The fashion and textile industry is changing fast. More brands are shifting to on-demand textile production to reduce waste and meet customer expectations. Instead of making large batches that may never sell, manufacturers now focus on producing only what’s needed. This approach helps cut costs, save materials, and support sustainability goals.

Sustainability isn’t just a trend—it’s a must. From fabric waste to energy use, every part of the production process matters. And one of the smartest ways to make a difference is through precision.

Why Waste Reduction Matters

Fabric waste is a hidden problem in many factories. Every scrap, wrong cut, or rejected item means:

- Lost money: Fabric is expensive, and waste eats into profits

- Environmental harm: Most textile waste ends up in landfills

- Extra work: Fixing mistakes takes time and energy

When these issues happen often, they add up fast. That’s why reducing waste is good for both the planet and the bottom line.

The Circular Economy in Textiles

The circular economy is all about keeping materials in use and cutting down on waste. In fashion, this means:

- Designing products that last

- Recycling fabrics and fibers

- Using every roll of material wisely

On-demand textile production fits right into this model. By making only what’s needed, factories avoid overproduction and reduce leftover stock. But even before recycling starts, precision machinery helps cut waste at the source.

Precision Technology: Small Changes, Big Impact

Big changes don’t always need big investments. Machines that cut fabric with accuracy, run efficiently, and reduce errors can make a huge difference.

Here’s how precision machinery helps:

- Less fabric waste: Every cut is clean and exact

- Fewer mistakes: Consistent quality means fewer rejects

- Lower energy use: Efficient machines run faster and smarter

- Longer machine life: Durable tools need fewer replacements

These small upgrades support on-demand textile production by making each step more efficient and less wasteful.

Real-World Impact: Knitwear and Trims

Think about a factory making trims for t-shirts. If they use old cutting methods, they might waste 5–10% of their fabric. But with modern precision cutters:

- Every strip is cut perfectly

- Waste drops by several meters per run

- Quality stays high, so there’s less rework

This kind of setup supports on-demand textile production by allowing quick changes and small batch runs without losing efficiency.

Sustainability as a Competitive Edge

Today’s shoppers care about the planet. Brands that show they’re eco-friendly often win more trust and more business. For manufacturers, this means:

- Getting contracts with green-focused brands

- Meeting global rules on waste and emissions

- Standing out in a busy market

Using precision machinery and switching to on-demand textile production helps factories prove they’re serious about sustainability.

Make the Smart Choice Now

Sustainability starts with smart choices. By using precision tools and embracing on-demand textile production, manufacturers can cut waste, save money, and meet modern demands.

Ready to make your production line more efficient and eco-friendly?

📩 Contact Håkan Steene for a product demo at h.steene@svegea.se or visit https://www.svegea.se to learn more.

Image courtesy of Services – Fashinnovation

The fashion industry thrives on change—but in recent years, that change has accelerated into a full-blown revolution. No longer are brands defined by two seasonal collections and predictable production cycles. Today’s consumers demand personalization, limited editions, and lightning-fast turnaround. They expect garments that feel tailor-made, not mass-produced—and they want them now.

For garment and textile manufacturers, this shift isn’t just a trend—it’s a wake-up call. Meeting these demands requires more than creativity; it calls for operational reinvention. From design to delivery, every stage must be faster, smarter, and more adaptable. That’s where automated textile production enters the picture, enabling manufacturers to respond with precision, speed, and scalability.

At the heart of this transformation lies one powerful principle: flexibility.

The Rise of On-Demand Production

If one trend is reshaping the textile landscape, it’s on-demand production. Instead of stockpiling inventory and gambling on what might sell, brands now produce in smaller, agile batches—sometimes even one item at a time.

Why is this happening?

- Personalization sells. Whether it’s a custom sports jersey or a limited-edition streetwear drop, consumers crave uniqueness.

- Sustainability matters. Overproduction is one of fashion’s biggest environmental pitfalls. On-demand production helps reduce waste by making only what’s needed.

- Agility wins. Smaller runs allow brands to test the market, pivot quickly, and scale up with confidence.

In short, mass customization is overtaking mass production. And manufacturers who fail to adapt risk being left behind.

Flexibility on the Factory Floor

On-demand production sounds ideal—but it’s not without challenges. Small-batch runs and rapid turnarounds demand machinery that can:

- Switch between materials and specs with minimal downtime

- Deliver consistent precision from the first piece to the last

- Handle custom orders without compromising efficiency

This is where a robust textile solution becomes essential. Automated textile production systems allow manufacturers to pivot seamlessly between orders while maintaining quality and controlling costs. Flexibility isn’t just a feature—it’s the foundation of future-ready manufacturing.

Real-World Impact: Sportswear & Activewear

Take the booming sportswear market. Teams, clubs, and fans expect customized gear—jerseys with names, leggings in unique colorways, and performance wear tailored to niche needs.

