The Impact of Fast Fashion vs. Slow Fashion

The fashion industry is at a crossroads. On one side, fast fashion dominates with its rapid production cycles, low-cost garments, and ever-changing trends. Conversely, slow fashion is gaining momentum, advocating for sustainability, ethical production, and long-lasting quality. Understanding the differences between these two approaches is crucial for consumers and manufacturers alike.

The Environmental and Social Implications of Fast Fashion

Fast fashion has revolutionized the industry, making trendy clothing accessible. However, this convenience comes at a significant cost.

Environmental Consequences

The fast fashion industry is one of the most significant contributors to pollution worldwid e. It generates excessive textile waste, consumes vast amounts of water, and releases harmful chemicals into the environment. Consider these alarming statistics:

e. It generates excessive textile waste, consumes vast amounts of water, and releases harmful chemicals into the environment. Consider these alarming statistics:

- The fashion industry accounts for 10% of global carbon emissions and produces 20% of global wastewater.

- A single cotton shirt requires 2,700 liters of water—enough to sustain one person for 2.5 years.

- Synthetic fibers used in fast fashion take up to 200 years to decompose.

These figures highlight the urgent need for sustainable alternatives.

Social Consequences

Beyond environmental concerns, fast fashion has severe social implications. Many garment factories operate under challenging conditions, where workers often receive wages that may not fully meet the cost of living. In regions like Bangladesh, where the textile industry is a vital economic driver, efforts continue to improve labor standards and create more sustainable working environments. Supporting ethical production and fair compensation remains essential in shaping a more responsible and equitable fashion industry.

The widespread demand for affordable clothing presents challenges in ensuring ethical labor practices. As the fashion industry evolves, businesses and consumers play a key role in promoting fair wages and responsible sourcing to create a more sustainable and equitable future.

Slow Fashion and Sustainability

Slow fashion prioritizes quality over quantity, focusing on durable, ethically produced garments. This movement is supported by innovative textile machines that enhance sustainability and efficiency.

Tips for Manufacturers Transitioning to Sustainable Practices

For manufacturers looking to embrace slow fashion, adopting sustainable practices is essential. Here are key strategies to facilitate the transition:

1. Optimize Energy Efficiency

Investing in energy-efficient textile machines can significantly reduce operational costs and environmental impact. Technologies such as variable frequency drives and energy recovery systems help minimize energy consumption.

2. Use Sustainable Raw Materials

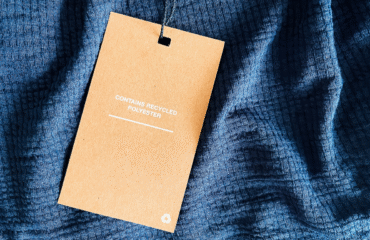

Choosing organic cotton, recycled fabrics, and biodegradable materials can drastically reduce pollution and resource depletion. Sustainable sourcing ensures ethical production while maintaining high-quality standards.

3. Implement Waste Reduction Strategies

Advanced textile machines, like those from Svegea, help manufacturers cut fabric efficiently, reducing excess material waste. Additionally, adopting zero-waste design techniques can further minimize environmental impact.

4. Reduce Water Usage and Pollution

Traditional textile production consumes vast amounts of water. Modern dyeing machines now recycle water, significantly lowering consumption. Manufacturers should also explore low-impact dyeing techniques to reduce chemical pollution.

5. Promote Supply Chain Sustainability

Partnering with ethical suppliers and ensuring fair labor practices throughout the supply chain is crucial. Transparency in sourcing and production fosters consumer trust and strengthens brand reputation.

6. Foster a Culture of Sustainability

Educating employees and stakeholders about sustainable practices encourages long-term commitment to eco-friendly production. Companies should integrate sustainability goals into their business strategies to drive meaningful change.

Sustainable Textile Production

Svegea of Sweden specializes in innovative textile machinery that supports sustainable and efficient garment production. Their advanced solutions help manufacturers reduce waste and optimize processes by:

- Maximizing fabric usage through precision cutting and automation, minimizing material waste.

- Enhancing energy efficiency, reducing overall consumption and environmental impact.

- Improving garment durability, promoting longevity, and contributing to a circular economy.

By integrating Svegea’s technology, manufacturers can transition to eco-friendly production methods without compromising efficiency or profitability.

More than a Trend

The battle between fast fashion and slow fashion is more than a trend—it’s a movement toward a more sustainable future. While fast fashion continues to dominate, its environmental and social consequences cannot be ignored. Slow fashion, supported by innovative textile machines like those from Svegea of Sweden, offers a viable solution for manufacturers seeking ethical and sustainable production.

By adopting energy-efficient technology, sustainable materials, and waste reduction strategies, manufacturers can contribute to a greener industry while maintaining profitability. The shift toward slow fashion is not just necessary—it’s inevitable.

Let’s embrace sustainability and redefine the future of fashion. If you’re looking to enhance the productivity and sustainability of your garment production processes, reach out to Håkan Steene at h.steene@svegea.se to learn more about Svegea’s advanced textile machinery and solutions.