The textile industry is transforming significantly as companies increasingly bring production back to local markets. This trend, known as onshoring and reshoring, is gaining momentum in regions such as Europe and North America. Various factors, including supply chain resilience, cost-effectiveness, and the desire for high-quality production, drive the shift. In this blog, we will explore the global trend of onshoring and reshoring in the textile industry, discuss how Svegea’s machinery can support manufacturers in achieving their goals, and highlight the benefits of reduced supply chain risks and faster turnaround times.

The Global Trend of Onshoring and Reshoring

In recent years, the textile industry has seen a notable shift towards onshoring and reshoring. This movement involves relocating production processes closer to home, reversing the decades-long trend of offshoring to countries with lower labor costs. Several factors contribute to this shift:

1. Supply Chain Resilience: The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting companies to reconsider their reliance on distant manufacturing hubs. By bringing production closer to home, businesses can mitigate risks associated with disruptions and ensure a more stable supply chain.

2. Cost-Effectiveness: Rising labor costs in traditional offshoring destinations, coupled with increased tariffs and transportation expenses, have eroded the cost advantages of overseas production. Onshoring allows companies to better control costs and improve profitability.

3. Quality Control: Local production enables manufacturers to maintain higher quality standards and ensure compliance with stringent regulations. This is particularly important in the textile industry, where product quality and sustainability are paramount.

Benefits of Reduced Supply Chain Risks and Faster Turnaround Times

Onshoring and reshoring offer several benefits that can significantly impact the textile industry:

1. Reduced Supply Chain Risks: By relocating production closer to home, companies can reduce their exposure to geopolitical tensions, transportation delays, and other disruptions. This leads to a more reliable and resilient supply chain.

2. Faster Turnaround Times: Local production allows for quicker response to market demands and faster delivery of products. This agility is crucial in the textile industry, where fashion trends and consumer preferences can change rapidly.

3. Improved Customer Satisfaction: Faster turnaround times and higher quality control contribute to better customer satisfaction. When products are delivered on time and meet quality expectations, customer loyalty and brand reputation are enhanced.

Reshaping the Textile Industry

The trend of onshoring and reshoring in the textile industry is reshaping the global production landscape. By bringing manufacturing processes closer to home, companies can achieve cost-effective, high-quality production while reducing supply chain risks and improving turnaround times. Svegea’s advanced machinery plays a pivotal role in supporting this transition, offering efficiency, sustainability, and flexibility to manufacturers.

Enabling Cost-Effective, High-Quality Production

Svegea, a leading provider of advanced textile machinery, plays a crucial role in supporting manufacturers as they transition to onshoring and reshoring. Svegea’s innovative equipment offers several advantages:

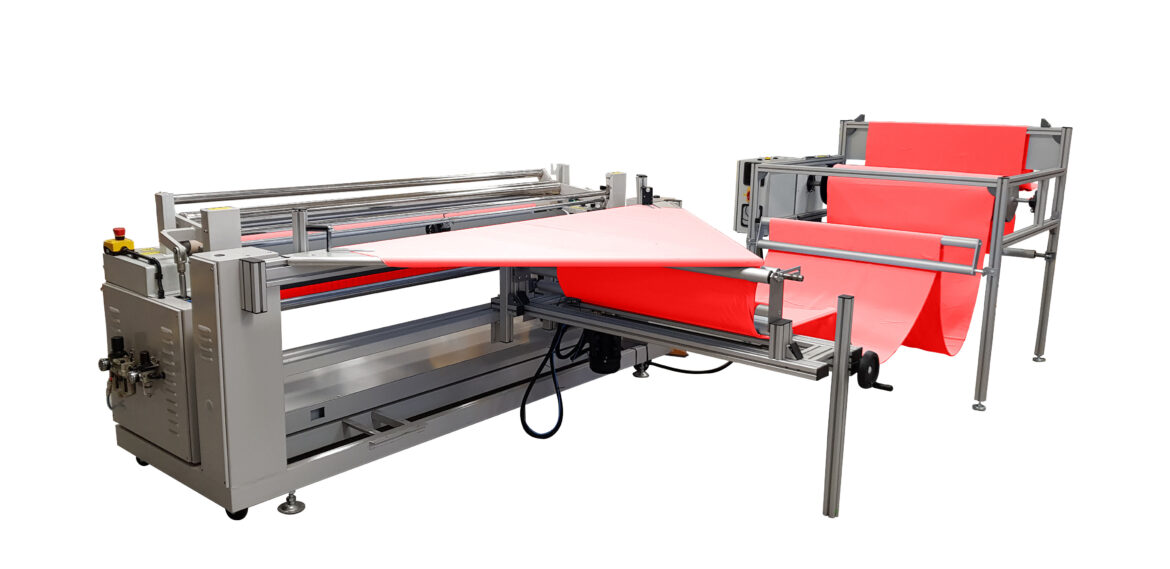

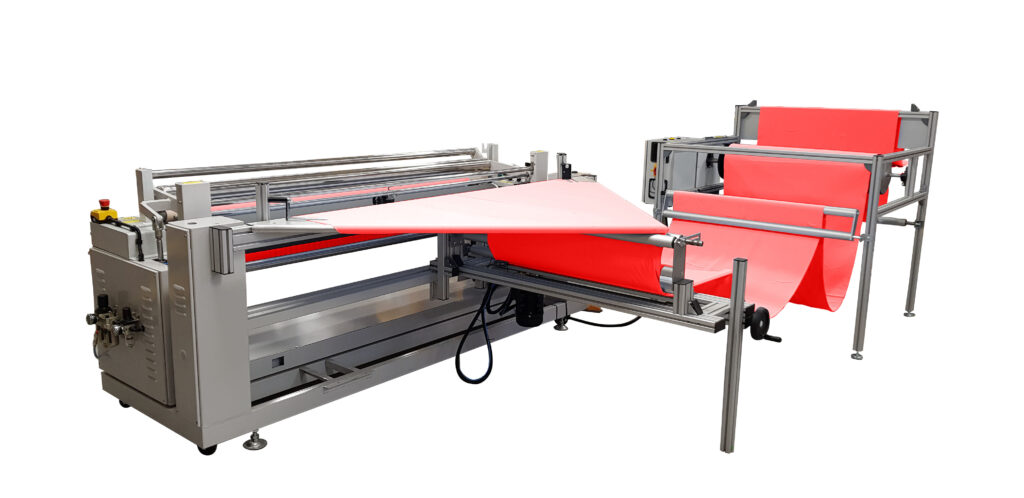

1. Efficiency and Automation: Svegea’s automated textile machines, such as the Fully Automatic Roll Slitting Machine, enhance production efficiency by minimizing waste and maximizing consistency. These machines are designed to handle large volumes quickly and reliably, helping manufacturers meet tight deadlines without compromising quality.

