Garment factories across India, Bangladesh, Vietnam, and South America are facing a new reality. Global demand is rising, lead times are shrinking, and buyers expect consistent quality at competitive prices. To stay ahead, manufacturers must rethink how they produce — and that starts with smarter machines.

One of the most effective ways to improve efficiency is by investing in intelligent textile machines for apparel production. These machines don’t just automate tasks. They optimize them. From slitting tubular knits to cutting collarettes, intelligent systems help reduce waste, speed up output, and increase return on investment.

The Hidden Cost of Manual Processing

Many factories still rely on manual or semi-automated systems for fabric preparation. While this may seem cost-effective at first, it often leads to:

- Uneven cuts and inconsistent sizing

- Higher fabric waste

- Slower production cycles

- Increased labor fatigue and errors

These issues add up. Over time, they affect profitability, delivery timelines, and customer satisfaction.

Smarter Machines, Better Results

Intelligent textile machines for apparel production solve these problems with precision and consistency. They’re designed to handle high volumes with minimal supervision, making them ideal for export-driven factories and fast fashion suppliers.

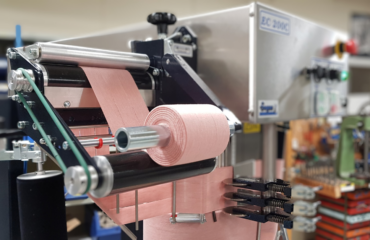

Take the Svegea TSO 380 Tubular Knit Slitter, for example. This machine is built for speed and accuracy. It slits tubular knitted fabrics open with clean edges, ready for further processing. It’s easy to operate, requires minimal maintenance, and integrates smoothly into existing production lines.

Efficiency That Pays Off

Factories using machines like the TSO 380 report:

- Up to 15% reduction in fabric waste

- Faster turnaround times

- Fewer production errors

- Lower labor costs

These improvements lead to measurable ROI — often within the first year of installation. That’s why more manufacturers are turning to intelligent textile machines for apparel production as a long-term strategy.

Flexibility and Integration

Modern apparel production demands flexibility. Machines must adapt to different fabric types, styles, and order volumes. The best systems are designed to handle knits, wovens, and technical textiles without constant retooling.

Svegea’s machines are known for their versatility. Whether you’re processing tubular knits or cutting narrow strips, their equipment delivers consistent results across a wide range of materials.

Reliability You Can Count On

Downtime is expensive. That’s why reliability matters. Manufacturers need machines that run smoothly, require minimal maintenance, and come with strong technical support.

Svegea of Sweden has built its reputation on engineering excellence and long-term durability. High-volume factories around the world — including across Asia and Latin America — rely on the intelligent textile machinery backed by responsive teams for support.

Investing in Smart Solutions

The future of garment manufacturing belongs to those who invest in smart, scalable solutions. By integrating intelligent textile machines for apparel production, factories can boost efficiency, reduce waste, and stay competitive in a fast-moving global market.

If you’re ready to upgrade your production line, explore Svegea’s TSO 380 Tubular Knit Slitter and other solutions at www.svegea.se.

For a product demo, email Håkan Steene at h.steene@svegea.se