In today’s competitive garment and textile industry, efficiency isn’t just a technical benchmark—it’s a bottom-line imperative. Outdated machinery may seem serviceable, but behind the scenes, it’s quietly draining profits through excessive energy use, frequent breakdowns, and mounting maintenance costs.

As global demand intensifies and margins tighten, manufacturers are rethinking their approach. The shift toward cost-saving textile machinery isn’t just about modernization—it’s about survival. Smarter, more sustainable equipment is helping producers cut waste, optimize workflows, and unlock new levels of profitability

The True Cost of Outdated Equipment

While legacy machines may still function, they often demand more attention than they’re worth. Repairs become more frequent. Production slows. Fabric waste increases due to inconsistent cuts and poor precision. These issues don’t just affect workflow—they directly impact your bottom line.

Moreover, older systems typically lack automation features that modern factories depend on. As a result, labor costs rise, and throughput suffers. In an industry where speed and consistency are critical, falling behind can mean losing contracts or missing seasonal demand.

Upgrading to advanced textile machinery can dramatically shift your cost structure. Today’s machines are designed for high-speed, precision performance and built to last. The benefits are clear:

- Reduced Material Waste: Precision cutting minimizes fabric loss and maximizes yield.

- Lower Maintenance Costs: Durable engineering reduces downtime and service interventions.

- Energy Efficiency: Optimized motor systems consume less power, resulting in lower utility bills.

- Increased Output: Automation and speed enhancements enable the production of more garments per hour.

To illustrate how modern machinery delivers these benefits, let’s look at a real-world example.

One standout example is Svegea of Sweden’s EC300-S Collarette Cutter. Known for its high-speed precision and low maintenance requirements, it’s a favorite among garment manufacturers aiming to streamline production. The EC300-S reduces fabric waste, boosts output, and consumes less energy—making it a smart investment for both profitability and sustainability.

Real-World ROI: Efficiency That Pays Off

Consider a mid-sized garment factory that replaces its aging collarette cutter with a high-speed model. Within a year, production increases by 20%, fabric waste drops by 15%, and maintenance calls are reduced by nearly a third. These improvements don’t just save money—they create capacity for growth.

Even better, the return on investment often exceeds the initial purchase cost within the first 12 months. That’s not just smart—it’s strategic.

Sustainability Meets Profitability

Efficiency isn’t only about saving money. It’s also about reducing environmental impact. Machines like the EC300-S support eco-conscious manufacturing by using less energy and producing less waste. For brands focused on ESG goals, this alignment is essential.

Invest in What Moves You Forward

Standing still in textile manufacturing is a risk. Upgrading your machinery isn’t just a technical decision—it’s a business move that affects quality, speed, sustainability, and profitability. Whether you’re scaling up or streamlining operations, investing in cost-saving textile machinery can be the difference between surviving and thriving.

Ready to rethink your production strategy?

Explore how smarter textile machinery can reshape your efficiency, reduce waste, and support sustainable growth. Learn more about proven solutions like the EC300-S Collarette Cutter and discover what modern upgrades could mean for your bottom line. Contact Håkan Steene at h.steene@svegea.se to learn more, request product details, or schedule a hands-on demonstration tailored to your needs.

Are you ready to witness the latest innovations in textile manufacturing and processing? Mark your calendars for Texprocess Americas 2025, the premier event that brings together industry leaders, innovators, and professionals to explore cutting-edge technologies and trends shaping the future of textiles.

Discover the Latest Innovations

Texprocess Americas 2025 promises an exciting lineup of exhibitors showcasing the newest advancements in textile machinery, software, and materials. This is your chance to see first-hand how industry pioneers are revolutionizing the textile landscape with state-of-the-art solutions designed to enhance efficiency, sustainability, and creativity.

Texprocess Americas, co-produced by SPESA, creates an opportunity for retail, brand, manufacturing executives, and professionals involved in the sewn products industry to meet with leading international manufacturers and distributors of machinery, equipment, parts, supplies, systems, technology, supply chain solutions, and other products and services used for the development of sewn products.