2. Sustainability: Modern textile machinery from Svegea is built with sustainability in mind. These machines consume less energy, use fewer chemicals, and produce less waste. For example, advanced dyeing machines from Svegea use less water and chemicals, reducing the environmental footprint of the dyeing process.

3. Flexibility: Svegea’s equipment is highly adaptable, allowing manufacturers to produce various materials and meet diverse client needs. This flexibility is essential for staying competitive in a rapidly evolving market.

As the textile industry continues to evolve, embracing onshoring and reshoring will be essential for staying competitive and meeting the demands of a dynamic market. To learn more about how Svegea’s machinery can help your business achieve its goals, visit www.svegea.se and contact Hakan Steene at h.steene@svegea.se for personalized assistance.

Photo by Remy Gieling on Unsplash | Photo by Geoff Oliver on Unsplash

Are you ready to witness the latest innovations in textile manufacturing and processing? Mark your calendars for Texprocess Americas 2025, the premier event that brings together industry leaders, innovators, and professionals to explore cutting-edge technologies and trends shaping the future of textiles.

Discover the Latest Innovations

Texprocess Americas 2025 promises an exciting lineup of exhibitors showcasing the newest advancements in textile machinery, software, and materials. This is your chance to see first-hand how industry pioneers are revolutionizing the textile landscape with state-of-the-art solutions designed to enhance efficiency, sustainability, and creativity.

Texprocess Americas, co-produced by SPESA, creates an opportunity for retail, brand, manufacturing executives, and professionals involved in the sewn products industry to meet with leading international manufacturers and distributors of machinery, equipment, parts, supplies, systems, technology, supply chain solutions, and other products and services used for the development of sewn products.

Learn from Industry Experts

The event will feature a series of thought-provoking sessions and workshops led by renowned experts. Attendees will gain invaluable insights into the latest trends, best practices, and strategies to stay ahead in the ever-evolving textile industry. Whether you’re looking to expand your knowledge, network with like-minded professionals, or discover new business opportunities, Texprocess Americas is the place to be.

Join the Celebration of Innovation

In 2023, Svegea of Sweden had the honor of being recognized at the TPA Innovation Awards for our groundbreaking Svegea EC-450XF Collarette Cutting System. This advanced system is celebrated for its unparalleled precision, efficiency, and versatility in textile manufacturing. The Svegea EC-450XF features rapid start and stop capabilities. It is also equipped with swift adjustability of bandwidths and a unique guide system that ensures seamless operations. Crafted from high-quality Swedish steel, it emphasizes durability and longevity, making it a true game-changer in the industry.

Register Now and Be Part of the Future

Don’t miss this opportunity to be at the forefront of the textile revolution. Register now for Texprocess Americas 2025 and secure your spot at the event where innovation meets inspiration. Visit the official website to sign up and stay updated on the latest event news and announcements.

As Svegea of Sweden won’t be physically present, our US counterpart, SewnProducts, will have a booth showcasing their innovative solutions.

Join us at Texprocess Americas 2025 and experience the future of textiles. Let’s innovate, connect, and thrive together!

The fashion industry is in the midst of a seismic shift. Consumers no longer settle for mass-produced garments—they crave unique, customized pieces that reflect their individuality. This surging demand is reshaping brand strategies, revolutionizing production, and redefining how we express ourselves through fashion.

The Rise of Personalized Fashion

Personalization isn’t a new concept—bespoke tailoring has been around for centuries. But thanks to groundbreaking technology, what was once an exclusive luxury is now accessible to the masses.

According to McKinsey’s The State of Fashion 2023 report, 71% of consumers expect brands to deliver personalized experiences, and 76% become frustrated when those expectations aren’t met. () This consumer-driven revolution is forcing the fashion industry to rethink everything, from design to production and delivery.

The Tech Behind the Transformation

Innovation is fueling the personalization boom. Here’s how cutting-edge technology is turning made-to-order fashion into a scalable, profitable reality:

3D Printing: Reinventing Manufacturing

Adidas is a pioneer in this space, integrating 3D printing into their Futurecraft line. Their custom midsoles adapt to individual foot pressure points and gait, providing unparalleled comfort and performance. But the potential extends beyond footwear—startups are now 3D-printing entire garment components, minimizing waste and unlocking design possibilities previously unimaginable.

AI & Machine Learning: Next-Level Personalization

Brands like Stitch Fix blend human stylists with AI-driven algorithms to curate hyper-personalized fashion recommendations. With over 4 million active users, Stitch Fix exemplifies how AI can decode individual style preferences with incredible accuracy.

Body Scanning: Precision Fit, Every Time

Uniqlo has introduced body scanning technology in select stores, allowing customers to create digital avatars for accurate sizing recommendations. This technology eliminates guesswork, reduces returns, and ensures a flawless fit.

The Machinery Powering Personalization

While digital advancements steal the spotlight, specialized machinery is the backbone of small-batch, custom production. One standout player in this arena is Svegea of Sweden.

Svegea’s Role in Personalized Fashion

Svegea, a leader in textile machinery manufacturing, develops precision bias-cutting machines that enable small-batch production without sacrificing quality. Their collarette cutting machines, crucial for trim and binding production, make detailed customization viable at scale.

Automation: The Secret to Scalable Customization

Contrary to popular belief, automation isn’t the enemy of personalization—it’s the key to making it efficient.

Smart Factories: Rapid, Flexible Production

Advanced robotics and computer-controlled cutting systems can switch between personalized designs seamlessly, drastically cutting lead times. What once took weeks can now be produced in days, meeting consumer expectations for speed and exclusivity.

On-Demand Manufacturing: Redefining Fashion’s Business Model

The traditional model of mass-producing inventory is fading. Instead, agile, on-demand production is emerging as the future.

