The textile industry is transforming. With growing concerns about environmental impact, manufacturers are shifting towards sustainable textile practices. From reducing waste to adopting energy-efficient machinery, the industry is embracing innovation to create a greener future.

The Rise of Circular Fashion

Circular fashion is revolutionizing the textile industry. Instead of the traditional linear model, where clothes are made, used, and discarded, circular fashion promotes recycling and reusing materials. Brands are now designing garments with longevity in mind, using biodegradable fabrics and closed-loop production systems.

Key Circular Fashion Strategies:

-

- Recycling & Upcycling: Old textiles are repurposed into new garments, reducing landfill waste.

- Closed-Loop Production: Materials are continuously reused, minimizing resource depletion.

- Biodegradable Fabrics: Natural fibers like organic cotton and hemp decompose without harming the environment.

Zero-Waste Manufacturing: Eliminating Textile Waste

Traditional textile production generates excessive waste. However, zero-waste manufacturing aims to eliminate fabric scraps and optimize material usage.

How Zero-Waste Manufacturing Works:

-

- Precision Cutting: Advanced machinery ensures minimal fabric waste.

- Fabric Optimization: Designers create patterns that maximize fabric efficiency.

- Waste Repurposing: Leftover materials for accessories or insulation.

Eco-Friendly Dyeing Techniques: Reducing Water & Chemical Usage

Dyeing is one of the most polluting processes in textile manufacturing. Fortunately, eco-friendly dyeing techniques are emerging to reduce water consumption and chemical waste.

Sustainable Dyeing Methods:

- Natural Dyes: Extracted from plants and minerals, these dyes are biodegradable.

- Waterless Dyeing: Innovative technologies like CO₂ dyeing eliminate water usage.

- Low-Impact Dyes: Require fewer chemicals, reducing environmental harm.

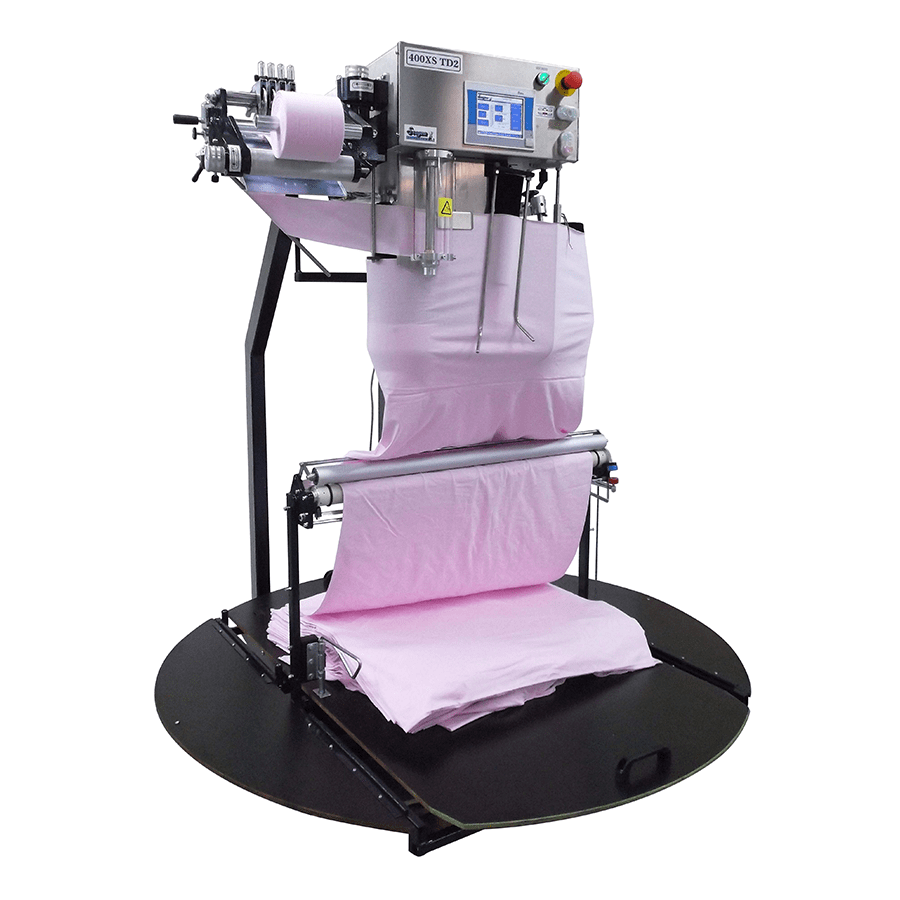

Automation & Advanced Machinery: Reducing Energy Consumption

Automation is reshaping textile manufacturing by driving smarter, more sustainable operations. With advanced machinery and AI-powered systems, manufacturers reduce energy consumption, cut material waste, and boost productivity. These technologies fine-tune power usage to lower carbon footprints while delivering consistent speed and precision. By minimizing errors and maximizing efficiency, automation gives textile producers a competitive edge and a cleaner path forward.

Sustainable Textile Manufacturing

Svegea is at the forefront of sustainable textile production. Their innovative machinery enhances efficiency while reducing environmental impact. By integrating automation and precision engineering, Svegea helps manufacturers adopt greener practices without compromising quality.

For more information on sustainable textile manufacturing and product demos, contact Hakan Steene at h.steene@svegea.se.