In today’s fast-paced textile industry, precision, speed, and sustainability are no longer optional — they’re essential. That’s why manufacturers around the world are turning to Swedish textile cutting machinery — specifically Svegea, a company that’s been redefining automated cutting solutions since 1952.

Svegea’s Swedish-engineered solutions help manufacturers by focusing on automation, sustainability, and user-friendly design to improve efficiency, reduce waste, and adapt to market demands. Their machines support the creation of smarter, more connected factories through integration with Industry 4.0 principles, making them ideal partners for reshoring efforts and sustainable production goals.

Automation: The Foundation of Competitive Manufacturing

High-Speed Precision Cutting

Svegea’s textile cutting machinery from Sweden is engineered for high-speed, precise cutting, which helps produce consistent quality and faster production times. Every machine is designed to maintain exacting standards even at maximum operational speeds, ensuring that manufacturers can scale production without sacrificing quality.

- EC-450XF Collarette Cutting System: Awarded at Texprocess 2023 for its innovation and sustainability, this fully automatic system delivers high-speed, low-waste performance with precision that’s become the industry benchmark.

- Euro-Collarette Fully Automatic Series: These models feature the intuitive E Drive 2 panel and two-step cutting for multiple bands — ideal for high-volume operations requiring consistent output.

Automated Processes That Reduce Labor Dependency

Svegea integrates automatic tube sewing units for creating sewn tubes in rolled or flat-folded forms, reducing the need for operator assistance and minimizing human error.

- TSU 200 A/AF Tube Sewing Unit: Minimal operator input, maximum efficiency. This system exemplifies how automation enables manufacturers to redirect skilled labor to higher-value tasks.

- Bias Cutter / Winder 200: Smooth unwinding and rewinding into single ply rolls with minimal manual intervention.

- Bias Cutter CMB 1800: Versatile and adaptable across fabric types, streamlining the entire bias binding process.

Supporting Reshoring with Smart Automation

Automation facilitates reshoring operations by making local manufacturing more competitive and efficient. Sweden’s textile cutting machinery industry leads this transformation, offering manufacturers the tools they need to bring production home without sacrificing cost-effectiveness.

Sustainability: Engineering for a Better Future

Precision That Reduces Waste

Precision cutting and automation help maximize fabric usage, minimizing material waste. Svegea’s machines are engineered to optimize every centimeter of fabric, contributing directly to both profitability and environmental responsibility.

- Strip Cutter CMS 1800A2: High-speed cutting for bias tape, trims, and bindings with advanced nesting algorithms that reduce offcut waste.

- TSO 380 G/GF Tubular Knit Slitter: Reduces waste and improves material yield through intelligent cutting patterns.

Energy-Efficient Engineering

Svegea’s machinery is designed to be energy efficient, lowering consumption and environmental impact. Every system is optimized for minimal power draw without compromising performance, making textile cutting machinery from Sweden a smart choice for manufacturers committed to reducing their carbon footprint.

- RRS-800 Fully Automatic Roll Slitting Machine: Offers motorized knife control and adjustable speed for consistent quality while maintaining low energy consumption throughout extended production runs.

Supporting Circular Economy and Recycled Materials

By improving garment durability and promoting longevity through efficient production, Svegea’s machines contribute to a more circular economy. The advanced technology can support the use of recycled materials in production, accommodating the varied characteristics of reclaimed fabrics without compromising cut quality.

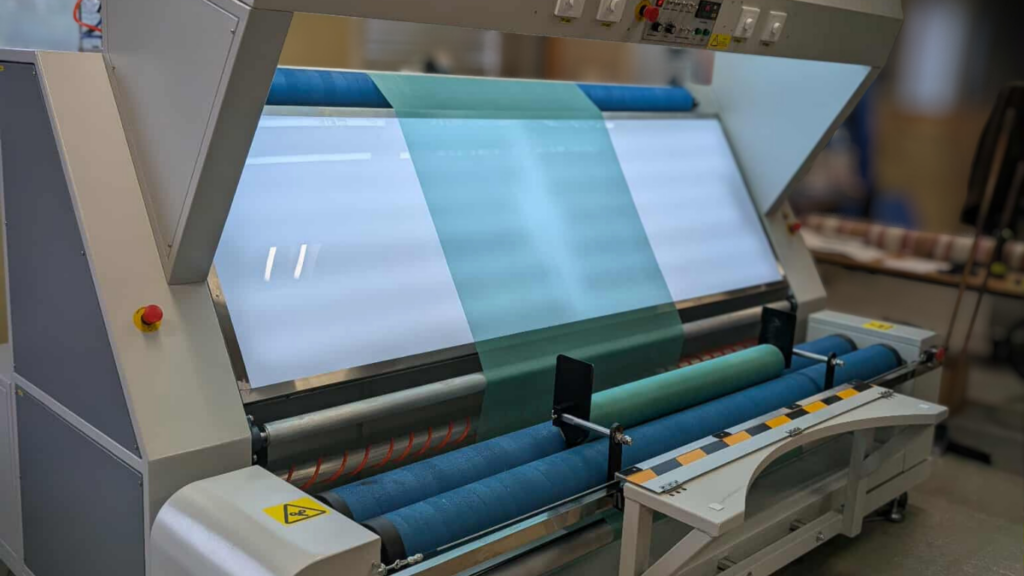

- FIM CMI 210 R / ZR Fabric Inspection Machine: Detects defects and inconsistencies in both virgin and recycled materials before they reach the cutting floor, ensuring quality regardless of source.