- Made-to-Order Success Stories: Companies like Proper Cloth create perfectly tailored shirts based on individual measurements, eliminating inventory waste and boosting customer satisfaction.

- Microfactories for Localized Production: The concept of small, tech-powered production hubs is gaining traction. According to Fashion for Good, micro-factories can reduce carbon emissions by up to 35% compared to traditional supply chains.

Why Consumers Love Customization

Beyond the cool factor, there are deeper reasons why personalized fashion is taking over:

1. A Unique Identity

In a world of fast fashion, standing out is more important than ever. Studies show that 80% of consumers are more likely to buy from brands that offer personalized experiences.

2. The Perfect Fit

Sizing inconsistencies have plagued shoppers for decades. Custom-fitted clothing eliminates this issue, reducing costly returns—an issue that costs the fashion industry $300 billion annually.

3. Sustainability at Its Core

Personalized fashion isn’t just stylish—it’s eco-friendly.

- Less Waste: On-demand production slashes overproduction and reduces landfill-bound inventory.

- Longer Wear: Research suggests personalized items stay in a consumer’s wardrobe up to 50% longer than mass-produced alternatives.

Brands Leading the Charge

Several fashion giants are proving that personalization isn’t just a gimmick—it’s a game-changer.

- Nike By You (formerly NIKEiD) allows customers to customize every element of their sneakers, adding over $1 billion in direct-to-consumer revenue.

- Ministry of Supply offers 3D-printed knit blazers, tailored to individual measurements in under 90 minutes.

- Unspun uses body scanning to create zero-inventory, custom-fit jeans, reducing carbon emissions by up to 40%.

Challenges & The Future of Personalized Fashion

Despite its rapid growth, personalized fashion isn’t without obstacles:

- Cost & Scaling: Custom production is still pricier than mass manufacturing, but as technology advances, costs are dropping—Deloitte reports a 30% decrease in price premiums for personalized products over the past decade.

- Consumer Awareness: Many shoppers still see personalization as a luxury. Brands must invest in educating consumers on its accessibility and long-term value.

The Future: Customization as the New Norm

Fashion’s transformation is just beginning. As technology evolves, personalized fashion will become an everyday expectation rather than an exclusive option. Brands that embrace this shift will benefit from stronger customer loyalty, reduced waste, and a more sustainable future.

The era of mass-produced fashion is fading. In its place? A world where every piece of clothing tells a unique story—your story.

Photo by Malicki M Beser on Unsplash

Artificial Intelligence (AI) is emerging as a game-changer in the ever-evolving landscape of textile manufacturing. From design to production, AI is revolutionizing the industry, enhancing efficiency, reducing waste, and driving innovation. This blog delves into how AI is transforming textile manufacturing, spotlighting Svegea’s innovative solutions.

The Role of AI in Textile Manufacturing

AI is making significant strides in various aspects of textile manufacturing. One of the most notable areas is automated design and pattern-making. AI tools like Adobe’s Textile Designer analyze vast amounts of trend data from fashion shows, online retail platforms, and consumer behavior studies. This analysis helps predict future trends in patterns, colors, and materials with high accuracy, enabling designers to create collections that align closely with market demands.

Moreover, AI is enhancing the fabric inspection process. Advanced systems equipped with high-resolution cameras and sophisticated AI software, such as the Uster Quantum 4.0, conduct real-time textile analysis. These systems meticulously scan for defects like misweaves, pattern irregularities, and color deviations, ensuring only top-quality fabrics move forward in the production line. This precision significantly reduces waste and elevates product quality.

Enhancing Manufacturing Efficiency

AI-driven automation is streamlining textile manufacturing processes. Predictive maintenance, for instance, uses AI to foresee equipment failures before they happen, minimizing downtime and repair costs. Advanced AI-powered robotics and automation streamline tasks such as fabric cutting, sewing, and quality inspection, leading to faster production cycles and reduced labor costs.

