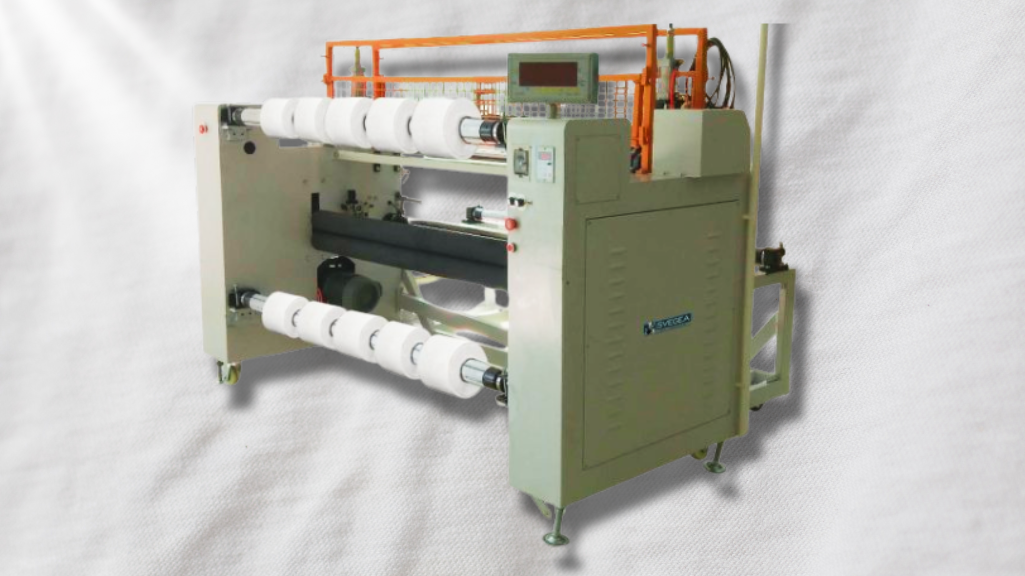

In the fast-paced world of textile manufacturing, precision and efficiency are paramount. The Roll-to-Roll Slitting Machine RRS-800 is a cutting-edge solution that meets these demands, allowing textile producers to optimize their processes and deliver high-quality products. In this article, we’ll explore the key features of this machine, its specifications, and its impact on the industry.

Key Features:

Motorized Knife with Adjustable Speed

The heart of this efficient slitting machine lies in its motorized knife. This advanced feature allows operators to control the cutting speed, ensuring precise slitting without compromising quality. Whether it’s delicate fabrics or heavy-duty materials, the RRS-800 adapts effortlessly.

Adjustable Cutting Widths

Flexibility is essential in textile production. This state-of-the-art textile machine achieves this by allowing operators to adjust cutting widths. By moving the placement of the knives, manufacturers can tailor the machine to their specific needs.

Optional Electronic Meter Counter

Keeping track of material usage is crucial for cost management. It offers an optional electronic meter counter, enabling real-time monitoring. This feature ensures efficient resource allocation and minimizes waste.

Pneumatic Lift Kit for Easy Loading and Start-Up

Loading and starting up a slitting machine can be labor-intensive. The RRS-800 streamlines this process with its pneumatic lift kit. Operators can effortlessly raise the knife shaft, reducing downtime and enhancing productivity.

Re-Rolling Efficiency

After slitting, re-rolling becomes essential. This cost-effective machine excels in this aspect by utilizing two independent air-expanding shafts. These shafts handle the re-rolling of slit rolls, ensuring uniform tension and preventing material distortion.

Three Shafts for Optimal Performance

The RRS-800 boasts a total of three shafts:

- One for the master roll

- Two for re-rolling

This configuration allows seamless transitions between processes, minimizing downtime and maximizing throughput.

Customizable Air-Shaft Sizes

Different materials require different handling. This slitting machine caters to this diversity by offering customizable air-shaft sizes upon request. Garment manufacturers can fine-tune the machine to match their specific textile types and dimensions.

The RRS-800 combines innovation, precision, and adaptability, making it a valuable asset for textile manufacturers worldwide. As the industry continues to evolve, machines like the RRS-800 are pivotal in meeting production demands while maintaining product quality.