As global demand for ethical and efficient clothing production increases, manufacturers are reevaluating every step of their production process. One area gaining renewed attention is bias cutting—a technique that enhances stretch, durability, and fabric utilization. While often overlooked, bias-cutting systems play a vital role in advancing sustainable garment production.

What Is Bias Cutting and Why Does It Matter?

Bias cutting involves slicing fabric diagonally across its grain, typically at a 45-degree angle. This method allows textiles to stretch naturally, conform to body shapes, and resist fraying. It’s especially useful in garments requiring flexibility, such as:

- Activewear

- Lingerie

- Children’s clothing

- Knit trims and collarettes

By improving fit and performance, bias cutting contributes to the creation of longer-lasting garments—an often underappreciated aspect of sustainability.

Automation and Efficiency in Bias Cutting

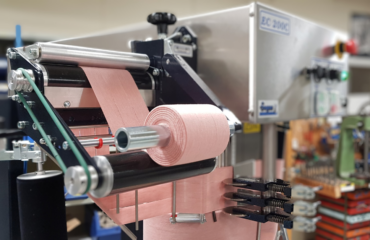

Traditionally, bias cutting was done manually. This process was slow, inconsistent, and wasteful. Today, automated bias-cutting systems have transformed the landscape. These machines:

- Align fabric edges with precision.

- Adjust cutting widths for different materials

- Join bias strips seamlessly using integrated sewing units

- Wind fabric under controlled tension for easy handling

As a result, manufacturers can reduce labor costs, minimize waste, and maintain consistent quality across production batches.

Sustainability Beyond the Buzzwords

Sustainability isn’t just about organic cotton or recycled polyester. It’s also about how garments are made. Bias cutting systems support sustainable garment production by:

- Reducing fabric waste through accurate slitting and joining

- Optimizing material usage, especially in high-volume runs

- Lowering energy consumption with efficient, high-speed operation

- Extending product life by improving garment performance

These benefits align with global sustainability goals and industry certifications, making bias-cutting systems a strategic investment—not just a technical upgrade.

Relevance Across Global Markets

From Southeast Asia to Scandinavia, textile manufacturers face similar challenges: rising costs, stricter regulations, and shifting consumer expectations. Bias cutting systems offer scalable solutions for:

- Localized production hubs

- Fast fashion models require agility

- Technical textile producers working with complex fabrics

Whether you’re a small-scale knitwear producer or a large garment exporter, bias cutting technology can support your sustainability roadmap.

Ready to Explore Smarter Solutions?

If you’re looking to enhance your production efficiency while supporting sustainable garment practices, it’s worth exploring what modern bias cutting systems can offer.

Contact Håkan Steene (h.steene@svegea.se) or visit www.svegea.se to learn more about how their bias-cutting solutions align with your sustainability goals.