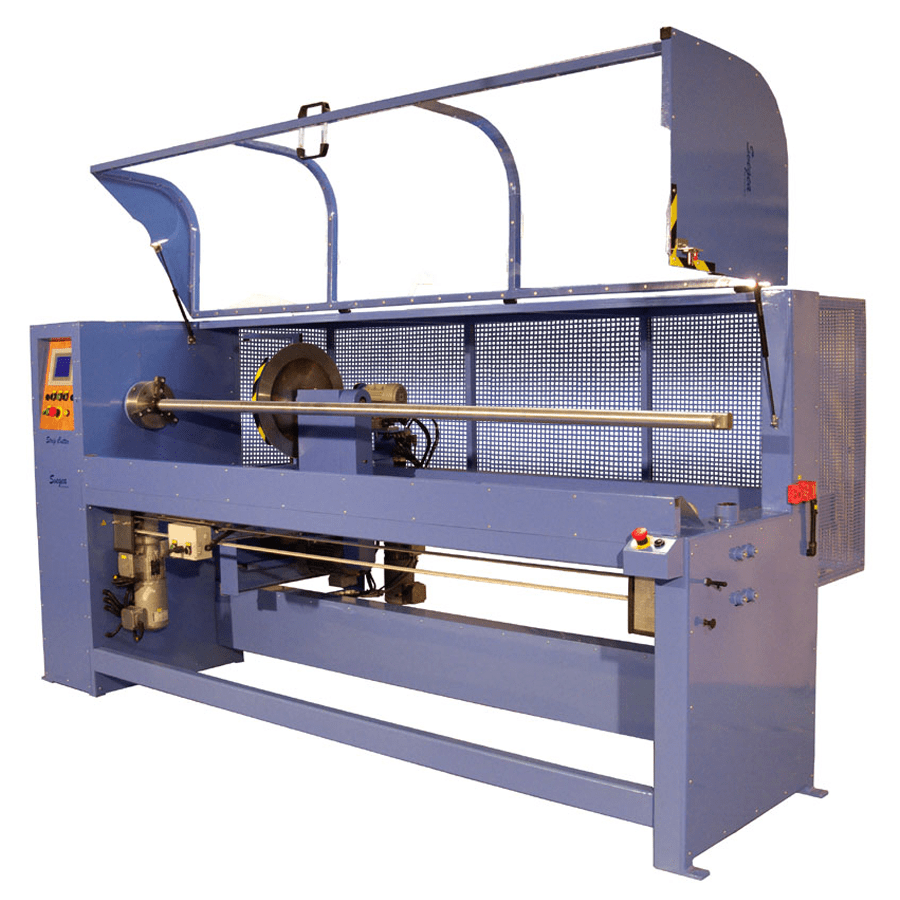

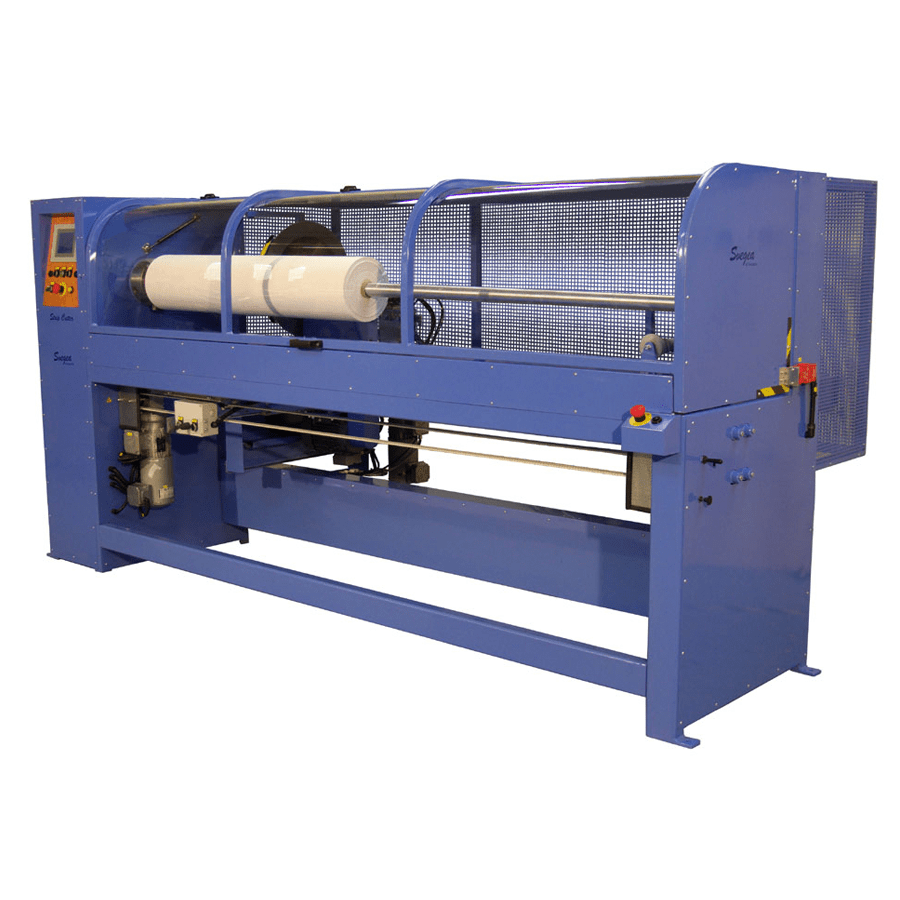

Svegea, a leader in textile manufacturing solutions, exemplifies the integration of AI in production. Their EC-450XF Collarette Cutting System, recognized with the Texprocess Americas 2023 Innovation Award, achieves unparalleled precision and efficiency. This system, along with other advanced machines like the SWS automatic roll cutting/slitting machines and the Strip Cutter CMS-1800A3, showcases Svegea’s commitment to cutting-edge technology.

Optimizing Supply Chains

AI plays a crucial role in optimizing supply chains within the textile industry. Machine learning models predict demand patterns, allowing manufacturers to adjust production schedules and inventory levels accordingly. AI-driven analytics also help identify the most efficient routes for shipping and logistics, reducing transportation costs and carbon footprint. This level of optimization ensures that products reach consumers promptly, enhancing customer satisfaction.

Revolutionizing Quality Control

Quality control is a critical aspect of textile production, and AI is enhancing this process through advanced inspection technologies. Computer vision systems equipped with AI algorithms can detect defects and inconsistencies in fabrics with high precision. These systems analyze images of textiles in real time, identifying issues such as color variations, weave irregularities, and fabric flaws that might be missed by human inspectors. This results in higher quality products and fewer returns.

Personalizing Consumer Experiences

AI is transforming how brands interact with consumers by enabling personalized shopping experiences. AI-powered recommendation engines analyze user behavior, purchase history, and preferences to offer tailored product suggestions. Virtual fitting rooms, driven by AI, allow customers to try on clothes virtually, enhancing the online shopping experience and reducing the likelihood of returns.

Svegea’s Innovative Solutions

Svegea of Sweden AB stands out as a beacon of innovation in textile manufacturing. With over 72 years of experience, Svegea offers a wide array of products and services that redefine the textile landscape. Their product portfolio includes the Tube Sewing Unit 200A, Roll to Roll Slitter RRS 800, and Strip Cutter FA 600, all designed for exceptional performance and efficiency.

Svegea’s commitment to cutting-edge technology is evident in its award-winning products. The EC-450XF Collarette Cutting System, for example, sets new benchmarks in production excellence. Svegea’s global presence and bespoke services ensure that each solution addresses specific client needs, ensuring customer satisfaction and success.

The Future of AI in Textile Manufacturing

The integration of AI in textile manufacturing is just beginning. As technology continues to advance, we can expect even greater efficiencies and innovations. AI will likely play an increasingly important role in areas such as sustainable production, where it can help reduce waste and optimize resource use.

AI is revolutionizing textile manufacturing, driving efficiencies, and fostering innovation. Companies like Svegea are leading this transformation, offering advanced solutions that set new industry standards. As AI continues to evolve, the future of textile manufacturing looks brighter than ever. To learn more about how Svegea can help your business stay ahead of the curve, contact Håkan Steene at h.steene@svegea.se today!

As we step into 2025, the textile industry is undergoing significant transformations. From sustainability to smart textiles, the trends this year are set to revolutionize both fashion and home decor. Let’s explore the key textile trends for 2025 and how they are shaping the future of the industry.