Without flexible cutting equipment, these orders would be slow, error-prone, and costly. But with Svegea’s Automatic Collarette Cutters:

- Factories can switch quickly between team orders with different trims

- Precision cutting ensures every collar and band fits perfectly

- Small-batch customization becomes streamlined and scalable

This isn’t just operational efficiency—it’s a strategic edge.

Flexibility = Future-Proofing

Fashion moves fast. Trends go viral and vanish in weeks. Consumer loyalty shifts with every swipe. But one thing remains constant: the demand for speed, uniqueness, and sustainability.

For textile manufacturers, that means flexibility is no longer optional—it’s survival.

A modern textile solution—especially one built on automated textile production—gives factories the agility to adapt, the precision to deliver, and the confidence to scale. In a world where fashion waits for no one, that’s the difference between leading and lagging

Automated Textile Production is The Future

We can’t stress this enough. On-demand production isn’t a trend—it’s the future. Manufacturers who embrace mass customization will win contracts, delight customers, and reduce waste.

Embracing the right textile solution is essential for bridging the gap between traditional efficiency and the demands of modern flexibility. As fashion trends evolve rapidly and customization becomes the norm, manufacturers must equip their production lines to respond with speed, precision, and adaptability. The ability to shift seamlessly between small-batch orders and large-scale runs is no longer a luxury—it’s a competitive necessity.

Automated textile production is the backbone of this evolution—empowering manufacturers to meet demand without compromising quality or speed.

Svegea’s Textile Solution for Mass Customization

At Svegea of Sweden, flexibility isn’t just a feature—it’s our foundation. Our automated textile production solutions, including Automatic Collarette Cutters, Slitting Machines, and Band Cutting Machines, are engineered for speed, precision, and adaptability.

Here’s how Svegea supports the shift to on-demand production:

- Quick setup times: Ideal for switching between small and large batch runs

- Consistent precision: Every piece meets exact specifications, whether it’s 100 or 10,000 units

- Material versatility: Handles everything from lightweight knits to heavy-duty fabrics

- Just-in-time readiness: Designed for manufacturers who produce exactly what’s needed—no excess, no waste

By enabling manufacturers to meet the demands of today’s fast-paced, customized market, Svegea’s textile solution makes mass customization not only possible but profitable.

📩 Ready to future-proof your factory?

Contact Håkan Steene for a product demo at h.steene@svegea.se or visit https://www.svegea.se to explore our full range of textile solutions.

