In an era where sustainability is paramount, the circular economy offers a transformative approach to how we produce and consume goods. Central to this concept are closed-loop systems and circular design, both of which aim to minimize waste and make the most of our resources.

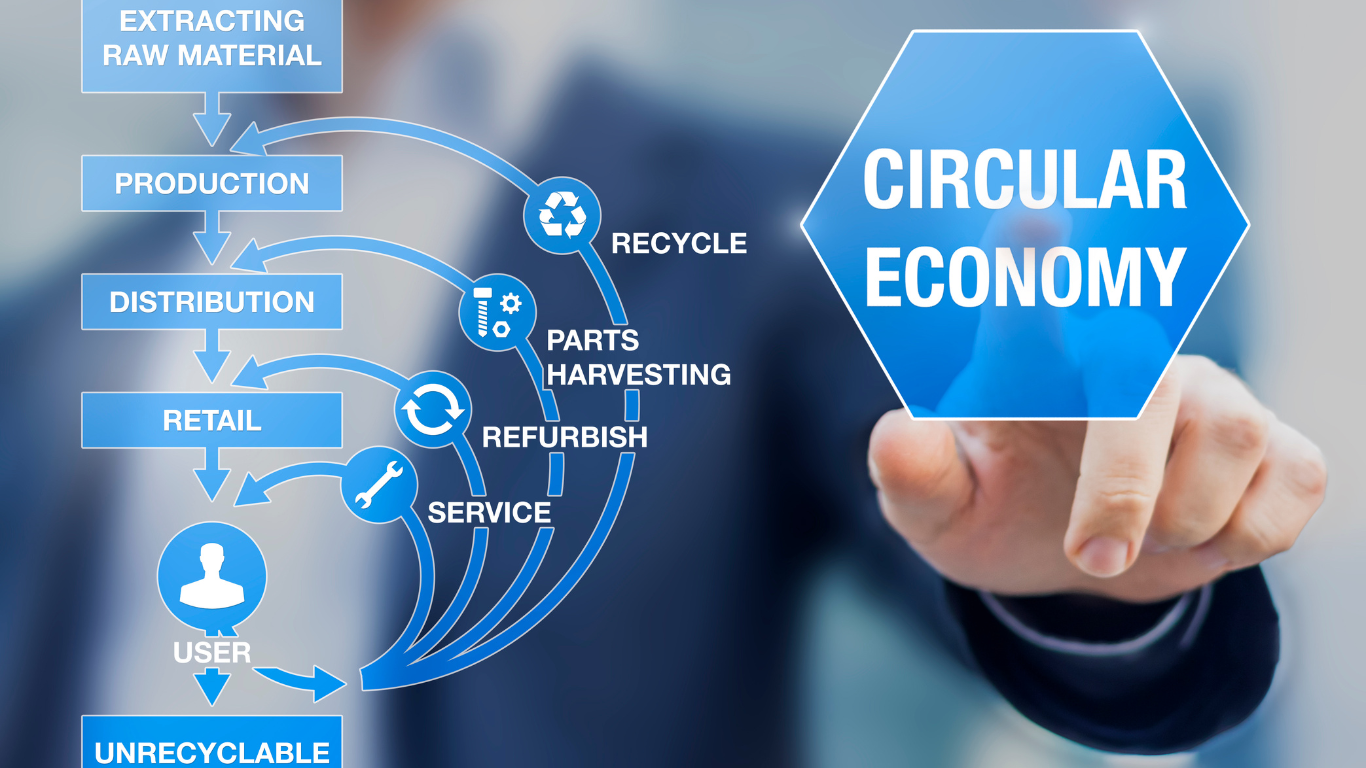

Understanding Closed-Loop Systems

Closed-loop systems are designed to create a continuous cycle of use and reuse, effectively reducing waste. In these systems, the output of one process becomes the input for another, ensuring that materials are constantly recycled and repurposed. This approach not only conserves resources but also significantly reduces environmental impact.

The Importance of Circular Design

The circular design is a key element of the circular economy. It involves designing products with their entire lifecycle in mind, from creation to disposal. Circular design focuses on durability, reparability, and recyclability, making products easy to disassemble and reuse. This process reduces the need for new raw materials and minimizes waste.