Learn from Industry Experts

The event will feature a series of thought-provoking sessions and workshops led by renowned experts. Attendees will gain invaluable insights into the latest trends, best practices, and strategies to stay ahead in the ever-evolving textile industry. Whether you’re looking to expand your knowledge, network with like-minded professionals, or discover new business opportunities, Texprocess Americas is the place to be.

Join the Celebration of Innovation

In 2023, Svegea of Sweden had the honor of being recognized at the TPA Innovation Awards for our groundbreaking Svegea EC-450XF Collarette Cutting System. This advanced system is celebrated for its unparalleled precision, efficiency, and versatility in textile manufacturing. The Svegea EC-450XF features rapid start and stop capabilities. It is also equipped with swift adjustability of bandwidths and a unique guide system that ensures seamless operations. Crafted from high-quality Swedish steel, it emphasizes durability and longevity, making it a true game-changer in the industry.

Register Now and Be Part of the Future

Don’t miss this opportunity to be at the forefront of the textile revolution. Register now for Texprocess Americas 2025 and secure your spot at the event where innovation meets inspiration. Visit the official website to sign up and stay updated on the latest event news and announcements.

As Svegea of Sweden won’t be physically present, our US counterpart, SewnProducts, will have a booth showcasing their innovative solutions.

Join us at Texprocess Americas 2025 and experience the future of textiles. Let’s innovate, connect, and thrive together!

Texprocess 2024, set against the dynamic backdrop of Frankfurt Am Main from April 23 to 26, 2024, is gearing up to be a monumental event in textile and garment manufacturing. With thousands of exhibitors from around the globe converging at this international trade fair, the stage is set for a groundbreaking display of innovation and industry prowess.

A Global Phenomenon

Texprocess 2024 isn’t merely an event—it’s a global convergence of textile and garment manufacturing’s top minds. From industry giants to emerging innovators, diverse exhibitors will showcase cutting-edge advancements shaping the industry’s future.

The sheer scale of Texprocess 2024 is awe-inspiring. Spanning across vast exhibition halls, attendees can explore a myriad of exhibits, demonstrations, and interactive sessions. Each booth tells a unique story of innovation, sustainability, and technological prowess, offering a glimpse into the ever-evolving landscape of textile production.

Econogy

One of the defining features of Texprocess 2024 is its emphasis on sustainability and eco-friendly practices. Exhibitors will be showcasing state-of-the-art machinery and processes. They will also be highlighting their commitment to environmental stewardship. Sustainability takes center stage at this prestigious event, from eco-friendly materials to energy-efficient manufacturing solutions.

Attendees at Texprocess 2024 will find abundant networking, collaboration, and knowledge-sharing opportunities, fostering new partnerships and staying updated on industry trends.

Techtextil x Texprocess

Techtextil, running parallel to Texprocess, adds another layer of depth to the event. The expo likewise broadens exploration, showcasing materials, applications, and tech driving industry progress.

Texprocess 2024 isn’t just about showcasing products and services; it’s about driving meaningful conversations, fostering innovation, and charting the course for a sustainable and prosperous future. It’s where ideas converge, collaborations thrive, and the industry’s brightest minds come together to shape tomorrow’s textile landscape.

Experience the grand spectacle of innovation and opportunity at Texprocess 2024 in Frankfurt Am Main from April 23-26, 2024. Celebrate the industry’s ingenuity and potential with us! Don’t forget to drop by Svegea’s booth in Hall 8.0 Stand D49!

In the fast-paced realm of textile manufacturing, precision and innovation reign supreme, shaping industry standards and pushing boundaries. Svegea of Sweden AB emerges as a beacon of cutting-edge technology, offering a wide array of products and services that redefine the textile landscape.