User-Friendly Design: Versatility Meets Accessibility

Adaptable Across Material Types

The cutting machines can handle a wide range of materials, from delicate silks to heavy-duty industrial textiles. This versatility makes Swedish textile cutting machinery ideal for manufacturers serving diverse market segments.

- SV/BK Band Knife Series: Precision cutting for everything from delicate silks to heavy-duty fabrics, with easily adjustable settings for quick material transitions.

- Strip Cutter FA 500: Heavy-duty and reliable, perfect for long production cycles with materials ranging from PVC to non-woven fabrics.

Quick Changeovers for Maximum Productivity

User-friendly interfaces and the ability to quickly switch between patterns and materials reduce downtime and enhance productivity. The intuitive E Drive 2 control panel makes complex operations accessible to operators at all skill levels.

- Euro-Collarette Semi-Automatic Series: A semi-automatic option that cuts two bands simultaneously, with widths ranging from 16 to 140 mm — changeable in minutes, not hours.

Customization for Niche Applications

Svegea provides custom-specific machines and units for niche applications like bias cutting, and can adapt to diverse customer preferences. This flexibility ensures that whether you’re producing standard collarettes or specialized technical textiles, there’s a solution engineered specifically for your needs.

- W 2100S Fabric Rewinding Machine: Perfect re-rolls every time, with customizable tension and speed settings for different fabric types.

Industry 4.0 Integration: Building Smarter Factories

Sweden’s textile cutting machinery leads the way in smart manufacturing integration. Designed to connect seamlessly with modern factory management software the Svegea system enables:

- Real-time production monitoring and quality control

- Predictive maintenance scheduling to minimize downtime

- Data-driven optimization of cutting patterns and material usage

- Integration with inventory and supply chain management systems

This connectivity transforms individual machines into components of an intelligent manufacturing ecosystem. The result? Long-term competitiveness in an increasingly digital industry.

The Swedish Advantage: Seven Decades of Innovation

Textile cutting machinery from Sweden represents more than a geographic label — it’s a commitment to quality, innovation, and sustainability. Svegea embodies the best of Swedish engineering: meticulous attention to detail, long-term reliability, and environmental responsibility.

Svegea has been serving global textile manufacturers since 1952, continuously innovating to meet the evolving demands of modern production. This heritage of excellence makes Swedish textile cutting machinery a global benchmark for quality, sustainability, and technological advancement.

Ready to Transform Your Production Line?

Experience how premium Swedish textile cutting machinery can revolutionize your operations. Whether you’re looking to reshore production, reduce waste, improve efficiency, or build an Industry 4.0-ready factory, Svegea has the solutions you need.

Explore Svegea’s full range of automated textile solutions at svegea.se. For a personalized product demo and consultation, contact Håkan Steene at h.steene@svegea.se.

Let’s build the future of sustainable, efficient textile manufacturing — together.

The fashion revolution isn’t just a trend—it’s a full-blown transformation. It’s bold, it’s beautiful, and it’s reshaping everything from haute couture to humble factory floors. Circular fashion, once a niche concept whispered among eco-warriors, is now the heartbeat of the industry. And guess what? It’s not just designers and influencers leading the charge. Garment and textile manufacturers are stepping into the spotlight, armed with smart machines and sustainable strategies.

Circular Fashion: More Than Just a Buzzword

Let’s be real. Fashion has always been about reinvention. But the fashion revolution is different. It’s not about chasing the next look; it’s about changing the way we make, wear, and reuse clothing. Circular fashion means designing garments that last longer, can be repaired, recycled, or repurposed, and don’t end up as landfill clutter.

Consumers are loving it. From thrifted treasures to biodegradable sneakers, they’re choosing pieces that tell a story—and respect the planet. But behind every conscious choice is a manufacturer making it possible.

The Factory Floor Joins the Revolution

Here’s where things get exciting. The fashion revolution isn’t just happening on runways or in retail. It’s happening in factories, where smart technology is turning sustainability into profitability.

Modern fabric inspection systems now detect flaws before cutting begins, reducing waste and improving quality. Automated cutting machines use AI to map out the most efficient layouts, saving material and time. These innovations aren’t just cool—they’re crucial.

According to the Stockholm Resilience Centre, circular fashion models are key to reducing environmental impact and building resilient supply chains. And manufacturers who embrace these models are seeing real results.

Fashion Revolution = ROI Revolution

Let’s talk numbers. The fashion revolution isn’t just good for the Earth—it’s good for business.

By optimizing material use with smart inspection and cutting tech, manufacturers reduce fabric waste, lower production costs, and increase output. That means better margins and faster turnaround. Plus, sustainable practices attract eco-conscious brands and consumers, boosting demand and loyalty.