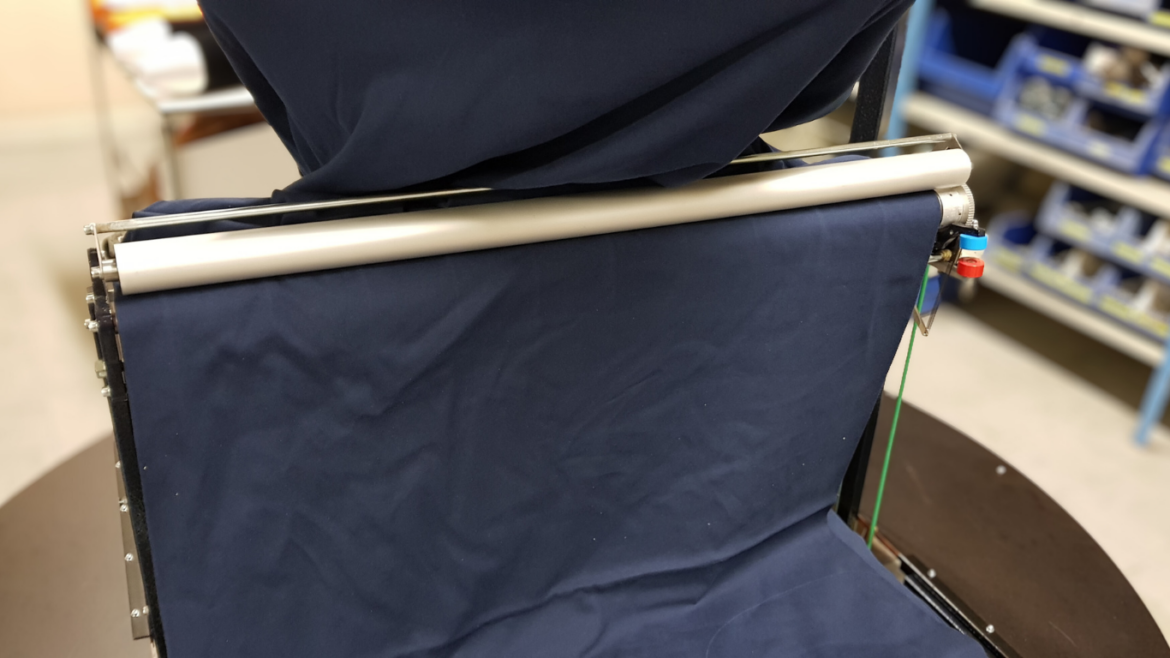

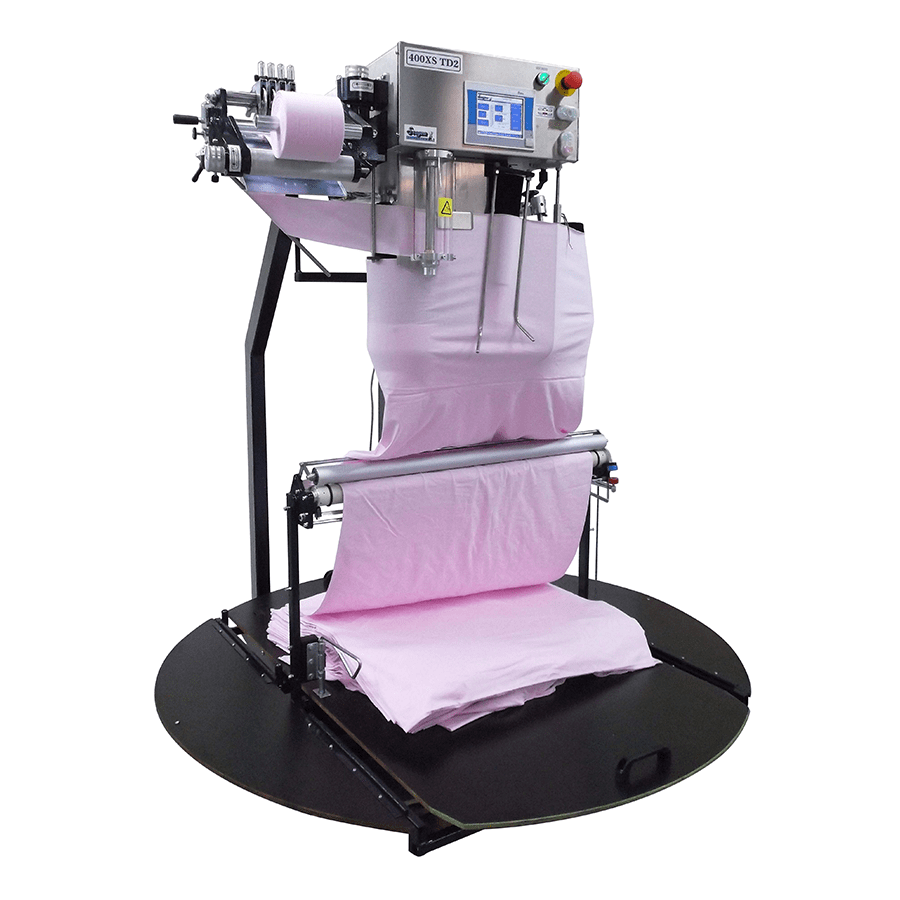

In modern textile manufacturing, adaptability is no longer optional—it’s essential. As demand grows for flexible production, especially in knitwear and activewear, manufacturers are turning to adaptive garment machinery to streamline operations and maintain quality.

Why Tubular Knit Slitting Matters

Tubular knit fabrics are produced in a continuous loop, which is ideal for circular knitting but not for cutting, printing, or sewing. Before these fabrics can be processed further, they must be slit and opened into flat sheets.

Without proper slitting:

– Edges may distort or curl

– Automated cutting systems can misalign

– Waste increases due to poor edge control

– Finished garments may suffer in quality

This step, though often overlooked, directly affects efficiency and product consistency.

The Role of Adaptive Machinery

Adaptive garment machinery refers to equipment that adjusts dynamically to different fabric types, production speeds, and operational conditions. In tubular knit slitting, this means:

- Automatic edge guiding for alignment

- Adjustable slitting widths for varied outputs

- High-speed operation with minimal waste

- Compatibility with both light and heavy knits

These features allow manufacturers to respond quickly to changing production needs without sacrificing precision.

Integration into Production Lines

Slitting machines are typically placed early in the workflow—after knitting and before cutting or printing. To integrate effectively, they must:

- Fit within existing layouts

- Offer intuitive controls for operators

- Require minimal maintenance

- Support continuous, high-volume use

When adaptive slitting technology is used, production lines become more responsive and less prone to bottlenecks.

Industry Applications

This machinery is especially relevant for:

- On-demand fashion production

- Mass customization models

- Sustainable textile workflows

- Technical and performance apparel

By enabling consistent slitting across diverse knit fabrics, adaptive systems support manufacturers aiming for speed, flexibility, and reduced waste.

A Significant Small Step

Tubular knit slitting may seem like a small step, but its impact is significant. With adaptive garment machinery, manufacturers gain the precision and flexibility needed to meet modern demands.

If you’re exploring ways to improve your knitwear production, consider how adaptive slitting can elevate your workflow.

To learn more or request a consultation, email Håkan at (mailto:hakan@svegea.se) or contact us.

As global demand for ethical and efficient clothing production increases, manufacturers are reevaluating every step of their production process. One area gaining renewed attention is bias cutting—a technique that enhances stretch, durability, and fabric utilization. While often overlooked, bias-cutting systems play a vital role in advancing sustainable garment production.

What Is Bias Cutting and Why Does It Matter?

