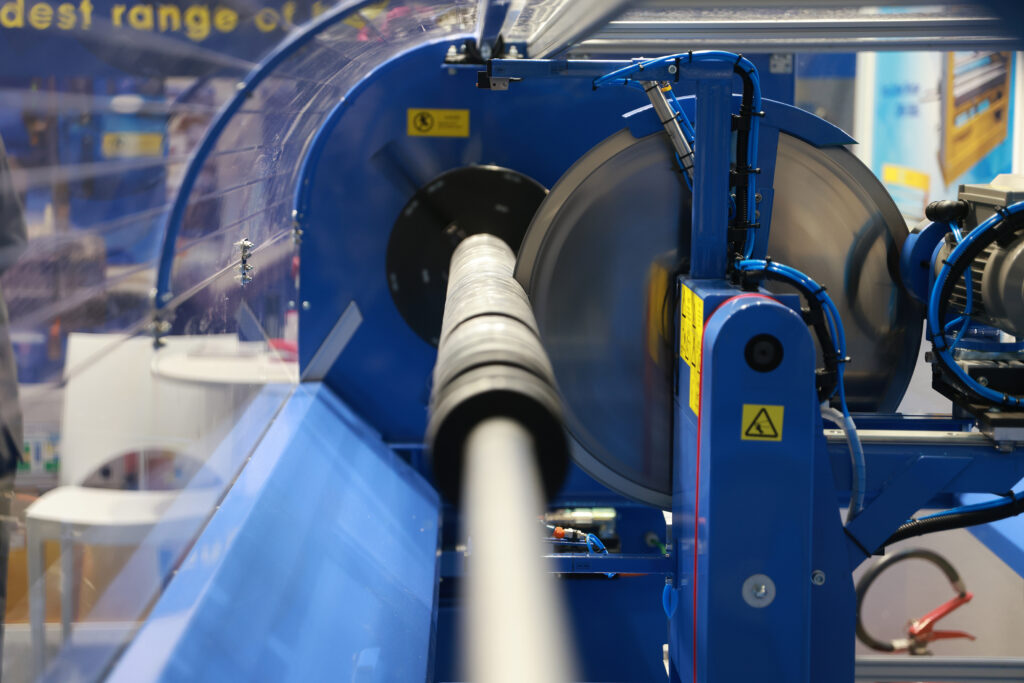

In the ever-evolving landscape of textile machinery, Svegea of Sweden has consistently led the way in innovation. From its inception in 1952, one of its remarkable contributions has been the Collarette Cutter—a cutting-edge solution that has revolutionized the textile industry.

Fast forward almost 72 years, and the spirit of innovation continues. Last year, at the Texprocess Americas 2023 exhibit in Atlanta, Georgia, Svegea, in collaboration with SPEC, clinched the New Technology award for the groundbreaking Svegea EC-450XF.

The Cutting Edge: Revolutionizing Textile Manufacturing

Traditional fabric-cutting methods grappled with challenges in precision, speed, and waste reduction before the advent of the Collarette Cutter. Svegea, recognizing the imperative for an advanced solution, embarked on a development journey that transformed the landscape.

Discover the prowess of this groundbreaking invention and how it’s redefining standards for precision and efficiency.

- Rapid Start and Stop for Unmatched Speed: Experience an exceptionally high running speed with the soft start and stop feature. This is to ensure top-notch quality from the first to the last meter.

- Versatility Redefined in Tubular-Knitted Fabric Cutting: The machine showcases unparalleled versatility and adaptability.

- Swift Adjustability of Bandwidths: Effortlessly adjust bandwidths for different fabric specifications. This provides flexibility and efficiency in handling various materials.

- Precision Amplified with Electronic Soft Start and Stop: Guaranteeing the highest quality at the beginning and end of each band roll, the electronic soft start and stop emphasize precision in every cut.

- Seamless Operations with a Unique Guide System: A distinctive guide system ensures trouble-free cutting contributing to the smooth flow of operations.

- Uncompromised Durability with High-Quality Materials: Crafted from the highest-grade Swedish steel, the cutting knives and pressure rollers emphasize durability and longevity.

- Efficiency Maximization with Auto-Stop Feature: The auto-stop feature halts the operation when the band roll reaches the required preset size.

- Adaptability Enhanced with Automatic Major Fabric Flow Detectors: Automatic major fabric flow detectors elevate the machine’s adaptability to different fabrics.

- Operator Safety Prioritized with Safety Guards: Equipped with safety guards, the machine prioritizes operator safety, providing maximum protection during operation.

Svegea’s Collarette Cutter stands as an innovation powerhouse, reshaping the landscape of textile manufacturing. With precision cutting, unparalleled versatility, high-speed operation, and a user-friendly interface, it’s a true game-changer. The best part? We can customize it to meet your company’s specific needs!

Ready to elevate your cutting precision? Reach out today, and let’s help you revolutionize your textile operations!