In the ever-evolving world of fashion, trends dictate what consumers wear and drive substantial changes in the textile manufacturing industry. As styles and preferences shift with each season, so does the demand for specific fabrics and production techniques. Understanding this dynamic interplay between fashion and textile manufacturing sheds light on why agility and innovation are critical for industry players.

The Influence of Fashion Trends on Textile Choices

Fashion trends, often birthed on global runways, have a profound impact on the types of fabrics that manufacturers produce. For example, the rising demand for eco-conscious clothing has propelled the use of organic cotton, recycled polyester, and other sustainable materials. Consumers are becoming increasingly discerning, and their demand for environmentally friendly products directly affects the supply chain.

Moreover, certain styles influence fabric preferences. For instance, the resurgence of Y2K fashion has led to increased production of shiny, stretchy fabrics like spandex and laminated textiles. On the other hand, minimalism has sparked a preference for clean, soft fabrics such as linens and organic blends.

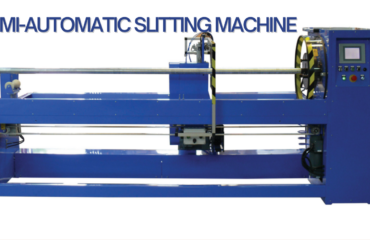

Svegea of Sweden exemplifies innovation in this space. By offering state-of-the-art slitting machines and tubular fabric slitters, Svegea empowers textile manufacturers to adapt to these shifts effectively. These technologies streamline production processes, enabling manufacturers to work seamlessly with both traditional and modern fabrics.

Adapting to Seasonal Patterns

Seasonality is another major driver of demand in textile manufacturing. The winter months see a surge in production of wool, fleece, and thermal fabrics, while spring and summer collections demand lightweight materials like cotton and chiffon. Transitioning between these seasonal demands requires adaptability in both sourcing and production techniques.

Evolving Production Techniques to Meet Trends

As fashion becomes more experimental, production techniques have also evolved. Digital printing, for instance, has revolutionized textile manufacturing by allowing vibrant, custom patterns to be applied directly to fabrics. This method is widely used for fast fashion, where speed and creativity are paramount.

Similarly, advancements in dyeing technology have paved the way for more sustainable practices. Waterless dyeing, for example, is gaining traction as brands seek to reduce environmental impact while achieving rich and consistent colors.

The Role of Technology in Shaping the Industry

The role of technology in modern textile manufacturing cannot be overstated. With the rise of smart textiles and wearable technology, manufacturers are now required to incorporate functionality into traditional fabrics. Materials that can monitor body temperature, adjust to environmental conditions, or charge electronic devices are gaining popularity.

Advanced machinery plays a crucial role in this transformation. By enabling precision and adaptability, such equipment ensures that manufacturers can keep up with the increasing complexity of fabrics and design requirements.

Sustainability: A Growing Priority

The global shift toward sustainability is perhaps one of the most significant trends shaping the textile manufacturing industry. Consumers, designers, and brands are aligning with eco-friendly practices, demanding transparency and accountability in production processes.

For manufacturers, this means adopting methods that minimize waste and reduce environmental impact. Textile production companies should align with these principles by offering machinery that enhances material efficiency and reduces waste.

Meeting Consumer Expectations

Ultimately, consumer expectations drive every facet of textile manufacturing. From runway to retail, shoppers seek products that reflect current trends while being high-quality, functional, and sustainable. Manufacturers who can predict these demands and adapt accordingly will remain competitive in this fast-paced industry.

Immense Power of Fashion Trends

Fashion trends wield immense power over textile manufacturing, shaping the demand for fabrics, influencing production techniques, and steering innovation. To remain competitive, manufacturers must embrace agility, invest in cutting-edge technology, and prioritize sustainability.

Companies like Svegea of Sweden are pivotal in this landscape, offering tools and solutions that enable manufacturers to keep pace with ever-changing demands. By bridging the gap between runway inspiration and factory production, the textile industry continues evolving, driving creativity and functionality forward.

Are you ready to adapt to the latest trends in textile manufacturing? Contact Hakan Steene at h.steene@svegea.se for a product demo!