Sustainability: The Green Revolution

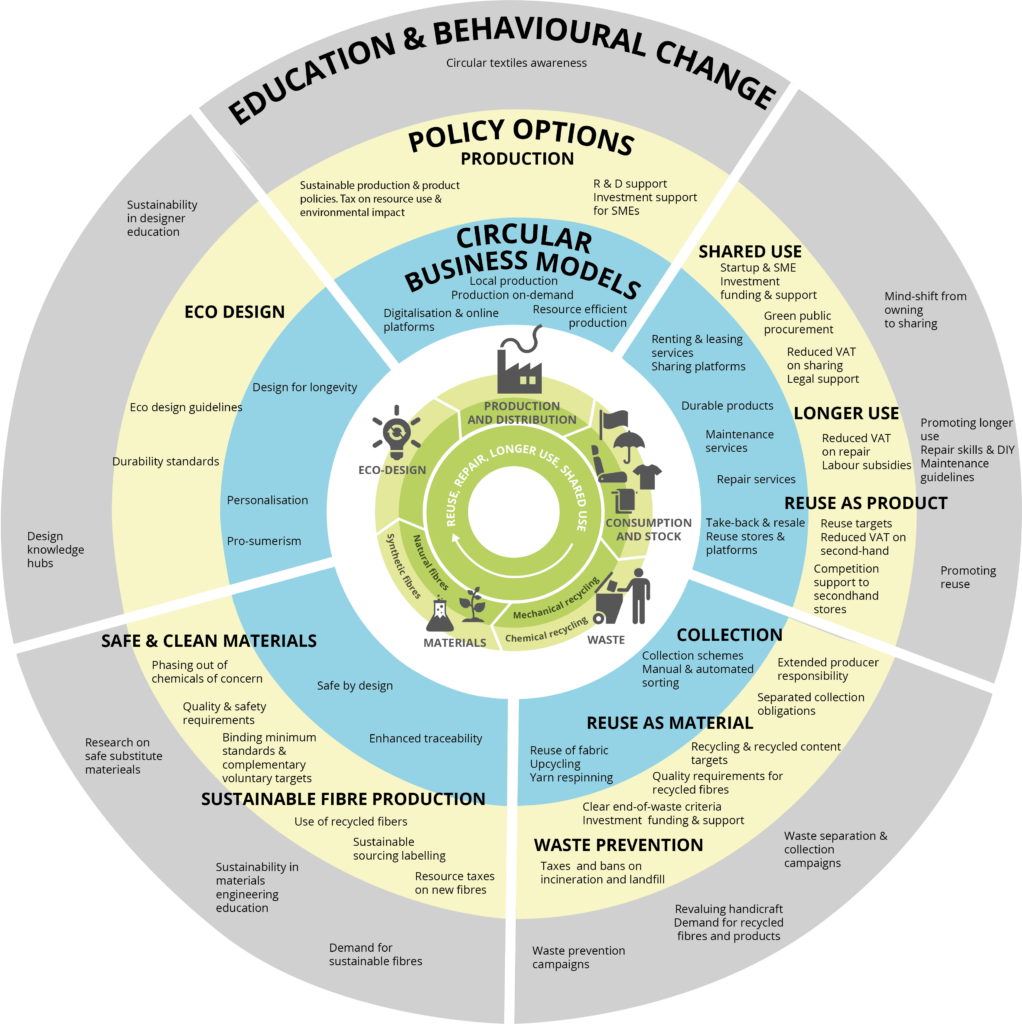

Sustainability continues to be a driving force in the textile industry. Consumers are increasingly demanding eco-friendly and ethically sourced materials. This trend is leading to a rise in the use of organic cotton, bamboo, hemp, and Tencel. Brands are also focusing on traceable supply chains and circular fashion, which includes repairable and biodegradable fabrics. This shift towards sustainability is not just a trend but a necessary evolution for the industry.

Sustainability continues to be a driving force in the textile industry. Consumers are increasingly demanding eco-friendly and ethically sourced materials. This trend is leading to a rise in the use of organic cotton, bamboo, hemp, and Tencel. Brands are also focusing on traceable supply chains and circular fashion, which includes repairable and biodegradable fabrics. This shift towards sustainability is not just a trend but a necessary evolution for the industry.

Smart Textiles: The Future is Now

The integration of advanced technology into fabrics is creating smart textiles that can monitor health metrics and regulate temperature. These innovations are set to revolutionize both fashion and home decor. Imagine clothing that can adjust to your body temperature or fabrics that can track your fitness levels. The possibilities are endless, and the future is now.

Digital Printing: Customization at Its Best

Digital printing technology is allowing for more intricate and customizable designs on textiles. This innovation enables brands to produce unique patterns and reduce waste compared to traditional printing methods. With digital printing, the textile industry can offer more personalized products, catering to the individual tastes of consumers.

Textures and Layers: Creating Visual Appeal

Mixing different textures and layers is becoming increasingly popular in home decor. Combining materials like velvet, linen, and wool can create visually appealing and inviting spaces. This trend is all about creating depth and interest in interior design, making homes feel more cozy and luxurious.

Bold Patterns: Making a Statement

Bold and eye-catching patterns are expected to be a major fashion trend in 2025. These patterns add personality and flair to both fashion and home textiles. Whether it’s a striking geometric design or a vibrant floral print, bold patterns are here to make a statement.

Advanced Apparel Manufacturing: Efficiency and Innovation

The use of 3D technologies and automation in apparel manufacturing is increasing efficiency and allowing for more innovative designs. These advancements are streamlining production processes and enabling the creation of complex and unique garments. The future of apparel manufacturing is bright, with technology leading the way.

Customization and Personalization: Meeting Consumer Demands

Consumers are seeking more personalized and customized textile products. This trend is driving brands to offer bespoke designs and tailored solutions. From custom-fit clothing to personalized home decor, the demand for unique and individualized products is on the rise.

AI and Data Analytics: Optimizing the Industry

Artificial intelligence and data analytics are being used to predict trends, optimize supply chains, and enhance the overall efficiency of textile production. These technologies are providing valuable insights that help brands stay ahead of the curve and meet consumer demands more effectively.

Innovation with the Right Tools

Having the right machinery is crucial to keeping up with these dynamic trends. For instance, the Svegea EC 450 XF Collarette Cutting System exemplifies how advanced technology can enhance textile production. Known for its precision and efficiency, this machine supports sustainable practices by minimizing material waste and optimizing resource use. Its versatility makes it a valuable addition to any textile manufacturing setup, aligning perfectly with the industry’s move towards automation and smart textiles.

