Modern car design relies on much more than just metal and glass. Today, engineers use high-performance fabrics to make vehicles safer, lighter, and more comfortable. By 2026, experts expect the global market for technical textiles in the automotive industry to exceed $34 billion.

Why Engineers Choose Fabric Over Metal

The rise of Electric Vehicles (EVs) is the primary driver of this trend. As a result, manufacturers must find ways to reduce vehicle weight to improve battery range. Technical textiles in the automotive industry provide a perfect solution because they deliver strength without the heavy weight of traditional materials.

In addition to weight savings, textiles play a critical role in safety. Manufacturers use specialized fibers like Nylon 6,6 to create airbags and seatbelts. These materials must withstand extreme heat and pressure without failing.

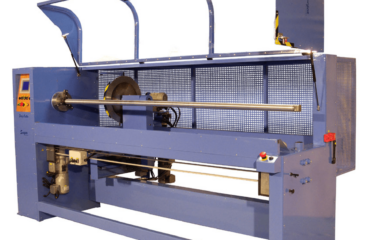

Solving the Challenges of Precision Slitting

Working with technical materials requires a different approach than working with fashion fabrics. Many automotive materials feature multiple layers, such as foam backings or protective coatings. Cutting these materials often presents a challenge. Because synthetic fibers are sensitive to heat, traditional blades can sometimes melt the edges. To solve this, manufacturers use specialized slitting machines that offer:

- Cold-Cutting Technology: Clean edges without fusing layers.

- High Dimensional Tolerance: Exact measurements for safety-critical parts.

Automated systems eliminate human error, leading to higher quality and lower costs.

Meeting New Environmental Regulations

Looking ahead to 2026, global governments are introducing the Waste Framework Directive. This means car manufacturers must take more responsibility for the waste they create during production. By using precision slitting, a factory maximizes raw materials and complies with new laws. This ensures that technical textiles in the automotive industry continue to support sustainability goals.

Invest in Machinery that Powers the Next Generation of Automotive Interiors

At Svegea, we provide the machinery that powers the next generation of automotive interiors. We invite you to learn more about our high-precision solutions. Contact Håkan Steene at h.steene@svegea.se or visit our Contact Us page for more details and a product demo. Let us know how we can help you meet the strict demands of automotive manufacturing.

Photo by Altered Vision on Unsplash