In modern textile manufacturing, adaptability is no longer optional—it’s essential. As demand grows for flexible production, especially in knitwear and activewear, manufacturers are turning to adaptive garment machinery to streamline operations and maintain quality.

Why Tubular Knit Slitting Matters

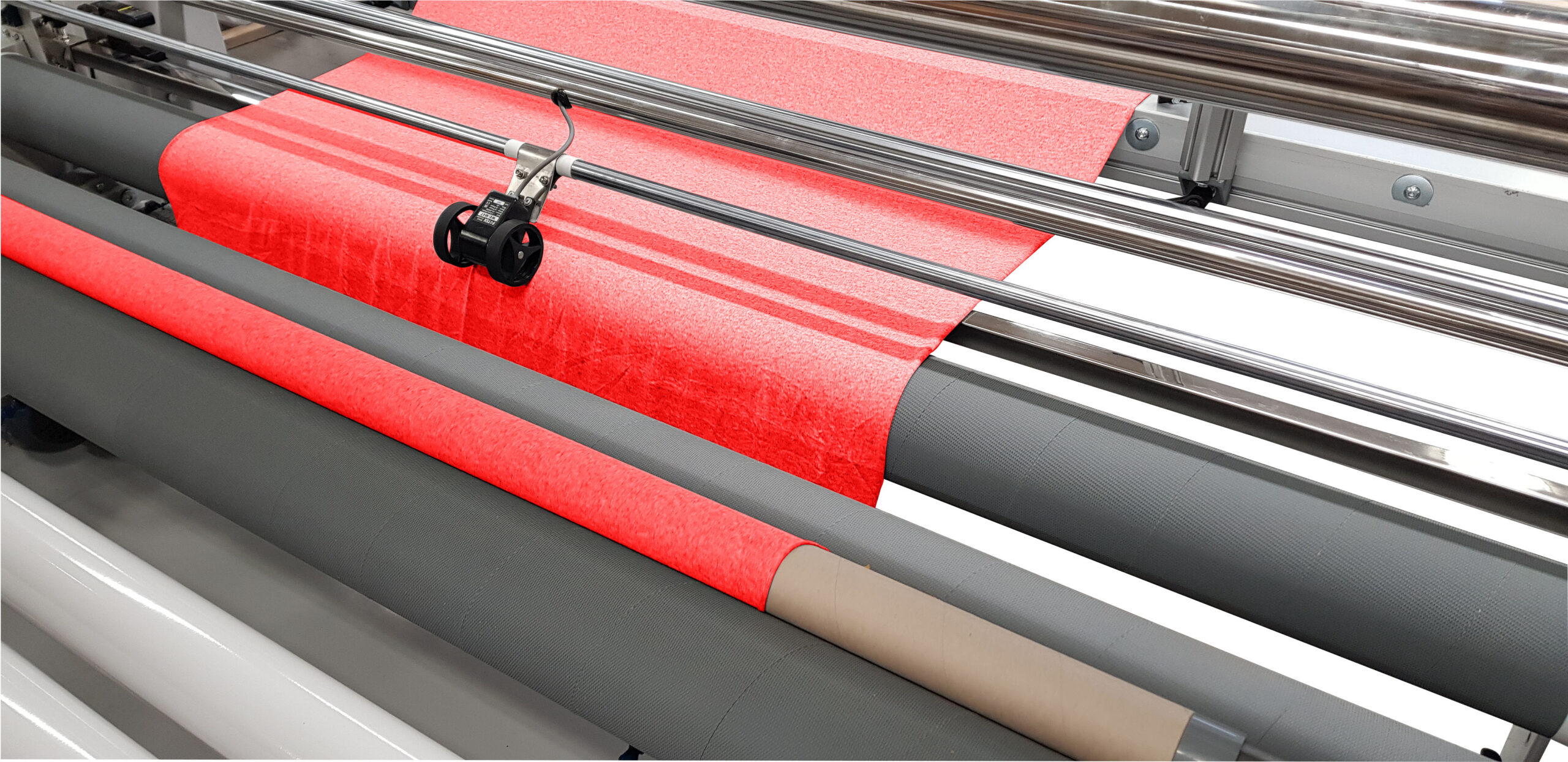

Tubular knit fabrics are produced in a continuous loop, which is ideal for circular knitting but not for cutting, printing, or sewing. Before these fabrics can be processed further, they must be slit and opened into flat sheets.

Without proper slitting:

– Edges may distort or curl

– Automated cutting systems can misalign

– Waste increases due to poor edge control

– Finished garments may suffer in quality

This step, though often overlooked, directly affects efficiency and product consistency.

The Role of Adaptive Machinery

Adaptive garment machinery refers to equipment that adjusts dynamically to different fabric types, production speeds, and operational conditions. In tubular knit slitting, this means:

- Automatic edge guiding for alignment

- Adjustable slitting widths for varied outputs

- High-speed operation with minimal waste

- Compatibility with both light and heavy knits

These features allow manufacturers to respond quickly to changing production needs without sacrificing precision.

Integration into Production Lines

Slitting machines are typically placed early in the workflow—after knitting and before cutting or printing. To integrate effectively, they must:

- Fit within existing layouts

- Offer intuitive controls for operators

- Require minimal maintenance

- Support continuous, high-volume use

When adaptive slitting technology is used, production lines become more responsive and less prone to bottlenecks.

Industry Applications

This machinery is especially relevant for:

- On-demand fashion production

- Mass customization models

- Sustainable textile workflows

- Technical and performance apparel

By enabling consistent slitting across diverse knit fabrics, adaptive systems support manufacturers aiming for speed, flexibility, and reduced waste.

A Significant Small Step

Tubular knit slitting may seem like a small step, but its impact is significant. With adaptive garment machinery, manufacturers gain the precision and flexibility needed to meet modern demands.

If you’re exploring ways to improve your knitwear production, consider how adaptive slitting can elevate your workflow.

To learn more or request a consultation, email Håkan at (mailto:hakan@svegea.se) or contact us.