A study published by MDPI found that circular economy strategies like reuse, recycling, and reduction are not only environmentally beneficial—they’re economically viable. In other words, sustainability sells.

From Catwalk to Cutting Table

Designers may sketch the vision, but manufacturers bring it to life. The fashion revolution depends on this partnership.

Imagine a designer creating a zero-waste collection. To make it real, the factory needs machines that can handle unconventional fabrics, cut with precision, and minimize leftovers. That’s where innovation meets execution.

Why Manufacturers Should Care

Still wondering if the fashion revolution is worth the investment? Let’s break it down:

- Relevance: Brands are demanding sustainable production. If you can’t deliver, they’ll find someone who can.

- Efficiency: Smart machines reduce waste, save time, and improve consistency.

- Compliance: Regulations around textile waste are tightening. Circular practices help you stay compliant.

- Growth: Eco-conscious consumers are driving demand. Be ready to scale sustainably.

This isn’t just a movement—it’s a market shift. And manufacturers who adapt will thrive.

The Future Is Circular—and Smart

Circular fashion is here to stay. And the fashion revolution is only getting stronger. From recycled fibers to AI-powered cutting tables, the tools are ready. The demand is real. And the opportunity is massive.

If you’re a garment or textile manufacturer, now is the time to act. Don’t just watch the revolution—join it.

“The fashion revolution is not just about what we wear—it’s about how we make it. At Svegea, we’re committed to helping garment and textile manufacturers stay ahead by innovating our machinery to support circular fashion models. Sustainability and profitability can go hand in hand.” — Hakan Steene, Managing Director, Svegea of Sweden

Contact Hakan Steene at h.steene@svegea.se to explore Svegea’s innovative textile machinery. These sustainable solutions are designed to help your company stay relevant, reduce waste, and boost ROI in the age of the fashion revolution.

Fashion is changing—and fast. Today, being eco-friendly isn’t just a trend. It’s a smart move. People care more about the planet, and they want clothes made responsibly. That’s where fabric innovation comes in. It’s helping fashion brands create better materials and use smarter machines to make clothes in cleaner ways.

Let’s explore how new fabrics and modern machines are working together to build a more sustainable fashion industry.

New Materials, New Possibilities

For years, most clothes were made from cotton or polyester. These materials use a lot of water, chemicals, and energy. But now, designers are using things like fruit peels, mushrooms, and even carbon from the air to make fabric.

Here are a few examples:

- Mylo: A soft, leather-like material made from mushroom roots. It feels like real leather but is biodegradable and doesn’t harm animals.

- Orange Fiber: Made from leftover citrus peels. It’s silky and smooth, perfect for dresses and scarves.

- Piñatex: Created from pineapple leaves. It’s strong and flexible, often used in shoes and bags.

These new fabrics are stylish, durable, and better for the environment. They break down naturally and don’t need as many resources to produce. People want to know where their clothes come from, and brands are responding with cleaner, smarter choices.

Machines That Make It Happen

These cool new fabrics wouldn’t exist without the right machines. Today’s textile machines are smarter and greener than ever. They use less water, less energy, and fewer chemicals.

Let’s break down what these machines do:

- Dyeing machines with closed-loop systems: These machines clean and reuse water during the dyeing process. That means less pollution and lower water bills.

- Spinning machines with smart sensors: These sensors adjust the yarn tension automatically. This helps reduce waste and keeps the fabric smooth and strong.

- Aluminum extrusion frames: These lightweight frames make machines faster and easier to maintain. They also use less energy during production.

This is where fabric innovation meets smart engineering. By using better materials and better machines, factories can make high-quality clothes while protecting the planet.

Why Going Green Is Good for Business

Being sustainable isn’t just good for the Earth—it’s good for business too. Brands that use fabric innovation often save money and attract more customers.

Here’s how:

- Lower energy costs: Machines that use less electricity help reduce monthly bills.

- Fewer labor expenses: Automated systems do more work with fewer people, saving time and money.

- Longer-lasting products: Strong, recyclable fabrics mean fewer returns and happier customers.

Also, governments are starting to set stricter rules about waste and pollution. Companies that switch to cleaner methods now will be ready for the future—and avoid fines or delays.

Recycling Clothes: The Circular Fashion Idea

One of the coolest parts of fabric innovation is how it helps with recycling. Instead of throwing old clothes away, companies can now turn them into new fabric.

Here are some exciting developments:

- Fiber-to-fiber recycling: This process breaks down old clothes and spins them into fresh yarn. It keeps materials in use and out of landfills.

- Carbon capture polyester: Some companies are turning carbon dioxide from factory smoke into polyester fabric. It’s a smart way to clean the air and make clothes.

- Lab-grown cotton: Scientists are growing cotton in labs without using farmland or pesticides. It’s clean, safe, and doesn’t harm the soil.

These ideas are already being tested in places like Europe and Asia. They help reduce trash, save resources, and even create new jobs.

Working Together to Make It Work

To make all this happen, people across the fashion world need to team up. Garment manufacturers, fabric developers, and clothing brands must share ideas and work together.