Cutting-Edge Technology

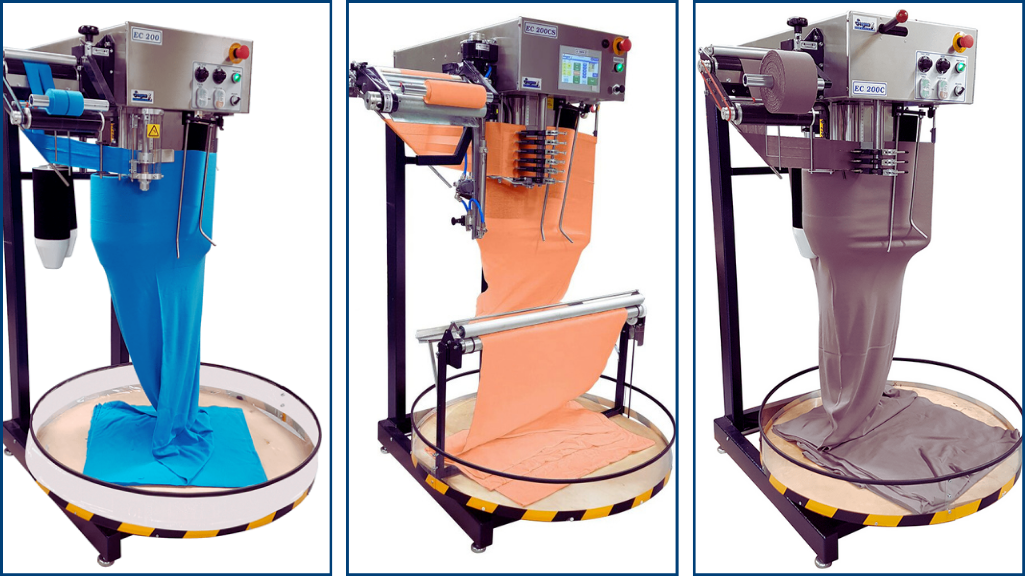

A steadfast commitment to cutting-edge technology lies at the core of Svegea’s success. The Svegea EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, epitomizes this dedication. This advanced system achieves unparalleled precision and efficiency, setting new benchmarks in production excellence. From automatic roll cutting/slitting machines like the SWS to the Strip Cutter CMS-1800A3, Svegea’s lineup showcases technological prowess.

Product Portfolio

Diversity and quality define Svegea’s product portfolio. The Tube Sewing Unit 200, Roll to Roll Slitter RRS 800, and Strip Cutter FA 600 are just a glimpse of the diverse offerings tailored to meet the textile industry’s demands. The Euro Collarette range, featuring models like the EC200C and EC200CS, is designed for exceptional performance, ensuring seamless operations and optimal results.

Global Presence and Bespoke Services

With a global presence extending across continents, Svegea delivers innovative solutions and bespoke services to clients worldwide. Whether it’s fabric inspection machines such as the CMI 210 R or the Complete Bias System, Svegea’s commitment to meeting client needs remains steadfast. Their tailored approach ensures that each solution addresses specific requirements, ensuring customer satisfaction and success.

Award-Winning Innovation

Svegea’s relentless pursuit of excellence has earned them recognition and accolades in the textile industry. Their award-winning innovation is evident in every product, from the Tube Sewing Unit 200 A/AF to the Euro Collarette range. This dedication to pushing boundaries positions Svegea as a leader in innovation and customer satisfaction.

Svegea of Sweden AB stands as a testament to innovation, quality, and customer-centricity in the textile industry. With cutting-edge technology, a diverse product portfolio, a global presence, bespoke services, and award-winning innovation, Svegea continues to redefine standards and shape the future of textile manufacturing. Experience excellence with Svegea – where innovation meets precision, and possibilities are limitless.

In a Dynamic World: Texprocess as a Beacon for Sustainability

Texprocess emerges as a guiding light for sustainable practices, providing a dedicated platform for green pioneers in the ever-evolving landscape of the textile industry.

Econogy: Merging Economy and Ecology

At the heart of Texprocess’s commitment to sustainability lies the term “Econogy” from Messe Frankfurt’s Texpertise Network. This term seamlessly blends concepts of economy and ecology, highlighting sustainability’s pivotal role in driving a company’s economic success.