Bias cutting involves slicing fabric diagonally across its grain, typically at a 45-degree angle. This method allows textiles to stretch naturally, conform to body shapes, and resist fraying. It’s especially useful in garments requiring flexibility, such as:

- Activewear

- Lingerie

- Children’s clothing

- Knit trims and collarettes

By improving fit and performance, bias cutting contributes to the creation of longer-lasting garments—an often underappreciated aspect of sustainability.

Automation and Efficiency in Bias Cutting

Traditionally, bias cutting was done manually. This process was slow, inconsistent, and wasteful. Today, automated bias-cutting systems have transformed the landscape. These machines:

- Align fabric edges with precision.

- Adjust cutting widths for different materials

- Join bias strips seamlessly using integrated sewing units

- Wind fabric under controlled tension for easy handling

As a result, manufacturers can reduce labor costs, minimize waste, and maintain consistent quality across production batches.

Sustainability Beyond the Buzzwords

Sustainability isn’t just about organic cotton or recycled polyester. It’s also about how garments are made. Bias cutting systems support sustainable garment production by:

- Reducing fabric waste through accurate slitting and joining

- Optimizing material usage, especially in high-volume runs

- Lowering energy consumption with efficient, high-speed operation

- Extending product life by improving garment performance

These benefits align with global sustainability goals and industry certifications, making bias-cutting systems a strategic investment—not just a technical upgrade.

Relevance Across Global Markets

From Southeast Asia to Scandinavia, textile manufacturers face similar challenges: rising costs, stricter regulations, and shifting consumer expectations. Bias cutting systems offer scalable solutions for:

- Localized production hubs

- Fast fashion models require agility

- Technical textile producers working with complex fabrics

Whether you’re a small-scale knitwear producer or a large garment exporter, bias cutting technology can support your sustainability roadmap.

Ready to Explore Smarter Solutions?

If you’re looking to enhance your production efficiency while supporting sustainable garment practices, it’s worth exploring what modern bias cutting systems can offer.

Contact Håkan Steene (h.steene@svegea.se) or visit www.svegea.se to learn more about how their bias-cutting solutions align with your sustainability goals.

Small Manufacturers, Global Expectations

In today’s fast-paced apparel industry, small garment manufacturers are under increasing pressure to meet global standards of quality, speed, and sustainability. From trims in Portugal to activewear in North Carolina and knitwear in Vietnam, the demand for scalable textile machinery for garment production is transforming how lean operations compete.

Fortunately, innovation is no longer exclusive to mega-factories. Today’s scalable textile machines are compact, intelligent, and built to empower small manufacturers—allowing them to grow efficiently without compromising craftsmanship. These advanced tools are reshaping how factories adapt, expand, and thrive in a global marketplace.

Success starts with choosing the right machinery—and scaling smart from the start.

The Power of Precision in a Compact Package

Gone are the days when automation was reserved for mega-factories. Today’s machines are modular, compact, and built to integrate seamlessly into lean production environments. They offer:

- High-speed performance without overwhelming your floor space

- Energy-efficient motors that reduce operational costs

- User-friendly interfaces that minimize training time

- Consistent output that supports quality control

Take the Svegea CMS 1800A2 Strip Cutter, for example. It’s engineered for high-speed strip cutting from tubular or open-width fabric—ideal for bias tape, trims, and bindings. Its compact footprint and low-maintenance design make it a smart fit for small operations looking to scale without stress.

Why Scalability Beats Size

Scalability isn’t about becoming a giant—it’s about being ready. With scalable machinery, you can:

- Respond quickly to seasonal surges

- Take on new contracts with confidence

- Maintain consistent quality across product lines

- Reduce reliance on manual labor during peak periods

This flexibility is especially critical in regions where labor costs are rising or skilled operators are in short supply. Machines like the CMS 1800A2 help bridge that gap, offering reliability without complexity.

Sustainability: A Strategic Advantage

Eco-conscious production is no longer a niche—it’s a requirement. Buyers across Europe and North America are demanding transparency, traceability, and reduced environmental impact. Textile machinery plays a pivotal role in meeting these expectations.

Modern machines consume less energy, produce less waste, and support cleaner workflows. For manufacturers aiming to align with ESG goals or attract sustainability-focused clients, upgrading equipment is a strategic move—not just a technical one.

Empowering Craft, Not Replacing It

Small manufacturers often pride themselves on craftsmanship. That shouldn’t change. But smart machines can support that craft by handling repetitive tasks, freeing up skilled workers to focus on design, finishing, and quality assurance.

It’s not about replacing people—it’s about enabling them to do their best work.

Transitioning Without Turbulence

Worried about disruption? Designers create today’s textile machines for smooth integration. With proper planning, upgrades can be implemented with minimal downtime. Scalable textile machinery systems for garment production offer multilingual interfaces and remote support, making onboarding faster and easier.

The CMS 1800A2, for instance, has an intuitive setup and reliable performance—making it a low-risk, high-reward investment.