Here’s what that looks like:

- Engineers designing new machines: These machines can handle unusual fabrics like mushroom leather or pineapple fiber.

- Designers experimenting with new styles: They’re testing how these new materials feel, look, and move.

- Factory owners rethinking production: They’re changing how they plan, cut, and ship products to reduce waste and save money.

This teamwork is what makes fabric innovation so powerful. It’s not just about one product—it’s about changing the whole system.

Fashion Innovation is Growing Every Day

If you’re a garment maker, designer, or business owner, this is your moment. The tools are ready. The materials are here. And the demand for sustainable fashion is growing every day.

“At Svegea, we believe fabric innovation is the heartbeat of modern fashion. That’s why we’re constantly evolving our machinery—making it smarter, cleaner, and more adaptable—so garment and textile manufacturers can stay ahead in a fast-changing industry.” — Hakan Steene, Managing Director of Svegea of Sweden

Reach out to Hakan Steene at h.steene@svegea.se to explore how Svegea’s textile machinery can help you lead the way. Whether you’re upgrading your factory or starting fresh, Svegea offers smart solutions that fit your goals—and your budget.

Fabric shrinkage is one of the most overlooked challenges in garment manufacturing. It can lead to misaligned patterns, wasted material, and inconsistent sizing. If you want to prevent fabric shrinkage before cutting, you need to understand what causes it and how to control it.

Let’s explore practical ways to reduce shrinkage and improve cutting accuracy — without adding complexity to your workflow.

Why Does Fabric Shrink?

Shrinkage happens when fibers contract due to heat, moisture, or mechanical stress. Natural fabrics like cotton, rayon, and linen are especially prone to this. Even synthetic blends can shrink slightly under certain conditions.

When fabric is cut before it stabilizes, the final garment may twist, pucker, or lose its intended shape. That’s why it’s essential to prevent fabric shrinkage before cutting — not after.

Pre-Shrinking vs. Relaxing: What’s the Difference?

Pre-shrinking involves washing or steaming the fabric before cutting. While this method works, it’s often inconsistent and time-consuming. Relaxing, on the other hand, allows the fabric to settle naturally. It reduces internal tension caused by rolling, folding, or transport.

For knitwear and stretch fabrics, relaxing is especially effective. It helps prevent fabric shrinkage before cutting by allowing fibers to return to their natural state.

5 Proven Ways to Prevent Fabric Shrinkage Before Cutting

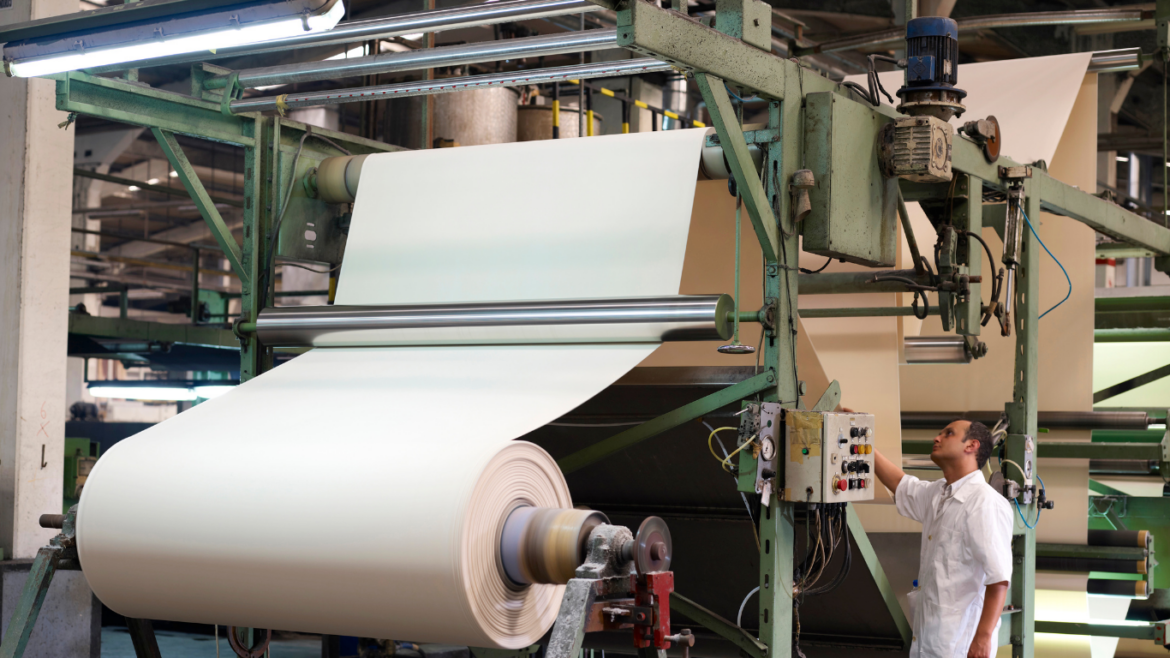

1. Use a Fabric Relaxing Machine

A fabric relaxing machine gently unwinds and settles the fabric. It reduces tension and helps stabilize the material. This is one of the most reliable ways to prevent fabric shrinkage before cutting in high-volume production.