Inspired by David Suzuki’s call to put the ‘eco’ back into economics, Econogy signifies a paradigm shift towards conscientious and ecologically harmonious business approaches.

Decade of Action: Accelerating Sustainable Development Goals (SDGs)

Aligned with the global efforts of the Decade of Action to achieve the Sustainable Development Goals (SDGs) by 2030, the Messe Frankfurt Texpertise Network utilizes its expansive reach of over 50 textile events worldwide. These events become platforms to raise awareness about the SDGs, creating a ripple effect from Frankfurt to New York, Atlanta, Shanghai, and Paris.

As a proud member of the United Nations Fashion and Lifestyle Network, the Texpertise Network collaborates with industry stakeholders, governments, and UN entities to showcase responsible business practices guided by the SDGs.

Svegea of Sweden: Advocating Sustainable Textile Solutions

In this landscape of sustainability, Svegea of Sweden proudly stands as an advocate for sustainable textile solutions. As a key participant in Texprocess 2024, Svegea positions itself at the forefront of sustainable practices. Svegea is actively contributing to the event’s overarching goal of fostering eco-conscious innovation in the textile industry.

Texprocess 2024: A Convergence of Sustainability and Textile Expertise

Texprocess 2024 is more than just an event; it marks the convergence of sustainability and textile expertise. Join us from April 23-26 in Frankfurt to explore the realm of “Econogy,” where sustainability seamlessly intertwines with textile expertise.

Experience firsthand how Texprocess weaves together the realms of economy and ecology. And forging a transformative path toward a greener and more responsible industry.

Secure Your Spot at Texprocess 2024

Don’t miss the opportunity to be a part of this transformative event. Secure your place at Texprocess 2024 by obtaining your tickets now. Click here for ticket info.

For more information about Texprocess 2024, head to the Texprocess main page now!

Setting the Stage: Texprocess and Techtextil Convergence

As the textile industry gears up for a revolutionary showcase, Texprocess and Techtextil join forces in Frankfurt Main from April 23 to 26. Explore the cutting-edge world of garment manufacturing, machinery, and innovation.

Sustainable Threads: Texprocess Champions Eco-Conscious Practices

Texprocess 2024 takes a stand for sustainability in a world in constant flux. Discover how the trade fair becomes a platform for green pioneers, promoting sustainable production through various measures and initiatives.

Digital Weaving: Navigating the Textile Industry’s Digital Future

How is digitalization reshaping the textile industry‘s landscape? Join the conversation at Texprocess 2024 as experts unravel the impact of digitalization on innovativeness. Invited speakers will also address the challenges and explore the latest developments in a panel discussion.

Growth Unveiled: Panel Discussion on Digitalization’s Role

Ahead of Techtextil and Texprocess 2024, industry experts gather to preview the trade fairs and engage in a dynamic panel discussion. Dive into the insights on how digitalization is the driving force propelling growth in the textile industry.

Texprocess 2024 is not just a date on the calendar; it’s an invitation to witness the evolution of textile manufacturing. Save the date – April 23 to 26, 2024, in Frankfurt Main – and immerse yourself in the future where sustainability meets digital innovation. Don’t forget to drop by our booth at Hall 8.0 Stand D49!

Interested? Find out more here – https://texprocess.messefrankfurt.com/frankfurt/en.html

Revolutionizing Production Capabilities:

Svegea of Sweden AB, based in Uddevalla, has recently enhanced the production capabilities at Löffler‘s plant with the installation of advanced machinery. Celebrating its 50th anniversary in 2023, Löffler GmbH, a renowned sports and knitwear specialist in Ried im Innkreis, Austria, now boasts the integration of an EC300-S collarette cutter and an FA350 automatic roll slitter.

Innovative Fabric Expertise

Löffler’s plant accommodates 25 circular knitting machines and 3 seamless knitting machines, generating an annual fabric output of approximately 905,000 m². The company is notably recognized for its transtex undergarments. This item pioneered the 2-layer principle, combining hydrophobic polypropylene (PP) with fibers like cotton or merino wool. This ensures moisture absorption by PP, transferring it for evaporation, and keeping the skin dry.