Embrace the Future of Textiles

The textile trends for 2025 highlight the exciting innovations and shifts happening in the industry. From sustainability to smart textiles, these trends are shaping the future of fashion and home decor. As we embrace these changes, staying informed and adapting to the evolving landscape is essential.

Keeping up with these trends requires the right machinery for those in the textile production industry. Contact Svegea of Sweden for all your textile production machinery needs. With its advanced technology and expertise, Svegea can help you stay ahead in this dynamic industry.

Choosing the right textile machinery can be a daunting task, especially with the plethora of options available in the market. The decision impacts your production efficiency, product quality, and overall business profitability. Here are some key tips to help you navigate this critical process.

1. Understand Your Production Needs

Before investing in textile machinery, it’s crucial to understand your specific production needs. Different types of machinery serve various purposes, from weaving and knitting to dyeing and finishing. Determine the scale of your operations, the types of textiles you produce, and your production goals. This understanding will guide your choice of machinery that best suits your requirements.

2. Evaluate Technology and Features

Modern textile machinery comes with a range of advanced technologies and features designed to enhance productivity and quality. Look for machines that offer automation, precision control, and energy efficiency. For instance, Svegea of Sweden offers cutting-edge machinery equipped with the latest technology, ensuring high efficiency and minimal waste. Our products are known for their durability and innovative features.

3. Consider Quality and Reliability

Quality and reliability are paramount when choosing textile machinery. Investing in high-quality machines may come with a higher initial cost, but it ensures long-term performance and fewer breakdowns. Research and compare different brands, read reviews, and consider the manufacturer’s reputation. Modesty aside, our brand has a proven track record of producing reliable and high-quality textile machinery.

4. Assess After-Sales Support and Maintenance

After-sales support and maintenance services are crucial for the smooth operation of textile machinery. Ensure that the manufacturer offers comprehensive support, including installation, training, and regular maintenance services. We provide excellent customer support and maintenance services, ensuring that your machinery operates optimally.

5. Analyze Cost and Return on Investment (ROI)

While the cost of textile machinery is a significant factor, it’s essential to consider the return on investment (ROI). A more expensive machine with advanced features and higher efficiency can lead to cost savings in the long run. Calculate the total cost of ownership, including maintenance and operational costs, and compare it with the expected benefits. Opt for machines that offer the best value for money.

6. Environmental Considerations

Sustainability is a growing concern in the textile industry. Choose machinery that is energy-efficient and environmentally friendly. Machines that reduce water and chemical usage, minimize waste, and consume less energy are ideal. This Swedish textile company is known for producing sustainable textile machinery that aligns with eco-friendly production practices.

7. Compatibility with Existing Systems

Ensure that the new machinery is compatible with your existing systems and processes. Incompatibility can lead to production delays and additional costs. Consult with the manufacturer or a technical expert to evaluate the integration process. A company that offers flexible machinery solutions that can be seamlessly integrated into various production setups, should be the right choice.

Explore Svegea of Sweden’s Textile Machinery

Choosing the right textile machinery is a critical decision that impacts your production efficiency and product quality. By considering factors such as your production needs, technology and features, quality, after-sales support, cost, environmental impact, and compatibility, you can make an informed choice. Svegea of Sweden’s innovative machinery solutions are designed to meet diverse production requirements while ensuring high efficiency and sustainability.

Curious about how we can elevate your textile production process? Visit our product page for more information and start your journey towards optimal textile production today.

In the dynamic world of textile manufacturing, automation is a cornerstone of innovation, driving unprecedented efficiency, precision, and sustainability. As an expert with over two decades of experience in textile automation, we have witnessed firsthand the transformative power of these technologies. Today, we’ll explore how automation is reshaping the fabric of our industry.

The Evolution of Textile Automation

The journey from hand-spun fibers to today’s high-tech production lines tells a story of relentless innovation. Early mechanization during the Industrial Revolution laid the groundwork, but modern automation has catapulted us into a new era of manufacturing excellence.

Key milestones include:

1. 1960s-1970s: Introduction of computer-controlled looms

2. 1980s-1990s: Development of robotic systems for material handling

3. 2000s-2010s: Integration of AI and machine learning in quality control

4. 2020s and beyond: Emergence of fully automated, smart textile factories

Core Areas Transformed by Automation

Spinning: Precision at Lightning Speeds

Modern spinning systems, such as rotor and air-jet technologies, have revolutionized yarn production. These systems can produce yarn up to 20 times faster than traditional ring spinning, with unparalleled consistency.

Weaving: Intelligent Looms for Flawless Fabrics

Today’s computerized looms are marvels of engineering. There are machines for example that use real-time adaptive tension control to adjust warp tension on the fly, ensuring fabric quality remains consistent even as conditions change during production. This level of precision was unthinkable just a decade ago.

Dyeing and Finishing: Sustainability Meets Efficiency

Automated dyeing and finishing processes have dramatically reduced water and energy consumption while improving color consistency. Digital textile printing, exemplified by machines can print complex designs directly onto fabric at up to 1,000 m²/hour, revolutionizing small-batch and customized production.

Spotlight on Innovation: Svegea’s EC 450 XF Collarette Cutting System

The EC 450 XF Collarette Cutting System by Svegea represents the cutting edge of textile automation. As the winner of the Texprocess Americas 2023 Innovation Award, this system exemplifies how targeted automation can solve specific industry challenges.

Key features include:

– Multi-material compatibility for unparalleled versatility

– Precision cutting with minimal waste

– Rapid changeover times, boosting overall productivity

The EC 450 XF doesn’t just cut fabric; it redefines efficiency in garment manufacturing. For manufacturers looking to stay competitive, systems like this are not just beneficial—they’re essential.

The Tangible Benefits of Automation

1. Quality Assurance: Automated systems consistently produce high-quality textiles, reducing defects by up to 90% compared to manual processes.

2. Increased Productivity: Modern automated lines can operate 24/7, increasing output by 200-300% over traditional methods.

3. Cost Reduction: While initial investment is significant, automated systems can reduce labor costs by 40-60% and material waste by 20-30% over their lifetime.

4. Customization at Scale: Automation enables quick changeovers, making small-batch and customized production economically viable.