Final Stitch: Invest in What Moves You Forward

The garment industry is evolving. Markets are more demanding, timelines are tighter, and sustainability is non-negotiable. For small and mid-sized producers, the path forward isn’t paved with massive capital—it’s built on smart, scalable decisions.

Modern textile machinery offers a way to grow without losing control. It’s not about chasing volume—it’s about building resilience.

Ready to explore how one machine could reshape your production flow? Contact Håkan Steene (h.steene@svegea.se) for a product demo or more details. No pressure—just possibilities.

In today’s competitive garment and textile industry, efficiency isn’t just a technical benchmark—it’s a bottom-line imperative. Outdated machinery may seem serviceable, but behind the scenes, it’s quietly draining profits through excessive energy use, frequent breakdowns, and mounting maintenance costs.

As global demand intensifies and margins tighten, manufacturers are rethinking their approach. The shift toward cost-saving textile machinery isn’t just about modernization—it’s about survival. Smarter, more sustainable equipment is helping producers cut waste, optimize workflows, and unlock new levels of profitability

The True Cost of Outdated Equipment

While legacy machines may still function, they often demand more attention than they’re worth. Repairs become more frequent. Production slows. Fabric waste increases due to inconsistent cuts and poor precision. These issues don’t just affect workflow—they directly impact your bottom line.

Moreover, older systems typically lack automation features that modern factories depend on. As a result, labor costs rise, and throughput suffers. In an industry where speed and consistency are critical, falling behind can mean losing contracts or missing seasonal demand.

Upgrading to advanced textile machinery can dramatically shift your cost structure. Today’s machines are designed for high-speed, precision performance and built to last. The benefits are clear:

- Reduced Material Waste: Precision cutting minimizes fabric loss and maximizes yield.

- Lower Maintenance Costs: Durable engineering reduces downtime and service interventions.

- Energy Efficiency: Optimized motor systems consume less power, resulting in lower utility bills.

- Increased Output: Automation and speed enhancements enable the production of more garments per hour.

To illustrate how modern machinery delivers these benefits, let’s look at a real-world example.

One standout example is Svegea of Sweden’s EC300-S Collarette Cutter. Known for its high-speed precision and low maintenance requirements, it’s a favorite among garment manufacturers aiming to streamline production. The EC300-S reduces fabric waste, boosts output, and consumes less energy—making it a smart investment for both profitability and sustainability.

Real-World ROI: Efficiency That Pays Off

Consider a mid-sized garment factory that replaces its aging collarette cutter with a high-speed model. Within a year, production increases by 20%, fabric waste drops by 15%, and maintenance calls are reduced by nearly a third. These improvements don’t just save money—they create capacity for growth.

Even better, the return on investment often exceeds the initial purchase cost within the first 12 months. That’s not just smart—it’s strategic.

Sustainability Meets Profitability

Efficiency isn’t only about saving money. It’s also about reducing environmental impact. Machines like the EC300-S support eco-conscious manufacturing by using less energy and producing less waste. For brands focused on ESG goals, this alignment is essential.

Invest in What Moves You Forward

Standing still in textile manufacturing is a risk. Upgrading your machinery isn’t just a technical decision—it’s a business move that affects quality, speed, sustainability, and profitability. Whether you’re scaling up or streamlining operations, investing in cost-saving textile machinery can be the difference between surviving and thriving.

Ready to rethink your production strategy?

Explore how smarter textile machinery can reshape your efficiency, reduce waste, and support sustainable growth. Learn more about proven solutions like the EC300-S Collarette Cutter and discover what modern upgrades could mean for your bottom line. Contact Håkan Steene at h.steene@svegea.se to learn more, request product details, or schedule a hands-on demonstration tailored to your needs.

