The textile industry is no stranger to innovation. From early mechanization to today’s cutting-edge technologies, it has continually evolved to meet growing demands. In this era, automated textile machines are leading the charge with their state-of-the-art efficiency.

The Role of Automated Textile Machines

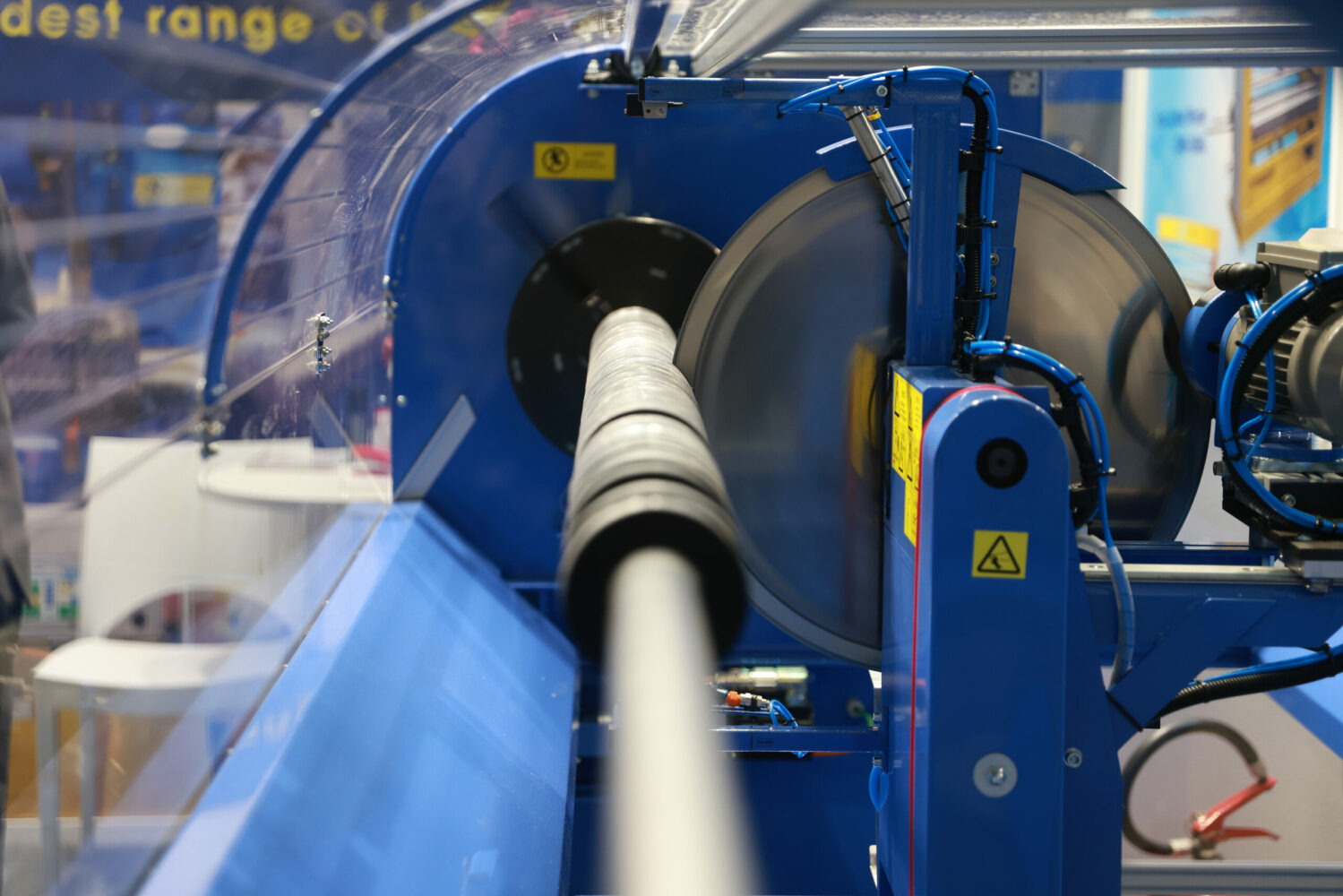

Automation has become a cornerstone of modern textile manufacturing, enabling greater precision and efficiency. Svegea’s automated systems, such as the Fully Automatic Roll Slitting Machine, exemplify how technology can optimize production while maintaining exceptional quality.

Efficiency at Its Core

Automated machines offer unmatched speed and precision. Svegea’s Roll Slitting Machine, for instance, transforms raw materials into finished rolls with minimal waste and maximum consistency. This efficiency helps manufacturers meet tight deadlines without compromising quality.

A Safer Workplace

Safety is critical in any manufacturing environment. Svegea incorporates advanced safety features into its machines, protecting operators and reducing risks. Intuitive controls and built-in safeguards ensure smooth, secure operations while minimizing downtime caused by accidents.

Automation: Transforming the Textile Landscape

1. Faster Production

Automation significantly accelerates production cycles. Machines like Svegea’s are designed to handle large volumes quickly and reliably, helping manufacturers keep pace with market demands.

2. Improved Quality

Automated systems incorporate sensors and monitoring technologies to ensure uniform results. Svegea’s machines deliver consistent, defect-free products, enhancing customer satisfaction and reducing rework.

3. Cost Efficiency

Although automation requires an initial investment, it reduces long-term expenses. Lower labor costs, minimized errors, and reduced material waste translate to significant savings for manufacturers.

4. Flexibility

Modern textile machines are highly adaptable. Svegea’s equipment can be tailored to produce various materials, enabling manufacturers to meet diverse client needs in a competitive market.

The Future of Textile Automation

1. Integration with IoT and AI

As the industry embraces smart manufacturing, technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) will play a pivotal role. IoT-enabled devices can optimize workflows, while AI-driven analytics can predict maintenance needs, enhancing efficiency. Svegea is exploring these innovations to further enhance its product offerings.

2. Sustainability in Focus

Automated machines contribute to greener production by reducing energy use and waste. Svegea is committed to designing sustainable solutions that help manufacturers minimize their environmental impact.

3. Robotics and Advanced Automation

Robotic systems are increasingly performing complex tasks with remarkable accuracy. Svegea integrates robotics into its machines, pushing the boundaries of what textile automation can achieve.

Redefining Textile Automation

Automation is redefining textile manufacturing, driving efficiency, safety, and sustainability. Svegea’s innovative solutions empower manufacturers to stay ahead in an ever-evolving industry. As technology advances, Svegea remains dedicated to shaping the future of textile production.

For more information about Svegea’s solutions, reach out to us at info@svegea.se.