In today’s fast-evolving manufacturing landscape, innovation isn’t a luxury—it’s a necessity. As textile producers face increasing pressure to boost productivity, cut costs, and maintain precision, one solution is proving itself indispensable: semi-automatic textile machines. These smart, efficient systems are revolutionizing how factories operate—bridging the gap between manual control and full automation.

Let’s dive into how semi-automatic machinery is transforming textile production lines around the world, and why forward-thinking manufacturers are weaving it into the fabric of their future.

The Rise of Smart Manufacturing in Textiles

Over the last decade, the textile and garment industry has undergone a significant technological shift. From digitized workflows to AI-enhanced design, the entire supply chain is changing shape—and fast. Semi-automatic textile machines represent a pivotal step in this evolution.

They offer the best of both worlds: human control and machine precision. Operators maintain oversight, while machines handle repetitive tasks with consistent accuracy. The result? Fewer errors, faster output, and less downtime.

Why “Semi-Automatic” Is the Sweet Spot

You might be wondering—why not go fully automatic? While full automation certainly has its place in large-scale operations, semi-automatic systems often prove more practical and cost-effective for small to mid-sized manufacturers.

Here’s why:

- Flexibility: Semi-automatic machines adapt quickly to different fabric types, roll sizes, or production goals without requiring complex reprogramming.

- Cost Efficiency: They’re more affordable than fully automated systems—both in upfront investment and maintenance.

- Precision and Control: Operators can intervene when needed, minimizing mistakes and maximizing material utilization.

When integrated strategically, these machines deliver a near-instant upgrade to any production line.

Real-World Impact: Boosting Output Without Compromising Quality

Let’s talk numbers. In many cases, textile producers using semi-automatic slitting or cutting machines have reported:

- Up to 40% increase in production efficiency

- 25% reduction in material waste

- Significantly lower labor fatigue and error rates

This is especially critical when working with high-value or delicate fabrics, where precision isn’t optional—it’s everything.

Svegea, a trusted innovator in textile machinery, has been at the forefront of this shift. Their range of semi-automatic textile machines offers cutting-edge features that balance performance with user-friendly operation. Whether you’re slitting rolls, trimming edges, or cutting fabric panels, Svegea’s equipment ensures precision without the steep learning curve.

Key Benefits for Manufacturers

Still wondering if it’s the right move for your operation? Here are five compelling benefits of semi-automatic textile machines you can’t ignore:

1. Increased Throughput

By automating repetitive motions while keeping decision-making in human hands, these machines dramatically speed up production without sacrificing quality.

2. Reduced Operational Downtime

Thanks to straightforward interfaces and intuitive controls, troubleshooting and adjustments can be made quickly, keeping your lines running smoothly.

3. Better Resource Management

Semi-automatic systems optimize how material is handled and processed, leading to lower waste and higher yield.

4. Enhanced Product Consistency

Uniform cutting, slitting, and trimming mean fewer reworks and returns.

5. Safer Work Environment

These machines eliminate many of the risks associated with manual cutting tools, creating a safer space for your workforce.

