Factories face three hard truths: fabric costs keep rising, buyers want faster delivery, and sustainability matters to customers and regulators. Improving garment manufacturing efficiency puts these pressures into practical order. Get this right and you cut costs, gain speed, and reduce waste.

Where waste really bites

Small mistakes cost big. A mis-inspected roll can mean meters of unusable fabric. Manual checks slow lines and create rework. Labor shortages and rising wages exacerbate every inefficiency. That is why garment manufacturing efficiency must be a daily focus, not a quarterly idea.

Trends pushing factories to change

Across the industry, manufacturers are adopting digital tools. Marker optimization reduces raw material use. Real-time dashboards track defects. Automation speeds repetitive tasks while freeing people to solve problems. Together, these moves enhance garment manufacturing efficiency and make factories more scalable.

Tools that move the needle

Automation is not a single gadget. It is a set of targeted investments that deliver repeatable gains. Start with quality control. Automated inspection and reliable cutting reduce rework and scraps. Next, connect systems so design files, markers, and production data flow without manual transfers. That reduces setup time and avoids costly mistakes. Focused improvements add up fast when your goal is garment manufacturing efficiency.

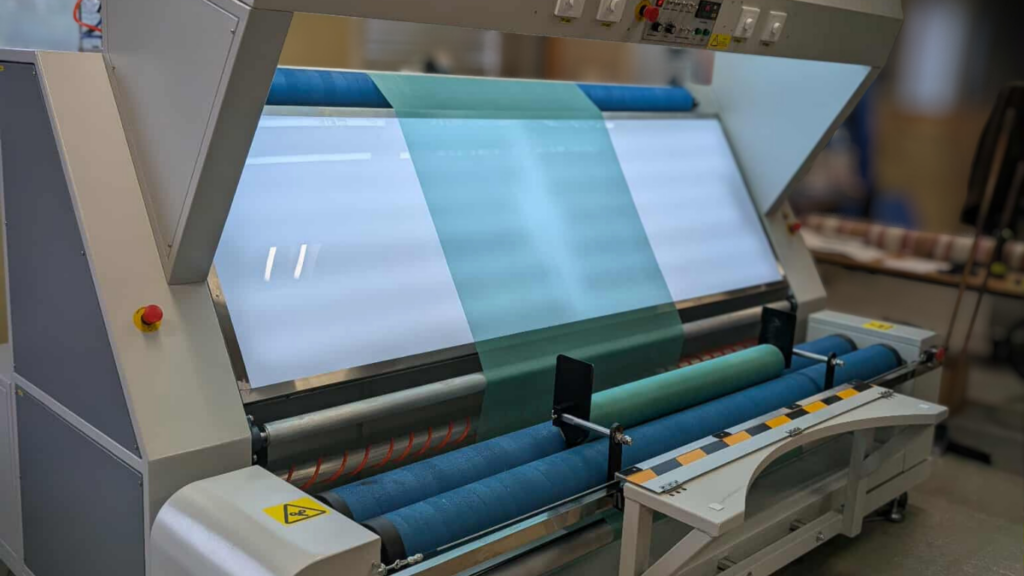

Fabric inspection: the unsung hero

A lot of manufacturers undervalue inspection. A good inspection line catches faults before cutting, preventing defects that would otherwise propagate through sewing and finishing. The CMI 210 ZR fabric inspection machine is built for that exact role. It handles rolls up to 2100 mm, runs roll-to-roll or roll-to-flat, and offers variable electronically controlled speed, photocell edge alignment, and electronic tension adjustments. That level of control reduces hidden waste at the source.

Collarette cutting: precision where it matters

Certain parts of a garment reveal flaws instantly. Collarette and binding components need uniform width and clean edges. Svegea’s collarette cutting machines cover semi-automatic and fully automatic models. They handle tubular knitted fabric with adjustable widths from about 16 to 140 mm. The standard setup cuts two bands at once, and knife units can be added for more. For high-volume runs, the automatic systems remove variability and keep quality consistent.

What success looks like in real numbers

When factories prioritize process control and the right equipment, they see measurable results. Expect fabric waste to drop, lead times to shorten, and quality rejects to decline. These improvements drive margin expansion and help with sustainability reporting. In short, garment manufacturing efficiency converts directly into competitive advantage.

A simple plan to get started

Start methodically. First, audit the cutting and inspection rooms to find where most scrap and rework come from. Next, pilot one change. Try a fabric inspection line or a semi-automatic collarette cutter on a single product style or order run. Train the operators, collect data, and tweak. Finally, scale what proves out. This stepwise approach helps you manage cost and avoid disruption.

The business case

The math usually lands in your favor. Less waste means lower material spend. Tighter quality control means fewer returns and less rework. Faster setup times mean you can run smaller batches and respond to demand. That combination raises throughput without endless headcount increases. If you want to improve garment manufacturing efficiency, this is the route most executives choose.

Focusing on the right tools

Efficiency is not glamorous, but it is decisive. Focus on the right mix of inspection, precise cutting, and connected workflows, and you will see both cost and time benefits. Machines that support those goals, whether a robust inspection unit like the CMI 210 ZR or a scalable Euro-Collarette cutter, are tools that turn good intentions into measurable results.

For a demo or to discuss how this fits your production, contact Håkan Steene at h.steene@svegea.se or visit the Svegea product pages.