2. Control Room Conditions

Humidity and temperature affect fiber behavior. Keep your cutting room at a consistent humidity level (around 60–70%) and avoid sudden temperature changes.

3. Let Fabric Rest

If you don’t have a relaxing machine, lay the fabric flat and let it rest for 12–24 hours. This passive method still helps reduce shrinkage and curling.

4. Test Shrinkage Rates

Before bulk cutting, test a small swatch. Wash or steam it, then measure the change. This helps you adjust your cutting patterns and prevent shrinkage before cutting large batches.

5. Avoid Immediate Cutting

Fabric fresh off the roll is often under tension. Give it time to settle before cutting to avoid distortion and waste.

Why It Matters

Controlling fabric shrinkage before cutting is essential for consistent garment quality. Shrinkage can distort patterns, misalign seams, and lead to costly rework. By stabilizing fabric early—through relaxing, resting, or testing—you reduce waste and improve production accuracy. This not only protects your materials but also strengthens your brand’s reliability. Manufacturers who take shrinkage seriously deliver better-fitting garments and fewer returns. In a competitive market, precision matters. Starting with properly prepared fabric sets the tone for everything that follows.

Integrating Fabric Relaxing System

Want to improve cutting accuracy and reduce waste? Start by integrating fabric relaxing into your workflow. Whether through manual rest periods or automated systems, the results will speak for themselves.

Many manufacturers now rely on purpose-built equipment like fabric relaxing machines to stabilize material before cutting. These systems gently release tension in the fabric, helping reduce shrinkage and distortion. One example is the CR-210 Fabric Relaxing Machine, which is designed to support high-volume production environments where consistency is key.

By making fabric relaxation a standard part of your process, you set the stage for cleaner cuts, better fit, and fewer production errors.

For a product demo or expert guidance, email Håkan Steene at h.steene@svegea.se

Garment factories across India, Bangladesh, Vietnam, and South America are facing a new reality. Global demand is rising, lead times are shrinking, and buyers expect consistent quality at competitive prices. To stay ahead, manufacturers must rethink how they produce — and that starts with smarter machines.

One of the most effective ways to improve efficiency is by investing in intelligent textile machines for apparel production. These machines don’t just automate tasks. They optimize them. From slitting tubular knits to cutting collarettes, intelligent systems help reduce waste, speed up output, and increase return on investment.

The Hidden Cost of Manual Processing

Many factories still rely on manual or semi-automated systems for fabric preparation. While this may seem cost-effective at first, it often leads to:

- Uneven cuts and inconsistent sizing

- Higher fabric waste

- Slower production cycles

- Increased labor fatigue and errors

These issues add up. Over time, they affect profitability, delivery timelines, and customer satisfaction.

Smarter Machines, Better Results

Intelligent textile machines for apparel production solve these problems with precision and consistency. They’re designed to handle high volumes with minimal supervision, making them ideal for export-driven factories and fast fashion suppliers.

Take the Svegea TSO 380 Tubular Knit Slitter, for example. This machine is built for speed and accuracy. It slits tubular knitted fabrics open with clean edges, ready for further processing. It’s easy to operate, requires minimal maintenance, and integrates smoothly into existing production lines.

Efficiency That Pays Off

Factories using machines like the TSO 380 report:

- Up to 15% reduction in fabric waste

- Faster turnaround times

- Fewer production errors

- Lower labor costs

These improvements lead to measurable ROI — often within the first year of installation. That’s why more manufacturers are turning to intelligent textile machines for apparel production as a long-term strategy.

Flexibility and Integration

Modern apparel production demands flexibility. Machines must adapt to different fabric types, styles, and order volumes. The best systems are designed to handle knits, wovens, and technical textiles without constant retooling.

Svegea’s machines are known for their versatility. Whether you’re processing tubular knits or cutting narrow strips, their equipment delivers consistent results across a wide range of materials.

Reliability You Can Count On

Downtime is expensive. That’s why reliability matters. Manufacturers need machines that run smoothly, require minimal maintenance, and come with strong technical support.

Svegea of Sweden has built its reputation on engineering excellence and long-term durability. High-volume factories around the world — including across Asia and Latin America — rely on the intelligent textile machinery backed by responsive teams for support.

Investing in Smart Solutions

The future of garment manufacturing belongs to those who invest in smart, scalable solutions. By integrating intelligent textile machines for apparel production, factories can boost efficiency, reduce waste, and stay competitive in a fast-moving global market.

If you’re ready to upgrade your production line, explore Svegea’s TSO 380 Tubular Knit Slitter and other solutions at www.svegea.se.

For a product demo, email Håkan Steene at h.steene@svegea.se

Factories face three hard truths: fabric costs keep rising, buyers want faster delivery, and sustainability matters to customers and regulators. Improving garment manufacturing efficiency puts these pressures into practical order. Get this right and you cut costs, gain speed, and reduce waste.

Where waste really bites

Small mistakes cost big. A mis-inspected roll can mean meters of unusable fabric. Manual checks slow lines and create rework. Labor shortages and rising wages exacerbate every inefficiency. That is why garment manufacturing efficiency must be a daily focus, not a quarterly idea.