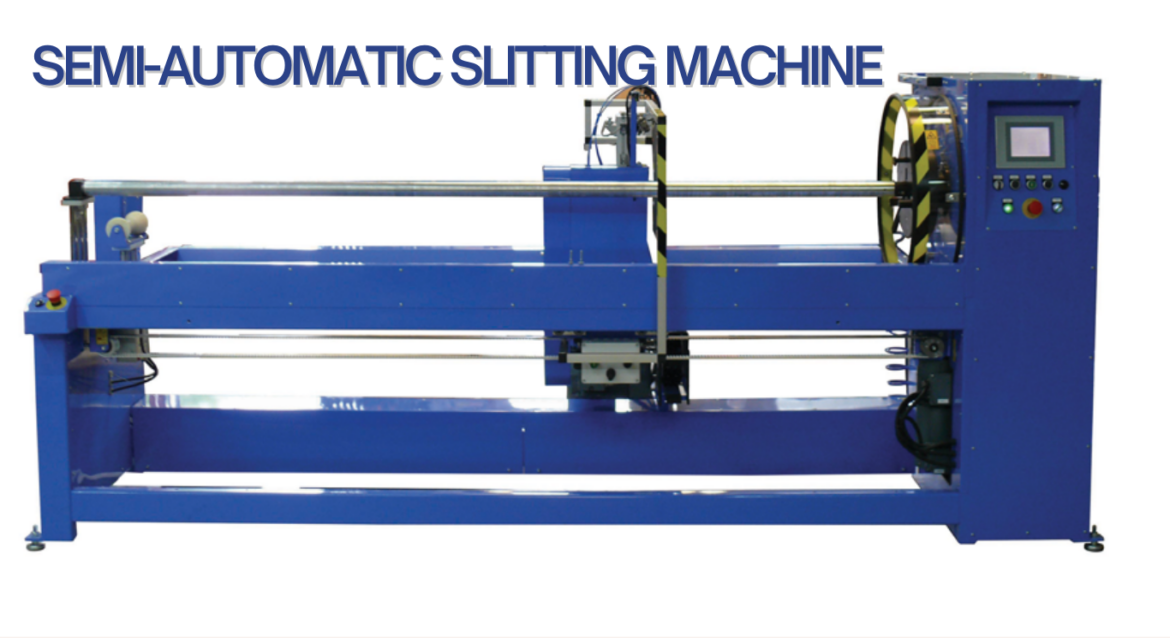

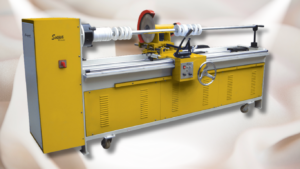

In today’s fast-evolving manufacturing landscape, innovation isn’t a luxury—it’s a necessity. As textile producers face increasing pressure to boost productivity, cut costs, and maintain precision, one solution is proving itself indispensable: semi-automatic textile machines. These smart, efficient systems are revolutionizing how factories operate—bridging the gap between manual control and full automation.

Let’s dive into how semi-automatic machinery is transforming textile production lines around the world, and why forward-thinking manufacturers are weaving it into the fabric of their future.

The Rise of Smart Manufacturing in Textiles

Over the last decade, the textile and garment industry has undergone a significant technological shift. From digitized workflows to AI-enhanced design, the entire supply chain is changing shape—and fast. Semi-automatic textile machines represent a pivotal step in this evolution.

They offer the best of both worlds: human control and machine precision. Operators maintain oversight, while machines handle repetitive tasks with consistent accuracy. The result? Fewer errors, faster output, and less downtime.

Why “Semi-Automatic” Is the Sweet Spot

You might be wondering—why not go fully automatic? While full automation certainly has its place in large-scale operations, semi-automatic systems often prove more practical and cost-effective for small to mid-sized manufacturers.

Here’s why:

- Flexibility: Semi-automatic machines adapt quickly to different fabric types, roll sizes, or production goals without requiring complex reprogramming.

- Cost Efficiency: They’re more affordable than fully automated systems—both in upfront investment and maintenance.

- Precision and Control: Operators can intervene when needed, minimizing mistakes and maximizing material utilization.

When integrated strategically, these machines deliver a near-instant upgrade to any production line.

Real-World Impact: Boosting Output Without Compromising Quality

Let’s talk numbers. In many cases, textile producers using semi-automatic slitting or cutting machines have reported:

- Up to 40% increase in production efficiency

- 25% reduction in material waste

- Significantly lower labor fatigue and error rates

This is especially critical when working with high-value or delicate fabrics, where precision isn’t optional—it’s everything.

Svegea, a trusted innovator in textile machinery, has been at the forefront of this shift. Their range of semi-automatic textile machines offers cutting-edge features that balance performance with user-friendly operation. Whether you’re slitting rolls, trimming edges, or cutting fabric panels, Svegea’s equipment ensures precision without the steep learning curve.

Key Benefits for Manufacturers

Still wondering if it’s the right move for your operation? Here are five compelling benefits of semi-automatic textile machines you can’t ignore:

1. Increased Throughput

By automating repetitive motions while keeping decision-making in human hands, these machines dramatically speed up production without sacrificing quality.

2. Reduced Operational Downtime

Thanks to straightforward interfaces and intuitive controls, troubleshooting and adjustments can be made quickly, keeping your lines running smoothly.

3. Better Resource Management

Semi-automatic systems optimize how material is handled and processed, leading to lower waste and higher yield.

4. Enhanced Product Consistency

Uniform cutting, slitting, and trimming mean fewer reworks and returns.

5. Safer Work Environment

These machines eliminate many of the risks associated with manual cutting tools, creating a safer space for your workforce.

Meet the Machines Making It Happen

Svegea’s lineup of semi-automatic machines includes slitting systems, band knife machines, and edge trimmers—all engineered for ease of use and long-term reliability. Designed and manufactured in Sweden, these machines combine high-performance mechanics with modern design standards.

Each model is created with specific applications in mind, including:

- Roll-to-roll precision slitting

- Multilayer fabric processing

- Durable textile cutting with minimal fabric distortion

Whether you’re producing garments, upholstery, technical fabrics, or industrial textiles, Svegea offers purpose-built equipment to meet your unique needs.

What Industry Leaders Are Saying

Manufacturers across Europe and Asia who’ve adopted Svegea’s semi-automatic machines are seeing tangible improvements not just in throughput, but in staff satisfaction and operational control.