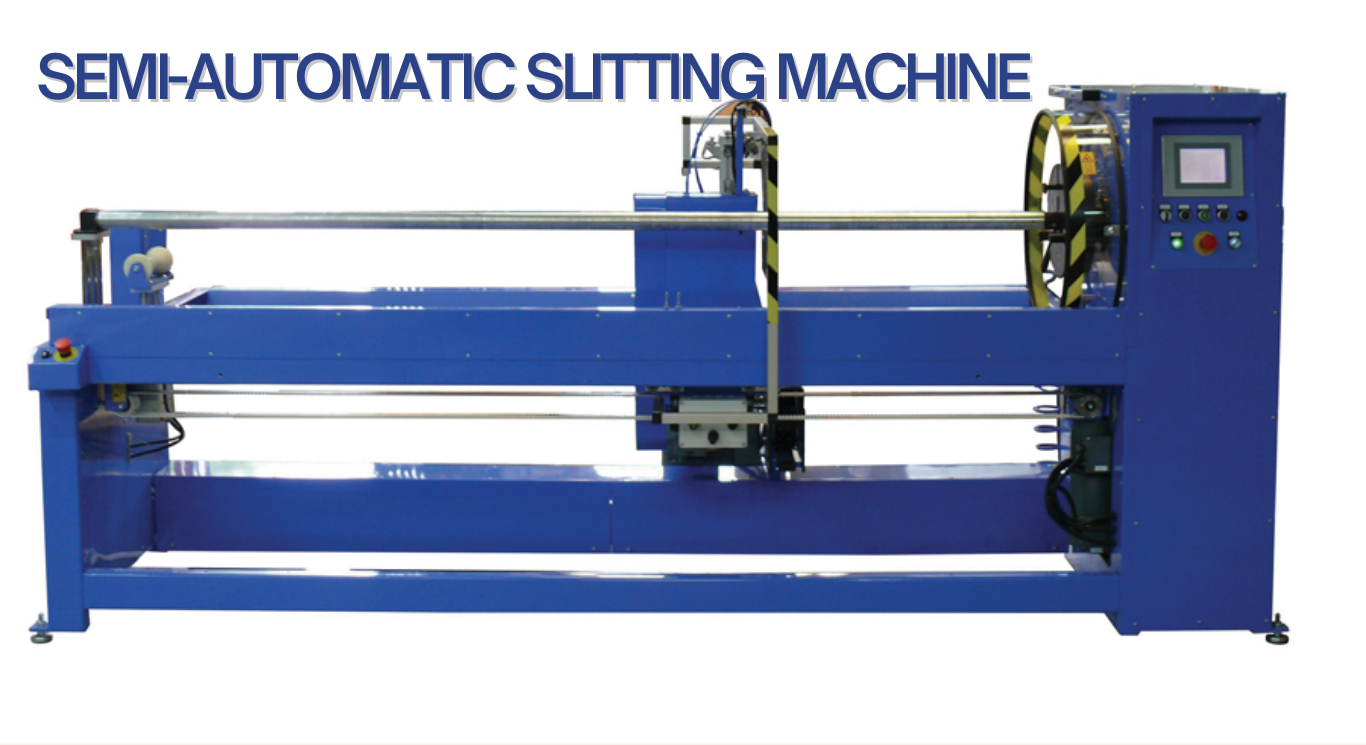

Meet the Machines Making It Happen

Svegea’s lineup of semi-automatic machines includes slitting systems, band knife machines, and edge trimmers—all engineered for ease of use and long-term reliability. Designed and manufactured in Sweden, these machines combine high-performance mechanics with modern design standards.

Each model is created with specific applications in mind, including:

- Roll-to-roll precision slitting

- Multilayer fabric processing

- Durable textile cutting with minimal fabric distortion

Whether you’re producing garments, upholstery, technical fabrics, or industrial textiles, Svegea offers purpose-built equipment to meet your unique needs.

What Industry Leaders Are Saying

Manufacturers across Europe and Asia who’ve adopted Svegea’s semi-automatic machines are seeing tangible improvements not just in throughput, but in staff satisfaction and operational control.

“We upgraded to a Svegea roll slitting machine last year, and the difference was immediate,” one production manager shared. “The machine paid for itself in less than six months through time saved and reduced waste.”

These are results that any manufacturer can get behind.

Future-Proofing Your Production Line

With labor shortages, rising material costs, and fluctuating market demands, investing in adaptable machinery is more critical than ever. Semi-automatic systems give you the edge today, while preparing your facility for the continued rise of smart manufacturing.

They also allow for easier integration with upstream and downstream processes, including material handling systems, labeling, and packaging, streamlining your entire workflow.

Ready to Step Up?

If you’re ready to enhance efficiency without losing control, Svegea’s semi-automatic textile machines could be your perfect fit. Designed for manufacturers who need to move fast, stay lean, and deliver quality with every yard, Svegea solutions are here to keep your production future-ready.

📩 Contact Håkan Steene today at h.steene@svegea.se to learn more, get product specs, or schedule a live demo.

You can also explore the range online here: https://svegea.se/product-category/roll-slitting-machines/semi-automatic-roll-slitting-machines/