Trends pushing factories to change

Across the industry, manufacturers are adopting digital tools. Marker optimization reduces raw material use. Real-time dashboards track defects. Automation speeds repetitive tasks while freeing people to solve problems. Together, these moves enhance garment manufacturing efficiency and make factories more scalable.

Tools that move the needle

Automation is not a single gadget. It is a set of targeted investments that deliver repeatable gains. Start with quality control. Automated inspection and reliable cutting reduce rework and scraps. Next, connect systems so design files, markers, and production data flow without manual transfers. That reduces setup time and avoids costly mistakes. Focused improvements add up fast when your goal is garment manufacturing efficiency.

Fabric inspection: the unsung hero

A lot of manufacturers undervalue inspection. A good inspection line catches faults before cutting, preventing defects that would otherwise propagate through sewing and finishing. The CMI 210 ZR fabric inspection machine is built for that exact role. It handles rolls up to 2100 mm, runs roll-to-roll or roll-to-flat, and offers variable electronically controlled speed, photocell edge alignment, and electronic tension adjustments. That level of control reduces hidden waste at the source.

Collarette cutting: precision where it matters

Certain parts of a garment reveal flaws instantly. Collarette and binding components need uniform width and clean edges. Svegea’s collarette cutting machines cover semi-automatic and fully automatic models. They handle tubular knitted fabric with adjustable widths from about 16 to 140 mm. The standard setup cuts two bands at once, and knife units can be added for more. For high-volume runs, the automatic systems remove variability and keep quality consistent.

What success looks like in real numbers

When factories prioritize process control and the right equipment, they see measurable results. Expect fabric waste to drop, lead times to shorten, and quality rejects to decline. These improvements drive margin expansion and help with sustainability reporting. In short, garment manufacturing efficiency converts directly into competitive advantage.

A simple plan to get started

Start methodically. First, audit the cutting and inspection rooms to find where most scrap and rework come from. Next, pilot one change. Try a fabric inspection line or a semi-automatic collarette cutter on a single product style or order run. Train the operators, collect data, and tweak. Finally, scale what proves out. This stepwise approach helps you manage cost and avoid disruption.

The business case

The math usually lands in your favor. Less waste means lower material spend. Tighter quality control means fewer returns and less rework. Faster setup times mean you can run smaller batches and respond to demand. That combination raises throughput without endless headcount increases. If you want to improve garment manufacturing efficiency, this is the route most executives choose.

Focusing on the right tools

Efficiency is not glamorous, but it is decisive. Focus on the right mix of inspection, precise cutting, and connected workflows, and you will see both cost and time benefits. Machines that support those goals, whether a robust inspection unit like the CMI 210 ZR or a scalable Euro-Collarette cutter, are tools that turn good intentions into measurable results.

For a demo or to discuss how this fits your production, contact Håkan Steene at h.steene@svegea.se or visit the Svegea product pages.

The textile industry has always moved fast. But today, speed alone isn’t enough. With fashion brands demanding rapid turnarounds and consumers expecting personalized, eco-conscious products, manufacturers face a new kind of pressure—one that demands agility, intelligence, and sustainability.

This is where sustainable textile machinery enters the picture. As the backbone of Industry 4.0, these advanced systems are reshaping how garments and textiles are produced. From automated cutting to digitally integrated workflows, the right machinery doesn’t just improve efficiency—it transforms entire operations.

Why Smart Automation Is No Longer Optional

Traditional production methods struggle to meet the demands of today’s market. Seasonal collections have given way to micro-drops, and global buyers expect consistency across every batch. Meanwhile, rising labor costs and environmental regulations are pushing manufacturers to rethink their processes.

Smart automation addresses these challenges head-on. Machines now deliver faster throughput, precise cutting, and scalable production—all while minimizing waste. For textile manufacturers, this isn’t just about saving time or money. It’s about staying competitive in a global market that rewards innovation and sustainability.

Cutting Technology That Drives Efficiency

While robotics and AI often steal the spotlight, cutting and trimming remain some of the most critical—and overlooked—stages in textile production. Components like collarettes, bands, and trims may seem minor, but they directly impact garment quality, fit, and durability.

Svegea of Sweden has long recognized this. Our sustainable textile machinery solutions, including the Automatic Collarette Cutter and Band Cutting Machines, are engineered for precision and reliability. These systems ensure every piece is cut to exact specifications, whether it’s the first or the ten-thousandth. Integrated into smart production lines, they enable seamless data flow and real-time adjustments.

Proven Impact on the Factory Floor

Consider a factory producing thousands of garments daily. Without automation, band cutting becomes a bottleneck—dependent on manual precision that varies from worker to worker. With Svegea’s cutting technology, that same factory sees:

- A 25–30% increase in throughput

- Significant reduction in fabric waste

- Consistent quality that meets international standards

These gains translate into faster delivery times, fewer returns, and stronger relationships with global buyers. More importantly, they demonstrate how sustainable textile machinery can deliver measurable ROI.