“We upgraded to a Svegea roll slitting machine last year, and the difference was immediate,” one production manager shared. “The machine paid for itself in less than six months through time saved and reduced waste.”

These are results that any manufacturer can get behind.

Future-Proofing Your Production Line

With labor shortages, rising material costs, and fluctuating market demands, investing in adaptable machinery is more critical than ever. Semi-automatic systems give you the edge today, while preparing your facility for the continued rise of smart manufacturing.

They also allow for easier integration with upstream and downstream processes, including material handling systems, labeling, and packaging, streamlining your entire workflow.

Ready to Step Up?

If you’re ready to enhance efficiency without losing control, Svegea’s semi-automatic textile machines could be your perfect fit. Designed for manufacturers who need to move fast, stay lean, and deliver quality with every yard, Svegea solutions are here to keep your production future-ready.

📩 Contact Håkan Steene today at h.steene@svegea.se to learn more, get product specs, or schedule a live demo.

You can also explore the range online here: https://svegea.se/product-category/roll-slitting-machines/semi-automatic-roll-slitting-machines/

As the fashion world gears up for Summer 2025, textile manufacturers and garment producers have a golden opportunity to meet growing demands with innovative materials, smart production techniques, and trend-driven designs. This season is all about sustainability, tech-infused textiles, and nostalgic yet bold aesthetics, making it crucial for manufacturers to stay ahead of the curve.

Consumers are ready to refresh their wardrobes, and retailers will be on the lookout for efficient, cost-effective solutions to stock their shelves with the latest trends. But how can manufacturers prepare for this seasonal surge without compromising on quality, speed, or sustainability?

Let’s explore the top Summer 2025 fashion trends and uncover ways textile producers can maximize their production capabilities while minimizing costs.

Fashion Trends Manufacturers Must Watch

Fashion is a dynamic industry that continuously reinvents itself. As we move into summer, some exciting trends have emerged that manufacturers should integrate into their production planning.

1. Sustainable Elegance: Eco-Friendly Fabrics Take Center Stage

Sustainability is more than just a buzzword—it’s a movement shaping fashion’s future. Consumers are increasingly aware of their environmental impact, leading to a surge in demand for eco-friendly textiles such as:

- Organic cotton

- Recycled polyester

- Plant-based dyes

- Biodegradable fabrics

For manufacturers, adopting sustainable textile options can open doors to new partnerships with eco-conscious brands and appeal to consumers seeking ethical fashion.

2. Tech-Infused Textiles: The Future of Fabric Innovation

Innovation isn’t just for smartphones—it’s transforming textiles too! Expect to see high-tech materials gaining popularity, including:

- Moisture-wicking fabrics for activewear

- UV-resistant textiles for summer essentials

- Temperature-regulating fabrics for everyday wear

- Smart textiles with embedded sensors for health & wellness tracking

By incorporating cutting-edge textile machinery, manufacturers can streamline production processes for these innovative fabrics, ensuring high demand doesn’t slow down efficiency.

3. Retro Revival & Bold Colors: Nostalgic Yet Fresh

Fashion takes a trip down memory lane with 90s-inspired silhouettes, vibrant hues, and retro prints. Think oversized blazers, wide-leg pants, and bright florals.

Manufacturers should focus on:

– Versatile multi-use fabrics

– Cost-effective digital printing techniques for bold designs

– Flexible dyeing processes to create custom hues

With bold statement pieces leading the season, production processes need to be agile while ensuring quality craftsmanship.

How Textile Manufacturers Can Stay Ahead of the Competition

With demand soaring, efficiency is key. Here’s how manufacturers can optimize production and take advantage of fashion’s seasonal boom:

1. Upgrade to Advanced Textile Machinery

The backbone of textile manufacturing is high-performance machinery. Investing in automated systems and AI-driven technologies can dramatically boost production speed while reducing labor costs.

For manufacturers looking to upgrade with minimal expenses, innovative textile machinery from industry leaders like Svegea can provide cost-effective solutions tailored for mass production.

2. Adopt Sustainable Production Methods

Green practices aren’t just a trend—they’re a necessity. Implementing low-waste production techniques and using renewable energy sources in factories can:

– Improve brand image

– Attract eco-conscious retailers

– Reduce long-term costs

3. Leverage Automation for Faster Turnaround

Automated cutting, digital printing, and AI-driven production systems allow manufacturers to:

– Scale production without increasing overhead

– Meet tight deadlines effortlessly

– Reduce fabric waste through precision cutting

Preparing for the Summer 2025 Rush

Textile manufacturers and garment producers have a prime opportunity to take advantage of the Summer 2025 fashion wave. With sustainability, smart textiles, and retro-inspired designs dominating the industry, manufacturers need to stay flexible and innovative.

To supercharge production and reduce costs, partnering with Svegea of Sweden for state-of-the-art textile machinery is a game-changer.

Contact Hakan Steene today at h.steene@svegea.se and get ready to transform your production capabilities!