5. Enhanced Safety: Automation minimizes human exposure to hazardous processes, reducing workplace accidents by up to 80% in some facilities.

Overcoming Implementation Challenges

While the benefits of automation are clear, implementation comes with challenges:

1. Initial Investment: The upfront cost of automation can be substantial. However, ROI typically occurs within 2-5 years, depending on the scale of implementation.

2. Workforce Transition: Shifting to automated systems requires retraining staff. Forward-thinking companies are investing in upskilling programs to transition workers into higher-value roles.

3. System Integration: Ensuring new automated systems work seamlessly with existing processes is crucial. Careful planning and phased implementation can mitigate disruptions.

The Future of Textile Automation

Looking ahead, several trends will shape the future of textile automation:

1. AI and Machine Learning: These technologies will enable predictive maintenance and real-time quality control, further improving efficiency and reducing downtime.

2. Internet of Things (IoT): Connected devices will create smart factories where every aspect of production is monitored and optimized in real-time.

3. Sustainable Automation: Future systems will focus even more on reducing environmental impact, with closed-loop water systems and energy-efficient processes.

4. Collaborative Robotics: Cobots will work alongside humans, handling repetitive tasks while allowing human workers to focus on high-value activities.

Embracing the Automated Future

Automation in textile manufacturing isn’t just about replacing human labor—it’s about augmenting human capabilities, driving innovation, and creating a more sustainable, efficient industry. As we look to the future, it’s clear that automation will play an increasingly central role in shaping the textiles of tomorrow.

For manufacturers, the message is clear: embrace automation or risk being left behind. The future of textiles is automated, and that future is now.

To explore cutting-edge automation solutions like Svegea’s EC 450 XF Collarette Cutting System, contact us now! For those ready to take the next step in their automation journey, now is the time to act.

Textile innovation is a fascinating journey that transforms raw ideas into tangible fabrics. This process involves creativity, technology, and a deep understanding of materials. In this blog, we will explore the stages of textile innovation, highlight the role of Svegea of Sweden, and provide insights into how modern machinery is revolutionizing the industry.

The Birth of an Idea

Every textile innovation begins with a concept. Designers and engineers brainstorm to create new fabrics that meet specific needs. Whether it’s for fashion, sports, or industrial use, the initial idea is crucial. This stage involves extensive research and development to ensure the concept is viable.

Research and Development

Research and development (R&D) are at the heart of textile innovation. Scientists and engineers work together to test new materials and techniques. They experiment with different fibers, dyes, and weaving methods to create fabrics that are not only functional but also aesthetically pleasing. This phase is critical as it lays the foundation for the entire process.

Prototyping and Testing

Once the concept is solidified, the next step is prototyping. This involves creating a small batch of the fabric to test its properties. Prototyping allows designers to see how the fabric performs in real-world conditions. They can make adjustments to improve durability, comfort, and appearance.

Importance of Testing

Testing is an essential part of the innovation process. Fabrics are subjected to various tests to ensure they meet industry standards. These tests include checking for strength, flexibility, and resistance to wear and tear. By rigorously testing prototypes, manufacturers can guarantee the quality of the final product.

Production and Manufacturing

After successful prototyping and testing, the fabric moves to the production phase. This is where innovative machinery plays a significant role. Companies like Svegea of Sweden provide state-of-the-art textile machinery that enhances efficiency and precision in manufacturing.

Role of Svegea of Sweden

Svegea of Sweden is a leader in textile machinery innovation. Their machines are designed to handle complex weaving and knitting processes with ease. By incorporating advanced technology, Svegea ensures that fabrics are produced with the highest quality standards. Their machinery is known for its reliability and efficiency, making them a preferred choice for many textile manufacturers.

Sustainability in Textile Innovation

In today’s world, sustainability is a key consideration in textile innovation. Manufacturers are increasingly focusing on eco-friendly materials and processes. This includes using organic fibers, reducing water consumption, and minimizing waste. Sustainable practices not only benefit the environment but also appeal to conscious consumers.

Eco-Friendly Materials

The use of eco-friendly materials is a growing trend in the textile industry. Organic cotton, bamboo, and recycled polyester are some sustainable fibers. These materials are not only environmentally friendly but also offer excellent performance characteristics. By choosing sustainable options, manufacturers can reduce their environmental footprint.

The Future of Textile Innovation

The future of textile innovation looks promising with continuous advancements in technology. Smart fabrics, which can monitor health or change color, are becoming a reality. Additionally, 3D printing is opening new possibilities for custom-made textiles. As technology evolves, the potential for innovation in textiles is limitless.

Embracing New Technologies

Embracing new technologies is essential for staying competitive in the textile industry. Companies that invest in advanced machinery and innovative processes are better positioned to meet the demands of modern consumers. Svegea of Sweden, with its cutting-edge textile machinery, is at the forefront of this technological revolution.

An Exciting Process

From concept to fabric, the journey of textile innovation is a complex and exciting process. It involves creativity, rigorous testing, and the use of advanced machinery. Companies like Svegea of Sweden play a crucial role in this journey by providing innovative solutions that enhance production efficiency and quality.

If you want to learn more about how innovative textile machinery can transform your production process, contact Svegea of Sweden today. Their expertise and state-of-the-art machines can help you stay ahead in the competitive textile industry.

The textile industry has always been a hub of innovation. Each technological leap has transformed production processes from the spinning jenny to modern automated systems. Today, textile-cutting machines stand at the forefront of this revolution, offering unparalleled precision, speed, and efficiency. This article delves into how automated cutting machines reshape the textile industry and highlights a cutting-edge product from Svegea.

The Evolution of Textile Cutting Machines

From Manual to Automated

Historically, textile cutting was a labor-intensive task. Workers relied on manual tools like scissors and rotary cutters, which were time-consuming and prone to errors. The advent of semi-automated machines marked a significant improvement, yet they still required considerable human intervention. Today, fully automated textile-cutting machines have revolutionized the industry, enabling manufacturers to produce high-quality products swiftly and cost-effectively.

Key Features of Modern Textile Cutting Machines

Modern textile cutting machines boast advanced features that significantly enhance their performance:

– Computer-Aided Design (CAD) Integration: This allows for precise pattern creation and modification.