Building the Smart Factory of Tomorrow

Automated cutting is just one piece of the smart factory puzzle. When paired with IoT-enabled equipment, ERP systems, and AI-driven planning tools, it becomes part of a fully connected ecosystem. In this setup, machines communicate, data drives decisions, and production adapts instantly to market shifts.

This is the promise of Industry 4.0: a future where textile manufacturers can balance speed, cost, and sustainability without compromise. And it starts with investing in the right machinery.

Commitment to Sustainable Innovation

At Svegea of Sweden, we’re proud to support the evolution of textile manufacturing. Our cutting solutions are designed not only for performance but also for sustainability. By reducing waste, improving accuracy, and integrating seamlessly into smart production lines, our machines help factories meet the demands of modern manufacturing.

If you’re ready to explore how sustainable textile machinery can future-proof your operations, we’re here to help.

📩 Contact Håkan Steene at h.steene@svegea.se for a product demo or more details. Let’s build the future of textiles—together.

The fashion and textile industry is changing fast. More brands are shifting to on-demand textile production to reduce waste and meet customer expectations. Instead of making large batches that may never sell, manufacturers now focus on producing only what’s needed. This approach helps cut costs, save materials, and support sustainability goals.

Sustainability isn’t just a trend—it’s a must. From fabric waste to energy use, every part of the production process matters. And one of the smartest ways to make a difference is through precision.

Why Waste Reduction Matters

Fabric waste is a hidden problem in many factories. Every scrap, wrong cut, or rejected item means:

- Lost money: Fabric is expensive, and waste eats into profits

- Environmental harm: Most textile waste ends up in landfills

- Extra work: Fixing mistakes takes time and energy

When these issues happen often, they add up fast. That’s why reducing waste is good for both the planet and the bottom line.

The Circular Economy in Textiles

The circular economy is all about keeping materials in use and cutting down on waste. In fashion, this means:

- Designing products that last

- Recycling fabrics and fibers

- Using every roll of material wisely

On-demand textile production fits right into this model. By making only what’s needed, factories avoid overproduction and reduce leftover stock. But even before recycling starts, precision machinery helps cut waste at the source.

Precision Technology: Small Changes, Big Impact

Big changes don’t always need big investments. Machines that cut fabric with accuracy, run efficiently, and reduce errors can make a huge difference.

Here’s how precision machinery helps:

- Less fabric waste: Every cut is clean and exact

- Fewer mistakes: Consistent quality means fewer rejects

- Lower energy use: Efficient machines run faster and smarter

- Longer machine life: Durable tools need fewer replacements

These small upgrades support on-demand textile production by making each step more efficient and less wasteful.

Real-World Impact: Knitwear and Trims

Think about a factory making trims for t-shirts. If they use old cutting methods, they might waste 5–10% of their fabric. But with modern precision cutters:

- Every strip is cut perfectly

- Waste drops by several meters per run

- Quality stays high, so there’s less rework

This kind of setup supports on-demand textile production by allowing quick changes and small batch runs without losing efficiency.

Sustainability as a Competitive Edge

Today’s shoppers care about the planet. Brands that show they’re eco-friendly often win more trust and more business. For manufacturers, this means:

- Getting contracts with green-focused brands

- Meeting global rules on waste and emissions

- Standing out in a busy market

Using precision machinery and switching to on-demand textile production helps factories prove they’re serious about sustainability.

Make the Smart Choice Now

Sustainability starts with smart choices. By using precision tools and embracing on-demand textile production, manufacturers can cut waste, save money, and meet modern demands.

Ready to make your production line more efficient and eco-friendly?

📩 Contact Håkan Steene for a product demo at h.steene@svegea.se or visit https://www.svegea.se to learn more.

Image courtesy of Services – Fashinnovation

The fashion industry thrives on change—but in recent years, that change has accelerated into a full-blown revolution. No longer are brands defined by two seasonal collections and predictable production cycles. Today’s consumers demand personalization, limited editions, and lightning-fast turnaround. They expect garments that feel tailor-made, not mass-produced—and they want them now.

For garment and textile manufacturers, this shift isn’t just a trend—it’s a wake-up call. Meeting these demands requires more than creativity; it calls for operational reinvention. From design to delivery, every stage must be faster, smarter, and more adaptable. That’s where automated textile production enters the picture, enabling manufacturers to respond with precision, speed, and scalability.

At the heart of this transformation lies one powerful principle: flexibility.

The Rise of On-Demand Production

If one trend is reshaping the textile landscape, it’s on-demand production. Instead of stockpiling inventory and gambling on what might sell, brands now produce in smaller, agile batches—sometimes even one item at a time.

Why is this happening?

- Personalization sells. Whether it’s a custom sports jersey or a limited-edition streetwear drop, consumers crave uniqueness.

- Sustainability matters. Overproduction is one of fashion’s biggest environmental pitfalls. On-demand production helps reduce waste by making only what’s needed.

- Agility wins. Smaller runs allow brands to test the market, pivot quickly, and scale up with confidence.

In short, mass customization is overtaking mass production. And manufacturers who fail to adapt risk being left behind.