The textile industry is transforming. With growing concerns about environmental impact, manufacturers are shifting towards sustainable textile practices. From reducing waste to adopting energy-efficient machinery, the industry is embracing innovation to create a greener future.

The Rise of Circular Fashion

Circular fashion is revolutionizing the textile industry. Instead of the traditional linear model, where clothes are made, used, and discarded, circular fashion promotes recycling and reusing materials. Brands are now designing garments with longevity in mind, using biodegradable fabrics and closed-loop production systems.

Key Circular Fashion Strategies:

-

- Recycling & Upcycling: Old textiles are repurposed into new garments, reducing landfill waste.

- Closed-Loop Production: Materials are continuously reused, minimizing resource depletion.

- Biodegradable Fabrics: Natural fibers like organic cotton and hemp decompose without harming the environment.

Zero-Waste Manufacturing: Eliminating Textile Waste

Traditional textile production generates excessive waste. However, zero-waste manufacturing aims to eliminate fabric scraps and optimize material usage.

How Zero-Waste Manufacturing Works:

-

- Precision Cutting: Advanced machinery ensures minimal fabric waste.

- Fabric Optimization: Designers create patterns that maximize fabric efficiency.

- Waste Repurposing: Leftover materials for accessories or insulation.

Eco-Friendly Dyeing Techniques: Reducing Water & Chemical Usage

Dyeing is one of the most polluting processes in textile manufacturing. Fortunately, eco-friendly dyeing techniques are emerging to reduce water consumption and chemical waste.

Sustainable Dyeing Methods:

- Natural Dyes: Extracted from plants and minerals, these dyes are biodegradable.

- Waterless Dyeing: Innovative technologies like CO₂ dyeing eliminate water usage.

- Low-Impact Dyes: Require fewer chemicals, reducing environmental harm.

Automation & Advanced Machinery: Reducing Energy Consumption

Automation is reshaping textile manufacturing by driving smarter, more sustainable operations. With advanced machinery and AI-powered systems, manufacturers reduce energy consumption, cut material waste, and boost productivity. These technologies fine-tune power usage to lower carbon footprints while delivering consistent speed and precision. By minimizing errors and maximizing efficiency, automation gives textile producers a competitive edge and a cleaner path forward.

Sustainable Textile Manufacturing

Svegea is at the forefront of sustainable textile production. Their innovative machinery enhances efficiency while reducing environmental impact. By integrating automation and precision engineering, Svegea helps manufacturers adopt greener practices without compromising quality.

For more information on sustainable textile manufacturing and product demos, contact Hakan Steene at h.steene@svegea.se.

The textile industry is undergoing a digital revolution, and AI in textile manufacturing is at the forefront of this transformation. Artificial intelligence reshapes how textiles are created, manufactured, and distributed, from optimizing design processes to enhancing production efficiency.

AI in Textile Design: Innovation Meets Creativity

AI is revolutionizing textile design by enabling faster, smarter, and more efficient pattern-making. Designers now use AI-powered tools to generate intricate patterns, predict fashion trends, and customize designs based on consumer preferences.

How AI Enhances Textile Design:

-

- Automated Pattern Generation: AI algorithms analyze vast datasets to create unique textile patterns.

- Trend Prediction: Machine learning models forecast upcoming fashion trends, helping designers stay ahead.

- Customization: AI-driven tools allow brands to personalize designs based on customer preferences.

AI in Textile Production: Efficiency and Precision

AI is streamlining textile production by automating processes, reducing waste, and improving quality control. Manufacturers are integrating AI into machinery to optimize operations and enhance productivity.

Key AI Applications in Textile Production:

AI is transforming textile production through targeted, high-impact applications. Automated  fabric inspection systems now use advanced vision technology to identify defects with precision, ensuring only high-quality materials move forward in the process. On the factory floor, smart manufacturing machines continuously adjust their settings in real time, maximizing efficiency and minimizing downtime. Meanwhile, AI-driven supply chain tools analyze demand patterns and guide resource allocation, keeping operations agile and responsive.

fabric inspection systems now use advanced vision technology to identify defects with precision, ensuring only high-quality materials move forward in the process. On the factory floor, smart manufacturing machines continuously adjust their settings in real time, maximizing efficiency and minimizing downtime. Meanwhile, AI-driven supply chain tools analyze demand patterns and guide resource allocation, keeping operations agile and responsive.

AI-Driven Innovations in the Textile Industry

AI is not just improving efficiency—it’s driving groundbreaking innovations in textile production.

Examples of AI-Driven Innovations:

-

- AI-Powered Smart Textiles: Fabrics embedded with AI sensors for enhanced functionality.

- Predictive Maintenance: AI anticipates machine failures, reducing downtime.

- Eco-Friendly AI Solutions: AI optimizes dyeing processes to minimize environmental impact.

The Future of AI in Textile

AI is transforming the textile industry, making design and production more efficient, sustainable, and innovative. As AI continues to evolve, manufacturers and designers must embrace these advancements to stay competitive.

For more information on AI in textile manufacturing and product demos, contact Hakan Steene at h.steene@svegea.se.