In the quest for sustainable fashion, choosing the right fabrics is crucial. Eco-friendly fabric choices not only reduce environmental impact but also promote ethical production practices. This guide explores some of the best sustainable fabrics and their benefits.

Understanding Eco-Friendly Fabrics

Eco-friendly fabrics are made from natural, renewable, or recycled materials that have a lower environmental footprint compared to conventional fabrics. These fabrics are produced using methods that minimize water usage, chemical treatments, and energy consumption.

Popular Eco-Friendly Fabrics

- Organic Cotton: Grown without harmful pesticides and synthetic fertilizers, organic cotton is a popular choice for sustainable fashion. It is soft, breathable, and biodegradable.

- Bamboo: Bamboo fabric is made from the pulp of bamboo grass, which grows quickly and requires minimal water and pesticides. It is naturally antibacterial and moisture-wicking.

- Hemp: Hemp is a highly sustainable crop that requires little water and no pesticides. It produces a durable and versatile fabric that is perfect for various types of clothing.

- Recycled Polyester: Made from recycled plastic bottles, recycled polyester reduces waste and conserves resources. It is often used in activewear due to its durability and moisture-wicking properties.

- Tencel (Lyocell): Tencel is a sustainable fabric made from wood pulp sourced from responsibly managed forests. It is biodegradable, soft, and has a silky feel.

The Environmental Impact

The Environmental Impact

Choosing eco-friendly fabrics significantly reduces the environmental impact of fashion production. These fabrics require fewer resources, produce less waste, and are often biodegradable or recyclable. By opting for sustainable fabrics, designers and consumers can contribute to a greener planet.

Economic Benefits

Sustainable fabrics are not only good for the environment but also for business. As consumers become more environmentally conscious, there is a growing demand for eco-friendly products. Brands that use sustainable fabrics can attract a loyal customer base willing to pay a premium for ethical and eco-friendly fashion.

Challenges and Innovations

While eco-friendly fabrics offer many benefits, there are challenges in their production and adoption. The cost of sustainable materials can be higher, and the supply chain may be less established compared to conventional fabrics. However, innovations in textile technology and increased consumer awareness are helping to overcome these challenges.

Success Stories

Many brands are leading the way in sustainable fashion by using eco-friendly fabrics. For example, Patagonia uses recycled polyester in its clothing, and Stella McCartney incorporates organic cotton and Tencel in her designs. These brands demonstrate that sustainability and style can coexist.

The Future of Fashion

The future of fashion lies in sustainability. By choosing eco-friendly fabrics, the industry can reduce its environmental footprint and create a more ethical production process. As more brands and consumers embrace sustainable practices, we can look forward to a fashion industry that is both stylish and environmentally responsible.

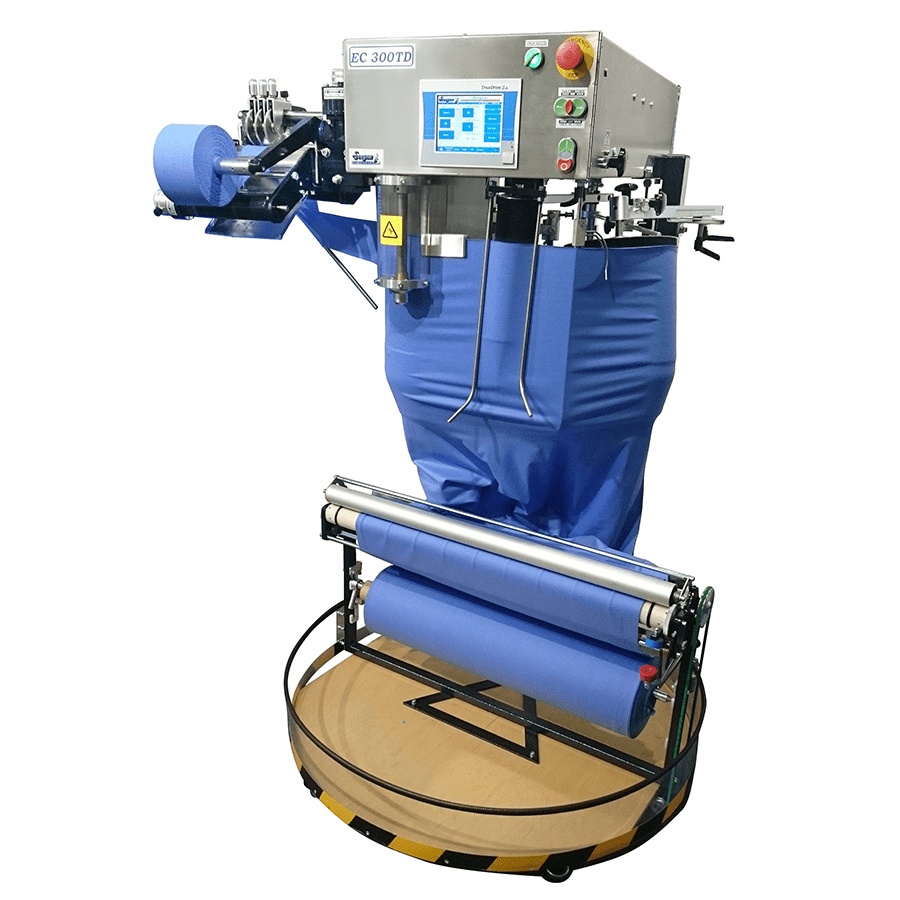

Cutting Edge Technology

Svegea of Sweden provides cutting-edge technology that complements the zero waste cutting process, enabling manufacturers to take their sustainability initiatives to the next level. With the Euro Collarette Cutter, Svegea offers a solution that not only minimizes fabric waste but also boosts production efficiency and cost-effectiveness. Euro Collarette Cutters are designed to optimize fabric cutting processes, providing highly efficient solutions that align with zero waste cutting principles. These machines are integral for manufacturers aiming to reduce fabric waste, streamline production, and meet sustainability goals.

Key Features of Svegea’s Euro Collarette Cutters:

- Precision Cutting: Euro Collarette Cutters are renowned for their precise, consistent cutting ability, reducing the amount of fabric waste that typically results from inefficient manual cutting techniques.

- Flexibility in Fabric Handling: These machines are capable of handling various fabric types and thicknesses, making them versatile for different garment production needs. This flexibility ensures minimal waste regardless of the fabric used, supporting zero waste pattern cutting.

- Automation and Efficiency: The advanced automation technology integrated into Svegea’s cutters allows for higher production speeds while maintaining precision. Automation reduces the likelihood of human error, further minimizing material waste.

- Sustainability-Driven Design: Svegea develops its cutting machines with a strong focus on sustainability, ensuring that they minimize fabric waste to nearly zero. These solutions seamlessly integrate into eco-conscious production environments, allowing manufacturers to adopt greener practices while enhancing efficiency.

- Cost Savings: By maximizing fabric use, these machines reduce raw material costs, contributing to both economic and environmental benefits for manufacturers adopting zero waste practices.

Contact us to explore how Svegea’s Euro Collarette Cutters can transform your production line for a more sustainable future.