In today’s competitive garment and textile industry, efficiency isn’t just a technical benchmark—it’s a bottom-line imperative. Outdated machinery may seem serviceable, but behind the scenes, it’s quietly draining profits through excessive energy use, frequent breakdowns, and mounting maintenance costs.

As global demand intensifies and margins tighten, manufacturers are rethinking their approach. The shift toward cost-saving textile machinery isn’t just about modernization—it’s about survival. Smarter, more sustainable equipment is helping producers cut waste, optimize workflows, and unlock new levels of profitability

The True Cost of Outdated Equipment

While legacy machines may still function, they often demand more attention than they’re worth. Repairs become more frequent. Production slows. Fabric waste increases due to inconsistent cuts and poor precision. These issues don’t just affect workflow—they directly impact your bottom line.

Moreover, older systems typically lack automation features that modern factories depend on. As a result, labor costs rise, and throughput suffers. In an industry where speed and consistency are critical, falling behind can mean losing contracts or missing seasonal demand.

Upgrading to advanced textile machinery can dramatically shift your cost structure. Today’s machines are designed for high-speed, precision performance and built to last. The benefits are clear:

- Reduced Material Waste: Precision cutting minimizes fabric loss and maximizes yield.

- Lower Maintenance Costs: Durable engineering reduces downtime and service interventions.

- Energy Efficiency: Optimized motor systems consume less power, resulting in lower utility bills.

- Increased Output: Automation and speed enhancements enable the production of more garments per hour.

To illustrate how modern machinery delivers these benefits, let’s look at a real-world example.

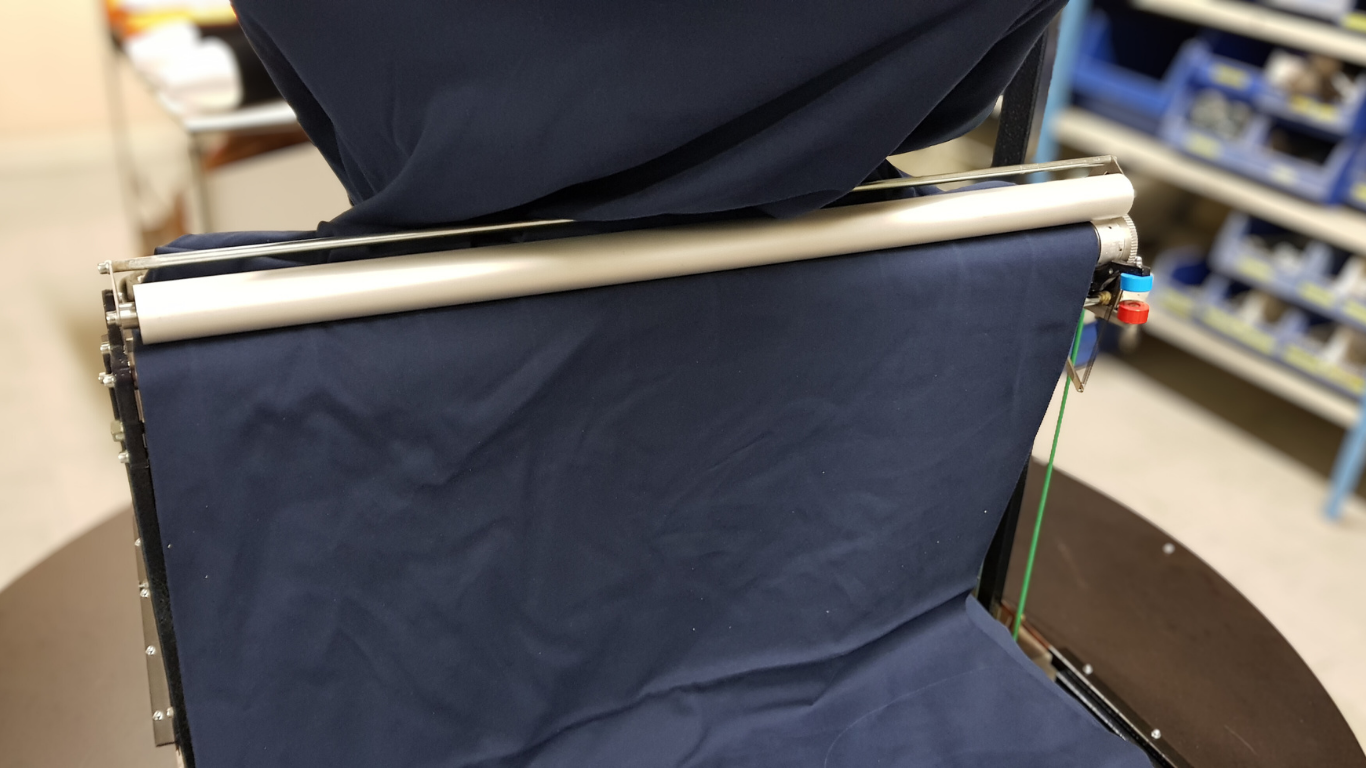

One standout example is Svegea of Sweden’s EC300-S Collarette Cutter. Known for its high-speed precision and low maintenance requirements, it’s a favorite among garment manufacturers aiming to streamline production. The EC300-S reduces fabric waste, boosts output, and consumes less energy—making it a smart investment for both profitability and sustainability.

Real-World ROI: Efficiency That Pays Off

Consider a mid-sized garment factory that replaces its aging collarette cutter with a high-speed model. Within a year, production increases by 20%, fabric waste drops by 15%, and maintenance calls are reduced by nearly a third. These improvements don’t just save money—they create capacity for growth.

Even better, the return on investment often exceeds the initial purchase cost within the first 12 months. That’s not just smart—it’s strategic.

Sustainability Meets Profitability

Efficiency isn’t only about saving money. It’s also about reducing environmental impact. Machines like the EC300-S support eco-conscious manufacturing by using less energy and producing less waste. For brands focused on ESG goals, this alignment is essential.

Invest in What Moves You Forward

Standing still in textile manufacturing is a risk. Upgrading your machinery isn’t just a technical decision—it’s a business move that affects quality, speed, sustainability, and profitability. Whether you’re scaling up or streamlining operations, investing in cost-saving textile machinery can be the difference between surviving and thriving.

Ready to rethink your production strategy?

Explore how smarter textile machinery can reshape your efficiency, reduce waste, and support sustainable growth. Learn more about proven solutions like the EC300-S Collarette Cutter and discover what modern upgrades could mean for your bottom line. Contact Håkan Steene at h.steene@svegea.se to learn more, request product details, or schedule a hands-on demonstration tailored to your needs.