Flexibility on the Factory Floor

On-demand production sounds ideal—but it’s not without challenges. Small-batch runs and rapid turnarounds demand machinery that can:

- Switch between materials and specs with minimal downtime

- Deliver consistent precision from the first piece to the last

- Handle custom orders without compromising efficiency

This is where a robust textile solution becomes essential. Automated textile production systems allow manufacturers to pivot seamlessly between orders while maintaining quality and controlling costs. Flexibility isn’t just a feature—it’s the foundation of future-ready manufacturing.

Real-World Impact: Sportswear & Activewear

Take the booming sportswear market. Teams, clubs, and fans expect customized gear—jerseys with names, leggings in unique colorways, and performance wear tailored to niche needs.

Without flexible cutting equipment, these orders would be slow, error-prone, and costly. But with Svegea’s Automatic Collarette Cutters:

- Factories can switch quickly between team orders with different trims

- Precision cutting ensures every collar and band fits perfectly

- Small-batch customization becomes streamlined and scalable

This isn’t just operational efficiency—it’s a strategic edge.

Flexibility = Future-Proofing

Fashion moves fast. Trends go viral and vanish in weeks. Consumer loyalty shifts with every swipe. But one thing remains constant: the demand for speed, uniqueness, and sustainability.

For textile manufacturers, that means flexibility is no longer optional—it’s survival.

A modern textile solution—especially one built on automated textile production—gives factories the agility to adapt, the precision to deliver, and the confidence to scale. In a world where fashion waits for no one, that’s the difference between leading and lagging

Automated Textile Production is The Future

We can’t stress this enough. On-demand production isn’t a trend—it’s the future. Manufacturers who embrace mass customization will win contracts, delight customers, and reduce waste.

Embracing the right textile solution is essential for bridging the gap between traditional efficiency and the demands of modern flexibility. As fashion trends evolve rapidly and customization becomes the norm, manufacturers must equip their production lines to respond with speed, precision, and adaptability. The ability to shift seamlessly between small-batch orders and large-scale runs is no longer a luxury—it’s a competitive necessity.

Automated textile production is the backbone of this evolution—empowering manufacturers to meet demand without compromising quality or speed.

Svegea’s Textile Solution for Mass Customization

At Svegea of Sweden, flexibility isn’t just a feature—it’s our foundation. Our automated textile production solutions, including Automatic Collarette Cutters, Slitting Machines, and Band Cutting Machines, are engineered for speed, precision, and adaptability.

Here’s how Svegea supports the shift to on-demand production:

- Quick setup times: Ideal for switching between small and large batch runs

- Consistent precision: Every piece meets exact specifications, whether it’s 100 or 10,000 units

- Material versatility: Handles everything from lightweight knits to heavy-duty fabrics

- Just-in-time readiness: Designed for manufacturers who produce exactly what’s needed—no excess, no waste

By enabling manufacturers to meet the demands of today’s fast-paced, customized market, Svegea’s textile solution makes mass customization not only possible but profitable.

📩 Ready to future-proof your factory?

Contact Håkan Steene for a product demo at h.steene@svegea.se or visit https://www.svegea.se to explore our full range of textile solutions.

In modern textile manufacturing, adaptability is no longer optional—it’s essential. As demand grows for flexible production, especially in knitwear and activewear, manufacturers are turning to adaptive garment machinery to streamline operations and maintain quality.

Why Tubular Knit Slitting Matters

Tubular knit fabrics are produced in a continuous loop, which is ideal for circular knitting but not for cutting, printing, or sewing. Before these fabrics can be processed further, they must be slit and opened into flat sheets.

Without proper slitting:

– Edges may distort or curl

– Automated cutting systems can misalign

– Waste increases due to poor edge control

– Finished garments may suffer in quality

This step, though often overlooked, directly affects efficiency and product consistency.

The Role of Adaptive Machinery

Adaptive garment machinery refers to equipment that adjusts dynamically to different fabric types, production speeds, and operational conditions. In tubular knit slitting, this means:

- Automatic edge guiding for alignment

- Adjustable slitting widths for varied outputs

- High-speed operation with minimal waste

- Compatibility with both light and heavy knits

These features allow manufacturers to respond quickly to changing production needs without sacrificing precision.

Integration into Production Lines

Slitting machines are typically placed early in the workflow—after knitting and before cutting or printing. To integrate effectively, they must:

- Fit within existing layouts

- Offer intuitive controls for operators

- Require minimal maintenance

- Support continuous, high-volume use

When adaptive slitting technology is used, production lines become more responsive and less prone to bottlenecks.

Industry Applications

This machinery is especially relevant for:

- On-demand fashion production

- Mass customization models

- Sustainable textile workflows

- Technical and performance apparel

By enabling consistent slitting across diverse knit fabrics, adaptive systems support manufacturers aiming for speed, flexibility, and reduced waste.

A Significant Small Step

Tubular knit slitting may seem like a small step, but its impact is significant. With adaptive garment machinery, manufacturers gain the precision and flexibility needed to meet modern demands.

If you’re exploring ways to improve your knitwear production, consider how adaptive slitting can elevate your workflow.

To learn more or request a consultation, email Håkan at (mailto:hakan@svegea.se) or contact us.