Strategies for Minimizing Waste

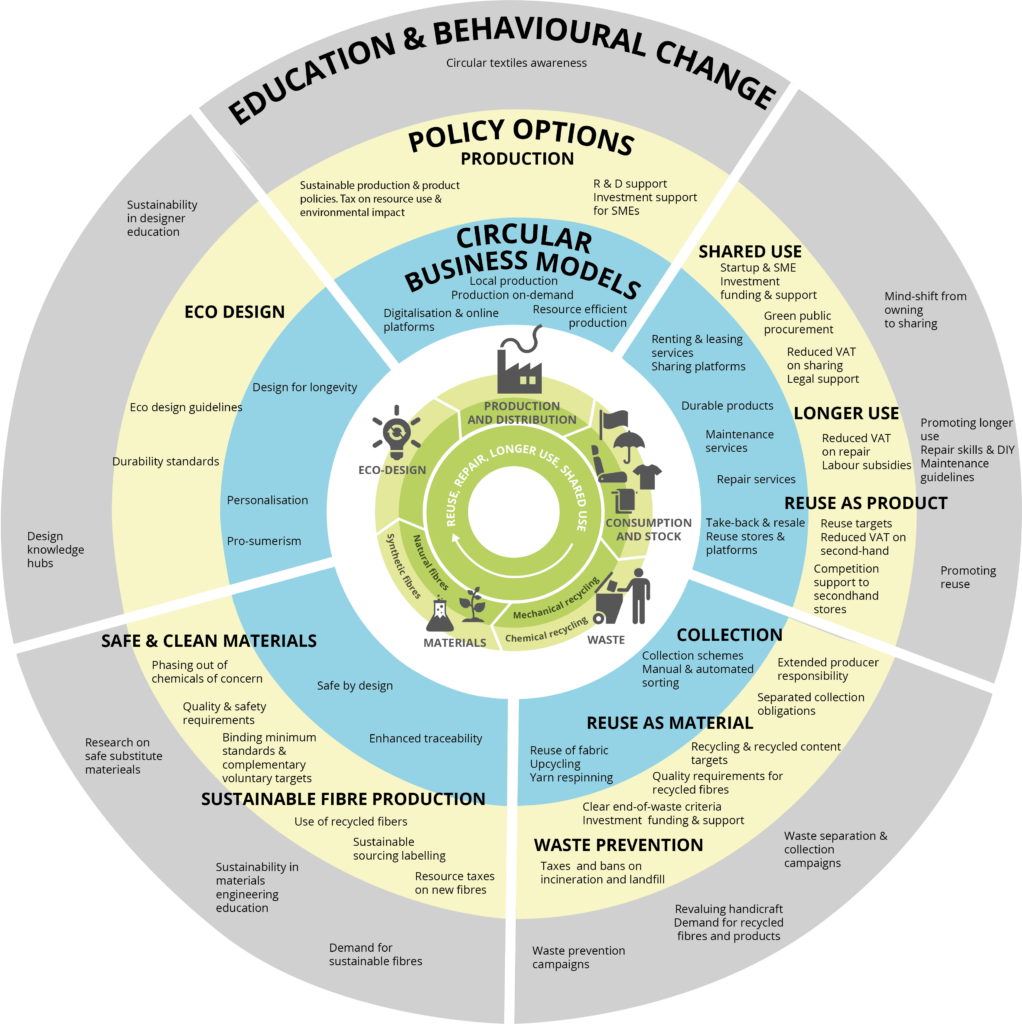

Minimizing waste is a fundamental goal of the circular economy. This process is achievable through various strategies, including:

- Design for Longevity: Creating products that last longer and are easily repairable.

- Material Innovation: Using materials that are easier to recycle and have a lower environmental impact.

- Efficient Manufacturing: Implementing processes that reduce waste and improve resource efficiency.

Real-World Applications

Many companies are now adopting circular principles to enhance sustainability. For instance, in the textile industry, some manufacturers are focusing on producing high-quality trim that aligns with circular design principles. By ensuring that their products are durable and recyclable, these companies contribute to a more sustainable future.

The Benefits of a Circular Economy

The shift towards a circular economy offers numerous benefits:

- Environmental Sustainability: By reducing waste and conserving resources, the circular economy helps protect the environment.

- Economic Efficiency: Reusing materials and improving efficiency can lead to cost savings for businesses.

- Innovation and Growth: The circular economy encourages innovation, leading to new business opportunities and economic growth.

Representing a Significant Shift

The circular economy represents a significant shift in how we think about production and consumption. By embracing closed-loop systems and circular design, we can minimize waste and make better use of our resources. This approach not only benefits the environment but also offers economic advantages.

Sustainable Textile Manufacturing

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

Svegea of Sweden is leading the way in sustainable textile manufacturing with their EC 450 XF Collarette Cutting System. This innovative machine exemplifies circular economy principles by ensuring precision cutting, which minimizes material waste. Its versatility allows it to handle various fabrics and applications, making it an essential tool for manufacturers committed to sustainability. The EC 450 XF boosts energy efficiency, cuts power consumption, and aligns with global sustainability goals. By integrating such advanced technology, Svegea is making significant strides toward a more sustainable future in the textile industry.

To learn more about how quality trim can align with circular principles, visit Svegea’s contact page and discover their commitment to sustainability.