– Laser Cutting Technology: Ensures clean, accurate cuts with minimal fabric wastage.

– Automated Material Handling: Reduces the need for manual labor and speeds up the production process.

– Multi-Layer Cutting Capability: Enables the cutting of multiple fabric layers simultaneously, boosting productivity.

Benefits of Automated Textile Cutting Machines

- Enhanced Precision and Accuracy

One of the most significant advantages of automated textile-cutting machines is their precision. These machines use advanced software and laser technology to cut fabric with incredible accuracy, ensuring that each piece meets exact specifications. This level of precision is particularly important in industries like fashion and automotive, where even minor deviations can lead to significant issues.

- Increased Production Speed

Automated cutting machines can operate at much higher speeds than manual or semi-automated methods. This increased speed translates to higher production rates, allowing manufacturers to meet tight deadlines and respond quickly to market demands. For example, a textile cutting machine can cut hundreds of fabric pieces in the time it would take a human worker to cut just a few.

- Cost Savings

While the initial investment in automated cutting machines can be substantial, the long-term cost savings are significant. These machines reduce labor costs by minimizing the need for manual intervention. Additionally, their precision reduces fabric wastage, leading to lower material costs. Over time, these savings can offset the initial investment and lead to increased profitability.

- Versatility and Flexibility

Modern textile cutting machines are incredibly versatile. They can handle a wide range of fabrics, from delicate silks to heavy-duty industrial textiles. This versatility allows manufacturers to diversify their product offerings and cater to different market segments. Moreover, the ability to quickly switch between different cutting patterns and materials enhances production flexibility.

Real-World Applications

Fashion Industry

In the fashion industry, precision and speed are paramount. Automated textile cutting machines enable designers to bring their visions to life with unparalleled accuracy. These machines can cut intricate patterns and delicate fabrics with ease, ensuring that each garment meets the highest quality standards. Additionally, the ability to quickly produce samples and prototypes allows designers to experiment with new ideas and stay ahead of trends.

Automotive Industry

The automotive industry relies heavily on textile materials for interior components like seats, carpets, and headliners. Automated cutting machines ensure that these components are cut to exact specifications, enhancing the overall quality and durability of the final product. The ability to cut multiple layers of fabric simultaneously also speeds up production, allowing manufacturers to meet the high demands of the automotive market.

Home Furnishings

From curtains to upholstery, the home furnishings industry requires precise and efficient fabric cutting. Automated cutting machines enable manufacturers to produce high-quality home textiles quickly and cost-effectively. The versatility of these machines also allows for the production of custom designs, catering to the growing demand for personalized home decor.

The Future of Textile Manufacturing

Integration with Industry 4.0

The future of textile manufacturing lies in the integration of automated cutting machines with Industry 4.0 technologies. This includes the use of IoT (Internet of Things) devices, AI (Artificial Intelligence), and big data analytics to optimize production processes. For example, IoT-enabled cutting machines can communicate with other devices in the production line, ensuring seamless coordination and reducing downtime.

Sustainable Manufacturing

Sustainability is becoming increasingly important in the textile industry. Automated cutting machines contribute to sustainable manufacturing by reducing fabric wastage and energy consumption. Additionally, the precision of these machines minimizes the need for rework, further reducing resource usage. As the industry continues to prioritize sustainability, the adoption of automated cutting machines is likely to increase.

Continuous Innovation

The field of automated textile cutting is constantly evolving. Manufacturers are continually developing new technologies and features to enhance the performance of cutting machines. For example, advancements in laser technology and AI are expected to further improve the precision and efficiency of these machines. As these innovations continue to emerge, the capabilities of automated cutting machines will expand, opening up new possibilities for textile manufacturers.

Featured Product: Svegea’s EC 450 XF Collarette Cutting System

Svegea of Sweden is a leader in textile cutting technology, known for its innovative solutions that enhance productivity and reduce waste. One of their standout products is the EC 450 XF Collarette Cutting System. This system is designed for high-speed, precision cutting of collarettes, making it ideal for manufacturers looking to improve efficiency and product quality. The EC 450 XF features advanced automation and user-friendly controls, ensuring seamless integration into any production line.

For more information on cutting-edge textile-cutting machines, visit Svegea of Sweden

In an era where sustainability is paramount, the circular economy offers a transformative approach to how we produce and consume goods. Central to this concept are closed-loop systems and circular design, both of which aim to minimize waste and make the most of our resources.

Understanding Closed-Loop Systems

Closed-loop systems are designed to create a continuous cycle of use and reuse, effectively reducing waste. In these systems, the output of one process becomes the input for another, ensuring that materials are constantly recycled and repurposed. This approach not only conserves resources but also significantly reduces environmental impact.

The Importance of Circular Design

The circular design is a key element of the circular economy. It involves designing products with their entire lifecycle in mind, from creation to disposal. Circular design focuses on durability, reparability, and recyclability, making products easy to disassemble and reuse. This process reduces the need for new raw materials and minimizes waste.

Strategies for Minimizing Waste

Minimizing waste is a fundamental goal of the circular economy. This process is achievable through various strategies, including:

- Design for Longevity: Creating products that last longer and are easily repairable.

- Material Innovation: Using materials that are easier to recycle and have a lower environmental impact.

- Efficient Manufacturing: Implementing processes that reduce waste and improve resource efficiency.

Real-World Applications

Many companies are now adopting circular principles to enhance sustainability. For instance, in the textile industry, some manufacturers are focusing on producing high-quality trim that aligns with circular design principles. By ensuring that their products are durable and recyclable, these companies contribute to a more sustainable future.

The Benefits of a Circular Economy

The shift towards a circular economy offers numerous benefits:

- Environmental Sustainability: By reducing waste and conserving resources, the circular economy helps protect the environment.

- Economic Efficiency: Reusing materials and improving efficiency can lead to cost savings for businesses.

- Innovation and Growth: The circular economy encourages innovation, leading to new business opportunities and economic growth.

Representing a Significant Shift

The circular economy represents a significant shift in how we think about production and consumption. By embracing closed-loop systems and circular design, we can minimize waste and make better use of our resources. This approach not only benefits the environment but also offers economic advantages.

Sustainable Textile Manufacturing

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

To learn more about how quality trim can align with circular principles, visit Svegea’s contact page and discover their commitment to sustainability.