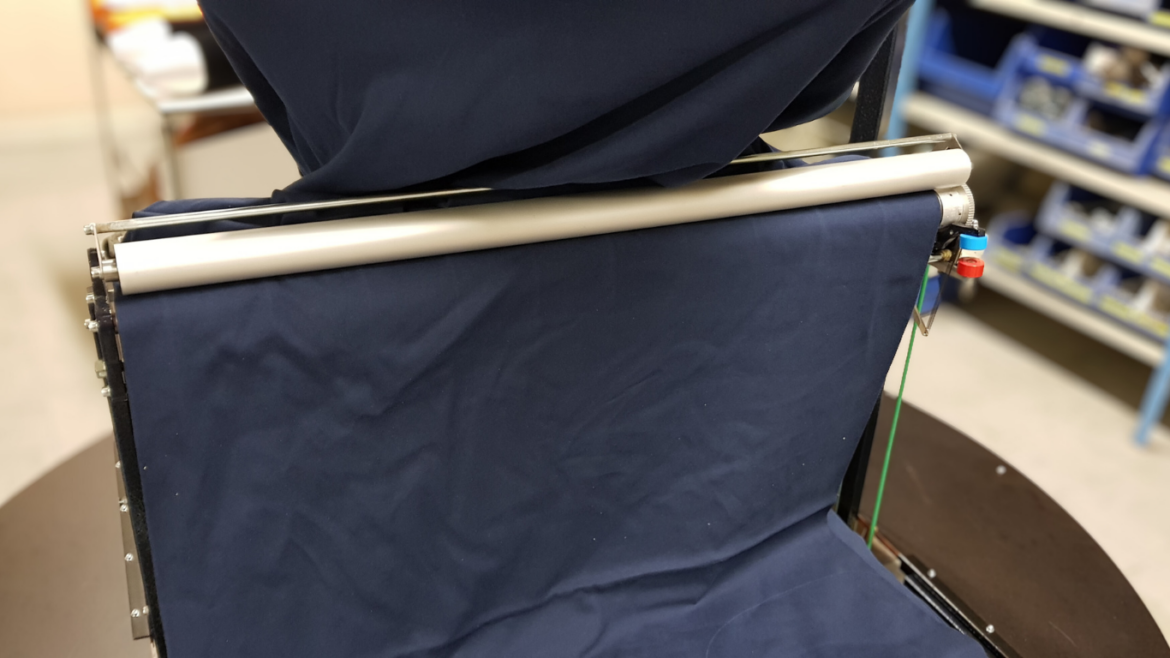

Precision in Tubular Apparel

Demonstrating a commitment to efficiency, Svegea installs the EC300-S collarette cutter, featuring True-Drive II and a high pre-feed device, dedicated to the precision production of tubular apparel components like cuff and neck tapes. Operating at speeds up to 20,000 m/hour, it ensures high-speed and precise manufacturing.

Svegea also incorporates the fully automatic FA350 roll slitter with three separately adjustable settings. This versatile machinery enables the cutting of three different bandwidths within a single cutting cycle, enhancing production flexibility and efficiency. Svegea actively integrates automatic tube sewing units. This process allows for diverse customer preferences and provides options for sewn tubes in either rolled or flat-folded forms.

Strategic Collaboration for Optimization

Collaborating seamlessly with Löffler, Svegea’s cutting-edge technology and automation actively drive the optimization of sewing operations. This alliance actively aligns with the industry’s demand for precision, speed, and flexibility. Svegea’s prowess shapes and refines sewing processes, dynamically exceeding innovation boundaries.

Embrace the future with Svegea’s cutting-edge solutions. Contact us today and revolutionize your sewing operations!

Originally published on February 10th, 2023.

Source: https://www.textiletechnology.net/technology/news/svegea-of-sweden-cutter-for-tubular-apparel-components-for-loeffler-33527

- 1

- 2